Technical characteristics of the grinding and grinding machine 3B634

The popular model 3B634 sharpening and grinding machine was produced by the Mukachevo Machine Tool Plant named after. Kirov, which is now called Mukachevo Machine Tool Plant OJSC. Thanks to its high reliability and ease of use, equipment of this model still operates successfully in many manufacturing enterprises. Today, this machine has been replaced by its improved model 3K634.

Grinding and grinding machine 3B634 in the production workshop

Information about the manufacturer of the universal sharpening machine 3M642

The manufacturer of the universal sharpening machine 3M642 is the Vitebsk grinding machine plant Visas , founded in 1897.

Since 1940, the company has specialized in the production of sharpening equipment and today is the only manufacturer in the CIS of machines for the manufacture and sharpening of any cutting tool. The plant's products are used in more than sixty countries around the world.

Machines produced by the Vitebsk sharpening machine plant, Visas

What technological operations can be performed on the 3B634 machine

Due to its technical characteristics and design features, the 3B634 machine, which belongs to the equipment of the sharpening and grinding group, allows you to perform the following technological operations:

- sharpening of cutters up to 100 mm high, made of high-speed steels or equipped with carbide cutting inserts;

- sharpening drills with a diameter from 12 to 50 mm;

- sharpening of various tools used to perform plumbing work;

- cleaning operations - removing burrs, forming chamfers on the surface of a part and other types of metalwork;

- grinding of parts, for which an abrasive belt is used;

- polishing operations.

The high functionality of the 3B634 sharpening and grinding machine is also ensured by the fact that its design provides two working wheels at once.

Features of the machine 3B634

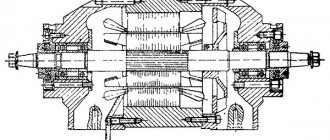

To impart rotational motion to the working circles of the sharpening and grinding machine of this model, a two-speed electric motor is used, which is installed in the inner part of the working head. The electric motor shaft protruding from both sides of its covers simultaneously plays the role of an equipment spindle.

View from the machine spindle side

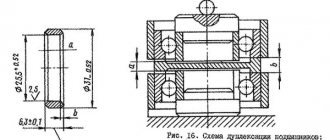

To ensure the stability of the protruding parts of the electric motor shaft and give them precise rotation, ball bearing supports are mounted in the covers of the working head. The main structural elements of such supports are high-precision angular contact ball bearings, in which axial play is additionally selected. There are sealing elements on both sides of the bearings: axial labyrinth (on the outside) and with grease grooves (on the inside).

The electric motor of sharpening and grinding equipment is subject to strong heating during operation, so it must be effectively cooled. In the 3B634 machine, such cooling is provided by air that circulates through the internal cavity of the frame and freely penetrates into the working head through the windows in its supporting part.

The characteristics of the sharpening and grinding machine of this model provide for the possibility of using it not only as sharpening equipment, but also for performing belt grinding and polishing work.

In order to provide such functionality, the 3B634 design provides for the possibility of attaching additional devices, for which special trunnions are mounted on the covers of the working head. With the help of such trunnions, in addition, the fixation of the protective casings of sharpening and grinding equipment is ensured. To securely fix the working head on the equipment frame, studs are used.

Machine Specifications

All structural elements of the grinding and grinding machine of this model are fixed on its frame, which is made of cast iron. The inner part of the frame is hollow; it houses electrical equipment mounted in a separate cabinet. Access to the electrical equipment of the grinding and grinding machine is provided by an opening in the front part of the bed, closed with a sealed lid.

To perform sharpening and other metalworking operations on the machine, wheels with a flat straight profile (400x50x203) and flat wheels with a recess (400x60x203) can be used. To fix the working wheels, adapter flanges are used, which are fixed to the machine spindle, which has a conical shape.

Working wheels on sharpening and grinding machines must be balanced after they are installed; for this purpose, there are three crackers on the outer part of the adapter flanges.

To ensure the safety of performing work on a grinding and grinding machine of this model, its working circles are protected with special casings made of sheet steel. In addition, the design of the machine includes special dust collectors connected to an exhaust system, which makes it possible to collect up to 40% of the dust created during work.

