Aluminum

Aluminum came into industrial and household use relatively recently. At the intersection of the 19th and 20th centuries, the production of this metal on an industrial scale was mastered.

The thing is that the production of many goods began in which aluminum was widely used, for example, in the construction of boats, railway cars, etc.

By the way, it was then that a car with a body made of aluminum was shown to the general public.

Anodized aluminum

Composition and structure of aluminum

Aluminum is the most common metal in the earth's crust. It is classified as a light metal. It has low density and mass. In addition, it has a fairly low melting point. At the same time, it has high ductility and shows good thermal and electrical conductivity characteristics.

Aluminum crystal latticeAluminum structure

The tensile strength of pure aluminum is only 90 MPa. But, if you add some substances to the melt, for example, copper and a number of others, then the tensile strength increases sharply to 700 MPa. The same result can be achieved using heat treatment.

Aluminum, which has extremely high purity - 99.99%, is produced for use in laboratory purposes. For industrial applications, commercially pure aluminum is used.

When producing aluminum alloys, additives such as iron and silicon are used.

They do not dissolve in the aluminum melt, and the additive reduces the ductility of the base material, but at the same time increases its strength.

Appearance of a simple substance

The structure of this metal consists of simple cells consisting of four atoms. This structure is called face-centric.

Calculations show that the density of pure metal is 2.7 kg per cubic meter.

Properties and characteristics

Aluminum is a metal with a silvery-white surface. As already noted, its density is 2.7 kg/m3. The temperature is 660°C.

Its electrical conductivity is equal to 65% of copper and its alloys. Aluminum and most of its alloys are resistant to corrosion. This is due to the fact that an oxide film forms on its surface, which protects the base material from exposure to atmospheric air.

In the untreated state, its strength is 60 MPa, but after adding certain additives it increases to 700 MPa. The hardness in this state reaches 250 HB.

Aluminum can be easily processed under pressure. To remove work hardening and restore ductility after processing, aluminum parts are annealed, and the temperature should be within 350°C.

The production of aluminum melt, like many other materials, occurs after thermal energy has been supplied to the original metal. It can be supplied either directly into it or from outside.

The melting point of aluminum directly depends on the level of its purity:

- Ultra-pure aluminum melts at a temperature of 660.3°C.

- With an aluminum content of 99.5%, the melting point is 657°C.

- With a content of this metal of 99%, the melt can be obtained at 643°C.

Aluminum meltAluminum production process

An aluminum alloy can contain various substances, including alloying ones. Their presence leads to a decrease in the melting point.

For example, if there is a large amount of silicon, the temperature can drop to 500°C. In fact, the concept of melting point applies to pure metals.

Alloys do not have any constant melting point. This process occurs within a certain heating range.

In materials science there is a concept - solidus and liquidus temperatures.

The first temperature indicates the point at which the melting of aluminum begins, and the second shows at what temperature the alloy will finally melt. In the interval between them, the alloy will be in a mushy state.

Decrease temperature

Before you start melting metal, you can perform certain operations that will reduce the melting temperature. For example, sometimes aluminum powder is melted. In a powdered state, the metal begins to melt somewhat faster.

But with such processing, there is a real danger that when interacting with oxygen contained in the atmosphere, aluminum powder will begin to oxidize with a large release of heat and the formation of metal oxides; this process occurs at a temperature of 2300 degrees.

The main thing is to prevent contact between the melt and water at this moment of melting. This will cause an explosion.

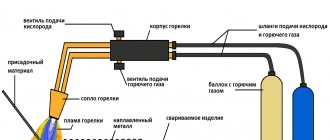

The relatively low melting point of aluminum allows this operation to be carried out at home.

It should be noted right away that using a powdered mixture as a raw material in a home workshop is too dangerous. Therefore, either ingots or cut wire are used as raw materials.

If there are no special quality requirements for the future product, then anything made from this metal can be used for melting.

Melting aluminum in a homemade forge

In this case, it is not particularly important whether the raw materials are coated with paint or not. When aluminum melts, all foreign substances will simply burn out and be removed along with the slag.

To obtain a high-quality melting result, it is necessary to use materials called fluxes. They are designed to solve the problem of binding and removing foreign impurities and contaminants from the melt.

A home craftsman who decides to melt aluminum at home should be aware that this is a rather dangerous process. And therefore it is impossible to do without the use of protective equipment.

