To pump flammable materials, pumping units of different power are used, the design of which is calculated in accordance with the viscosity readings of diesel fuel, gasoline, and technical oil. A 12-volt gasoline pump can pump diesel fuel in a volume of 20-80 liters per minute.

The consumer market offers pumps for pumping fuel from world brands with technical characteristics that allow fuel to be supplied at a horizontal distance of up to 30 meters and a height of up to 2 meters. The device for transferring diesel fuel from storage to the power unit can be self-priming and submersible.

Purpose of pumping equipment

A compact pump for pumping fuel with your own hands can be made from any hydraulic system: from a loader, manipulator or tractor. The device can be used in various areas of the national economy:

- Car park.

- Boat station.

- ONE HUNDRED.

- Private garage.

A productive device for transporting diesel fuel with a power of 12 volts is used when refueling boats, motor boats, and private flying club aircraft. The most popular are portable devices from well-known companies: Adam Pumps, Petroll, Piusi, Gespasa. Fuel units for fuel transfer have been tested in different climatic zones of the Russian Federation, high efficiency indicators are formed by protection class 1 and an automatic ventilation engine.

Scope of application

Everyone understands that devices used for pumping water from a well can immediately be excluded from the list of candidates for pumping gasoline or diesel fuel. For this purpose it is necessary to use a special device. Equipment of this type has a wide range of applications. It can be used in domestic conditions when it is necessary to pour fuel into cans and use it as needed in the required quantities.

Sometimes it becomes necessary to transfer fuel for storage into barrels and other containers, which can only be done quickly and safely using a special pump . Therefore, every owner who has a car at his disposal must ensure that his private home, country house or garage has such a pump

Such devices are actively used at gas stations, but here you can most often find models with high power and stationary performance.

It is also useful to have this equipment in workshops where it is often necessary to pump fuel from equipment received for repair. There are many other objects where such pumps can be used - industrial enterprises, airfields, ports and docks, car depots, etc.

Regardless of the specific area in which you are going to use this equipment, in any case, before purchasing, you need to carefully familiarize yourself with the presented models and their inherent technical characteristics.

Piston fuel pumps

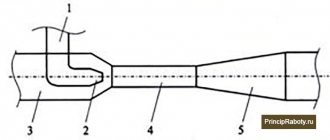

Electrical devices allow fuel to be pumped through a reciprocating motion. The water plunger pump is highly reliable due to the placement of the piston inside the sleeve of the device. The moving mechanism does not come into contact with the walls of the sleeve and does not wear out from friction.

The lightweight diaphragm fuel pump performs its operating functions by oscillating the plate under the action of the drive. An electrically driven vane pump has a rotor in its design, during operation of which pressure is created that presses the vanes to the inside of the housing. Compact electric pump with a power of 12-24 V, has high efficiency, reverse injection.

Dynamic devices for pumping out liquid media are divided into two groups, each of them has certain operating parameters and a method of fuel supply. When studying the design of devices, the following features should be highlighted:

- Dangerous pumps operating on a centrifugal or axial type. In centrifugal devices, fuel injection is carried out by rotating mechanisms. The axial pump operates on the principle of a fan.

- The friction pump is used in the chemical industry; the operating principle of the unit is based on the action of friction.

- A vortex electrical device sucks and expels fuel from the system. The positive properties of the pump include the ability to transfer fuel under high pressure, ease of maintenance, and availability of spare parts.

