Andrey Katanin, Doctor of Physical and Mathematical Sciences, Chief Researcher at the Institute of Metal Physics named after. M. N. Mikheeva Ural Branch of the Russian Academy of Sciences, Professor of the Russian Academy of Sciences

"Kommersant Science" No. 6, September 2017

The Earth's magnetism is determined by the iron and nickel in its core. But it is not yet entirely clear how exactly. Photo: Science Photo Library / AFP

People have known about terrestrial magnetism for several millennia, but its cause has not yet been clarified. Theoretical research by Ural physicists can answer this question.

The magnetic properties of iron were discovered several millennia BC. e. Thus, in China, pieces of magnetic materials were used to create a compass. In 1269, “The Book of the Magnet” was written by Peter Peregrin, and in 1600, William Gilbert wrote a treatise “On the Magnet,” describing the basic properties of magnets and analyzing the magnetism of the Earth. Today, iron, including its magnetic properties, has many different technological applications. Iron is not the only magnetic substance; nickel and cobalt can be noted, which became of interest to humanity much later and are also widely used today.

Despite such a long period of study of magnetism, this phenomenon still raises new questions. In everyday life, we feel magnetism as attraction or repulsion between bodies. In physics, magnetism is understood as the ability of a body to maintain residual magnetization (that is, its own magnetic field) in the absence of an external magnetic field. And this own field can influence other magnetic bodies.

History of discovery

The production of the metal, which has been successfully used by humans for many hundreds of years, was not associated with scientific discoveries; nickel first fell into the hands of people by accident. After the meteorite fell, its pieces were melted down into weapons and religious objects, and the warriors and priests who used them intuitively understood the special properties of the metal, its amazing strength, combined with malleability.

Interestingly, the name “nickel” itself was a contemptuous name, translated as “false copper ,” but gradually the characteristics of the element were appreciated.

It is known that scientists of ancient China back in 235 BC. e. wrote about the amazing material pafong, which was a nickel alloy with zinc and copper. This allows us to conclude that metal began to be used by humans a very long time ago. Later, the alloy was brought to Europe, where it was used for coinage.

The use of metal in industry began in the second half of the 18th century; various of its alloys began to be actively used in the production of spurs, weapons, and even in the jewelry industry.

The honor of discovering nickel in the alloy belongs to the Swedish researcher Kronsted, who established that nickel is a new and hitherto unknown metal to science, and not an alloy of previously known elements. After the death of the Swede, his conclusions were confirmed by T. Bergman.

I. Richter was able to identify the physical and chemical specifics of the metal. He also described its ductility and resistance to corrosion due to its special configuration.

Interesting Facts

There are a lot of interesting facts related to nickel. First of all, it is worth noting the fact that nickel is a rather allergenic substance. People with hypersensitivity may experience a nickel allergy. About 10% of all newborns have hypersensitivity to nickel. For 2008, the American Contact Dermatitis Society recognized nickel as the allergen of the year. There are quite a few interesting theories in the scientific world. One of these is that nickel released as a result of volcanic eruptions contributed to the growth of the bacteria Methanosarcina. This type of bacteria is capable of producing methane, and as a result of the Siberian Trap volcanic eruptions, all anaerobic organisms in this area died. The number of these bacteria has increased so much that the methane they produce simply displaces oxygen.

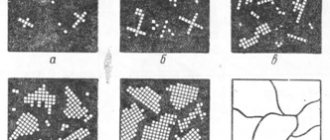

Specifics of the structure

A special feature of the mineral is that it belongs to the transition metals. It is also distinguished by its silvery-white hue and low chemical activity.

Researchers were able to identify the following structural features of nickel:

- The presence of a face-centered cubic lattice, the period of which is 0.35238 nm.

- The crystalline structure can withstand pressures of up to 70 GPa.

- Most often, the metal exists in the form of a b-modification with a cubic lattice with a period of 3.5236, and when cathode sputtering in an H2 atmosphere takes the form of an a-modification with a hexagonal lattice. It can transform into cubic when heated.

- The radius of an element's atom is 1.24 a.

- Density - 8.9 g/cm3.

The electronic formula for nickel is as follows: 1s2 2s2 2p6 3s2 3p6 4s2 3d8. The element has 28 electrons, 2 electrons are located on the 1s, 2s, 3s, 4s sublevels, 6 electrons are located on the 2p, 3p and 3d sublevels.

The oxidation state of atoms in compounds is 6, 4, 3, 2, 1, 0, -1. The structure of the nickel atom is a positively charged nucleus, inside of which there are 28 protons and 31 neutrons.

