Diamond paste is a fine emulsion made from synthetic diamonds. It is widely used for grinding surfaces and rough finishing.

When in contact with a surface, diamond paste, in addition to mechanical effects, also has a chemical effect. Thanks to this, a thin film is formed on the surface, facilitating the uniform distribution of diamonds in the working area.

Thanks to the presence of surface-active additives in the diamond paste, the process of washing parts and removing chips becomes easier. At the same time, as a result of absorption, faster grinding of the material is ensured.

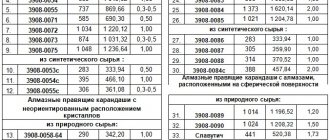

Prices for diamond pastes

| p/p | ASM/ASN | Diamond concentration in carats per 1 kg | Price per 1 kilogram | ||||

| N | P | IN | N | P | IN | ||

| 1 | 60/40 | 400 | 1 000 | 2 000 | 4000 | 10 000 | 20 000 |

| 2 | 40/28 | 400 | 1 000 | 2 000 | 4 000 | 10 000 | 20 000 |

| 3 | 28/20 | 300 | 750 | 1 500 | 3 200 | 7 500 | 15 000 |

| 4 | 20/14 | 300 | 750 | 1 500 | 3 200 | 7 500 | 15 000 |

| 5 | 14/10 | 300 | 750 | 1 500 | 3 200 | 7 500 | 15 000 |

| 6 | 10/7 | 200 | 500 | 1 000 | 2 400 | 5 000 | 10 000 |

| 7 | 7/5 | 200 | 500 | 1 000 | 2 400 | 5 000 | 10 000 |

| 8 | 5/3 | 200 | 500 | 1 000 | 2 400 | 5 000 | 10 000 |

| 9 | 3/2 | 100 | 250 | 500 | 1 500 | 2 500 | 5 000 |

| 10 | 2/1 | 100 | 250 | 500 | 1 500 | 2 500 | 5 000 |

| 11 | 1/0 | 100 | 250 | 500 | 1 500 | 2 500 | 5 000 |

| 12 | 0,5/0 | 100 | 250 | 500 | 1 800 | 3 500 | 7 500 |

| 13 | 0,3/0 | 100 | 250 | 500 | 1 800 | 3 500 | 7 500 |

The price indicated is for 1 kg. Pastes are packaged in 40, 50, 100, 200 and 500 grams. Excluding VAT.

Please check the availability of containers at the time of ordering.

Prices from ten kilograms are agreed upon individually

Elbor paste

| p/p | LM | Ct | Price for 1kg |

| 1 | 60/40 | 400 | 12 000 |

| 2 | 40/28 | 400 | 12 000 |

| 3 | 28/20 | 300 | 10000 |

| 4 | 20/14 | 300 | 10000 |

| 5 | 14/10 | 300 | 10000 |

| 6 | 10/7 | 200 | 6000 |

| 7 | 7/5 | 200 | 6000 |

| 8 | 5/3 | 200 | 6000 |

| 9 | 3/2 | 100 | 3500 |

| 10 | 2/1 | 100 | 3500 |

| 11 | 1/0 | 100 | 3500 |

Where is resin used?

Epoxy resin is a universal adhesive that hardens to a monolithic state. This material is familiar to many. Fiberglass impregnated with epoxy reinforces the bottoms of small boats and large ships. In the industrial sector, resin is used as a binding component in the manufacture of composite finishing tiles, slats, and deck boards.

In its pure form, the resin is used to create glossy transparent surfaces. After polymerization it acquires high density.

In its pure form, the resin is used to create glossy transparent surfaces.

In jewelry, polishing makes it possible to create real works of art. During processing, it acquires a noble appearance and retains its decorative effect for a long time. The two-component adhesive composition firmly adheres to the base, the resulting layer does not crack when drying due to changes in the internal structure.

Epoxy resin, poured into molds, after polymerization lends itself well to mechanical processing: cutting, grinding. In its solid state, the surface of a table filled with epoxy is comparable to artificial stone. The floors are poured with a polymer adhesive mixture. After processing, the resulting layer becomes transparent, through which the structure of the solid wood is clearly visible. The surface quality of finished products depends on what the epoxy resin is polished with.

In jewelry, polishing makes it possible to create real works of art.