In particular, gloves, an apron, and goggles should be used. The fact is that the melt temperature is within 600 degrees.

Therefore, it makes sense to use the protective equipment that welders use.

Using protective equipment when melting aluminum

By the way, when melting aluminum and using cleaning chemicals, it is necessary to protect the respiratory system from combustion products.

Selecting a mold for casting

When choosing a mold for casting aluminum, a home craftsman must understand for what purpose he is processing aluminum. If the future casting is intended for use as solder, then there is no need to use any special forms. To do this, you can use a metal sheet on which to cool the molten metal.

But if there is a need to obtain even a simple part, then the master must decide on the type of mold for casting.

The mold can be made from plaster. To do this, gypsum in a liquid state is poured into an oil-treated mold. After it begins to harden, a casting model is installed into it. In order for molten metal to be poured into the mold, a sprue must be formed.

To do this, a cylindrical part is placed in the mold. Forms can be detachable or not. The process of making a split mold is complicated by the fact that the model will be in two halves. After hardening, they are separated, the model is removed and connected again. The form is ready to use.

Aluminum casting die

To obtain high-quality castings, it is advisable to use metal molds (moulds), but it is advisable to produce them only in factory conditions.

Classification

Most combustion products are toxic substances. Therefore, speaking about their classification, it would be correct to introduce you to the following term:

Classification of the danger of substances according to the degree of impact on the body is the establishment (ranking) of the levels of danger of substances according to their damaging and damaging effects on the human and (or) animal body. Read more about this classification in the material at the link >>

Also check out the educational material on the topic:

Aluminum releases when heated

Aluminum is a combustible metal, atomic weight 26.98; density 2700 kg/m 3, melting point 660.1 °C; boiling point 2486 °C; calorific value -31087 kJ/kg. Aluminum shavings and dust can ignite under the local action of low-calorie ignition sources (match flame, spark, etc.).

When aluminum powder, shavings, and foil interact with moisture, aluminum oxide is formed and a large amount of heat is released, leading to their spontaneous combustion when accumulated in heaps. This process is facilitated by the contamination of these materials with oils. The release of free hydrogen when aluminum dust interacts with moisture facilitates its explosion.

The self-ignition temperature of a sample of aluminum dust with a dispersion of 27 microns is 520 °C; smoldering temperature 410 °C; lower concentration limit of flame propagation 40 g/m 3 ; maximum explosion pressure 1.3 MPa; pressure rise rate: average 24.1 MPa/s, maximum 68.6 MPa/s.

The maximum oxygen concentration at which ignition of the air suspension by an electric spark is excluded is 3% of the volume. Settled dust is a fire hazard. Self-ignition temperature 320 °C. Aluminum easily reacts at room temperature with aqueous solutions of alkalis and ammonia, releasing hydrogen.

Mixing aluminum powder with an alkaline aqueous solution may cause an explosion. Reacts vigorously with many metalloids. Aluminum turnings burn, for example, in bromine, forming aluminum bromide. The interaction of aluminum with chlorine and bromine occurs at room temperature, and with iodine - when heated. When heated, aluminum combines with sulfur.

If you add aluminum powder to the vapor of boiling sulfur, the aluminum will catch fire. Heavily ground aluminum reacts with halogenated hydrocarbons; the small amount of aluminum chloride present (formed during this reaction) acts as a catalyst, accelerating the reaction, in some cases leading to an explosion.

This phenomenon is observed when aluminum powder is heated with methyl chloride, carbon tetrachloride, a mixture of chloroform and carbon tetrachloride to a temperature of about 150 °C.

Aluminum in the form of a compact material does not interact with carbon tetrachloride. Mixing aluminum dust with some chlorinated hydrocarbons and alcohol causes the mixture to spontaneously ignite.

A mixture of aluminum powder with copper oxide, silver oxide, lead oxide and especially lead dioxide burns explosively. A mixture of ammonium nitrate, aluminum powder with coal or nitro compounds is an explosive.

Extinguishing agents: dry sand, alumina, magnesite powder, asbestos blanket. The use of water and fire extinguishers is prohibited.

Aluminum does not occur in nature in its pure form, because it is very quickly oxidized by atmospheric oxygen to form strong oxide films that protect the surface from further interaction.

