If you need to make a large diameter hole in a tree, you will have to use special devices, each of which has its own characteristics. We will consider all possible options and tell you about their main advantages and disadvantages so that you can choose the best option in accordance with the specifics of the work in a given situation.

In the photo: equipment for wood differs from equipment for concrete and ceramics

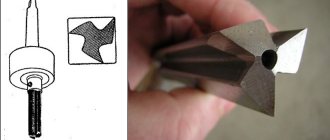

About Watts drill and Reuleaux triangle

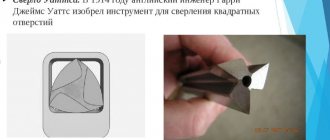

In order to understand how the Watts drill works, you need to take a short excursion into geometry. Back in the 15th century, mathematicians became interested in the interesting properties of flat figures with equal thickness. The most famous such figure is the circle. Another simple shape from this series is a rounded triangle.

This figure turns out like this. An equilateral triangle is taken as a basis. Then a circle with a radius equal to the side of the triangle is drawn from each vertex of the triangle. The result will be a new shape with arched sides (see picture below).

A little later, the scientist L. Euler drew attention to the interesting trajectory of rotation of a rounded triangle. Then the engineer Reuleaux saw that with a certain way of rotating the figure, the trajectory of its vertices describes a shape very close to a square. To do this, it is necessary to rotate with some eccentricity. With this movement, minor roundings are formed only in the inner corners of the resulting square. Such a triangle is today known as the Reuleaux triangle.

At the beginning of the 20th century, the English scientist Watts was able to invent and patent a technical solution that would ensure such movement of a metal-cutting tool that it would ultimately result in a square hole in the workpiece. The resulting tool became known as the Watts drill.

Classification of drills for square holes

In modern metalworking, almost all cutting tools that are used to produce square holes work on the principle of rotation of the Reuleaux triangle. A Watts drill (or as it is sometimes called a Reuleaux drill) allows you to make square holes of various sizes in metal parts of various thicknesses. This tool is classified according to its size, material of manufacture, and shank design.

A Watts metal drill must be made of high-speed steel. This tool is marked HSS (High Speed Steel). For domestically produced tools, tool steel U10 or alloy steels X12 and X12MF are used. The hardness of the tool should be between 52 and 60 HRC. A square drill can have different diameters depending on the size of the side of the square.

Note that buying a Watts drill is quite difficult. Don't expect it to be available in every hardware store. You may have to purchase it to order from a large tool store or buy it from an online store.

How to choose and what to pay attention to

Choosing a high-quality circular drill is quite easy

The main thing is to know the main points that you should pay attention to first, but also not to lose sight of the little things

The design is a very important point: a wood ballerina comes with one chisel or two or more. For frequent use, it is better to purchase an option with two or three cutting elements. It is easier to work with such devices and the quality of the processing performed will be at an acceptable level.

It would not be superfluous to be able to replace individual parts. Inexpensive circle drills can have a solid shank with a permanent center drill and rod.

Metal, its quality determines its strength and ability to withstand workloads. High-quality tools are made from high-strength steel or alloys. The shank and cutter holders are shaped using a machine tool. The rod is usually stamped and made of the same metal.

Cheap options often use soft metal or alloys, which can be brittle. Under load, parts may become deformed or break. Such a tool will not last long and it will also be difficult to achieve accuracy from it.

The quality of workmanship, the main feature is the absence of backlashes and distortions. All parts must fit together and be securely fastened with fixing screws.

The markings of a high-quality ballerina's barbell are stamped. Sometimes the divisions are highlighted with bright paint for better visibility.

Cutters and high-quality cutting elements are made from hardened tool steel. They are secured to the holders with rivets or soldering. Solid cutters with holders (made of the same metal) quickly become dull and are not durable.

Manufacturer, when choosing any tool and consumables, preference should be given to well-known and long-proven brands and brands. The most common are Topfix, Stayer, Irwin, Strum.

Purchasing an adjustable circular drill for use at home, or if you need to drill several holes, is completely worth it. This eliminates the need to purchase an expensive tool that may only be needed a few times.

Features of drilling square holes in wood

In furniture production, parts are often connected using a tongue-and-groove system. This connection assumes the presence of square grooves in the supplied parts. To make holes in wood, use a special square wood drill. It is a set of slotting tools. It consists of an internal wood drill and a chisel that fits onto it. Typically, the drill diameter ranges from 6 to 18 millimeters. The shank usually has a diameter of 19 millimeters. Such kits can be installed on slotting and drilling machines.

