Decoding electrodes OK 46

ESAB OK 46 electrodes have fairly simple markings. First of all, these are products of an internationally renowned company. The ESAB industrial plant has over 110 years of experience in the manufacture and development of welding consumables. The abbreviation OK used in international markings is nothing more than the initials of the founder of the manufacturing company, Oscar Kelberg. 46, or 46 00 - the maximum load that a seam resulting from the use of these electrodes can experience.

Electrodes OK 46: technical characteristics

electrodes ESAB OK 46 00

ESAB OK 46 electrodes are coated with rutile-cellulose coating. The rod is made of wire types Sv08 and Sv08A. The diameter can be 2mm, 3mm, 4mm (range is 1.6-5mm). After using them, the weld will consist of 0.08% carbon, 0.4% manganese, 0.3% silicon, 0.030% phosphorus and 0.025% sulfur.

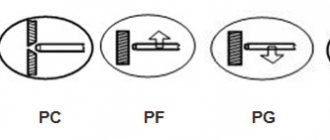

The open circuit voltage is 50 V. The yield strength is 400 MPa, the tensile strength is 510 MPa. Impact strength ranges from 35 J/cm2 to 70 J/cm2 at temperatures from -20°C to 0°C. Welding is possible in all positions. You can weld with short seams, form a root pass, and perform tack welds. In this case, both alternating current and direct current with reverse polarity are used.

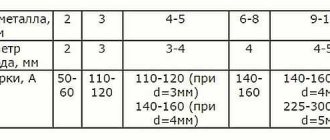

table of dependence of electrode diameter approx 46 on current strength and welding position

It is recommended to calcinate OK 4600 before welding. This is best done at temperatures between +70°C and +90°C. Drying time is at least an hour.

Description

Electrodes OK-46 according to GOST 9467-75 are produced with a diameter of 1.6;

2; 2.5; 3; 4 and 5 mm. For small sections ∅1.6 and 2 mm, the length is 300 mm, for the rest - 350 and 450 mm. The rods are made from welding steel wire SV-08 or SV-08A with rutile coating. Standard work productivity is 1.4 kg/hour. This is exactly the number of electrodes required to deposit 1 kg of metal. For calcination, you will need a mode of 70–90 °C and a heating duration of 1 hour.

Figure 2 - Technical parameters

The OK-46 designation indicates that the electrode is intended for manual arc welding. The finished connection can withstand a load of 46 kg/mm².

The properties of the finished weld determine the reliability of the future metal structure and the possibility of operation under the given conditions. These parameters depend on the chemical composition of the electrodes and the progress of the welding process. It is based on the technical characteristics and type of work performed that welders select electrodes.

The chemical composition of the deposited metal is characterized by the content of the following elements: C=0.08%, Si=0.3%, Mn=0.4%.

Mechanical properties of the seam:

- tensile strength – 510 MPa;

- yield strength – 400 MPa;

- tensile strength – 510 N/mm²;

- impact strength at temperatures -20...0 °C is 33–70 J/cm²;

- the yield of deposited metal in relative terms is 96%.

Characteristics of electrodes of different diameters

To know what type of OK electrodes you need, it is worth considering not only the type of base metal and equipment. We bring to your attention a description of the qualities of the electrodes based on user reviews.

- OK with a diameter of 2 mm cannot be used for pipeline repairs. Resistant to high temperatures.

- 2.5 mm. Such electrodes are best used when welding stainless and carbon steel, and with alternating current. Before starting welding, the working surface should be thoroughly cleaned of dirt and dust.

- 3 mm. They perform well when working on a pipeline. Viscous.

- 4 mm. Before welding, all rust must be removed from metal surfaces. The voltage must be constant.

- 5 mm. Cannot be used for short arc welding. They deposit metal very well and are used economically.

Welding modes

| Electrode diameter, mm | Consumption per 1 kg, pieces | Current strength depending on position, A | ||

| lower | vertical | ceiling | ||

| 2 | 50 | 40-80 | 40-60 | 50-70 |

| 2,5 | 45 | 60-100 | 60-90 | 60-110 |

| 3 | 39 | 80-160 | 80-140 | 80-180 |

| 4 | 19 | 110-210 | 110-200 | 90-220 |

| 5 | 13 | 150-300 | 150-280 | 150-270 |

OK-46 electrodes operate on direct and alternating current of any polarity. They can be connected to household power sources because they have a stable arc at a minimum current value and a low open-circuit voltage (50V).

Among the shortcomings identified by users, OK-46 electrodes have a high price, thick-walled metal is poorly welded, not everyone’s new electrode lights up the first time, and they no longer go through their slag. When they sit in an open package and collect moisture, the slag has to be beaten off in the usual way.