The machine is equipped with an exhaust system

Access of the workpiece to the surface of the working circle is ensured by the presence of openings in the protective covers. Transparent protective screens attached to the top of the casings make it possible to safely observe the processing process. Such screens, made integral with powerful lamps, can be rotated 15 degrees relative to the horizontal axis, which further increases the convenience of working on the sharpening and grinding equipment of this model.

The machine in question is very convenient for sharpening turning tools, since its design includes a rotary table and a tool rest. Thanks to movement along curved guides, the rotary table of a sharpening and grinding machine can even occupy an inclined position relative to the end of the working wheel. The movements of the rotary table, which occur in the horizontal plane, make it possible to easily compensate for the wear of the working circle.

The tool rest for sharpening and grinding equipment of this model has two working surfaces – flat and curved. They are used, respectively, when grinding parts with a flat and curved reference plane.

The right hand rest of the machine is equipped with a rotating device that allows you to change the angle of inclination of the supporting surface

3D642E universal sharpening machine with hydraulic drive. Purpose and scope

Universal sharpening machines 3D642E are designed for sharpening and finishing the main types of cutting tools: cutters, milling cutters, countersinks, etc. made of tool steel, hard alloy, metal ceramics with abrasive, diamond and CBN wheels.

The 3D642E sharpening machine has a cast iron frame, this increases the accuracy of processing and reduces vibrations caused during processing of the part. Additionally, the machines can be equipped with a sine plate for securing workpieces, a device for radius sharpening of cutters and multi-edge end tools, a device for external cylindrical grinding, for internal grinding, for sharpening right- and left-handed countersinks, etc.

The universal sharpening machine 3D642E is a modification of the 3D642 machine. Unlike its predecessor, the longitudinal movements of the table on the 3D642E machine are carried out by a hydraulic drive for the longitudinal movement of the table, this gives smooth movement of the table and increased productivity per shift.

The mechanized raising and lowering of the grinding head improves working conditions and reduces auxiliary time.

The machines sharpen tools from three work stations.

The spindle of the grinding wheel can be rotated in the horizontal plane by 360°, in the vertical plane by 20° up and 40° down relative to the horizontal axis, which simplifies adjustment to a given sharpening angle and expands the technological capabilities of the machines.

The 3D642E machine is manufactured in the following versions

- with stepless regulation of the rotation speed of the grinding spindle;

- with stepwise regulation of the grinding spindle speed.

According to the design of the guides, the machines are manufactured:

- with closed steel guides with preload;

- with open monolithic cast iron guides with preload.

At the customer's request, the machines can be equipped with devices for sharpening various tools, including devices for external cylindrical grinding and a dust extraction system.

With the use of backing plates and additional devices, it is possible to process parts with a diameter of up to 330 mm and a length of up to 1040 mm.

For an additional fee, the machine can be equipped with more than 38 additional devices, including a coolant supply system.

The climatic design and placement category of machines, separately located equipment and accessories comply with GOST 15150-69 for delivery to the areas:

with a temperate climate - UHL4;

Machine accuracy class – P.

The 3M642E machine is the previous analogue of the 3D642E machines.

The 3D642E machine is the previous analogue of the 3E642E machines.

The 3E642 (3E642E) machine is a previous analogue of the VZ-318 (VZ-318E) and VZ-818 (VZ-818E) machines.

Machines models 3E642 and 3E642E were discontinued in 1994.

Currently, production of the “legendary” models of sharpening machines 3E642E and 3E642 has been resumed.

Machines of the VZ-318 and VZ-318E models were discontinued in 2008.

Machine tools of the VZ-818 and VZ-818E models are currently produced by the plant.

Universal sharpening machines. General information

Sharpening machines are used for sharpening tools and are used in tool shops of factories and in sharpening departments of machine shops. According to the method of sharpening, they are divided into two groups:

- machines for abrasive sharpening and finishing of tools, working with a grinding wheel;

- machines for non-abrasive sharpening and finishing.

The first group is more widespread, especially since sharpening tools with diamond wheels has recently become of great importance. The use of diamond wheels significantly increases the productivity and quality of sharpening. Non-abrasive sharpening includes electric spark and anodic-mechanical methods.

According to their purpose, sharpening machines are divided into universal (for sharpening various types of tools) and special (for sharpening a certain type of tool).

