Thank you!

Our specialist will call you back shortly.

Contact us to get the best price

Find out the priceOrder Compare

Description

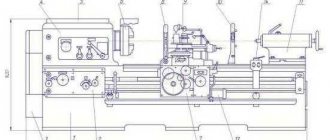

The 3K634 machine is designed for sharpening metal-cutting, woodworking and other tools, including cutters, drills and light roughing work.

Specifications

| Machine accuracy class | N | |

| Recommended height of sharpened cutters | 6-100 | mm |

| Diameter of sharpened drills | Jun.60 | mm |

| Drill tip angle | 70o-140o | hail |

| Back angle | up to 20o | hail |

| Grinding wheel type and dimensions | 400x40x203 | |

| Grinding speed with new grinding wheel | 30 | m/s |

| Height of grinding wheel centers from the floor | 900 | mm |

| Spindle speed | 1440 | rpm |

| Voltage, V/Frequency | 380/~50 | Hz |

| Power | 4 | kW |

| Dimensions | 1000x685x1230 | mm |

| Weight | 365 | kg |

Equipment

Check with the manager for information

This is interesting: Screw-cutting lathe 16K20 and its technical characteristics

PASSPORTS (manual, documentation) FOR SHARPENING MACHINES

MACHINE PASSPORT:

The passport is the main technical document containing data characterizing the machine, recommendations for its installation and care. The passport indicates the main dimensions of the machine, spindle and table speeds, feed rates, the maximum permissible torque on the spindle and power. It contains information about the main accessories and devices for the machine, about the drive, hydraulic mechanisms, machine control circuit, about eliminating defects during operation, provides electrical and hydraulic circuits, kinematic diagram, specification of bearings, gears, electric motors, spools, valves and others devices. The passport is used by the workshop technologist as a document for assigning processing modes, selecting devices, and planning the placement of the machine in the workshop. The passport is also necessary for mechanics and power engineers as a guide to the operation and repair of the machine; It contains data on repairs and modernization carried out. During the operation of the machine, various malfunctions may arise, which can be eliminated by the worker himself or reported to a repairman. Instructions on methods for correcting defects are given in the passport.

MACHINE DATA SHEET:

Each machine is supplied with a “Machine Operation Manual” by the manufacturer. The “Manual” contains: a brief description of the purpose and scope of the machine; instructions for moving (transporting), unpacking and installing the machine (with a drawing of the foundation); description of the design of the main assembly units (assemblies) of the machine; instructions for starting and servicing the machine; electrical equipment passport and electrical diagram of the machine. A separate component of the manual is the PASSPORT of the machine, drawn up on special standard forms. The passport contains: basic machine data (characteristics); specification of assembly units (assemblies) of the machine; table of the main parameters of gears, worms, screws and nuts; kinematic diagram of the machine; a table of the mechanics of the main movement (the position of the handles and the corresponding spindle speeds, the highest permissible torques, powers, efficiency, indications of weak links); table of the feed mechanism (position of the handles and corresponding feed values), layout and specification of bearings. The “Manual” contains drawings of the most frequently replaced machine parts. The machine operator begins familiarization with the new machine by studying the machine’s passport and the “Machine Operating Manual”. These documents are also used when repairing and adjusting the machine, changing lubricants, upgrading the machine or installing special devices on it.

Design features of the machine

Appearance

After an initial analysis, you can notice that the equipment differs from similar models in its simplicity of design and minimal operating requirements. The circuit of the 3K634 grinding and grinding machine consists of a vertical frame on which an electric motor is installed.

The power unit is built into the equipment head. The shaft of a two-speed electric motor simultaneously functions as a double-sided spindle. Abrasive wheels with different grain sizes and overall dimensions are installed on it. The main part of the electrical equipment (rotor, fan impeller and stator) is located in a closed unit. To access these elements, a cover is provided in the design.

Additionally, it is necessary to highlight the following design features of the 3K634 machine:

- ball bearing supports. They have a radial contact shape, which reduces the likelihood of backlash during operation;

- air cooling is carried out using a built-in impeller. The absence of a water system significantly reduces the weight of the machine;

- monolithic frame with control unit. It is made of cast iron with space for installing electrical equipment and controls;

- presence of protective covers. They not only increase operational safety, but also regulate the position of the tool relative to the abrasive wheel. For this purpose, at the bottom of the structure there are platforms with adjustment functions.