Nickel alloys and nickel steel grades

Alloy grades containing Ni are striking in their diversity:

- cathode sheets, plates and strips of nickel grades H0 and H1 - contain a mixture of cobalt and nickel, produced by electrolysis;

- strips, cathode sheets, granules, trimmings and other products from nickel grades H2, N3, H4 - contain a mixture of cobalt and nickel, produced by electrolysis, waste pressing, temperature refining, and also by remelting.

- wire, sheets, rods, tapes and strips – semi-finished products of the NP1, NP2, NP3, NP4 brands, which contain a mixture of cobalt and nickel;

- rods and sheets of semi-finished anodic nickel of the NPA1 and NPA2 brands - contain a mixture of nickel and cobalt;

- rods and sheets of non-passivable anodic nickel of the NPAN brand - semi-finished Ni, supplemented with cobalt-based additives;

- silicon nickel grade NKO,2 with cobalt-based additives – comes to the market in the form of wire;

- manganese nickel with cobalt-based additives (grades NMC1, NMC2, NMC2.5 and NMC5) – contains a mixture of Ni and cobalt, and is marketed in the form of wire.

Basic properties

The use of nickel by humans is based on the complex properties of this chemical element. The first thing to mention is malleability and ductility, which makes it possible to manufacture tubes and very thin sheets from metal. In addition, the following features can be highlighted:

- Brinell hardness is calculated to be 600-800 Mn/m2;

- tensile strength varies in the range of 400-500 Mn/m2;

- the yield strength is 120 MN/m2;

- the elastic limit is 80 Mn/m2.

Nickel is a yellowish or white-silver metal. It retains its color when exposed to open air and does not fade even with prolonged exposure to oxygen.

The metal is quite hard, but has a special property - it lends itself well to processing (polishing, forging), which makes it possible for it to be actively used by humans.

The products are thin and delicate, but at the same time strong and durable.

The concept of thermal resistance and thermal conductivity coefficient

If thermal conductivity characterizes the ability of metals to transfer the temperature of bodies from one surface to another, then thermal resistance shows an inverse relationship, i.e. the ability of metals to prevent such transfer, in other words, to resist. Air has high thermal resistance. It is he who, most of all, prevents the transfer of heat between bodies.

The quantitative characteristic of the change in temperature of a unit area per unit of time by one degree (K) is called the thermal conductivity coefficient. The international system of units usually measures this parameter in W/m*deg. This characteristic is very important when choosing metal products that must transfer heat from one body to another.

Physico-chemical characteristics

The magnetic properties of the element are preserved at very low temperatures, reaching -340 °C. In addition, its specificity is the lack of predisposition to corrosion.

The following physical characteristics of the metal can be distinguished:

- atomic number - 28;

- molar mass - 58.69 a. eat.;

- specific heat capacity - 0.443 J/(K mol);

- melting point - 1453 °C;

- boiling point - from 2730 to 2915 °C.

A special feature of nickel is the absence of negative reactions when exposed to air or water. This is due to the fact that nickel oxide NiO is formed on the surface - a protective film that protects the metal from subsequent oxidation.

At high temperatures, the element is able to react with oxygen and all halogens. In addition, the reaction is observed when it interacts with ammonia and nitric acid.

Moreover, the element is insoluble in phosphoric acid.

The concept of thermal resistance and thermal conductivity coefficient

If thermal conductivity characterizes the ability of metals to transfer the temperature of bodies from one surface to another, then thermal resistance shows an inverse relationship, i.e. the ability of metals to prevent such transfer, in other words, to resist. Air has high thermal resistance. It is he who, most of all, prevents the transfer of heat between bodies.

The quantitative characteristic of the change in temperature of a unit area per unit of time by one degree (K) is called the thermal conductivity coefficient. The international system of units usually measures this parameter in W/m*deg. This characteristic is very important when choosing metal products that must transfer heat from one body to another.

Thermal conductivity coefficient of metals at temperature, °C

Production organization

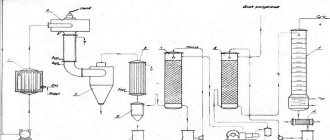

Nickel is one of the metals common in the earth’s crust, although it is not present in its pure form. The main source of production is copper-nickel ores, from which more than 75% of the metal can be extracted. The sequence of actions is as follows: first, the ore is enriched by flotation using a selective method, then concentrates, including nickel, are separated from it.

To obtain the metal in its pure form, the concentrate is melted, which requires reflective furnaces or electric shafts.

The waste rock is separated.

Before melting, the concentrate is often fired and pelletized.

It is customary to distinguish three methods of nickel production:

- Restorative. Obtaining a mineral from silicate ore with the participation of coal dust. As a result, pellets of iron and nickel are formed, the latter content being 5-8%. The resulting pellets are cleaned of sulfur, calcined and immersed in an ammonia solution.