Equipment catalog

Vacuum pumpsVacuum pumps (VVN, AVZ, NVR, VNK-2, VE, Vi) Vacuum pumps with oil seal (for pressure tables, vacuum forming) Oil-free (dry) vacuum pumps Equipment for refilling air conditioners, accessories for vacuum pumps (Vacuum gauges, hoses and etc.) Blowers

Fuel pumps

Pumps for diesel fuel and gasoline Pumps for diesel fuel and oil for 12V and 24V Mini gas stations for diesel fuel, gasoline and oil Pumps for oil (NK)

Drum pumps

Hand pumps for drums Pumps for drums and containers, electric, pneumatic Chemical pumps for drums Finish Thompson Chemical pumps for drums FLUX

Hand pumps

Hand pumps for wells and containers (P 0.8/30, RPN 1.3/30, RK-2)

Pumps for a summer house, a country house

Domestic pumps

Pressure testing pumps

Pumps for pressure testing (GN-60, -200M, -500, NR-60, UGI-1, Kompakt-50, Kompakt-Electro, PNU-2, -3, NP-150)

High pressure pumps (100…1000 atm)

Pumps and high-pressure washers TNA, ENA (from 120 to 1000 atm)

Pumps for oils, greases, bitumen

Bitumen pumps (DS-125, DS-134, DZ-212) Gear pumps (NMSh, Sh, BG, Calpeda: IM 25/4) Vane (rotary vane) pumps Three-screw pumps (A13V) Twin-screw pumps Pneumatic oil pumps Pressol and Ampika Manual and pneumatic lubricant dispensing units Pressol and Ampika Equipment for collecting used oil Pressol Osediagonal (screw) pumps (UDN)

Electric pumps for wells and wells

Budget pumps for water from wells Electric well pumps Pedrollo (4SR, NKm) and Grundfos (SQ, SQE, SB, SBA) Pumps for artesian wells ECV Premium well pumps ZDS Submersible well pumps Ciris (Livgidromash)

Water pumps

Automatic pumping stations Automatic pumping stations with 2 or more pumps Low-capacity pumps Vortex pumps (VKS, Pedrollo: PK, PKs PQ, Calpeda: CA, T, TP) Cantilever water pumps (K, KM, Calpeda: NM) Centrifugal console Livgidromash (K, 1K, 2K, KM) Pedrollo water pumps (CP, 2CP, NGA) Pedrollo industrial pumps (HF, F) Stainless steel pumps (MXH, NGX, AL-RED 135m, Aspri, Tecnoself) Pumps for swimming pools and hydromassage baths (Calpeda: Mpc, Spa. ESPA: Piscis, Tiper, Nadorself, Niper, Iris, Silen) Vertical multi-section pumps (TSNSG-AM, MXV, MK, Multi, TsNSv) Vertical pumps Boosta Multi-section horizontal pumps (TSNSG, Plurijet) Multistage vertical pumps GRUNDFOS (CR) Horizontal pumping units (D) Double-entry pumps with a horizontal housing split of the DeLium series Feed for boilers (AN 2/16, NG 1.6/1.6, TsVK, PQ 3000) Condensate (Ks) Centrifugal monoblock pumps SAER Pumps KORDIS Automatic pumping stations APD (on BOOSTA pumps)

Pumps for in-line heating systems

Circulation in line KML, TsNL, TsVTs-T 6.3-3.5 Pumps for circulation in heating systems (NC, NCD, NR, UPS, UPSD, Alpha)

Mortar pumps (SO)

Mortar pumps (SO-49M, VNP, UVN)

Equipment at a discount

Equipment at a discount

Water Spray Systems

Spray systems

Fuel filling kit

Refueling kits presented on the consumer market are designed to supply fuel to the fuel tank of engines of vehicles of various categories, as well as pumping fuel into storage stations at gas stations.

Unlike pumps, the filling kit, containing a 12-volt unit, has individual design features of the model . The performance characteristics of the device are determined by the presence of component elements:

- Mounting plates.

- Hoses.

- Refueling pistol.

- Fuel meter.

- Filters

- Fastening elements.

Nuances of choice

Before you go shopping for pumping equipment, we recommend that you familiarize yourself with the following recommendations to help you make the right choice:

- If you are faced with the task of transporting fuel over a distance of more than 30 m, then you will need several pumps, which should be placed in a line.