To increase comfort, transparent protective screens have lighting fixtures. They rotate at a certain angle, the value of which can reach 45°.

The tool rest has two working platforms – flat and curved. The first is used when processing smooth surfaces. If it is necessary to grind a curve, it is recommended to use a different type of working platform.

Information about the manufacturer of the universal sharpening machine 3K634

The grinding and grinding machine model 3K634 is produced by the Mukachevo Machine Tool Plant named after. Kirov is currently Mukachevo Machine Tool Plant, OJSC .

The 3K634 sharpening and grinding machine replaced the 3B364 model machine.

Machine tools produced by the Mukachevo Machine Tool Plant named after. Kirov

- 3B632, 3B632v

- sharpening and grinding machine for sharpening cutters 50 x 50 - 3B634

– floor-mounted grinding and grinding machine Ø 400 - 3D641e

- universal sharpening machine Ø 250 x 650 - 3K631

— tabletop grinding and grinding machine Ø 150 - 3K634

– floor-mounted grinding and grinding machine Ø 400 - 3L631

– tabletop grinding and grinding machine Ø 200

Grinding head

Grinding head of grinding and grinding machine 3B633

Spindle of grinding machine 3B633

Equipment for detailed processing of products

All this is special equipment for manual sharpening and finishing of various types of tools:

- The floor-standing grinding and grinding machine model 3K634 is equipped with two grinding wheels, type PP 400×50×203, PV 400×50×203.

- With a diameter from 110 to 450 mm or more, depending on the type of equipment and manufacturer.

- The height of the incisors to be sharpened should be in the range of 6–100.

- The permissible sharpening angle of the drill is from 70 to 140 degrees.

- Parts are processed with a universal wheel for detailed polishing of products H – 55 mm, D – 400 mm, Dpos – 50 mm.

- The spindle operates at a maximum speed of 30 m/min and a permissible rotation speed of 1.44 thousand revolutions per minute.

- Machine dimensions – 1000×665×1230 mm.

- The weight of the machine reaches 425 kg depending on the type of unit.

The equipment is mainly used for processing certain batches of parts; manipulations are carried out for finishing and repairing products for subsequent full-fledged work.

Equipping the machine with special equipment

The 3K634 machine is equipped with additional equipment - a support table, which is used to sharpen drills with an allowable diameter from 6 to 60 mm. It is also possible to carry out operations for chamfering and polishing workpieces with a preliminary selection of the operating mode of the machine.

Basic parameters for processing workpieces:

- Processing of the workpiece using the optional 300 cm sanding belt.

- Sharpening of cutters with parameters from 6 to 100 mm.

- Use of abrasive wheels with indicators:

- D- 400 mm;

- H – 50 mm;

- Dpos. - 203 mm.

- Sharpening of various drills with a permissible angle from 70° to 140°.

- Machining parts using a special polishing wheel with characteristics:

- D-400 mm;

- H-55 mm;

- Dpos.-50 mm.

- Spindle performance characteristics:

- permissible processing speed – 30 m/min.

- shaft rotation speed – 1440 rpm.

The 3K634 machine is used mainly for processing individual small batches of parts and when carrying out repair work.

This is interesting: Tile drills and features of drilling ceramic tiles

Capabilities of the machine model 3K634

The 3K634 machine, which belongs to the equipment of the sharpening and grinding group, is equipped with two working wheels at once, which allows it to effectively perform the following technological operations:

- sharpening of turning cutters up to 100 mm high, made of high-speed steels, and also equipped with cutting inserts made of carbide;

- sharpening drills with a diameter in the range of 6–60 mm;

- grinding parts using an abrasive belt;

- sharpening of various metalwork tools;

- chamfering parts, removing burrs, etc.;

- performing polishing operations.

Technical characteristics of the machine 3K634

Considering the characteristics of the sharpening and grinding machine of this model, it is undesirable to use it for stripping workpieces after casting and welding operations.

Operating rules

Machine in production

Before starting to operate the sharpening machine, you should familiarize yourself with the operating instructions. First of all, a flat area for installation is arranged. Since the height of the machine is relatively large, it is not necessary to make an additional elevation.

