Articles

All photos from the article

Wood sandpaper is an indispensable tool for wood processing, which has been known to mankind for a very long time. Currently, there is a large assortment on the market, which can complicate the choice for a beginner.

In this article we will get acquainted with the existing types of sandpaper and its classification.

Processing wood with sandpaper

How to sand oak correctly?

Grinding

We start with 80 grit. We work with it carefully, removing only large irregularities. Then we repeat the treatment with sandpaper at 120, then at 180 and 240. During the work, we must periodically remove dust and inspect the surface to identify unevenness and other defects.

Interesting materials:

Can the speaker be used as a microphone? Can quartz sand be used for an aquarium? Is it possible to use mineral water in a Nebulizer? Can mineral water be used in a Nebulizer? Can mineral water be used in a humidifier? Can mineral water be used instead of tonic? Is it possible to use regular rinse aid in the Irrigator? Can grinding be used to lubricate a chainsaw chain? Is it possible to use a vacuum cleaner without filters? Is it possible to use an iron with a steam generator without water?

Classification of sandpaper by grain size

There are different standards for classifying sandpaper by grit. Much depends on the country and year of production. In the international classification, the following designation is adopted for abrasive materials: the letter P (indicates that this is a material on a flexible basis. For materials that are not on a flexible basis, the letter F is used) and a number that indicates the grain size.

From small to large numbers, the graininess decreases.

• P40 – P60

. Used for primary rough processing of wood. This paper should be used if there are any knots, chips, or severe unevenness on the surface.

• P70 – P120

. Basic surface cleaning work. Removing old varnish or paint layer.

• P150 – P180

. Final surface treatment before applying decor, primer, and paint.

• P220 – P360

. Excellent for intermediate sanding stages. For example, interlayer sanding during varnishing, for polishing the paint layer.

“Sandpaper” with numbers starting from 400

used mainly for polishing surfaces, if necessary.

Types of sandpaper with grain size from 1000

are used mainly only in the professional activities of auto repair shops, carpentry, furniture shops, etc.

Separately, I would like to talk about such a convenient thing as an sandpaper holder. In cases where you have to grind large and smooth surfaces, you simply cannot do without it!

The holder (or grater) for sandpaper is a hard plastic block with clamps that secure the sandpaper.

Marking of sandpaper depending on its purpose: table

Depending on the specifics of the work, coarse sandpaper is divided into several main groups:

| Marking | Types of jobs |

| P22; P24;P36 | Preparatory work: rust removal Elimination of large surface defects |

| 80-N; 63-N; 50-N | |

| P40; P46; P60 | Rough surface treatment |

| 40-N; 32-N; 25-N | |

| P80; P90; P100; P120 | Pre-grinding |

| 20-N; 16-N; 12-N; 10-N | |

| P150; P180 | Final sanding and finishing |

| 8-H; 6-H |

Fine-grained sandpaper is also marked according to the features of use:

| Marking | Types of jobs |

| P240; P280 | Sanding hardwood |

| 5-H; M63 | |

| P400; P600 | Polishing surface preparation for painting |

| M28; M40; 2-H; 3-H | |

| Р1000 | Grinding of ceramic surfaces, plastics and metals |

| M20; 1-H | |

| P1200; P1500; P2000; Р2500 | Polishing and deglazing |

| M14; M10; M7; M5; N-0;N-00; N-01 |

When purchasing sandpaper, you may find other markings on the back side. Each of them carries a certain meaning, for example, the type of abrasive powder, the method of its attachment, the characteristics of the adhesive mixture and the type of base and its mechanical properties. Let's look at the basic notation.

- The name “P” indicates the abrasive structure of the material;

- The letter “L” denotes the form of release, in this case – sheet;

- The numbers “1” and “2” indicate the purpose of the abrasive cloth: 1 – for grinding soft surfaces, 2 – metal and other hard and especially hard materials;

- Resistance to moisture is indicated by the symbols “L1”, “L2” or M;

- The designation “P” indicates that exposure to moisture and dampness is extremely undesirable.

In addition to these designations, special attention must be paid to the properties of the abrasive particles themselves.

How to choose sanding paper grit

Specialists from the technological department of the Belgorod Abrasive Department have developed recommendations for selecting grinding tools, depending on what material needs to be processed and what operation is being performed. Recommendations can be found in Table 2.

Table 2.

| Operation to be performed | Grain | Tool |

| Processing of MDF boards, chipboards | ||

| calibration | P30, P36, P40, P50 | endless ribbons |

| intermediate grinding | P50, P60, P80 | endless ribbons |

| final sanding | P100, P120, P150 | endless ribbons |

| Processing of furniture parts and doors from MDF | ||

| pre-sanding before priming | P80, P100, P120 | self-fixing products |

| sanding after priming | Р150, Р180, Р220, Р240 | self-fixing products |

| sanding after painting | P320, P400 | self-fixing products |

| Processing of gypsum fiber and gypsum particle boards | ||

| grinding | P24, P30, P36, P40, P60, P80, P100 | endless ribbons |

| Processing of furniture panels and furniture parts | ||

| calibration | P36, P40, P60, P80 | endless ribbons |

| intermediate grinding | P100, P120 | endless ribbons |

| fine grinding | Р150, Р180, Р220 | endless ribbons |

| Processing parquet boards | ||

| calibration | P80 | endless ribbons |

| intermediate grinding | P120 | endless ribbons |

| fine grinding | Р150, Р180, Р220 | endless ribbons |

| Processing of rolled steel sheets | ||

| rough grinding, descaling | P24, P30, P36, P40, P50, P60 | endless ribbons |

| intermediate grinding | P80, P100, P120 | endless ribbons |

| fine grinding | Р150, Р180, Р220, Р240 | endless ribbons |

| polishing | Р320, Р360, Р400, Р500, Р600, Р800, Р1000, Р1200 | endless ribbons |

