Features of using MP-3 electrodes

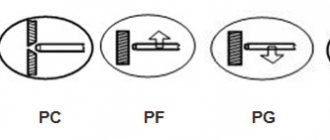

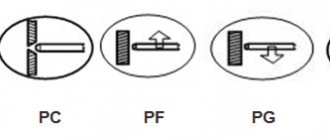

To work with MP-3 electrodes, both direct and alternating current sources can be used. The current sources used must provide an open circuit voltage (OCV) of at least 50V. If a direct current source is used, then welding should be performed with reverse polarity (the plus is connected to the electrode). Welding electrodes of the MP-3 brand allow you to perform work in different spatial positions.

Products of the MP-3 brand are distinguished by the following technological characteristics:

- the welding arc ignites easily and is characterized by high combustion stability;

- easy formation of a weld seam;

- minimal metal spattering;

- the slag crust that forms on the surface of the weld is easily separated;

- re-ignition of the arc is also easy;

- Welding work performed using MP-3 electrodes is characterized by high productivity, as well as the quality of the resulting seam.

The weld metal, like the deposited metal, has the following characteristics: mechanical tensile strength (temporary) - up to 46 kgf/mm2, which corresponds to 450 MPa; impact strength indicator - 8 kgf m/cm2 (80 J/cm2); relative elongation - 18%; bend angle (for a welded joint) - 150 degrees.

The welding current to which the power source must be adjusted depends both on the diameter of the electrode and on the spatial position of the seam being formed:

- Products D 3 mm: vertical seams - 90-110A, bottom seams - 100-140A, ceiling seams - 100-120A;

- D 4 mm: vertical seams - 140-180A, bottom - 160-220A, ceiling - 140-180A;

- D 5 mm: vertical seams - 160-200A, bottom - 180-260A;

- D 6 mm: only lower seams - 300-360A.

The technical characteristics of the electrodes also include their consumption for depositing a certain amount of weld metal. So, in order to deposit 1 kg of metal, 1.7 kg of MP-3 electrodes are needed. At the same time, electrodes of this brand provide a productivity equal to 1.7 kg/h (products D 4 mm), and the deposition coefficient corresponds to a value of 8.5 g/Ah.

Blue welding electrodes MP-3C

Table of the number of electrodes in a pack by diameter

In addition to weight, when calculating the volume of welding work, the number of elements in the box plays an important role. Experienced craftsmen know all the subtleties of choosing by eye, without studying the inscriptions on the packaging. Beginner welders and inexperienced people need more information. The table shows standard data on the number of electrodes in a pack.

We recommend reading Characteristics of LB 52U electrodes

| Diameter, mm | Length, cm | Weight, g | Capacity per box, pcs. | Gross weight, kg |

| 3 | 35 | 26,4 | 95 | 3 |

| 4 | 45 | 59,9 | 82 | 5 |

| 5 | 45 | 95 | 52 | 5 |

The packaging of MMA welding elements indicates the main technical parameters of the product. Among them:

- manufacturer;

- product brand;

- batch number;

- length and diameter of rods;

- industry of destination;

- date of manufacture.

The box also contains other relevant information (welding modes, calcination temperature, manufacturing features, safety measures, general recommendations).

Pack weight

GOST 94 466 – 75 regulates the mass of electrodes in a pack depending on the diameter. According to clause 6.2. of this document, the parameters should not exceed the following values:

We recommend! How to choose electrodes for manual arc welding

| ∅, mm | Weight, kg |

| 2,5 | 3 |

| 3,0-4,0 | 5 |

| over 4.0 | 8 |

Thus, these are not strictly fixed standards, but an indication of the permissible limit. However, manufacturers, as a rule, adhere to these figures. Other documents, such as GOST R ISO 2560-A and GOST 9467-75, impose requirements on the type of coating, mechanical strength of the weld metal, etc.

GOST 94 466 – 75. clause 6.2. The deviation of the mass of electrodes in a box or pack from that indicated on the label or marking should not exceed half the calculated mass of one electrode in the direction of decrease and the calculated mass of two electrodes in the direction of increase.

Electrodes OK 46.00 technical characteristics.

Due to the low heat input, it is possible to weld metal with wide gaps between them.

Also, the advantages include relatively low temperatures in the welding area, which prevents overheating, the formation of hot cracks and spattering.

Analogues: ANO 4, ANO 6, ANO 29M, ANO 23, OZS 6, OZS 12, MR 3.

Welding electrodes OK 46.00 are used throughout and in all industries, due to their qualities and speed of welding work. Their seams have high tightness and good resistance to aggressive environments.

