The machine was manufactured in 1950, but how well does the old model cope with the tasks of modern workpiece processing? The 1M63 lathe is a retro model, it amazes modern specialists with its efficiency.

In the post-war period, increased attention was paid to production capacity and improving the quality of processing of metal blanks. The innovative 1M63 machine came to the aid of ordinary, low-efficiency equipment models. The unit developed by Ryazan engineers had unique expanded functionality, which significantly increased work productivity.

Application area

The buyers of the 1M63 screw cutting machine were often machine-building plants with fairly large production volumes. This is due to the fact that the model’s lead screw allows processing of workpieces with a length of 750-10000 mm, depending on the RMC. However, today this screw-cutting lathe is significantly inferior to modern screw-cutting models in terms of productivity and processing accuracy. Purpose: you can sharpen cylindrical and cone-shaped parts, cut threads.

The 1M63 model lathe can be used to work with complex shapes and rounded types of workpieces. An additional purpose is cutting various standard threads. The equipment drawing assumes a very convenient design of the main spindle and the cutter itself; in addition, the following tools can be installed for operation: countersinks, drills, taps and dies. The workpiece itself for subsequent processing can be fixed directly in the chuck or supported by fasteners in the centers.

The main advantages of the machine are attributed to:

- ease of performing any operation;

- uncomplicated design of the machine's key elements;

- the bed of the 1M63 lathe is characterized by sufficient rigidity, and the standards of temperature stability and processing accuracy have also been increased;

- the characteristics of the installation’s engines have high power ratings, which facilitates metal processing;

- the wear resistance of each individual component unit is high;

- thread cutting speed is very high;

- the kinematic diagram is characterized by a certain rigidity, which has a positive effect on the overall performance of the installation;

- The 1M63 package includes electrical and standard mechanical interlocks, which provide maximum safety when performing any operation.

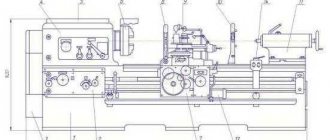

Design Features

The 1M63 has several qualities that distinguish it from other lathes:

- The 1M63 tool holder is designed so that tools made of special alloys and high-speed steel can be used. The tool holder is designed in such a way that it can be adjusted to fit the cutting tool and rotated to the desired angle.

- The 1M63 metal lathe belongs to the class of screw-cutting machines, which are responsible for the ability to carry out work on cutting threads. To do this, a guitar of interchangeable gears is installed. In addition, the gearbox has replaceable gears. By selecting gears, you can change the thread pitch.

- In order for the part to be turned at high speed and at high feed rates, the rigidity of the lower part of the support and the bed was increased.

- The 1M63 screw-cutting lathe is equipped with a special motor and feed box, which make it possible to speed up the movement of the support while turning the workpiece. The feed box also has hardened steel gears.

- When creating the upper part of 1M63, the possibility of movement was also provided. That is why, when installing a standard tool holder, it is possible to turn conical surfaces.

Guitar lathe 1M63

The passport of the 1M63 screw-cutting lathe indicates that the weight varies from 4200-13200 depending on the RMC indicator. Let's also review the main characteristics.

Download the passport (operating instructions) of the 1M63 screw-cutting lathe

A wide range of work performed on turning equipment of this model is ensured by individual design upgrades. Any operation of turning, creating cones and cutting threads is carried out quite easily, without fine scrupulous adjustments. Additional design features of the 1M63 installation are:

- the diameter of the workpieces has been increased to 700 mm;

- the permissible diameter of parts above the caliper is 350 mm;

- the permissible weight of workpieces has been increased, now you can work with parts up to 3.5 tons;

- the diameter of the cylindrical hole in the main spindle is 105 mm;

- there is a function of cross-shaped displacement of the calipers in the longitudinal plane – 5.2, in the transverse plane up to 2 m/minute;

- the power of the power unit was increased to 15 kW;

- The weight of the model is 5750 kg.

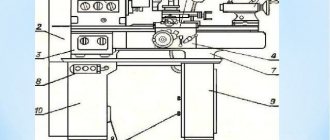

Lathe support 1M63

Large dimensions and increased functionality allow the 1M63 model to be installed in large workshops, where the emphasis is on the quantity of products produced. At the same time, the accuracy and efficiency of the machine also remains at a sufficient level.

List of lubricants recommended for lubrication of the machine 1M63.01

| I-20A GOST 20799-75 | I-30A GOST 20799—75 | CIATIM-203 GOST 8773-73 |

| Viscosity at 50°C 17—23 cSt | Viscosity at 50°C 27—33 cSt | Effective viscosity at -30°C — no more than 1000 Pz |

| Flash point (in open crucible) — not lower than 165°С | Flash point (in open crucible) — not lower than 180°С | Corrosion test - withstands |

| Pour point - 30°C | Pour point - 15°C | Content of free alkalis in terms of 0.1% |

| Acid number - no more than 0.14 mg KOH/1 g oil | Acid number - no more than 0.2 mg KOH/1 g oil | |

| Ash content — no more than 0.007% Content of mechanical impurities - absent | Ash content - no more than 0.007% Content of mechanical impurities - absent | Free organic acid content - none Water content - no more than 2.5% |

| Content of water-soluble acids and alkalis - none | Content of water-soluble acids and alkalis - none | The content of mechanical impurities is no more than 0.25% |

| Water content - none | Water content - none | |

| Replacement with IGP-18 TU38-1-273—69 is allowed | Replacement with IGP-30 TU38-1-273—69 is allowed |

In the absence of lubricants specified in the list, it is permissible to use only those oils whose main characteristics correspond to those given.

