The operation of mechanical components of machines is accompanied by a serious load on the surface of the parts, especially with regard to various holes. The upper contact layer of metal takes on the lion's share of mechanical influences and forces, preventing a destructive effect on the inner layers. The stronger this outer layer is, the higher the overall wear resistance of the product will be. To artificially strengthen the surface of the holes, a technological technique such as mandreling the holes is used.

In mechanical engineering, mandreling is the use of a process of strengthening the surface of a hole by calibrating or drawing a deforming one. In addition, burnishing allows for shaping or finishing of the hole bore. The layer that is strengthened can be of different thicknesses, it depends on the magnitude of the tension.

Purpose and scope of application of burnishing

As briefly mentioned above, burnishing is necessary to strengthen the surface of the hole shafts, giving them greater strength, thus increasing the wear resistance of the product. All this is accomplished due to the ability to plastically deform the metal throughout the contact zone using a mandrel. There are two types of mandrels: sliding and rolling. Most often, the process occurs when the workpiece is cold.

When the mandrel tool moves along the barrel with a certain level of tension, other problems are solved along with strengthening the walls:

- adjusting the diameter of the hole to the required parameters, the trunks of rectangular holes to the required dimensions;

- getting rid of irregularities and any roughness that were caused by the previous processing of the trunk;

- the ability to form a certain cross-sectional shape, for example, to create slots, grooves or an original pattern on the inner surface.

Mandrelization is used not only in civil engineering, but also in weapons production. With its help, gun barrels of tanks and other vehicles are strengthened and used in the manufacture of cartridges.

When it is planned to apply mandrel to a particular hole, it is important that the mandrel has a diameter larger than the cross-section of the hole's barrel by the tension thickness. All this is calculated very accurately so that there is no rupture of the workpiece.

Threads for attaching muzzle devices to hunting weapons

June 7, 2019

Weapon tuning is a very interesting and exciting activity, but it requires minimal knowledge about your weapon system. Let's talk about tabletop threads today. To use a flash suppressor, DTK (muzzle brake-compensator) or sound moderator (silencer for a weapon), you need to know what thread is cut on the barrel by the manufacturer. For convenience, manufacturers make standard threads, but sometimes rare ones are found on “exclusive” weapons.

First, let's decipher some abbreviations:

M

- Metric system.

For example, M14x1 LH

means that the measurements are in metric system, thread diameter is 14 mm in 1 mm increments, left hand.

5/8″- 24

– Inch system.

The value 5/8″

is the outer diameter in inches (0.625 inch or 15.875 mm),

24

is the number of threads per inch.

Lh

(or

L

) – Left Hand, left-handed, screwed counterclockwise.

Rh

(or

R

) – Right Hand, right-handed, winds clockwise.

For example, M16x1Rh.

If there is no Lh or Rh designation, Rh is used by default.

UNEF

– Unified National Extra Fine – Standard for unified threads for special applications.

Sometimes, instead of UNEF, they are denoted by the abbreviation TPI, this is not entirely correct, since threads per inch stands for - the number of turns per inch and indicates the last numerical value in the thread designation in the inch system.

.223Rem ( 5.56 NATO)

1/2″x28 UNEF

- the most common muzzle thread on carbines of the AR-15 system, in very rare cases others are found, for example, in the Steyr Aug carbine there is a M13x1Lh thread or Saiga MK 03 - M24x1.5

7.62x39

In AK-based carbines, this caliber is logically represented in the metric system, the most common being M14x1Lh

, with the exception of Saiga MK 03 with

M24x1.5

and PKM in caliber 7.62x54 -

M18x1.5Lh.

5.45×39

On AK 74 (AKS74, AKS74U and Vulkan TK) – M24x1.5

, and RPK -

14x1Lh

.308 Win

5/8″-24 UNEF

thread is the most common thread for AR-10 based carbines, such as the Zbroyar Z10, DPMS G2, Bushmaster ORC, NEA 25 and bolt-action rifles Remington 700 SPC, Zbroyar Z-008, Savage 110, Tikka T3x TACTICAL, KelTec 308Win Bla

M18x1 muzzle thread

, and Accuracy International -

M18x1.5

, Sauer S series -

M15x1

.22 LR, .22 MAG, .17 HMR

Standard thread for these gauges is 1/2″x28 UNEF

1/2″x20 UNEF

is also found - from Marlin and Sako

9mm (9x21)

1/2×28

- the most common thread for 9 mm weapons - both carbine and pistol. On a modern copy of the legendary MP38 submachine gun from the Ukrainian manufacturer Automatic, the thread is M16x1.5

.338LM

5/8″- 24 UNEF

- the most common for .338LM weapons, for example Savage 110 (111,112), McMillan TAC-338, etc.