Classification by purpose

Electrodes are intended for welding:

- Steels: low-carbon, high-carbon, alloyed - including stainless and heat-resistant (austenitic).

- Cast iron - alloys with a high carbon content - 2.14% or more.

- Aluminum and alloys.

- Copper, brass and bronze.

- For welding steels of different grades

- For working with cast iron alloys

- For aluminum welding

- For working with copper and its alloys

To ensure a high-quality connection, you need to try to ensure that the composition of the electrode material matches as closely as possible the alloy of the parts being welded.

What is Uoni 13 55?

UONI-13/55 electrodes with a basic coating are intended for manual electric arc welding of especially critical structures made of low-carbon, medium-carbon and low-alloy steels operating under alternating loads and negative temperatures down to -50 ° C.

Interesting materials:

What parts of chicken can a dog eat? What parts can be separated from the sheet? Which particles carry a positive charge? Which watch is the best? What character traits are needed to play sports professionally? What traits of the dog Sharik are manifested in the behavior of Sharikov? What structural features distinguish ciliates from other single-celled organisms? What trees and shrubs should I plant in the garden? What trees are depicted in Shishkin’s painting Morning in a Pine Forest? Which trees shed green leaves in the fall?

Pack weight depending on brand and manufacturer

Examples include weighing scales from the following brands and manufacturers:

| Brand | Manufacturing plant | Diameter, mm | Box weight, kg |

| OK 46.00 | ESAB-SVEL | 3,5 | 5,3 |

| 4 | 6,6 | ||

| SE-46 | Tyumen | 3 | 5 |

| 4 | 6 | ||

| 5 | 5,5 | ||

| UONII-13/55R | ESAB-SVEL | 3 | 4,5 |

| 4 | 6,0 |

Electrodes weight 1 piece. Electrode packaging

Many welders are interested in the question: “How much does one electrode weigh?” And for good reason. This indicator is very important for the selection of materials. Knowing reliable information, you will be able to avoid deception, but also choose rods with the required weight.

These indicators greatly influence the outcome of welding work, and also the condition of the finished joints. But don’t forget about the coating, diameter and condition of the products.

Our article will discuss the weight of a pack and a single electrode. You will find out how many parts are put in a single pack. With this information you will be protected.

- A short introduction

- Number of anticathodes

- Anticathode weight

- Let's sum it up

Number of electrodes

The number of electrodes in a pack is a very important parameter. The weight of the pack and one electrode largely depends on it. And this, in turn, affects the size of the package.

With quantity, everything is simple: the larger the diameter and length of the electrodes, the fewer of them there will be in the pack. In fact, it is not so important for you, as an ordinary buyer, to know the number of electrodes in a pack.

This information is more useful for wholesalers and those who purchase electrodes in large quantities. Below you can see how many electrodes are in a pack of the UONI-13/55 brand. These are average values and may vary depending on the manufacturer:

Welding electrodes - Monolith RC, diameter 2mm, package 1 kg.

Description

Universal electrode for wide use in industry and everyday life. Designed for manual arc welding on direct or alternating current of ordinary and critical structures made of low-carbon steel grades supplied in accordance with DSTU 2651/GOST 380 (St 0, St 1, St 2, St 3 of all groups A, B, C and all degrees of deoxidation – “KP”, “PS”, “SP”) and according to GOST 1050 (05kp, 08kp, 08ps, 08, 10kp, 10ps, 10, 15kp, 15ps, 15, 20kp, 20ps, 20), in all spatial positions (except vertical from top to bottom for electrodes with a diameter of 5.0 mm).

Delivery throughout the city of Simferopol and the Republic of Crimea.

HAVE QUESTIONS? CALL: +7-978-827-28-89

Characteristics

Chemical composition of deposited metal, %:

| Mn | Si | C | P | S |

| 0,40-0,65 | 0,15-0,40 | no more | ||

| 0,11 | 0,035 | 0,030 | ||

Mechanical properties of weld metal:

Welding data:

| Welding current strength (A), for electrode diameter, mm | |||||

| 2,0 | 2,5 | 3,0 | 3,2 | 4,0 | 5,0 |

| 40-80 | 50-90 | 70-110 | 80-120 | 120-170 | 160-220 |

Packing details:

| Diameter, mm | Length, mm | Electrode weight, g | Number of electrodes in a pack, pcs. | Pack weight, kg |

| 2,00 | 300 | 9-10 | 50-55; 100-110 | 0,5; 1 |

| 2,50 | 350 | 18-19 | 26-28; 53-55; 132-138 | 0,5; 1; 2,5 |

| 3,00 | 350 | 27-28 | 17-18; 36-37; 89-92 | 0,5; 1; 2,5 |

| 3,20 | 350 | 33-34 | 14-15; 29-30; 74-75 | 0,5; 1; 2,5 |

| 4,00 | 450 | 62-63 | 8; 15-16; 39-40; 79-80 | 0,5; 1; 2,5; 5 |

| 5,00 | 450 | 97-98 | 51 | 1; 2,5; 5 |

Calcination before welding:

Under normal storage conditions, no calcination is required before welding; in case of moistening, drying before welding: 110±10°C 25 - 30 minutes.

