Rules and features of using anchors

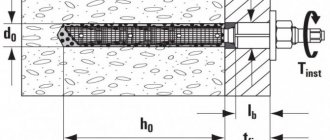

- To work with fastening devices intended for foam concrete and porous materials, a mesh sleeve is proposed, which is placed in a hole drilled in the working base before gluing the parts. It is better to drill with a diamond-tipped tool to obtain a smooth and perfectly round surface. The binder is injected into the sleeve from the tube through a plastic tube until the cavity is filled to two-thirds of the depth. Next, the threaded rod is pressed in and turned, to which the required part will be screwed in the future. After complete hardening, the composition will provide a strong, reliable and durable connection of the fastened elements.

- In any case, the drilled holes should first be cleaned of dust and blown with compressed air.

- A capsule anchor is a glass ampoule filled with an adhesive. One capsule is designed to fix one part. Suitable for installation in solid, dense structures. If such an element is inserted into the prepared hole and the required pin is driven into it with force, then the hardener flows out of the broken container and reacts with the main adhesive. Not recommended for filling large volumes.

- To economically use the contents of the cartridge with the mixture, it is recommended to use a calculator for the required amount of injection mass, which takes into account the diameter of the stud, the depth of the hole and the number of parts to be strengthened. This will significantly reduce installation costs.

- You should not use non-professional devices, such as pharmaceutical enemas, to clean the holes. Also, cavities should not be flushed with water, as this will unnecessarily increase the curing time and reduce the setting effect by up to 80 percent.

Technology of using chemical anchors

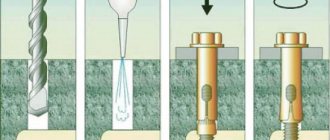

Working with anchors begins with marking the holes, then you need to drill the holes using special equipment, it is better to use a diamond one, this way you will get perfectly smooth surfaces.

Next you need to clean the walls of the holes with a brush and blow them out with a hand pump. Then install the anchor in the hollow base of the mesh sleeve, then also install the mixer on the cartridge and remove approximately ten centimeters of the contents until a homogeneous composition appears.

Through the mixer, squeeze the contents into the hole to fill two-thirds, at this time the mixer is inserted to the bottom. Install the fastener, at this time you can control its position until it hardens completely.

Return to contents

Chemical anchor calculation

Profile pipe: application, characteristics of types and weight calculation

For reliable and correct installation of the stud, in accordance with the technical regulations, the hole must be filled with adhesive to ⅔ (the excess should protrude beyond the edges of the hole only after installing the stud). It is easy to calculate the consumption of chemical anchors for installing one product yourself using the following formula:

V₁ = {:1000}·0.67, where

V₁ – volume of adhesive required to install one anchor (ml);

π – number “PI” (3.14);

h – hole depth (mm);

D – diameter of the drilled hole (mm).

For example, we use the composition “HIT-MM-Plus” and an M12 hairpin. Recommended by the manufacturer: drill diameter – 14 mm, hole depth for reliable fixation of the stud – 85 mm. We substitute our values into the formula and get:

V₁ = {:1000} 0.67 = 8.762 ml ≈ 9 ml

Since one press on the dispenser handle squeezes out about 5 ml of adhesive, for our example, two presses are enough to install one pin.

Advice! Since the manufacturer recommends replacing the dispenser after using the injection system, it is advisable to drill and clean the required number of holes in advance, and then install all the pins with a chemical adhesive composition.

Chemical anchors from various manufacturers are available on the modern market: Hilti, Himitex, Fischer, Sormat, MKT, Mungo. The choice of one type of anchor or another depends on the base material in which the stud will be installed, and on the planned load on it. Before purchasing, you must carefully read the manufacturer’s instructions, then your choice will be correct both technically and materially.

DIY making

Chemical anchors for concrete are quite expensive, so sometimes it makes sense to make them yourself. Due to the fact that manufacturers keep the glue recipe secret, it will not be possible to reproduce exactly the same anchor. But it is quite possible to make reliable and durable fasteners from existing adhesives.

Typically, epoxy resin is used as glue - a relatively inexpensive, durable material that has excellent adhesion to various structures and can be used to install metal bushings, studs, fittings, etc.

How to prepare chemical anchor glue:

- Take a certain amount of epoxy resin (ED-20), mix with a plasticizer in a volume of 5-10% of the total mass (DEG-1, DBP and other additives).

- Mix with filler (gypsum or cement) in sufficient volume to obtain the desired consistency.

- Add hardener (UP-583) to the composition in a ratio of 1:8 to 1:10, mix thoroughly and use the mixture.

The main advantages of such a homemade chemical anchor: minimal shrinkage coefficient during the solidification process, good strength, high level of wear resistance, and the ability to use at temperatures from -10 to +35C. The composition hardens within 2 hours, gaining strength only after 12 hours. Such chemical anchors can only be used on well-dried surfaces. It should also be noted that the composition releases a small amount of phenolic compounds into the atmosphere.