Scope of application of diamond pastes by type

| Paste type | Washability | Consistency | Application area |

| G | ABOUT | M | Processing of ferrous and non-ferrous metals, alloys, non-metallic materials, steels and semiconductor materials. |

| L | IN | M | Processing of alloy steels, cast iron. ceramics, cermets, hard alloys, ferrite, sapphire. |

| X | V, VO | M, T | Processing of glass, semiconductor materials, carbide tools, dies. |

| E | IN | M | Processing of glass, semiconductor materials, carbide tools. |

Diamond pastes are produced with different concentrations of diamond powder. The higher the concentration, the higher the processing performance. This is achieved by changing the abrasive ability, i.e. the amount of material ground per unit of time.

Based on the concentration of diamond powder, pastes are divided into:

N

- Pastes of normal concentration

P

- Pastes of increased concentration

B

- Pastes of increased concentration

For convenience, a dye is added to the paste, by which its properties and characteristics (grain size and mass fraction of diamonds) can be determined.

Below is a table of diamond paste colors.

| Paste and label color | Diamond Powder Grit | Mass fraction of diamonds in paste, % | ||

| N | P | IN | ||

| Lilac | 125/100 — 80/63 | 40 | 60 | — |

| Lilac | 63/50, 50/40 | 20 | 40 | — |

| Red | 60/40, 40/28 | 8 | 20 | 40 |

| Blue | 28/20 — 14/10 | 6 | 15 | 30 |

| Green | 10/7 — 5/3 | 4 | 10 | 20 |

| Yellow | 3/2 — 1/0 | 2 | 5 | 10 |

| Does not stain | 1/0,5 — 0,1/0 | 2 | 5 | 10 |

WHAT TO DIVIDE

Before use, GOI polishing paste requires preliminary softening. In its initial state, the paste can be quite dry, which will make it difficult to apply to a polishing cloth, and hard lumps will lead to the formation of unnecessary scratches on the glass during processing.

The list of liquids used to soften the material is quite extensive: from distilled water, industrial and motor oils to white spirit and purified gasoline for lighters.

It is not recommended to dissolve GOI paste with gasoline or white spirit due to their flammability, and then it is difficult to neutralize the specific pungent odor of these liquids. The following method is more practical:

- Apply a small amount of motor oil to a block of GOI solid paste using a syringe or pipette;

- the liquid is rubbed into the block using flannel or cotton cloth until the paste has a consistency similar to plasticine;

- With the resulting plastic mass, you can polish defective areas of glass or headlights without the risk of damage.

For greater homogeneity, the mixture of GOI paste with motor oil can be heated before use (for example, in the microwave) and mixed thoroughly.

Tip! Prepare the polishing mixture in batches. Over time, the liquid evaporates and the paste becomes solid again.

The glass or plastic surface to be treated must also be moistened with water and lubricated with industrial or motor oil. If you apply GOI paste on dry glass, there is a high probability that the outer layer will become dull.

Mass fraction of diamond powder in diamond pastes

| Diamond Powder Grit | Abrasive ability of paste, mg, not less | ||

| N | P | IN | |

| 60/40 | 67 | 127 | 175 |

| 40/28 | 62 | 123 | 163 |

| 28/20 | 57 | 112 | 157 |

| 20/14 | 52 | 102 | 153 |

| 14/10 | 47 | 97 | 148 |

| 10/7 | 42 | 93 | 143 |

| 7/5 | 37 | 82 | 137 |

| 5/3 | 32 | 65 | 108 |

Ways to remove scratches

Whichever glass restoration option is chosen from those proposed, be sure to wash the scratched surface before polishing. Next, be sure to wipe it dry.

Now let’s look at all the ways to remove scratches and abrasions of different types of glass.

Toothpaste

Toothpaste must have a whitening effect. It's more potent. You will also need cotton pads, with the help of which the paste will be applied.

A small amount of whitening toothpaste should be squeezed onto the disc and pressed firmly onto the damaged area for a few seconds. After this, polish the scratched area in a circular motion, first in one direction, then in the other direction. Thus, a kind of cleaning of the defect occurs.

Actions must be carried out until the desired result is achieved. After this, the product is wiped off excess paste with a soft towel and washed with clean water.