The electrical equipment is designed for connection to a 380 V power supply network. Therefore, it is necessary to provide the supply of an appropriate line, the parameters of which will take into account the rated power of the equipment. Since the power plant is cooled by air, forced ventilation must be present in the workroom.

Additionally, it is necessary to ensure the following conditions for normal operation of the machine:

- arrangement of a grounding loop;

- when the electric motor is connected to the network, its correct rotation is controlled;

- When overloads occur, the design includes an automatic switch. Its performance is checked periodically;

- the casing and system components are cleaned of abrasive dust, which will inevitably settle on the working parts of the equipment.

To operate the machine, personnel must undergo training courses. They include not only a detailed acquaintance with the structures, but also with the operating rules.

During operation, with constant switching on/off of the electrical part, natural wear of the contacts occurs. They must be checked at intervals that depend on the intensity of use.

Operating Safety

To operate the machine safely, a number of measures must be observed:

- The machine must be installed on a completely level area.

- It is necessary to observe safety precautions when operating the machine due to the use of V = 380 V.

- The room where the machine is installed must have forced ventilation.

- The machine must be grounded.

- When the electric motor is operating, constant monitoring of the operating modes of the machine must be carried out.

- All machine mechanisms must be periodically cleaned from abrasive dust.

3K634 after major overhaul

The use of the 3K634 machine can significantly increase labor productivity in production when performing operations related to sharpening and processing of parts.

3KS floor-mounted grinding and grinding machine. Purpose, scope

The 3K634 sharpening and grinding machine replaced the outdated machine model 3B634

.

The sharpening and grinding machine with two wheels model 3K634 is designed to perform the following operations:

- sharpening of high-speed cutters equipped with carbide plates with a height of up to 100 mm;

- sharpening drills with a diameter of 6..60 mm;

- sharpening of metalwork tools;

- removal of burrs, chamfers and other metalwork works;

- grinding parts with an abrasive belt;

- polishing parts

It is not recommended to use the machine for stripping cast and welded parts.

Design features and operating principle of the machine

Photo of sharpening and grinding machine 3k634

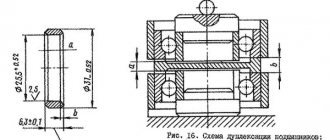

The main part of the machine is the head (Fig. 5). A two-speed electric motor is mounted in the head, the shaft of which is the spindle of the machine. The stator, rotor and fan impeller are located in a housing with two covers, which house ball bearing spindle supports (Fig. 6).

Ball bearing supports are double high-precision angular contact ball bearings No. B36209L with selected axial play. Axial labyrinth seals are made on the outer sides, and fatty grooves on the inner sides.

The electric motor is cooled by air circulation, for which the head support covers have windows connecting the internal cavities of the frame and the head. For fastening protective covers and some devices (for polishing, belt grinding, etc.) there are two trunnions on the head covers. The head is fastened to the frame using pins.

The frame is a cast iron with an electrical cabinet housed in it. A panel with electrical equipment is reinforced inside the frame. Access to electrical equipment is possible due to the presence of an opening in the front wall, hermetically sealed with a door.

Grinding wheels of types 1-400 x 50 x 203 (flat straight profile) and 5-400 x 60 x 203 (flat with recess) are installed on the machine The circles are mounted on adapter flanges mounted on the conical part of the spindle. The adapter flanges on the outside have three crackers, with the help of which the grinding wheels are balanced.

Grinding wheels are protected by protective covers made of sheet steel.

On the front wall of the casing there is a gap for access to the grinding wheel. In the upper part of the throat there is a visor, with the help of which a gap of no more than 6 mm is maintained between the visor and the grinding wheel, in the lower part of the throat there is a retractable flap for dust suction. When installing a device for sharpening drills, the flap is completely pushed into the casing. The side wall of the housing is hinged to the housing and can be quickly removed for replacement and inspection of the grinding wheel.

At the bottom of the casing there is a dust collector, which collects up to 40% of the dust sucked from the operating area of the machine. The dust collector must be cleaned of accumulated dust at least once per shift.

The casing is equipped with a pipe for connection to the exhaust system. A bushing for fastening the protective screen is welded to the top of the casing.

The protective screen (Fig. 9) is made integral with the lamps. For ease of use, the screen can be rotated about the horizontal axis by 15°. The lamps are equipped with two 41.6 W lamps, providing good illumination.