- To create high pressure, we recommend purchasing centrifugal-type pumping equipment.

- It makes sense to purchase axial pumps only if you are going to pump fuel in large volumes and the pressure force is not important to you, which in these installations is at a fairly low level.

- The most popular option among consumers are jet pumps, which are chosen primarily due to the absence of moving elements in their design.

- Vortex pumps are indispensable if you are looking for a lightweight, compact, inexpensive and easy to operate unit.

- Volumetric pumps are ideal for pumping fuel without foreign inclusions. They will allow you to save not only a lot of time, but also energy.

Gasoline pump

Pumps are a class of high-performance equipment that can be used to quickly transport gasoline and diesel fuel from tanks to cars, construction equipment and other devices. To operate, they require a 12 V or 24 V power source. The pump package usually includes:

- pump for pumping gasoline 24 V or 12 V without a cord;

- adapter for 2″ container.

Diesel fuel transfer pump 12V 50 DC12

This model is one of the most high-performance models for pumping fuel and has the following characteristics:

- Has a safety valve.

- Equipped with a mesh filter located in the intake line.

- Equipped with a built-in bypass valve.

- The main working elements are blades made of carbon steel and a rotor made of cast iron.

- Has thermal protection.

- There is a holder for a pistol.

- The operating cycle of the device provides for 30 minutes of continuous pumping of liquid and 30 minutes of break.

- It can suck up the pumped liquid from a depth of up to 7 m.

- A current of 20 A is required for operation.

- Supplied in a housing made of cast iron.

The 12V fuel transfer pump model is ideal for pumping various types of fuel: kerosene, gasoline and diesel fuel. The pump is supplied with a 4 m MBS hose and a gun with the ability to manually turn off the latter. If the consumer requires a different hose and dispensing gun, they will have to be purchased separately.

This model is not suitable for transporting fuel in large quantities. For these purposes, it is more advisable to purchase models ANSV-300, ANSV-1000, which will best cope with this task.

The need to pump fuel quite often arises in various areas. This may be required in industrial production or in households. But regardless of what specific object this operation was required to perform, it is necessary to have the most suitable unit available for this purpose. Most often, special pumps are used to pump fuel, which must meet certain requirements.

After all, if we are talking, for example, about an enterprise whose activities are related to oil refining, then a pump with a powerful engine that can easily cope with large volumes of fuel is best suited for it. In a similar way, you need to approach the selection of pumps for use at other facilities, paying attention first of all to the operating conditions of the purchased equipment.

Your own gas station: testing portable refueling pumps

Every car owner has probably encountered a situation where it is necessary to pour fuel for some non-automotive needs - for example, many often have to refuel various motor vehicles, from a scooter or quad to outboard motors and chainsaws with lawn mowers. Of course, you can’t carry a chain saw to a gas station, and you can’t even drive a “dacha” (read - without documents) motorcycle there - traffic cops often engage in seasonal raids at gas stations on old and left-handed “motos”... A separate topic is “tractor drivers”, owners of diesel cars Owners of equipment with unpretentious engines with simple and crude fuel equipment often set up a mini-gas station in their garage, where they store cheaply purchased diesel fuel in barrels from water and dirt. Workers of different teams who have daily use of gas-powered tools constantly have to transfer fuel in small volumes, and for employees of karting centers this takes up half of their working time. In short, pouring gasoline in garages, country houses, or even small-scale commercial settings is a common and commonplace occurrence.

If you are tired of regularly juggling with various funnels, cans and suction hoses, you can set up a small “gas station” for personal needs in your garage or dacha. Numerous and varied models of low-voltage gasoline pumps powered by conventional batteries are designed for this purpose. True, a “battery-powered gas station” is still a novelty for many and causes reasonable skepticism - just as, for example, until recently, every second person did not believe that a pocket lithium-ion “starter” the size of a couple of cigarette packs would start an engine with a completely dead battery. “Well, how will a gadget powered by AA batteries pump gas – drop by drop, or what?!”