Aluminum and its alloys are the most common materials among non-ferrous metals and are increasingly used in transport, construction, packaging, electrical engineering and the production of household items. Thanks to their unique set of properties, they successfully withstand competition from other structural materials such as steel, concrete, wood, plastics, glass, etc.

Unfortunately, in Russia, one of the world's largest producers of primary aluminum, the use of aluminum for these purposes lags significantly behind the level of developed countries. Of the 3.76 million tons of aluminum produced last year, only a little more than 600 thousand tons were used in the form of products for domestic consumption in the country. There are several reasons for this.

First of all, the low demand for aluminum products in Russia is due to a significant decline in industrial production.

However, an important role was played by the subordination of consumption in Soviet times to the needs of the military-industrial complex and, as a consequence, the hitherto insufficient awareness of producers and consumers of civilian industrial products about the properties of aluminum, its alloys and their advantages over other materials.

Hence many people have erroneous ideas, for example, about the toxicity or excessively high cost of aluminum, the low corrosion resistance or insufficient mechanical strength of its alloys, etc. And these stereotypes create an obstacle to the use of aluminum in products, structures and machines.

We came across another myth while getting acquainted with the materials of the round table on the problem “Ventilated facades: pros or cons” [1]. During the discussion there, concerns were expressed regarding the use of aluminum for these purposes: they say, “...aluminum-magnesium alloys burn... and materials scientists working in aviation know this very well...”.

Our almost forty years of experience in the aviation industry associated with melting, casting and hot forming of almost all grades of aluminum wrought alloys allows us to judge the fallacy of this statement.

It is known that combustion is a high-temperature oxidation, characterized by a high rate of process and the release of a significant amount of heat. Therefore, ideas about the flammability of aluminum and its alloys are primarily associated with the high affinity of aluminum for oxygen. From Fig.

1 [2] it follows that aluminum differs from copper and iron in its significantly higher heat of oxidation. Its oxide is very stable and is poorly reduced. This property is widely used in metallurgy, where aluminum is used as a deoxidizing agent.

Note that the difference in affinity for oxygen predetermined the chronology of the use of these metals by humanity.

In the Bronze Age, native copper was first used, and then its alloys with tin began to be obtained by inflating the forge with lungs through tubes. To obtain iron, it was necessary to reduce the ore with charcoal in cheese-blowing furnaces.

And only with the advent of electricity it became possible to break the strong bond between oxygen and aluminum and begin the production of this light metal.

It is known that when finely crushed aluminum is heated, it burns vigorously in air

In this case, 31 kJ of energy is released per 1 g of oxidized aluminum, which is slightly less than the heat generated by the combustion of 1 liter of natural gas. The more dispersed the aluminum particles are, the lower the heating temperature is required.

Thus, aluminum powder mixed with oxygen-releasing substances begins to burn intensely at an ignition temperature of 250–300 0C. It is widely used in pyrotechnics and rocket fuel production.

Aluminum powder with particle sizes less than 100 microns dispersed in the air is capable of forming an explosive mixture at room temperature.

Effect on the human body

The degree of toxicity of substances is related to their physical and chemical nature. Interacting with the body, combustion products cause pathological syndromes.

The International Classification of Diseases, Tenth Revision ICD-10, defines poisoning by combustion products with code T59 - “Toxic effects of other gases, fumes and vapors.”

According to the mechanism of action on humans, toxic components in smoke are divided into five groups.

- Substances that cause damage to the skin and mucous membrane. Symptoms of such poisoning by combustion products are itching, burning of the skin and its inflammation, pain in the eyes, eyelids, lacrimation, cough. Examples are tar fumes, sulfur dioxide, formaldehyde.

- Combustion products that cause acute inhalation poisoning. The victims complain of shortness of breath and cough. Upon examination, rapid breathing and cyanosis are noteworthy. High concentrations of toxic gas may cause respiratory arrest. Thus, signs of poisoning by PVC combustion products may appear within a few hours. Inhalation poisoning is caused by chlorine, ammonia, and nitric oxide.

- Combustion products produce toxic substances, which are called “blood poisons.” By binding hemoglobin, they disrupt the access of oxygen to tissues and trigger pathological reactions that affect the entire body. Examples: carbon monoxide, nitrogen dioxide.

- Combustion products for which the target organ is the nervous system. This is benzene, hydrogen sulfide.

- Enzyme poisons that affect tissue respiration, blocking oxygen activation processes. This is hydrogen sulfide, hydrocyanic acid.