Sako TRG uses M18x1

, Accuracy International -

M18x1.5

, Desert Tactical Arms

3/4″-24

, Surgeon PSR -

3/4″-28

, Blaser R8 -

M17x1

Manufacturers complete weapons when selling them with a DTK or cap to protect the threads from mechanical damage during operation.

Above we examined the most commonly used weapon threads for muzzle devices, and as you can see, it all comes down to about a dozen options. However, each rifle model may differ in thread; here, the manufacturer may be guided by the thickness of the barrel or other parameters when choosing.

Share on social media networks:

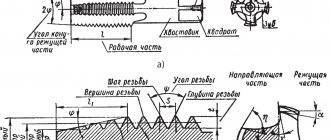

Burnishing technological process

The specifics of the mandrel process will technically depend on the choice of metal processing scheme, of which there are three:

- when stretching is applied;

- use compression;

- combine the process of compression and tension.

When using any of the first two schemes, the impact on the product takes place over a specific segment. Mandrelization according to the combined principle assumes that the load will be distributed over the entire surface of the part from the inside of the barrel.

If you need to process the barrel of a part in three-dimensional form, the following technological schemes are chosen:

- neutral counter tension;

- active;

- passive.

The use of these schemes is associated with the use of axial stress, and additional elements are needed - movable type supports so that the shortening of the product does not go beyond acceptable limits.

The use of different types of mandrels in any case assumes that the tool will move inside the bore under the influence of a special broaching mechanism or a hydraulically driven vibrating support. In this case, the channel is constantly lubricated in order to reduce friction with the metal layer and smoother passage.

Varieties

The types of mandrelization mean the free and non-free process of carrying out the operation.

When the mandrel is free, the product, namely its surface, is not limited in the possibility of deformation. This type of process is acceptable for large-scale work with electric-welded pipes or for seamless casting, where the thickness of the barrel wall is determined as an average value. Free mandrel is not suitable for workpieces such as pipes with thin barrel walls. Here, non-free blowing is used, which avoids the following consequences:

- axial displacement of the workpiece;

- decreased stability along the direction of the trunk;

- smoothing metal of insufficient quality.

To implement the non-free mandrel operation, the part is secured in special cages of a rigid and elastic structure before passing through the mandrel.

The use of any of the burnishing methods requires the use of lubricants to reduce friction, speed up the processing process, and avoid damage to the workpiece or tool.

Volumetric and surface burnishing

Mandrelization as a method of processing the bore of a hole, when there is no chip removal process, can be performed superficially or volumetrically.

With the volumetric method, the operation involves the entire workpiece (meaning the cross section). By making one pass with a tool, the working part of which is equipped with several teeth, an actual roughness in the range of 0.63–0.04 microns is achieved with great hole accuracy. Due to its effectiveness, volumetric burnishing is intended to replace a less effective method when workpieces are subjected to rough boring. Volumetric deformation is used to process any types of pipes and cylinders with a long barrel, while the straightness of the products is maintained within the required limits.

The use of surface burnishing makes it possible to obtain a roughness in the bore within the range of 0.32–0.04 microns. The main purpose of the method is to strengthen the surface layer and, possibly, to avoid complex technological techniques: reaming, grinding, smoothing and honing the metal.

Plastic deformation and sizing

The essence of plastic deformation is that a mandrel with a diameter of the working part larger than the bore of the hole is pressed into the latter under the influence of the force of the machine. Calibration of the inner surface of the pipes occurs when the area being treated is exposed to a source of thermal energy for heating and subsequent introduction of the mandrel into the area of the tool. The disadvantage of calibration is the possible change in the parameters of the workpiece and the greater complexity of the process regarding plastic deformation.

Shock pulse method

The method in which the mandrel tool is fed along the bore of the barrel not in a constant translational mode, but in shocks with the same frequency, is called the shock pulse method. This process is very effective, as it reduces the load on the tool and the channel and allows for maximum processing accuracy.

Practitioners in the field of metal processing and anyone who has direct experience with the process of mandreling holes, support the topic in the comments. For beginner craftsmen, your knowledge is invaluable!