Purpose of OK 46 electrodes

Electrodes OK 46 3mm and 4mm are widely used in construction, industry, shipbuilding, and installation. They are also suitable for household work. With the help of such electrodes, structures made of low-carbon and low-alloy steels, including those with wide gaps, are welded. Since it is possible to weld in a top-down position, and the arc can burn stably at a minimum current, OK 46 electrodes are used in the manufacture of thin metal parts. The probability of burning through the material is minimal, the seam is strong and neat. They can also be used to weld products that have a galvanic coating.

Technical parameters and characteristics

The OK-46 multifunctional electrode with excellent welding and technological properties has a dense coating and a stable arc, due to which the weld pool is protected from the influence of external factors. It ignites well even at low current at the beginning of operation and when re-igniting when the coating is already burnt or the end is melted.

Figure 1 - Welding result

OK-46 electrodes are universal in terms of the spatial position of the weld. They even cook in tight spaces and over painted surfaces. Suitable for making assembly tacks, applying short and root welds. They have proven themselves well in case of periodic arc breaks.

Key Features:

- used for welding galvanized products and other galvanic coatings;

- weld thin-walled parts well;

- easy ignition, including re-ignition;

- due to low heat input, they are well suited for filling large gaps;

- it is possible to apply a seam in a vertical position in the direction of descent;

- lack of sensitivity to dirt and rust makes edge preparation easier.

It is recommended to deposit metal in short sections, and break long-length seams into small sections.

Advantages and disadvantages

Before purchasing electrodes of this brand, you should familiarize yourself with their advantages:

- Welding can be carried out even on rusty and contaminated surfaces.

- Carrying out the first and subsequent ignitions of the product is quite simple.

- Any type of seam can be made.

- Metal spattering is minimal.

- No large heat input required.

- The products have appropriate certificates of conformity and a quality guarantee from the manufacturer.

- Packages weighing 2.5 kg, 2 kg and 1 kg are provided, which is quite convenient for household welding.

The disadvantages include:

- The angle of inclination cannot be less than 35 degrees.

- Relatively low impact strength.

- Surfacing of even long seams should be carried out in small sections.

To avoid other disadvantages, it is enough to carefully select the type of consumable material for each individual operation with metal, and also listen to the advice of experts.

Welding electrodes ESAB OK 46.00 Ø3.0x350mm. (pack 2.5 kg)

Coating type – rutile-cellulose.

OK 46 electrodes are manufactured by ESAB and are considered one of the best due to their excellent welding characteristics, versatility and quality. OK 46.00 electrodes are used to weld products and structures made of low-carbon and low-alloy steels. The electrode is used for welding in all spatial positions; welding can be carried out with direct current of reverse polarity and with alternating current. The distinctive characteristics of OK 46.00 are their low sensitivity to rust and other surface contaminants of the metal, as well as easy separation of slag and the formation of a smooth transition from the deposited bead to the base metal. OK 46 electrodes have very easy arc ignition, both starting and re-igniting, which makes this electrode optimal for root pass welding, short welding, tack welding and welding with periodic breakage of the welding arc. OK 46.00 differs from most other rutile electrodes in the ability to carry out vertical downward welding with a low welding current, which ensures stable arc burning. This makes it possible to use electrodes for welding metal that have a galvanic coating, as well as to weld thin-walled products.

Advantages of OK 46 electrodes:

• Versatility and the ability to use these electrodes when performing a wide range of welding jobs.

• Fast ignition and stable arcing at extremely low currents.

• Ability to work with short seams and tacks.

• Minimum amount of slag and sparks during operation.

• Ability to work in any spatial positions and directions.

• Stable arc burning.

OK 46 can and is recommended to be used for performing delicate and complex welding work, where other similar electrodes cannot provide the required level of reliability, quality and comfort during operation.

You can purchase these electrodes from our website by choosing the required diameter for your welding work.

Current: ~ / = (+/̶) Spatial positions during welding: 1, 2, 3, 4, 5, 6 Open circuit voltage: 50 V Calcination modes: 70-90°C, 60 min

Specifications

| Classification | GOST 9467: E46, GOST R ISO 2560-A: E 38 0 RC 1 2, EN ISO 2560-A: E 38 0 RC 1 2, AWS A5.1: E6013 |

| Endorsements | NAKS: Ø 2.5; 3.0; 3.2; 4.0; 5.0 mm, ABS: 2, BV: 2, DNV: 2, GL: 2, LR: 2, RS: 2, PPP: 2 |

| Yield strength σt, N/mm² (MPa) | 400 |

| Tensile strength σв, N/mm² (MPa) | 520 |

| Elongation δ, % | 28,0 |

| Impact strength KCV, J/cm² | ≥137 at +20°С 88 at 0°С ≥35 at -20°С |

| Impact strength KCU, J/cm² | ≥110 at +20°С ≥40 at -40°С |

Chemical composition of the surfacing. metal

| C, % | 0,08 |

| Mn, % | 0,40 |

| Si, % | 0,30 |

| P, % | max 0.030 |

| S, % | max 0.030 |

Ordering information

Art. 4600303WD0 — Welding electrodes ESAB OK 46.00 Ø3.0x350mm. (pack 2.5 kg)