Many toxins that form in combustion products are “universal”, since they cause damage to several body systems at once.

How to obtain aluminum from aluminum oxide? Chemical formulas

According to the nature of combustion of metals, they are divided into two groups: volatile and non-volatile. Volatile metals have relatively low phase transition temperatures - the melting point is less than 1000 K, the boiling point does not exceed 1500 K. This group includes alkali metals (lithium, sodium, potassium, etc.) and alkaline earth metals (magnesium, calcium).

The phase transition temperatures of non-volatile metals are much higher. The melting point, as a rule, is above 1000 K and the boiling point is more than 2500 K (Table 1). The combustion mechanism of metals is largely determined by the state of their oxide. The melting point of volatile metals is significantly lower than the melting point of their oxides.

Moreover, the latter are quite porous formations.

When the ignition source is brought to the surface of the metal, it evaporates and oxidizes. When the vapor concentration reaches the lower concentration limit, it ignites.

The diffusion combustion zone is established at the surface, a large portion of the heat is transferred to the metal, and it is heated to the boiling point. The resulting vapors, freely diffusing through the porous oxide film, enter the combustion zone.

Boiling of the metal causes periodic destruction of the oxide film, which intensifies combustion.

Combustion products (metal oxides) diffuse not only to the metal surface, promoting the formation of an oxide crust, but also into the surrounding space, where they condense and form solid particles in the form of white smoke. The formation of dense white smoke is a visual sign of burning of volatile metals.

In non-volatile metals with high phase transition temperatures, when burning, a very dense oxide film is formed on the surface, which adheres well to the surface of the metal.

As a result of this, the rate of diffusion of metal vapor through the film is sharply reduced and large particles, for example, aluminum and beryllium, are not able to burn. As a rule, fires of such metals occur when they are in the form of shavings, powders and aerosols.

They burn without producing dense smoke. The formation of a dense oxide film on the metal surface leads to the explosion of the particle.

This phenomenon is especially often observed when particles move in a high-temperature oxidizing environment and is associated with the accumulation of metal vapors under the oxide film, followed by its sudden rupture. This naturally leads to a sharp intensification of combustion.

The main parameters of their combustion are the ignition and combustion time. From the theory of diffusion combustion it follows that the combustion time of a metal particle tg is proportional to the square of its diameter do. Experimental data show that the actual dependence is somewhat different from the theoretical one. So, for aluminum tg

An increase in oxygen concentration in the atmosphere intensifies the combustion of the metal. Aluminum particles with a diameter of (53 ÷ 66) 10 -3 mm in an atmosphere containing 23% oxygen burn in 12.7 10 -3 s, and when the oxidizer concentration increases to 60% - in 4.5 10 -3 s.

However, for fire-technical calculations, it is not the combustion time of a metal particle that is of great interest, but the speed of flame propagation along the flow of a suspension of metal particles in the oxidizer. In table

2 shows experimental data on the speed of flame propagation and the mass burnout rate of a suspension of particles with diameters less than 10 -2 mm and 3·10 -2 mm of aluminum in air at different excess air ratios.

Production of aluminum sulfate

How to obtain aluminum sulfate from aluminum oxide?

The method is included in the school curriculum for eighth and ninth grades.

Aluminum sulfate is a salt of the form Al2(SO4)3. It can be presented in the form of plates or powder.

This substance can decompose into aluminum and sulfur oxides at temperatures above 580 degrees. Sulfate is used to purify water from the smallest particles; it is very useful in the food, paper, textile and other industries. It is widely available due to its low price. Water purification occurs due to some characteristics of sulfate.

The fact is that polluting particles have a double electrical layer around them, and the reagent in question is a coagulant, which, when penetrating the electric field of the particles, causes compression of the layers and neutralizes the charge of the particles.

Now about the method itself. To make sulfate, you need to mix the oxide and sulfuric (not sulfurous) acid.

The reaction between alumina and acid is:

Al2O3+3H2SO4=Al2(SO4)3+H2O

Instead of the oxide, you can add aluminum itself or its hydroxide.

In industry, to produce sulfate, they use the ore already known from the third part of this article - bauxite. It is treated with sulfuric acid and “contaminated” aluminum sulfate is obtained. Bauxite contains hydroxide, and the reaction in a simplified form looks like this:

3H2SO4 + 2Al(OH)3 = Al2(SO4)3 + 6H2O

Combustion - aluminum

The mass rate of evaporation pggf of the material in the boiling mode is determined by the rate of heat input from the combustion zone, which is proportional to the difference between the combustion temperatures Tg and boiling Tk.