Anti-Scratch Product

You can purchase this particular product or another similar one at a car store. This polish is specially created to combat shallow and medium-depth damage. Anti-Scratch can be used on both thin and thick glass.

How to polish scratches with it? Apply the required amount of the substance to a soft cloth and vigorously polish the glass. After this, wipe it with a clean napkin. More detailed information about use can be read directly on the tube with the product.

Paste GOI

GOI paste is also not a little-known product. You can even use it to remove scratches from a glass table. All that is required is to warm the paste a little (in a water bath) and treat the problem area with a cotton swab or soft cloth.

After actively rubbing the scratch with GOI paste, the glass will be perfectly polished, and not a trace will remain of the defect. You can use this paste both for gadget screens or watches, and for car windshields or ordinary windows.

Vegetable oil

This method is suitable for masking only the most minor scratches. It is recommended to use vegetable oil for small products. For example, to remove scuff marks on the glass of watches, phone screens, glasses, key fobs, etc.

You just need to pour any vegetable oil (sunflower, corn or olive) onto a flannel napkin and rub the scratch vigorously until it is perfectly polished. The screen will shine like new again, and the abrasion will not be as noticeable.

Dry mustard with vinegar

The use of the products is very simple. We get rid of small scratches like this: mix the ingredients in such proportions to obtain a thick consistency, like toothpaste. After which the resulting mixture is applied, for example, to the glass of glasses using a cotton pad, and intensively polished.

After the defect has been removed, wipe the glass product well with a clean damp cloth.

Clear nail polish

To remove shallow scratches on household glass products, it is good to use nail polish. It must be colorless.

It’s even better to choose not ordinary varnish, but “Smart Enamel” nail hardener. It adheres more firmly to the glass surface and looks almost invisible.

Before application, you need to not only wash the surface, but also degrease it. You can use nail polish remover or regular acetone.

It is necessary to carefully cover the scratch with varnish, and try to fill it without going beyond the limits. If, after all, the product has touched the entire surface, then this problem can be solved using a rubber spatula or other non-solid auxiliary tool

Excess varnish should be removed only after it has completely dried.

Polishing Features

The use of the paste-like substance GOI has many nuances. For example, many drivers have a question: do they need to dilute the paste-like substance with something? It is known to be quite hard and dense. The answer to this question is: it is possible and even necessary. In order to easily apply the product to a rag, you need to make it more liquid using machine oil. It is added at the rate of a few drops per small piece of product.

Preparation of a solution from GOI paste

If you decide to polish the plastic surfaces of your car, use the softest cloth (flannel or cotton). To process a metal body, you can take a coarser fabric: jeans, felt or tarpaulin.

The polishing process involves the following stages with their features:

- Before starting work, it is necessary to degrease the surface with shampoo, alcohol or glass cleaner. This will give a positive result when polishing;

- If there are scratches on the windshield, rear window or headlight, it would be much better to remove them using an electrical device, since doing it yourself will not give the desired effect. Carrying out all the processes manually will not only take you several hours, but will also make it possible to remove only the haze of the headlights. A polishing machine, unlike doing it yourself, does the same amount of work in half an hour;

Polishing with GOI paste using a drill

- you need to prepare the workplace (remove dust from nearby surfaces - it can interfere with work);

- The substance should be applied to a small area of the windshield, headlight or body. Only after thoroughly rubbing the product into the surface can you move on to the next area;

- After finishing work, you need to wash the headlights or the car body again, using non-contact foam (if grinding was carried out) or strong water pressure (for regular polishing).

Grinding technology

The process of grinding natural stone can be coarse or fine, depending on the result you plan to achieve. The simplest option is used when preparing building blocks, steps, and paving stones. In this case, rough grinding is sufficient to obtain an even, geometrically correct shape of the material without a mirror shine or smoothness. You can achieve this result using a grinder and a diamond cup.

Regardless of the choice of method, work with stone must be carried out outdoors or indoors with forced air outflow and high-quality filtration systems. The eyes and respiratory organs must be protected from contact with fine particles of minerals and rocks. It is also recommended to periodically clear the surface of the instrument from dust.

Simplified grinding technology is carried out in several stages.

Formation of an even cut. At this stage, all geometric imperfections of the workpiece are removed. You can remove excess and eliminate defects using a grinder or a special machine.