Universal sharpening machines are used for sharpening multi-edge tools made of tool steel and hard alloys. Grinding machines allow you to work with cylindrical and conical tools, countersinks and reamers. Grinding machines are also used for processing cutters, cutters and taps, cutters, hobs, gear-cutting heads and broaches, with screw and straight teeth, etc. on the front and rear surfaces located on the periphery and end with CBN, diamond and abrasive grinding wheels.

Grinding machines of this type can also perform cylindrical (external and internal) and flat grinding.

Structural elements of the 3B634 machine

The design of the grinding and grinding machine of this model includes the following elements:

- supporting frame;

- working head;

- device for fixing circles PP type;

- device for fastening circles type PV;

- two protective covers – left and right;

- transparent protective screens;

- turntable;

- handyman

Machine components

Electrical equipment of the machine

To operate the machine, a three-phase AC electrical network is used, and the lighting system requires direct current with a voltage of 12 V, which is supplied by a step-down transformer. The rotation of the working circles is ensured by a two-speed electric motor 1M.

To control the operation of the sharpening and grinding machine, a push-button station is used, conveniently located on the front of the bed. Using a push-button station allows you to effectively manage all the main and auxiliary processes of the equipment, such as:

- turning on (“START”) and turning off the machine (“STOP”);

- selection of wheel rotation speed (rotary switch “PS”);

- lighting of the processing area (automatically turns on when you press the “START” button).

All other electrical equipment of the machine, as mentioned above, is located in a special cabinet in the inner part of the frame. To prevent accidental access to the inside of the machine's electrical cabinet and protect it from negative external factors, a sealed cover is mounted on the front of the frame.

At the time when the machine of this model was still in production, it could be ordered in an improved configuration, which included equipping it with a 2M electric motor and a separate ventilation device.

Machine 3E642E. Universal sharpening. Manual. Hydraulic equipment

This instruction manual “Universal sharpening machine 3E642E” contains information necessary both for the maintenance personnel of this machine and for the employee directly involved in working on this machine. This manual is an electronic version in PDF format of the original paper version. This documentation contains the Manual (instructions) for operating the hydraulic equipment of the 3E642E universal sharpening machine.

Hydraulic circuit diagramPurpose of hydraulic equipmentDesign

- Hydrocommunication

- Hydropanel

Description of the hydraulic systemInstructions for installation and operation

- Safety instructions

- Preparing the hydraulic system for start-up

Possible malfunctions and methods for eliminating them

Organizer information

Name of organizer Organizer

JOINT STOCK COMPANY RADIO EQUIPMENT PLANT All purchases and tenders of ZRTO JSC

192012, Russian Federation, St. Petersburg, Obukhovskaya Oborony Avenue, 120, lit. X

192012, Russian Federation, St. Petersburg, Obukhovskaya Oborony Avenue, 120, lit. X

E-mail address

FULL NAME. contact person

Beresneva Anastasia Dmitrievna

Place for consideration of proposals

A range of business services for a supplier in the financial supermarket ETP GPB!

www.etpfs.ru

Similar auctions

We have a special client program, according to which you can take part in trading within 1 hour. Submit your application to participate in the program using the link below.

Supplies for the Gazprom Group of Companies

Supplies for customers-subjects of 223-FZ, as well as large commercial organizations (OMZ JSC, Russian Space Systems JSC, MASH JSC, Gazprom-Media Holding JSC, Ural Mash PJSC, Gazprombank JSC, Rosvodokanal group of companies and others.

Bidding for the sale of non-core assets of organizations (vehicles, apartments, premises, factories, land plots)

We have a special client program under which you can take part in bidding now

Payment security is ensured with the help of the acquiring bank (GAZPROMBANK (Joint Stock Company)), operating on the basis of modern protocols and technologies developed by the MIR, Visa International and Mastercard Worldwide payment systems (3D-Secure: Verified by VISA, Mastercard SecureCode, MirAccept). Processing of the received confidential data of the Cardholder is carried out at the Bank's processing center certified according to the PCI DSS standard. The security of transmitted information is ensured using modern Internet security protocols.

Before making a payment, the Cardholder must be sure that the Card Issuing Bank allows payments via the Internet and has activated the 3DS functionality for the card. If the Issuing Bank does not have the correct activation of 3DS and a link with a phone number, you simply will not receive an SMS to confirm the operation.