For sharpening cutters and cleaning parts, the machine is equipped with a rotary table (Fig. 10) and a tool rest (Fig. 11). The turntable is a steel plate screwed to a cast iron bracket that can move along a curved guide. Thus, the table can occupy an inclined position relative to the end of the grinding wheel. The table guide is attached to a bracket, which, in turn, is attached to the bed. As a result of two movements of the table in the horizontal plane, wear of the circle along the end and side surface is compensated.

The tool rest is a steel part with two working surfaces: flat and curved. It is recommended to use a flat working surface when grinding parts that have a supporting plane. If you need to grind the curved surface of a part in the absence of a good reference plane or if you need to frequently readjust the angle of the tool rest, you need to use a curved working surface of the tool rest. The attachment of the hand rest to the bracket is made in such a way that it can move in a circle, vertically and rotate around an axis. It is necessary to ensure that the gap between the circle and the tool rest is no more than 3 mm.

Grinding and grinding machines. General information

Synonyms: sharpening machine, electric sharpener, emery, grinding machine.

Sharpening and grinding machines are designed for manual sharpening and finishing of metal-cutting woodworking and other tools (drills, cutters, knives) with abrasive, diamond and CBN wheels. Grinding and grinding machines can be used for deburring, chamfering, cleaning and stripping parts, and manual grinding.

Depending on their purpose, sharpening machines can be divided into three groups:

- small desktop sharpening and grinding machines with grinding wheels with a diameter of 100-175 mm, used for sharpening and grinding small tools

- medium floor-mounted grinding and grinding machines with grinding wheels with a diameter of 200-350 mm, used in mechanical engineering for sharpening the main types of cutters

- large industrial grinding machines with wheels with a diameter of 400 mm or more, used mainly for manual grinding of parts, and also as roughing and grinding machines.

Sharpeners can be equipped with devices for sharpening drills, and grinding machines can be equipped with devices for belt grinding, polishing and dressing wheels.

By installing a polishing pad, grinding machines allow polishing.

3B633 Location of the main components of the grinding machine

Location of the main components of the 3B632 sharpening and grinding machine

3B633 list of main components of a grinding machine

- Bed - 3B633.10.000

- Head - 3B633.21.000

- Fastening the PP circle - 3B633.30.00

- Right casing

- Right rotary table - 3B633 46.000

- Dust collector - 3B633.54 000

- Pipe branch

- Left casing

- Visor - 3B633.44.00

- Screen

- Left hand rest - 3B633.43.000

- Retractable damper - 3B633.56.000

- Switch

- Switch with black pusher “Start”

- Switch with red pusher “Stop”

- Rotary table movement handle.

3B633 list of accessories for sharpening and grinding machine

- Device for sharpening drills with a diameter of Ø 12-50 mm - 3Б633.50.000

- Adapted for sharpening drills with diameters Ø 6-25 mm - 3Б633.50 000

- Device for belt grinding - 3B633.51.000

- Polishing device - 3B633.52.000

- Left rotary table - 3B633.53.000

- Device for dressing wheels - 3B633.55 000

- Right hand tool - 3B633.57.000

Device for straightening the encryption wheel

Device for sharpening drills Ø 12..50 mm

Device for sharpening drills Ø 6..25 mm

Belt Sanding Attachment

Technical characteristics of the grinding machine 3K634

| Parameter name | 3B634 | 3K634 | TS-3 |

| Grinding wheel | |||

| Number of grinding wheels | 2 | 2 | 2 |

| Type of grinding wheels | PP 400x50x203 PV 400x50x203 | 1-400x50x203 5-400x50x203 | GOST 2424-83 |