Description

Special properties:

— MONOLITH RC electrodes differ from similar products from other manufacturers in the reduced amount of emissions and the intensity of the formation of welding aerosol and manganese during metal welding. This was achieved through the selection of high-quality raw materials and a high level of control of technological processes in the production of electrodes. Institute of Electric Welding named after. E.O. Paton NAS of Ukraine and the Institute of Occupational Medicine of the Academy of Medical Sciences of Ukraine have confirmed that the release of manganese is reduced by more than 30%, the release of harmful substances in the welding aerosol by more than 28%. — MONOLITH RC electrodes are distinguished by easy initial and re-ignition, soft and stable arc burning, ensure low metal loss from spattering, uniform melting of the coating, excellent formation of the weld metal, and easy separation of the slag crust. — Easy handling of the electrodes makes it possible for novice welders to perform welding. — Welding in hard-to-reach places. Ability to bend the electrode without damaging the coating.

Conditions of use:

— Deposition coefficient – 8.5-9.0 g/Ah. Electrode consumption per 1 kg of deposited metal is 1.7 kg. Electrodes of the MONOLITH RC brand are intended for welding corner, butt, and overlap joints made of metal with a thickness of 3 to 20 mm. — Electrodes are insensitive to the quality of edge preparation, the presence of rust and other surface contaminants. — During installation welding, it is possible to work in all spatial positions without changing the welding current. Welding vertical seams using the top-down method is carried out with a short arc or support. Slag should not be allowed to flow ahead of the arc. To do this, the angle of elevation of the electrode to the vertical should be 40 – 70°. In the lower position, it is recommended to tilt the electrode in the welding direction by 20 - 40° from the vertical. Welding should be carried out with direct current of any polarity or alternating current from a transformer with an open circuit voltage of at least 50 V at the welding current values indicated in the table below. — Allows welding at extremely low currents. For small-diameter electrodes, welding can be done from power sources connected to a household network.

DO YOU HAVE ANY QUESTIONS? call

Requirements for transport packaging

Each cardboard box must be packed in polyethylene shrink film with a thickness of at least 100 microns.

To ensure transport and warehouse operations, boxes are stacked and secured on specially designed wooden pallets. Wooden pallets have dimensions of 630x960 mm. The support bars provide a clearance of 120 mm between the floor and decking. The height of the electrodes on the pallet should not exceed 600 mm. By agreement with the customer, electrodes can be laid on Euro pallets.

Boxes with electrodes on pallets have additional protection from dust and precipitation:

- on top - with plastic film laid on the boxes and (or) wrapped with stretch film;

- on the sides – wrapped with stretch film;

- A packing list is placed under the stretch film indicating the brand of electrodes, diameter, batch number and weight of the electrodes on the pallet.

Boxes with electrodes on pallets are additionally secured with polypropylene tape around the perimeter with steel clips.

Features of products of the MR-3 and MR-3s brands

MR-3s electrodes, like products of the MR-3 brand, allow welding with a long arc, as well as with short tack welding. What is important is that the technical characteristics of products of these brands allow you to work without wasting time on preliminary preparation of the metal to be welded. The surface of the parts that need to be connected can be:

- wet;

- not well cleaned from various contaminants and oxides;

- with traces of corrosion.

Electrodes of the MR-3s brand, as well as products of the MR-3 brand, can be used when welding must be performed along the existing gap. The welding current should be minimal, otherwise the finished seam may turn out porous.

In addition to MP-3 brand products, MP-3m and MP-3s electrodes are actively used. The first ones (MR-3m) are distinguished by the fact that they are coated with rutile-ilmenite coating. Electrodes of the MP-3c brand (blue) use a coating enriched with additional ionizing additives. Both MP-3m and MP-3s electrodes are almost identical to MP-3 brand products in their characteristics.

The coating applied to the MP-3s electrodes makes it easier to ignite the welding arc, which makes it possible to use them when working with low-power current sources. Products of this brand are also more environmentally friendly: when working with them, a significantly smaller amount of harmful substances are released than when working with MP-3 (0.6 grams of manganese for MP-3s and 1.25 for MP-3). Moreover, when working with them, the weld is of higher quality, which significantly improves the characteristics of the joint being formed.