Since Tm in the pressure range under consideration almost does not change, and Tk increases with increasing pressure, the difference Tg-Tk decreases with increasing pressure and at the same time the rate of gasification (evaporation) of the metal Tgf a (Tg-TK) / BISIA decreases.

Thus, as the pressure increases, the combustion zone approaches the metal surface and vapor-phase combustion may stop.

Consequently, during the combustion of aluminum, there is a pressure region in which the mechanism of aluminum combustion is controlled by the rate of its evaporation, and in this region there is a gradual transition from vapor-phase combustion in the presence of boiling to combustion in the absence of boiling, at which reactions on the metal surface can predominate. [31]

The combustion temperature of aluminum close to this value is given in [11, p. According to formula (1.15), which describes the boiling curve, a temperature of 3533 K corresponds to a pressure p 3 22 MPa. From this it is clear that at pressures greater than 3 22 MPa. [33]

Preparation of aluminum oxide

Much has been said about alumina above, but it has not yet been described how to obtain aluminum oxide. Formula - Al2O3.

All you need to do is burn aluminum in oxygen. Combustion is the process of interaction between O2 and another substance.

The simplest reaction equation looks like this:

4Al + 3O2 = 2Al2O3

The oxide is insoluble in water, but it is highly soluble in cryolite at high temperatures.

The oxide exhibits its chemical properties at temperatures above 1000°C. It is then that it begins to interact with acids and alkalis.

Under natural conditions, corundum is the only stable variation of the substance. Corundum is very hard, with a density of approximately 4000 g/m3. The hardness of this mineral on the Mohs scale is 9.

Aluminum oxide is an amphoteric oxide. It is easily converted into hydroxide (see above), and once converted, it retains all the properties of its group with a predominance of the basic ones.

Amphoteric oxides are oxides that can exhibit either basic (metal oxide properties) or acidic (non-metal oxide) properties depending on conditions.

Amphoteric oxides, excluding aluminum oxide, include: zinc oxide (ZnO), beryllium oxide (BeO), lead oxide (PbO), tin oxide (SnO), chromium oxide (Cr2O3), iron oxide (Fe2O3) and vanadium oxide (V2O5 ).

Class D Fires: Do Metals Burn?

The phrase “combustion of metals” causes confusion among many. People who are far from fire safety issues are sure that metals do not burn. However, this is not quite true. Some metals can not only burn, but even spontaneously ignite.

The main dangers posed by different metals are:

- Aluminum is a lightweight electrically conductive metal with a fairly low melting point (660°C), which is why aluminum structures can be destroyed in a fire. But the most dangerous is aluminum powder, which carries the threat of explosion and can burn.

- Cadmium and many other metals emit toxic fumes when exposed to high temperatures. Therefore, extinguishing burning metals should be done with protective masks.

- Alkali metals (sodium, potassium, lithium) react with water, forming hydrogen and the amount of heat required to ignite it.

- Powdered cast iron may explode when exposed to high temperatures or fire. Sparks from cast iron can ignite flammable materials nearby.

- Steel, which is not considered a combustible metal, can also catch fire if it is in powder or sawdust form.

- Titanium is a strong metal, the main element of steel alloys. It melts at high temperatures (2000°C) and does not burn in large structures or products. But small titanium parts can easily catch fire.

- Magnesium is one of the main elements in light alloys, giving them ductility and strength. Magnesium flakes and powder may burn. Solid magnesium can also ignite, but only if heated to temperatures above 650°C.

As you can see, mainly crushed metals in the form of powder, shavings, and sawdust can burn. In addition to these hazards, metals can also cause injury, burns, and injury to people.

D Fires

Products of combustion (combustion)

Combustion products are substances (gaseous, liquid or solid) and compounds formed as a result of the complex physical and chemical process of combustion of substances (materials).

Combustion products most often mean smoke, toxic combustion products, soot and others.

Dry grass combustion products

Knowledge of the properties and quantity of combustion products is necessary to calculate the heat of combustion, combustion temperature and other indicators used to assess the fire and explosion hazard of substances (materials) and objects containing these substances (materials).