Which barrel is better?

The old adage that the barrel shoots and the stock hits clearly shows how much importance is placed on the barrel when fitting a gun to the shooter. There are many ways to make barrels, each of which has its own characteristics, advantages and disadvantages. These individual traits are the topic of the article.

Whether the barrel will give the accuracy expected by the shooter depends not only on the pitch of the rifling, which is suitable for the caliber, weight of the bullet and powder charge, but, first of all, on the base material, the size match and the care with which the barrel is made. Almost all models of long-barreled weapons for shooting bullets (with the exception of certain models chambered for Flaubert and pneumatic weapons) have rifled barrels, that is, those that, for accurate shooting with single shots, have deep grooves inside and protruding fields with sharp edges. Such a screw thread cuts into the leading surface of the bullet and gives it a rotational movement relative to its own longitudinal axis, making possible stable movement of the bullet along the trajectory. The same function is performed by rounded arcs of a circle, smoothly flowing into each other, which form a soft-flowing polygonal profile without sharp edges. It deforms the bullet and also causes it to rotate.

This sometimes gives reason to assume that even today trunks are cut exclusively using traditional technology - by removing chips. But this is far from true. Previously, there was no alternative to this technology, but since then manufacturers have switched to more modern and much less material-intensive processes. For example, barrels can also be produced by mandrel burnishing (direct and reverse), forging and the so-called electrochemical method.

There are very few steel manufacturers in the world who can or have the desire to produce a source material that is absolutely specific in the totality of its properties and almost perfectly meets the requirements for gun barrels. One of them is the American company Carpenter Technology Corporation, whose headquarters are located in Reading, Pennsylvania. This company incurs particularly high production costs. Meticulous quality control (including constant monitoring of individual workpieces for scratches and deviations from cylindrical shape) throughout the entire technological process should ensure the absolute absence of structural defects in each workpiece. When it comes to the best starting base for producing stable, high-precision barrels of the highest quality, the legendary Carpenter stainless steels 416R (here R stands for rifle barrel steel) and 416RS for barrels are by far the first choice today. with particularly thick walls (here S stands for high sulfur content). In addition, these high chromium steel grades provide less wear on very expensive tools and allow for significantly higher machining speeds than most other steel grades.

Since the very beginning of mass industrial production, barrel blanks have been produced mainly by rolling. They are then machined, refined and drilled using a deep hole drilling machine. Finally, the surface of the bore is honed. After this, the cuts are obtained using one of the methods described in this article.

A rifled barrel is a barrel whose internal profile is formed in such a way that, due to controlled deformation of rotation, it stabilizes the bullet on its trajectory. This name goes back to one of the methods described here for obtaining an internal profile - the cutting method. And although there are other technological options, with the exception of barrels with a cylindrical internal surface, they are always called rifled.

CUTTING TRUNKS

The technologically outdated method of producing rifling by removing chips is today, of course, the rarest technological method. Here, each cut, one after another, is processed individually by the blade of a tool called a trellis, and by moving the tool in steps, it cuts deeper and deeper until the desired profile is obtained. In this case, either the fixed barrel blank or the trellis rod rotates to obtain spiral grooves (the author describes the technological process of cutting with a hook trellis; for more than a hundred years there has been a method of trellis cutting, in which the number of “brushes” - the cutting elements of the trellis is equal to the number of grooves, and cutting happens simultaneously - translator's note). The rifling is carried out on a barrel cutting machine, which allows you to precisely execute the desired rifling pitch, accurately preset the rifling depth, and accurately track the rifling with each pass.

The basis of the basics. The weapon barrel blank must meet high quality requirements, otherwise the finished barrel will not give the best results

Finally, rough surfaces are smoothed using a lapping surface. The minimal stresses that arise during this process are eliminated by heat treatment, in which the barrels in a vertical position are heated in a furnace to a certain temperature and cooled very slowly. After 24 hours, the trunks can be handled (at least with gloves) and removed from the oven. Disadvantage: This traditional cutting method cuts the fibers of the material and thereby destroys its internal structure. In this case, of course, strength suffers (compression, tension, bending, torsion). Despite this, elite barrels, for example from the American companies Bartline and Krieger, are still produced using this old method.