Hilti injection anchor systems

Calculation of electric current by power: formulas, online calculation, selection of machine

This type of chemical anchor (marked with the letters HIT) is a plastic cartridge with two sealed foil containers (one with adhesive filler, the other with a hardener). Today the company presents 7 varieties of this type of chemical anchor. The price of such anchors depends on the capacity of the cartridge (there are two types: 330 and 500 ml), the components of the composition, the area of application and the load that the stud installed with its use can withstand.

For example, the universal hybrid composition “HIT-MM-Plus” is a budget-class chemical anchor (the cost of one 330 ml cartridge is 650÷900 rubles). The two-component adhesive is made on the basis of urethane methacrylate. Recommended for installation of threaded rods in the range M6÷M16 in basic building materials such as brick (solid and hollow), lime-sand blocks, concrete, blocks made of cellular types of concrete, artificial and natural stone. For fastening studs in hollow blocks and bricks, the company offers specially designed perforated plastic sleeves, which increase the fastening strength and reduce the consumption of adhesive.

And the composition “HIT-RE-500-V3”, which closes the line of injection anchors, already costs 2700–3300 rubles for a package with a capacity of 330 ml and is intended for gluing the releases of working load-bearing reinforcement of floors, columns, foundations and flights of stairs. A composition based on epoxy adhesive with additives that allow the installation of studs and reinforcing bars with a diameter of 10÷55 mm even in holes completely filled with water.

We extrude the glue components using a mechanical hand dispenser. For chemical anchors with a capacity of 330 ml, the dispenser “HDM-330” is intended, for 500 ml - “HDM-500”. We insert the capsules into the plastic cassette of the dispenser (it is included in the kit), screw the mixer onto the threaded part of the cartridge (in which the components of the adhesive composition are mixed) and through its conical tube the glue enters the drilled hole. Parallel pistons are connected to the dispenser handle, and when it is pressed once, one portion of the adhesive composition (about 5 ml) is supplied.

Video about using the “HIT-MM-Plus” composition and the “HDM-330” dispenser:

For professional use in large volumes of anchoring work, the pneumatic dispenser “P-8000-D” and the battery dispenser “HDE-500-A22” are used.

Types of anchors and their features

Currently, Hilti produces several types of anchors:

- chemical;

- spacer;

- driving.

Chemical anchors

A chemical anchor is a special dowel that is equipped with an adhesive composition for fixation in materials such as:

- hollow brick;

- expanded clay concrete;

- shell rock;

- limestone and so on.

Thanks to its features, the attachment to porous substrates is highly durable and extremely reliable. However, replacing such a fastening element, if necessary, will be quite difficult, since the base will have to be somewhat destroyed.

Currently, chemical anchors are produced in two types:

- Chemical capsules (marked HVU). The devices are a container (most often made of polyethylene) of a certain size, inside of which there is a two-component adhesive composition. Upon contact with a metal dowel, the container depressurizes and, under the influence of air, mixes and hardens, thereby fixing the fastening element. The main advantages of this type are the speed and ease of installation. Negative qualities include the relatively high cost and dosage of the adhesive composition, which does not allow achieving strong fixation of the anchor when installed in large-volume voids.

Capsule chemical anchor

Only one fastening element can be secured using the anchor capsule.

- Chemical injections (marked HIT) are two-capacity ampoules, one of which contains the adhesive composition, and the other contains the hardener. Unlike capsules, injection dowels can be produced in different volumes, which facilitates reliable fastening even in voids. Another advantage of this type is the lower cost, justified by the use of glue of a different composition. A significant disadvantage of the injection anchor is the need to purchase (rent) additional equipment for installation.

Injection Type Chemical Anchor

With the help of injection anchors, several fastening elements can be secured simultaneously.

Expansion anchors

Unlike a chemical anchor, an expansion anchor is a more standard fastening element. As the threaded rod is tightened, the spacer part of the anchor increases along its entire length, which allows you to create strong fastenings even for massive structures.

Standard anchor for fastening heavy structures

Depending on the type of base to which additional elements need to be attached, the following types of anchors are distinguished:

- for concrete with cracks – HST/HST3. this type can also be used for installation in areas with seismic activity;

- for solid bases - HSA or HSV (a more budget option, also highly durable);

- for fastening heavy structures - HSL 3 or 3G.

Unlike chemical fasteners, expansion anchors can be replaced without destroying part of the base.

Drive-in anchors

The last type - drive-in anchors are easy to install. Such fasteners are intended for fixing sheathing (plasterboard, wall panels, etc.), insulating materials or light loads (light weight structures).

They can be made:

- made of metal. They are more durable, but at the same time more expensive;

Drive-in anchor made of metal

- made of plastic. Designed for fastening lightweight structures.

Drive-in anchors made of plastic

Advantages of the Hilti HIT-RE-100 adhesive anchor

Main types of anchors: from classic bolts to dental pins

When using HIT-RE-100 adhesive for anchors in concrete, consumers can count on the following advantages of this product:

- Possibility of use indoors and outdoors with the base material, regardless of its current state (dried, moistened, filled with moisture, etc.).

- Large selection of additional accessories (metal brushes, electric dispenser, injection pistons).