| Outer diameter of the circle, mm | 400 | 400 | 400 |

| Circle height, mm | 50 | 50 | 50 |

| Wheel diameter, mm | 203 | 203 | 127 |

| Diameter of worn circle, mm | 240 | ||

| Unbalance class | 1, 2 | ||

| Height of centers from base, mm | 900 | 900 | 950 |

| Recommended height of sharpened cutters, mm | 6-100 | 6-100 | |

| Diameter of sharpened drills, mm | 6-60 | 6-60 | |

| Drill tip angle, degrees | 70-140 | 70-140 | |

| Rear angle, degrees | up to 20 | up to 20 | |

| Rotation angle, degrees | +20..-1 | +20..-1 | |

| Contact roller diameter, mm | 400 | 400 | |

| Sanding belt width, mm | 80 | 80 | |

| Sanding belt length, mm | 3000 | 3000 | |

| Sanding belt tension force, N | up to 1000 | up to 1000 | |

| The largest diameter of the polishing wheel, mm | 400 | 400 | |

| Maximum height of the polishing wheel, mm | 55 | 55 | |

| Polishing wheel hole diameter, mm | 50 | 50 | |

| Spidel | |||

| Rotation speed, 1/min | 720/ 1440 | 1440 | 950 |

| Maximum cutting speed, m/s | 15/ 30 | 30 | 20 |

| Grinding spindle end (diameter/length), mm | 40/ 40 | 40/ 40 | |

| Electrical equipment | |||

| Drive electric motor, kW | 3,2/ 5,3 | 4 | 3,0 |

| Dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 1000 x 665 x 1230 | 1000 x 680 x 1230 | 660 x 600 x 1670 |

| Machine weight, kg | 425 | 358 | 220 |

- Dibner L.G., Tsofin E.E. Sharpening machines and semi-automatic machines, 1978

- Demyanovsky K.I., Dunaev V.D. Sharpening wood cutting tools, 1965

- Kudryashov A.A. Tool production machines, 1968

- Lisova A.I. Design, adjustment and operation of metal-cutting machines, 1971

- Menitsky I.D. Universal sharpening machines, 1968

- Paley M. M. Technology of production of metal-cutting tools, 1982

- Rozhkov D.S. Design, setup and operation of equipment for sharpening wood-cutting tools, 1978

Bibliography:

Related Links. Additional Information

Directory catalog of sharpening machines

Data sheets and manuals for sharpening machines

Buy a catalog, directory, database: Price list of information publications

Technical characteristics of the grinding machine for sharpening cutters 3B633

Technical characteristics of the grinding and grinding machine 3B633

- Grinding and grinding machine 3B633. Operating instructions, Tiraspol, 1967

- Grinding and grinding machine 3B633. Operating instructions, Dushanbe,

- Dibner L.G., Tsofin E.E. Sharpening machines and semi-automatic machines, 1978

- Demyanovsky K.I., Dunaev V.D. Sharpening wood cutting tools, 1965

- Kudryashov A.A. Tool production machines, 1968

- Lisova A.I. Design, adjustment and operation of metal-cutting machines, 1971

- Menitsky I.D. Universal sharpening machines, 1968

- Paley M. M. Technology of production of metal-cutting tools, 1982

- Rozhkov D.S. Design, setup and operation of equipment for sharpening wood-cutting tools, 1978

Bibliography:

Related Links. Additional Information

- Classification and main characteristics of the grinding group

- Repair, restoration and modernization of grinding machines: the American approach

- Cylindrical grinding. Processing on cylindrical grinding machines. Grinding Methods

- Setting up a cylindrical grinding machine when installing parts in centers

- CNC grinding machines

- Marking of grinding wheels

- Testing and checking metal-cutting machines for accuracy

- Grinding machines. Market of grinding machines in Russia

- Directory of grinding machine manufacturers

- Directory of factories producing metal-cutting machines

- Directory of surface grinding machines

- Articles on the topic

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

Unit design

The 3M634 grinding machine has a very simple design that does not require complex maintenance; it is enough to carry out a certain list of operations. All technical characteristics are included in the passport.

The equipment consists of the following components and parts:

- power electric motor 380 V;

- floor stand – 358 kg;

- start and stop control buttons;

- two abrasive wheels and their protection;

- protective casing for the housing;

- lighting elements.

Main mechanisms of the unit:

- rotor;

- starter.

A modern 3K634 machine has a main unit responsible for the rotation of roughening, grinding and grinding wheels - a head with a two-speed electric motor. The housing with two covers houses the rotor, fan, stator and motor shaft; it replaces the spindle.

The fan is protected by a special casing to ensure safe operation; the cover is hinged to facilitate repairs or access to the object.

The 3K634 machine is equipped with a spindle support, due to which the wheels rotate accurately. Additionally, this element is responsible for the strength and reliability of the equipment of the entire unit. The supports have fatty grooves on the inside and axial labyrinth elements on the outside.

Since the engine heats up during operation, the manufacturer provides a fan that effectively cools it with circulating air flows inside the head and frame.