- Carbonyl (Mond method). Copper-nickel matte is obtained from sulfide ore, after which pure metal is extracted under high temperatures.

- Aluminothermic. Recovery of element from oxide ores.

The second method allows you to obtain the purest nickel.

Thermal conductivity of metals depending on temperature

The table shows the thermal conductivity of metals depending on temperature at negative and positive temperatures (in the range from -200 to 2400°C).

The table of thermal conductivity of metals contains the thermal conductivity values of the following pure metals: aluminum Al, cadmium Cd, sodium Na, silver Ag, potassium K, nickel Ni, lead Pb, cobalt Co, beryllium Be, lithium Li, antimony Sb, bismuth Bi, magnesium Mg, zinc Zn, tungsten W, tin Sn, uranium U, iron Fe, palladium Pd, zirconium Zr, manganese Mn, platinum Pt, gold Au, copper Cu, rhodium Rh, thallium Tl, molybdenum Mo, tantalum Ta, iridium Ir.

It should be noted that the thermal conductivity of metals varies over a wide range and can differ tens of times under the same conditions. For example, of the metals listed in the table, the metal such as silver Ag has the greatest thermal conductivity - its thermal conductivity coefficient is 392 W/(m deg) at 100°C and this is the most thermally conductive metal. The lowest value of thermal conductivity at the same temperature corresponds to the metal bismuth Bi with a thermal conductivity of only 7.7 W/(m deg).

The thermal conductivity of most metals decreases when heated. Their maximum thermal conductivity is achieved at low negative temperatures. For example, at a temperature of minus 100°C, silver has a thermal conductivity of 419.8, and bismuth - 11.9 W/(m deg).

Note: The table also shows the thermal conductivity values of ultra-high purity metals (up to 99.999%). The value of the thermal conductivity coefficient in the table is indicated in the dimension W/(m deg).

- Thermophysical properties and freezing point of aqueous solutions of NaCl and CaCl2

- Thermophysical properties, composition and thermal conductivity of aluminum alloys

Classification of deposits

Metal mining is carried out in several deposits, which are usually classified into four groups. The first is copper-nickel sulfide, they are located in Australia, Canada, and the CIS countries. The next ones are nickel silicate and cobalt-nickel silicate, ferronickel oxide-silicate. They are available in Australia, Cuba, Indonesia, as well as in the south of the Urals and the Bug region.

Copper-pyrite deposits and vein sulfide-arsenide basins are not so widespread and are considered secondary.

On the territory of the Russian Federation, mineral extraction is carried out in the following main deposits: Oktyabrskoye, Zhdanovskoye, Talnakhskoye, Buruktalnoye. They are located in the territories of the Taimyr Autonomous Okrug, Murmansk and Orenburg regions. Reserves of the mineral are considered sufficient; shortages are not expected in the coming centuries.

A potential source for mining nickel ores is the ocean floor, since there is a lot of ferromanganese ores there.

Importance in everyday life and production

Why is it important to consider thermal conductivity? A similar value is indicated in various tables for each metal and is taken into account in the following cases:

In the manufacture of various heat exchangers. Heat is one of the important carriers of energy. It is used to provide comfortable living conditions in residential and other premises. When creating heating radiators and boilers, it is important to ensure rapid and complete heat transfer from the coolant to the end consumer.- In the manufacture of outlet elements. You can often encounter a situation where you need to remove heat rather than supply it. An example is the case of heat removal from the cutting edge of a tool or gear teeth. To ensure that the metal does not lose its basic performance qualities, rapid removal of thermal energy is ensured.

- When creating insulating layers. In some cases, the material should not conduct thermal energy transfer. For such operating conditions, a metal is selected that has a low heat conductivity coefficient.

The indicator under consideration is determined when testing under various conditions. As previously noted, the thermal conductivity coefficient may depend on the operating temperature. Therefore, the tables indicate several of its values.

Areas of use

Thanks to its outstanding physicochemical properties, in particular, corrosion resistance, strength combined with ductility, nickel has become widely used in various spheres of human life. Initially, its use was limited to jewelry making and coinage, but the discovery of pure nickel with a valence of 2 significantly expanded its scope.

Main areas:

- Nickel plating of other metals. Nickel is resistant to corrosion, so applying it to the surface of products helps eliminate the risk of rust.

- Used in combination with iron, cadmium, hydrogen or zinc to produce batteries.

- Used as a catalyst for chemical reactions.

- In medicine it is used to make braces and dentures.

- In the music industry it is used for winding strings of musical instruments.

- A large number of heat-resistant superalloys, projectiles, equipment, and wire are made based on nickel.