- High level of efficiency for use in solid concrete foundations without cracks.

- Long curing period, due to which you can make the necessary adjustments during installation.

- Easy to clean, making installation much easier.

The cost of adhesive for anchors in concrete Hilti HIT-RE-100 starts from 1,500 rubles for a 330 ml container.

Types of HILTI anchors

The unique hybrid chemical composition of anchors of this class makes them indispensable in construction, furniture production, and when performing minor repair work on household items. For each type of application, special, most suitable and easy-to-use polymer formulations have been developed.

- Hilti HIT-RE 500 chemical anchors are used in damp environments, damp concrete, and when installing load-bearing structures. These fasteners are indispensable when working in water.

- HILTI HIT-HI 70 is excellent for fastening parts to hollow (energy-saving) partitions, aerated concrete and other loose materials.

- HFX is suitable for home renovations, fastening household appliances and plumbing elements. It is extremely easy to use and does not require any special skills. It hardens quickly, is injected without a dispenser and allows you to get distracted for a short time if necessary. The degree of hardening is monitored by color changes.

- HIT-ICE works perfectly even at temperatures below -20 degrees Celsius. Dosed easily and quickly.

- HIT-RE 100 is a standard epoxy adhesive used for securing anchors and reinforcement in concrete foundations.

- HIT-HI 200-A is a unique development of a hybrid adhesive for the restoration of anchor connections and reinforcement outlets in critical areas.

- HIT-MM PLUS is an inexpensive and reliable material used for installation in concrete and brick.

Chemical capsule anchors "Hilti"

This type of Hilti glue for anchors is presented in the form of a capsule. Each capsule is designed for mounting one fastener element. The capsules themselves are represented by cylindrical containers filled with glue. This is a two-component composition, the mixing of which is carried out during installation.

Such products are marked HVU, which indicates:

- depth of permissible mounting hole;

- thread of the anchor stud.

For example, if a product is marked HVU M14X100, then this indicates a hole depth of 100 mm in the base and an anchor pin with M14 thread.

The process of installing a stud using such a capsule is approximately as follows:

- First, a hole of the required diameter and depth is drilled in the base. The manufacturing company advises choosing a drill diameter 2-3 mm larger for studs with threads from M8 to M16, and 3-4 mm larger for studs with threads from M20 to M39.

- Then the drilled hole must be cleaned of dust using compressed air or any mechanical method.

- Next, you need to insert the Hilti chemical capsule into the hole.

- After this, you need to screw the pin clockwise into the hole (it will damage the capsule, due to which the components will mix and the solution will begin to harden).

At positive ambient temperatures, the solution will completely harden in about 20-60 minutes. At temperatures around zero or below, it will take several hours to harden. To install metal products that experience severe dynamic loads during operation, it is recommended to use special HVU-TZ capsules.

Hilti chemical capsule anchors

This type of chemical anchor is clearly dosed for the installation of only one fastening element. It is a cylindrical polyethylene container filled with an adhesive composition. The two components of the adhesive mixture are separated by an impenetrable partition. Mixing of the mixture components occurs at the time of installation. Products of this type are marked with the letters HVU, indicating the thread of the anchor pin and the depth of the mounting hole for it. For example, the marking “HVU M16X125” means that this capsule is intended for fastening an anchor rod with an M16 thread, a hole depth in concrete of 125 mm. The line of capsules is presented quite widely: from M8 to M39.

The technology for installing a stud using an adhesive capsule is quite simple:

- We drill a hole of the required diameter and depth in the base. The manufacturer recommends choosing a drill or drill diameter 2 mm larger for studs M8÷M16, and 3÷4 mm larger for M20÷M39. For example, for the “HVU M12X110” capsule you will need a drill with a diameter of 14 mm and a hole depth of 110 mm.

- Carefully clean the hole from dust using air or a brush.

- Insert the capsule into the hole.

- We twist the pin into the hole clockwise: the lower end of the pin breaks the capsule and when screwed in, the components of the adhesive composition are mixed.

The final hardening time of the adhesive composition, after which maximum loads can be applied to the stud, depends on the ambient temperature: from 20 minutes at a temperature of +20˚С to 5 hours at a temperature of -5˚С.

For studs experiencing increased dynamic loads, the company has developed special “HVU-TZ” capsules. The line of these types of capsules is designed to install studs from M10 to M20.

Advantages and disadvantages of Hilti

In conditions of loose environments, poor accessibility, low temperatures and high humidity, even working in water, Hilti certainly surpasses in its quality and reliability all available analogues of metal fastening devices. Storage and transportation of capsules and tubes does not involve any inconvenience. An open container of adhesive can be stored for up to one year after initial use. You just need to close it tightly. Lime-sand blocks and products made of cellular concrete are beyond the strength of metal dowels without the use of special labor-intensive technologies, while the use of a chemical anchor allows you to quickly and effectively solve the problem.

During sudden changes in temperature conditions, chemical compounds do not create a compressive or expanding effect, which is an additional guarantee of the reliability of the connection.

Disadvantages include the relatively high cost, short shelf life (up to one year) and the length of the hardening period.