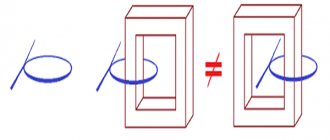

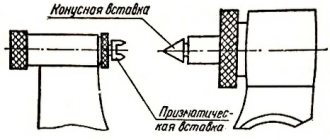

Burling (punching and pulling) refers to methods of cold deformation without removing chips. Here, on a machine, with great force, a hard metal rod, the so-called mandrel with an outer profile opposite to the profile of the barrel bore, is pressed or pulled through a fixedly fixed barrel blank with a smooth hole with a diameter slightly smaller than the caliber. This mirror-like mandrel not only forms fields and grooves, but also simultaneously compacts the material and thus provides a noticeably lower surface roughness compared to traditional machining methods by chip removal. Since mandrel barrels currently have a tensile strength of up to 1050 N/mm2 and their surface must be carefully honed to reduce the pressing force, they are almost as good as forged barrels in terms of surface quality. But still, after such a difficult operation, the trunks often need to be straightened - this is what is called restoring the straightness of the bore axis.

From a solid workpiece: after deep drilling of the workpiece, the holes should be concentric with the outer surface along the entire length

Due to the fact that deformation occurs “only” on the inner surface, such large stresses do not arise in the metal structure as during forging. They are eliminated by vacuum tempering, which involves heating the barrels, placed individually in an oven, where they are then slowly cooled overnight. Often, at the end, additional deep cooling is carried out in a liquid nitrogen environment. And since during mandrel it can often happen that the profile of the barrel bore is not 100% located along the axis of the barrel blank and is imprinted unevenly, then when manufacturing precision barrels, a mandrel soldered to the holder with a profile opposite to the channel with rifling is pulled through the barrel bore. At the same time, the mandrel makes a forced screw movement, and as a result, the axis of the barrel bore from the muzzle to the breech runs exactly along the axis of symmetry of the barrel. Then an experienced specialist checks the straightness in the old proven way, with the naked eye, using a shadow triangle, and, if necessary, straightens the barrel.

FORGING METHOD

In so-called rotational forging, which is also a method of cold deformation without chip removal, preparation is carried out in a similar way. But it is necessary to distinguish between two methods. The method used by the Austrian firm GFM GmbH Steyr is called "hydraulic forging" because their machines forge barrels with standing prismatic firing pins that are hydraulically driven while the barrel blank rotates. Since in many cases the chamber is also forged together, large degrees of deformation occur with correspondingly strong stresses in the material. With the so-called “rotational forging” method, which is used by Metalltechnik Menges GmbH and Heinrich Mueller Maschinenfabrik GmbH, deformation is carried out by mechanical action. In this case, the radially moving strikers quickly rotate around the slowly rotating barrel. Since in this case the processing occurs at very low degrees of deformation (the decrease in the outer diameter is approximately 2 mm) and an improved metal with high ductility that has undergone special heat treatment is used, almost no stress occurs in the metal, and final heat treatment can be abandoned.

The finishing operation of making a gun barrel: rough spots on the surface of the hole are removed by reaming, and the bore is brought, so to speak, to its final dimensions

More precisely, the forging process occurs as follows: a polished, precisely ground (honed) steel pipe, which in this case has a larger internal diameter, is forged on a forging machine from the outside on a mandrel, which is a tool made of high-strength hard material, the shape of which is made in the form of a reverse profile bore, with fields and rifling. From two to eight (usually four) strikers located concentrically around the barrel, which move in the radial direction and with high frequency, compress the workpiece with great force, which moves in the axial direction at low speed. At the same time, they compact the metal of the barrel from the outside and inside so much that fields and rifling are imprinted in the channel.

The result is an exceptionally smooth interior surface that requires minimal (if any) post-processing and is also very resistant to lead and copper deposits and erosion due to its low roughness. But during forging, due to changes in the source material in both of the above methods, the highest stresses are generated in the structure along the entire length, since the barrel is lengthened by about one-third during this operation. Then, of course, these stresses must be eliminated (mainly during the manufacture of barrels using the “hydraulic” forging method) by other time-consuming processes (stress relief tempering, deep cooling in liquid nitrogen). Their implementation requires high qualifications.

With a cutter: on a CNC lathe, threads are cut on the barrel of a self-loading rifle with the highest precision

The instability of the internal diameter of the initial workpiece does not play such a big role in this case, since forging is carried out along the mandrel and the differences are smoothed out. Any initial defects are simply sealed away, and often appear only when the weapon begins to be used, and the barrel heats up. Therefore, not a single manufacturer of high-precision benchrest barrels in the USA or Europe uses this method.