- Nickel steel is actively used in mechanical engineering, as it helps to obtain light-weight but very durable parts. This is its significant advantage, distinguishing the inexpensive metal from its more labor-intensive “relatives.”

In addition, nickel is an element necessary for the normal functioning of the human body; it affects normal growth and full development. Its deficiency negatively affects the functioning of the kidneys and liver, but most often doctors are diagnosed with excess nickel. It is important to remember that the daily norm of the element is no more than 30-60 mcg. It is found in soybeans, peas, chickpeas, beans, beef liver, various types of rice, and oatmeal.

Although nickel looks rather modest, resembling a faded copy of silver or steel, it is very useful to humanity and is used in various areas of modern industry.

Factors influencing the thermal conductivity value

The thermal conductivity of materials used in construction depends on their parameters:

At the beginning of the measurement, the initial stationary temperature state is assumed. The measuring sensor and the sample form two semi-infinite regions. The linear part of the curve is parameterized by the used capacitance of the flat source and the thermal insulation properties of both adjacent half-spaces.

In general, the calculation of the thermal conductivity value can be expressed by the equation. During practical measurements, measurement results on reference materials were applied to select the optimal measurement interval and optimal heat source power output with respect to maximizing measurement accuracy and repeatability.

- Porosity – the presence of pores in the structure of a material disrupts its homogeneity. When a heat flow passes, part of the energy is transferred through the volume occupied by pores and filled with air. It is accepted to take the thermal conductivity of dry air (0.02 W/(m*°C)) as a reference point. Accordingly, the larger the volume occupied by air pores, the lower the thermal conductivity of the material will be.

- Pore structure – the small size of the pores and their closed nature help reduce the rate of heat flow. In the case of using materials with large communicating pores, in addition to thermal conductivity, heat transfer processes by convection will be involved in the heat transfer process.

- Density - at higher values, particles interact more closely with each other and are more conducive to the transfer of thermal energy. In general, the thermal conductivity values of a material depending on its density are determined either on the basis of reference data or empirically.

- Humidity – the thermal conductivity value for water is (0.6 W/(m*°C)). When wall structures or insulation get wet, dry air is displaced from the pores and replaced with drops of liquid or saturated moist air. Thermal conductivity in this case will increase significantly.

- The effect of temperature on the thermal conductivity of a material is reflected through the formula:

λ=λо*(1+b*t), (1)

Determination of the thermal conductivity coefficient of building materials using non-stationary flat measuring equipment. Due to its design, non-stationary flat measuring equipment has many advantageous properties. With this device, you can easily and quickly measure the value of the thermal conductivity coefficient for any building material.

The measurement itself lasts only a few seconds, and therefore the value of the thermal conductivity coefficient can be determined depending on the humidity of the test sample. The flat sensor provides the ability to determine the thermal conductivity coefficient of significantly inhomogeneous materials. The sample size requirements are significantly smaller compared to other methods. For these reasons, it is possible to determine the thermal conductivity coefficient even in a part of building products, since with standard samples the thermal technical properties can differ greatly from those of the final products. Measurement accuracy. As with any measurement method, even with a non-stationary flat meter, the greatest error comes from the test sample. If the surface of the test sample is uneven.

- Measurement speed.

- Unlike classical methods, this method is incomparably faster.

- Flexibility of measurements.

Due to its favorable properties, the measuring device can be used to determine the measurement of thermal conductivity in a wide variety of materials and products, for example.

where, λо – thermal conductivity coefficient at a temperature of 0 °C, W/m*°C;

b – reference value of the temperature coefficient;

t – temperature.

Which thermal conductivity measurement method is best for your material?

There are methods for measuring thermal conductivity such as LFA, GHP, HFM and TCT. They differ from each other in the sizes and geometric parameters of the samples used to test the thermal conductivity of metals.

These abbreviations can be deciphered as:

- GHP (hot guard zone method);

- HFM (heat flow method);

- TCT (hot wire method).

The above methods are used to determine the coefficients of various metals and their alloys. At the same time, using these methods, they study other materials, for example, mineral ceramics or refractory materials.

The metal samples on which the research is carried out have overall dimensions of 12.7 × 12.7 × 2.

Nickel plating

This is the name given to applying a coating to the surface of another material. The purpose of this is to protect the product from corrosion. Coating is applied in a galvanic bath. To carry out high-quality galvanic operations, electrolytes containing sodium and boron salts, various surface-active components and glossy elements are used. The thickness of the nickel coating is up to 36 microns. To improve the quality of the applied coating, it is allowed to apply a layer of chromium on top of the nickel.

There is a way to apply nickel without using electricity. That is, the coating is applied in a mixture that includes nickel and sodium salts.