| Stainless steel pipe processing | ||

| cleaning the weld | P40, P60, P80, P100, P120 | endless ribbons |

| pre-grinding, matting | Р150, Р180, Р220, Р240 | endless ribbons |

| grinding | P280, P320, P360, P400 | endless ribbons |

| fine grinding/polishing | Р500, Р600, Р800, Р1000, Р1200 | endless ribbons |

| Carbon Steel Pipe Processing | ||

| removal of scale, rust | P40, P60, P80 | endless ribbons |

| fine grinding | P100, P120, P150, P180 | endless ribbons |

| Wire processing | ||

| grinding | P40, P60, P80, P100, P120, P150 | endless ribbons |

| Processing of medical instruments, cutlery | ||

| rough grinding, deburring | P60, P80, P100 | endless ribbons |

| fine grinding | P100, P120, P150, P180 | endless ribbons |

| Processing of radiators and aluminum parts | ||

| rough grinding, deburring | P40, P60 | endless ribbons |

| fine grinding | P80, P100 | endless ribbons |

| General metalworking | ||

| rough grinding | P36, P40, P60 | flap wheels, self-fixing grinding discs |

| intermediate grinding | P80, P100, P120 | flap wheels, self-fixing grinding discs |

| fine grinding | Р150, Р180, Р220 | flap wheels, self-fixing grinding discs |

| polishing | Р240, Р320, Р360, Р400, Р500, Р600, Р800 | flap wheels, self-fixing grinding discs |

| Processing of paint and varnish coatings | ||

| preparing metal for coating; removal of old coating, rough leveling of putty | P40, P60, P80 | self-fastening sanding sheets and discs |

| grinding rough scratches and scratches on the surface of the prepared material; pre-grinding, putties | P100, P120 | self-fastening sanding sheets and discs |

| smoothing out marks from the previous abrasive, completing the leveling; preparation for applying filling primer; | Р120, Р150, Р180 | self-fastening sanding sheets and discs |

| final sanding of putty | P180 | self-fastening sanding sheets and discs |

| surface preparation for priming | P220, P240, P320 | self-fastening sanding sheets and discs |

| rough ground grinding | P400 | self-fastening sanding sheets and discs |

| final sanding of soil | P600, P800 | self-fastening sanding sheets and discs |

| sanding the primer when painting in dark colors | Р1000 | self-fastening sanding sheets and discs |

| sanding after painting, removing paint defects | Р1000, Р1200, Р1500 | self-fastening sanding sheets and discs |

| sanding paintwork after P1500 or immediately after painting | R2000, R2500 | self-fastening sanding sheets and discs |

Table 2 shows the most common applications for sandpaper.

Flexible grinding tools are actively used in more than 50 segments. In addition to wood and metal, the materials processed can be stone, rubber, leather, glass, and plastic.

When selecting a tool, you can independently refer to our recommended tables, or contact the sales department specialists of BAZ OJSC and receive detailed information on the products.

Recommended articles:

Composition and scope of application of sanding paper.

Grinding grain: types, properties and applications.

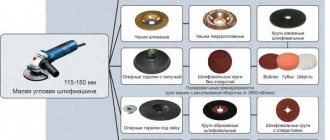

Sanding wood with an orbital sander

An orbital sander allows you to sand large flat surfaces and hard-to-reach areas. Ideal for soft wood, no dents or protrusions. For example, it works well on countertops and door surfaces. You can sand corners with the machine because it has a sanding foot.

Ideal for amateurs - it's easy to check. It uses an oscillating motion, works calmly and gently, so that the novice user will not damage the sanded surface.

When choosing an orbital sander, remember that the larger the sanding pad, the faster and more efficient the work. Don't go overboard with the size, as a larger tool reduces the room you have to maneuver when working on a smaller, more difficult-to-reach surface. The small triangular shaped foot makes it easier to work in areas that larger sanders cannot reach. Due to their ease of use, such models are recommended for buyers with less experience.

You can choose abrasive discs with different grinding power for your orbital sander. When working with hard and durable wood, choose blades with a coarser grain. Finer granulation will be beneficial for delicate materials and finishes.

Grinding quality control

They check the quality of grinding in the same way as identifying coating defects before starting work. A beam of light is directed at the wall at an acute angle. A shadow will appear in places where unevenness remains.

It’s more difficult to sand the ceiling, but if you want, you can handle this job without any problems

If everything is done efficiently, then even without painting the surfaces will look great.