ELECTROEROSION METHOD

Completely different paths are taken when using methods that do not relate to either cutting or plastic deformation. They are used, for example, to produce premium match barrels for pistols known under the Briley and Nowlin brands. But in comparison with the methods already described, they are so complex that for a better understanding they need to be explained in more detail.

Stress Relief: In order for the barrel steel to withstand stress, the barrels are heated in a furnace in a vertical position, thereby minimizing stress

At first it was an electrical discharge process, abbreviated as EDM (Electrical Discharge Machining). In this case, we are talking about the technological process of thermal removal of a layer from a conductive material, which is based on the process of an electrical discharge (spark) that occurs between the electrode (tool) and the electrically conductive workpiece. The processing process itself takes place in a non-conducting medium, the so-called dielectric (most often this is oil or deionized water). It occurs either in a bath that is filled with a dielectric, or the surface to be treated is washed with a hose. The electrode is brought to the workpiece with a small gap of 0.004 to 0.5 mm until a spark occurs, which melts the material pointwise and turns it into gas. Depending on the intensity, frequency, duration, length, interelectrode gap and polarity of the discharges, different metal removal is obtained. Even geometrically complex shapes are made. The choice of electrode material always depends on the material being processed; however, as a rule, these are copper, brass, graphite and copper alloys (most often with tungsten).

ELECTROCHEMICAL METHOD

With the electrochemical principle, metal removal is carried out, for example, by the classical method of electrochemical machining, abbreviated ECM (Electro Chemical Machining - electrochemical machining (English)). It is suitable not only for very hard materials and simple deburring, but also for obtaining very complex spatial shapes. Further developments of this method are called PE CM (Pulsed Electro Chemical Machining) and PEM (Precise Electro Chemical Machining).

The workpiece is polarized as the anode (positive pole) and the tool as the cathode (negative pole). Almost always, an external voltage source is used here to obtain the current necessary for this. In some cases, such as in metallography, electrochemical etching is used to reveal the microstructure of a metal. Here, the potential difference at the micro level serves as an internal voltage source to obtain the desired material removal.

Left. Output: untreated muzzle of the barrel. Here you can clearly see that the hole in the workpiece is located exactly along the axis. In the center. Top notch: This light varmint barrel is a Stainless Select Match Grade. On right. Change of material: this barrel is made of chrome-molybdenum steel (C mark), Match Grade quality, hand-faced (XX mark)

With the described ECM method, the shape of the cathode tool determines the contour of the workpiece. The physics of the process determines the absence of tool wear. Depending on the electrical parameters and electrolyte flow parameters, there should be a gap of 0.05 to 1 mm between the tool and the workpiece. The transfer of electric charge in this gap is carried out by an electrolyte solution, for example, an aqueous solution of sodium chloride (NaCl - table salt) or sodium nitrate (NaN03).

The resulting flow of electrons separates metal particles from the workpiece, which then react with particles of the split electrolyte at the anode. These residues react again at the cathode with water. The end product of the reaction is metal hydroxide, which settles as dirt and must be removed. In addition, the dependence of the gap between the anode and the cathode on electrical and hydromechanical parameters makes it difficult to pre-calculate the cathode shape.

In general, this method can be used to make all flat parts, such as turbine blades, due to the fact that they have a simpler relationship between shape and size. This results in significantly lower costs for preparing the operation. The achievable surface quality (parameter Rz is the average height of microroughness at 10 points relative to the center line of the profile - translator's note)) with this only processing method by removing a layer of metal, which does not affect the boundary zones, ranges from 3 to 10 microns.

The abbreviation EDCM stands for Electro Chemical Discharge Machining; this is the name of the hybrid technological process, since it is a combination of two technological methods - electrical discharge (EDM) and electrochemical dissolution (ECM); it combines their technical advantages. Here, electrically conductive materials can be processed through electrical discharges that are generated in an electrolytic solution consisting of demineralized water and powdered salt. It is also used to produce small holes in injection systems in the automotive industry.