Main characteristics

The design of the clutch of the 1M63 lathe, as well as its other elements, complies with the established standards in 1982. The model belongs to accuracy class H and must meet the established standards. The technical specifications are as follows:

- 1M63 spindle bearings support rotation speeds ranging from 10 to 1,250 rpm.

- A lathe can have a very different RMC. During operation, both fixing elements are motionless.

- The model can be used for processing long and non-rigid parts with different RMC values. For this purpose, it is possible to install a steady rest. However, it is worth considering that the steady rest is not supplied. The steady rest for the 1M63 lathe is used to limit the deformation of parts when processing.

- The tool holder is made in a classic style: the tool itself is stationary, only the support moves. The distance between the axis of the centers and the edge of the tool holder is 32 cm. In the manufacture of the tool holder, durable material is used, which eliminates the possibility of deformation of the structure. Adjusting the tool holder allows you to select optimal turning performance.

- The holes in the spindle are 65 mm. The spindle is used to install workpieces with a diameter of 630 mm. A straight rod can be installed and fed as it is turned on the 1M63 screw-cutting lathe in question.

- The tailstock is installed on the screw-cutting lathe in question, and with its power, the rear end is fixed.

- The gearbox allows you to adjust the speed in 22 ranges.

- The support has longitudinal and transverse feed in automatic mode.

- The kinematic mechanism is quite complex. There is a front and back stock. There is a gearbox in the headstock. The tailstock allows you to fix the second end of the part. The position of the tailstock can be changed. Overrunning clutches 1M63 are also used, which are responsible for maintaining the accuracy of operation.

- When considering gearboxes and feeds, we note their high strength and reliability. The maintainability of the boxes makes the 1M63 screw-cutting lathe more attractive.

- The electrical cabinet is located in the headstock, which is confirmed by the drawing of the 1M63 lathe.

- The apron of the 1M63 lathe is controlled using a special switch.

- The characteristics of the replacement wheels allow you to cut inch, metric, modular and pitch threads. The technical potential of the model is quite large. You can install replaceable wheels for turning threads of various types

You should purchase a steady rest to improve the quality of processing when you need to carry out high-precision turning of deformable workpieces. Lunettes can be made from a wide variety of materials. If you do not use a steady rest, a strong feed will lead to deformation of the workpiece. Steady rests can be installed and removed depending on the tasks assigned.

Machine lubrication map 1M63.01

| Headstock | Auto | I-20A GOST 20799-75 | Annually (approximately 700 operating hours) | Fill—1; drain—2 |

| Gearbox | Auto | I-20A GOST 20799-75 | Annually (approximately 700 operating hours) | Fill—3; drain—4 |

| Caliper apron | Auto | I-30A GOST 20799-75 | Annually (approximately 700 operating hours) | Fill—5; drain—6 |

| Bed guides | Auto, using apron lubrication system | I-30A GOST 20799-75 | 11 | |

| Cross slide, top slide | Manual | I-30A GOST 20799-75 | Weekly | 8,10 |

| Tailstock | Manual | I-30A GOST 20799-75 | Weekly | 9 |

| Replacement gears | Manual | CIATIM-203 GOST 8773-73 | Daily | 12 |

| Tool holder | Manual | I-30 AGOST 20799-75 | 1 time per shift | 7 |

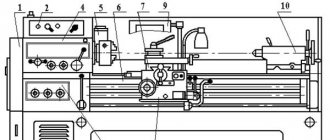

Electrical equipment and kinematic diagram

Kinematic diagram of the 1M63 machine

The 1M63 screw-cutting lathe, the electrical circuit of which has 4 electric motors, also has a detailed description of each node module in its passport. The main motor can operate from a 50 Hz or 60 Hz network. The electrical diagram indicates that the motor has a power of 13 kW.

The operating instructions provide for cooling the system. A large motor is also installed for this purpose. The kinematic diagram indicates the need to supply 22 liters of liquid per minute. Electric motor power 0.12 kW.

The kinematic mechanism is also represented by a motor, which ensures accelerated movement of the caliper. The cutter moves along with the support thanks to the installation of a motor with a power of 1.1 kW.

The kinematic diagram of the 1M63 machine also indicates the presence of four couplings. The 1M63 friction clutch is responsible for the movement of the carriage: longitudinal and transverse passage is carried out during turning, the internal mechanical element allows you to quickly bring the cutting tool. The electromagnetic type of the device allows you to quickly change the position of the carriage. There is a 1M63 direct friction clutch, which is designed to ensure smooth direct feeds in the equipment.

Electrical circuit of the machine 1M63

Instructions for the initial start-up of the machine 1M63.01

During the initial start-up of the 1M63.01 machine, it is necessary to check the reliability of grounding and the quality of installation of electrical equipment by external inspection. After inspection, disconnect the power wires of all electric motors at the terminal sets in the control cabinet and connect the machine to the workshop network using the input circuit breaker. Check the operation of all locking devices

- Using manual controls, check the precise operation of magnetic starters and relays.

- Once smooth operation of all electrical devices located in the control cabinet is achieved, connect the previously disconnected wires to the terminal sets.

- By alternately turning on the electric motors of the main drive and quickly moving the caliper, check the correct direction of their rotation.

- After making sure that the electric motors rotate correctly, you can begin testing the machine in operation.

Repair of equipment

Working on any equipment involves both scheduled and complex repairs. Measures to restore the functionality of individual mechanisms are required for the 1M63 model quite rarely. But a gradual loss of stability and loosening of individual structural components leads to a decrease in the accuracy of operations and a decrease in processing speed.

To carry out a comprehensive repair from the manufacturer, the customer must send the following documents together with the machine: a technical passport of the installation, special reports of previous technical inspections and a statement that reflects information about the assembly node modules.