Let's check!

Berkut SP1010EP

This “micro gas station” runs on 4 AA batteries. It consists of two flexible hoses connected by a housing, inside of which there is a compartment for batteries and control electronics. The body is screwed onto the threaded neck of a canister with a volume of 20-30 liters, after which the latter turns into your compact personal gas station! The pump can pump gasoline, diesel fuel, kerosene, antifreeze or process water. In principle, the device can also handle low-viscosity oils, such as flushing oils.

The device is screwed onto the threaded neck of the canister and, in fact, can live directly on it, replacing the standard cap. The thread on the pump is suitable for some types of canisters, but for those that are not suitable, the Berkut SP1010EP kit includes three threaded adapters of different diameters:

1 / 2

2 / 2

The gadget is powered either by two AA batteries or rechargeable batteries, or by four - with a proportional increase in operating time (from 2 batteries it can pump up to 700 liters, from 4 - to 1,500 liters of fuel). Turning on and off is divided into different buttons without fixing. The controls are simple – “turn on/off”.

1 / 3

2 / 3

3 / 3

An interesting feature of the model is an automatic shut-off system when the container is full. It works in exactly the same way as the one built into the pistol at an “adult” gas station - a sensor in the tip of the outlet hose turns off the pump when it touches gasoline. It works reliably - if the sensor first touches the level, and then for some reason (tilt of the container, etc.) becomes exposed, the motor will not turn on/off jerkily from splashing liquid, but will remain turned off until the next manual restart.

The only limitation on the use of the pump is the diameter of the pumping cartridge at the end of the flexible suction hose - it is 31 millimeters. Accordingly, the internal diameter of the canister neck must be at least 32 mm for the pump to fit into it. Almost all canisters have a suitable diameter, although there are exceptions.

The pump's performance is indicated in the user manual as “up to 9 liters per minute” - but these are the maximum capabilities, taking into account power supply from AA batteries with the best possible current and capacity parameters. We used regular AA batteries for the test. On them, Berkut SP1010EP pumped 20 liters of gasoline from canister to canister in 2 minutes 45 seconds. That is, the pump productivity was 7.2 liters per minute. A set of good batteries will be enough for most to use in country-garage conditions for the whole summer.

Berkut SP2000EP

This is a more thorough device that has a miniature gas dispensing pistol at the end of the hose, which allows you to dose fuel as accurately as possible - not by turning off the pump with a button, but by releasing the pistol handle. The pump module in it is, in principle, the same as that of the previous model (including a diameter of 31 mm), and the capabilities are similar. The gadget is designed for pumping gasoline, diesel fuel, kerosene, light oils with low viscosity, antifreeze, technical (not drinking) water.

By the way, the device comes with a coarse filter, which allows the device to work as a drainage pump - for example, to drain water from an aquarium.

1 / 3

2 / 3

3 / 3

The SP2000EP runs on D type batteries – popularly known as “thick round” batteries. This is in some way its drawback - such batteries are still not sold on every corner, unlike “finger batteries”. But the service life of these batteries is much higher: from one set, for example, you can pump up to 4,000 liters of gasoline.

1 / 2

2 / 2

The Berkut SP2000EP does not have a fuel level sensor or automatic shutdown - in fact, this is not necessary with a pistol grip. But there is... a shower head! The pump can be used as a camp shower for campers - however, if you have previously pumped fuel with it, some smell of gasoline is still inevitable. You can minimize the aroma if you first rinse the pump at home before going out for a few days. To do this, you need to put the gadget to work for 5-10 minutes in a bowl of hot water with added “Fairy” type detergent (lowering the outlet hose into the same container from which the pump pumps, and driving the water in a circle).

1 / 2

2 / 2

In general, a “battery-powered gas station” is a very real thing. And useful! Eh, if only it had a magical self-filling canister...