The principle of operation and design of the Watts drill

Drilling square holes using a Watts drill is based on the principle of rotational movement of the Reuleaux triangle along a specific eccentric trajectory.

The shape of the drill does not exactly follow the rounded triangle, but its cutting edges fit into its shape.

The drill has such a shape of cutouts in order to remove chips from the working area, as well as to minimize the moment of inertia of the tool. In addition, reducing the weight of the tool helps reduce the load on the spindle of the metal-cutting machine, and sharpened edges increase the cutting capabilities of the drill.

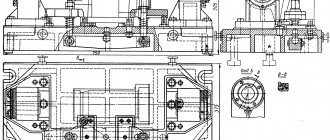

In addition to the Watts drill, the work will definitely require an adapter spindle, which will provide an alternating displacement of the center of the tool and set the trajectory required for the work.

It consists of an adapter for connection to the machine spindle, a ring gear, a drive gear and an engagement gear, as well as oscillating bushings. To use a square drill with household power tools, manufacturers produce special attachment templates with a cardan drive.

Operating principle and design of the Reuleaux triangle

The Reuleaux triangle is a flat geometric figure. It is formed by connecting the vertices of an equilateral triangle with circular arcs drawn from each vertex of the same triangle.

The peculiarity of the Reuleaux triangle is that when performing a rocking motion, its vertices describe the trajectory of an almost perfect square.

The only drawback of this rotation of the Reuleaux triangle is that small roundings remain in the corners of the square.

If it is necessary to obtain a square hole with internal angles of 90 degrees, it will have to be modified. This can be done manually using files and rasps or on a slotting machine.

Cutting Tips

- We transfer pre-printed drawings or templates onto the workpiece using carbon paper.

- If the structure has through sections, we make starting holes with a thin drill.

- Insert a file or jigsaw blade into the hole. Secure the free end of the file with a fastening screw or clamp.

- We make a cut along the intended line, pressing the workpiece to the workbench. The saw moves either automatically (for electric jigsaws) or manually.

Alternative options for making a square hole

Although the Watts drill is the most productive and accurate tool for making square holes, there is more to be said about how to drill a square hole using other methods.

There are several good methods for this. When working with square drills, the resulting hole in the workpiece will have small radius roundings, which then need to be eliminated by other operations. In addition, there is no possibility of working with parts of significant thickness.

Let's take a closer look at these methods:

- In production conditions, the most accurate finishing method for cutting a square hole is laser cutting. But for this it is necessary to have expensive complex CNC machines in the equipment park.

- Another method is to drill a round hole in the part with the diameter of a circle circumscribed by a square. Then the corners of the hole are welded with the template inserted. This method requires a welding machine and appropriate skills.

- In mass production conditions, when working with sheet and thin-walled metal, square holes are produced by sheet stamping. In single production this is not relevant, since it requires the manufacture of cutting or punching dies.

- When working at home, if you need a square hole that is not very small in size, then you can drill it in the following way. A round hole with the diameter of a circle inscribed in a square is made in the part using an ordinary metal drill. Then the imaginary corners and edges of the square are straightened using a file and chisel.

- For working with thin metal, special square punches are also available. Their maximum size is 70 by 70 millimeters.

Why do you need a plywood circle?

Before you think about how to cut a circle in plywood with a jigsaw , you need to clearly understand why it is needed. Subsequently, either the resulting round-shaped blank itself or a plywood sheet with a hole of the correct shape can be used.

- for making various crafts and templates for them;

- used as a base for a wall clock;

- used for subsequent figure cutting or decoupage;

- act as the seat of a stool, the top of a kitchen or coffee table, etc.

- for creating various souvenirs, for example, boxes, etc.

You may also need to cut out the correct circle from plywood for subsequent use of a sheet with a hole:

- installing a mortise sink into the countertop;

- obtaining a ceiling with a cutout for round-shaped lighting fixtures (spotlights or one chandelier);

- for the production of furniture with decorative facades and other elements, etc.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

You must always see the markings, so sawdust must be removed from the material being cut by hand, and under no circumstances should you blow it away, as it can get into your eyes. If you want to clarify something, please contact me!