Top left. No limits: As can be seen from the outer contours of these custom-made white finished barrels, there are few limits placed on the customer's wishes. Top right. Step by step: from a rod, which is then turned into a blank, and after many stages of the technological process, a barrel ready for installation on a weapon appears, in accordance with the wishes of the client. Bottom center. Versatility: Lothar Weather produces barrels in more than 100 calibers, various external contours, from blanks and finished barrels for rifles and short-barreled weapons to barrels for black powder weapons

Physical principle: after an electric voltage is applied to the tool (cathode) and the workpiece (anode), which are located at a distance of several micrometers from each other, gas is first formed in the electrolyte solution located between the tool and the workpiece at the cathode (hydrogen) and products of electrochemical dissolution (anode material) are deposited. This means that the development of the electrochemical phase (ECM) of the ECDM process occurs here. During the process, gases that move towards the workpiece rush towards the cathode, so that the electrical resistance of the interelectrode gap thereby gradually increases. Then the gases reach the surface of the workpiece and thereby create complete electrical insulation in the interelectrode gap. The subsequent electrical discharge, the occurrence of which marks the beginning of the electrical discharge phase (EDM) of the EDCM process, causes the workpiece and tool to melt.

An essential feature of all processes similar to electrochemical machining is the lack of contact between the tool and the workpiece. As a result, no mechanical forces are transmitted and the process does not depend on material properties such as hardness or viscosity. But factors such as melting point, thermal and electrical conductivity matter. Methods in this group are suitable, without exception, for processing electrically conductive workpieces, for example, made of carbon steel, austenitic steels, as well as nickel alloys, for which it is especially important to ensure targeted metal removal. With their help, you can also process deep, narrow and hard-to-reach grooves, very complex surfaces with variable roughness, extremely hard, difficult-to-cut materials (hardened steels, titanium, hard metals, high-strength electrically conductive ceramic materials), and deburr edges.

Problems arising from unwanted interactions in boundary zones when machining methods reach their limits can also be resolved. Their application possibilities go far beyond the boundaries of conventional cutting technology, since they can be used to process workpieces made of very hard materials, such as hardened steels, titanium or hard metals, very precisely and without the formation of burrs. In this case, even sharp edges can be obtained.

Force operation: during cold forging in a forging machine, the barrel material is deformed under a force of several tons

The disadvantage is not only the large preparatory time for making the electrode; each one needs to be designed, drawn and manufactured, but also takes a very long time to set up the machine. For each electrode, it is necessary to measure the deviation from symmetry, perimeter and length and transfer the measurement data to the machine. If you need to work very accurately, then all surfaces subjected to electrical discharge processing must be periodically measured and, if necessary, modified. But, as many years of experience show, stable quality is ensured only in rooms with stable climatic conditions, since temperature fluctuations lead to inaccuracy in manufacturing. Due to the significant overall costs required, these otherwise advantageous methods generally result in the highest costs for tool making and shaping.

DISCUSSION OF BARREL MANUFACTURING METHODS

Which of the above methods is the best in terms of barrel quality? To this day, even among experts in the field of barrel technology, there is no consensus on the best method for producing barrels, since each of these methods has its own advantages and disadvantages. With traditional cutting, more metal is required than necessary, the structure of the metal is disrupted and, thereby, its phase structure is destroyed, which reduces strength. All methods that do not use a cutting process save material and time, in addition, they compact and smooth the surface, but always create more or less strong, unwanted stresses in the barrel, which can be eliminated by heating the barrel and then deeply cooling it in liquid nitrogen. And technological methods based on spark erosion often produce a rough surface, especially in long shafts, because due to repeated voltage fluctuations between the tool and the workpiece, metal removal occurs unevenly. And then these unevennesses must be eliminated by prolonged manual shuffling.

Anyone who wants to know this for sure can download the relevant detailed information from the websites of barrel manufacturers. Even more important than the method of obtaining the barrel (and the opinions of various experts do not differ on this) is the care in choosing the barrel material and the accuracy in subsequent processing down to the smallest detail. Only when the tolerances on the barrel remain at a level of no more than 0.003 mm, is constant uniformity at the level of 0.001 mm ensured in the bore and outside (apparently, this means deviation from cylindricity - translator's note) and, in particular, if the circumference of the fields and the rifling is absolutely concentric and this is maintained along the entire length, then we can expect the maximum achievable accuracy. And even achieve it if all other factors, including the shooter, contribute to this. Because even the best barrel will produce excellent results over time only when it is regularly and expertly cleaned, and the remaining bullet casing and powder deposits are completely removed.

The know-how of different barrel manufacturers is very specific, they are often worked out during tedious experiments at the company, which sometimes take decades and, of course, such professionals, due to competition, have the seal of the strictest secrecy on them!

Gabriel Wagner Translation by Mikhail Dragunov