When paying, your plastic card details are entered on the Bank's payment page using a secure channel. Information is transmitted in encrypted form and processed only on a specialized bank server.

After clicking the “pay” button, you will be directed to the secure payment page of the Bank’s processing center, where you must enter your plastic card details.

In case of successful authorization, you will receive a notification from the site that the payment has been made and/or a description of the procedure for receiving the product/service.

General description of the model

Grinding and sharpening machine - passport 3b 634. It is based on an electric motor with 2 speeds and located in the inside of the working head. The protruding shaft is a spindle designed to perform rotational movements.

The main components of the structure include:

- frame with cast iron;

- an electrical cabinet located inside the frame, accessible through an opening in the front part;

- hermetically sealed door in the opening;

- grinding wheels, size 40x60x203, attached to the conical part of the adapter flanges and rotating due to crackers (3 pcs.);

- spindles that help balance grinding wheels;

- pipe connected to the hood;

- a bushing in the upper part of the casing as a mount for a protective screen;

- a dust collector located in the lower part of the casing with the ability to collect dust up to 48% and absorb debris from the working area of the equipment;

- turntable;

- a tool rest with the ability to move vertically along the grinding wheel and around its axis.

The model also has a special visor located at the top of the equipment on the left, the function of which is to maintain a gap of 6 mm between the built-in lamps and light bulbs (41.6 W) to provide better lighting.

A turntable in the form of a steel plate, attached to cast iron brackets, rotating along curved guides. Thus, when moving horizontally, the table performs a compensation function and does not lead to wear of parts during grinding.

The main thing, when working at the machine, is to ensure that there is no gap between the tool rest and the grinding wheels, the diameter of which must be at least 2.8 mm.

Passport for the machine for sharpening cutters 3B632V

Documentation printing: Mukachevo Machine Tool Plant named after Kirov Year of documentation printing: 1964 Number of folders: 1 Number of pages, sheets: 52

Find out the cost of documentation

The passport and documentation for this machine model are in our archive, in electronic form. The documentation set includes, in sections, according to the content:

Maintenance Manual Contents: 1. Purpose of the machine 2. Unpacking and transportation of the machine 3. Foundation of the machine, installation and installation 4. Preparing the machine for initial start-up 5. Starting the machine 6. Description of the machine 7. Coolant supply unit 8. Table, oscillating with accessories 9. Device for sharpening the back surfaces 10. Connecting the machine to the ventilation network 11. Tools supplied with the machine 12. Adjusting the grinding spindle bearings 13. Lubrication instructions 14. Instructions for balancing wheels 15. Electrical equipment General information Instructions for servicing electrical equipment Specification of purchased electrical equipment 16. Instructions for the safe operation of the machine 17. Recommendations Passport Basic data of the machine Basic data of the device Device for applying chip-breaking holes Specification of the main components of the machine Specification of control elements Drive Equipment list of the device Machine acceptance certificate Drawings of wearing parts

Schemes and drawings of the machine: - General view of the machine - Scheme for slinging the box with the machine - Scheme for transporting the machine - Head drawing - Fastening the wheel ABC drawing - Fastening the wheel A5P drawing - Fastening the circle ChTs drawing - Oscillating table drawing - Device for sharpening the rear and side surfaces drawing — Device for sharpening the front surfaces of bent cutters drawing — Scheme for setting up the device for applying chip-breaking holes — Method for determining the grinding values of the internal spacer ring of a bearing unit — Electrical circuit diagram — Electrical installation diagram — Schemes for setting the machine when sharpening cutters on the front and rear surfaces — Layout diagram lubrication of spindle bearing units - Machine for sharpening and mounting of cutters; relative position of units and controls

Brief description of the machine: The machine for sharpening cutters model 3B632V is designed for sharpening and finishing carbide cutters with diamond wheels. The machine can also be used for sharpening cutters with abrasive wheels. The machine produces fine sharpening of the cutters along the main and auxiliary rear and front surfaces, as well as applying a chip-breaking hole on the front surface of the cutter using a special device. To perform these operations, three wheels are installed on the machine: two on the spindle of the grinding head and one on the motor of the device for applying chip breaking holes. Thanks to the presence of 2 speeds of rotation of the grinding wheels of the spindle of the grinding head - 30 and 15 m/sec., high precision bearing units, equipping the machine with oscillating tables, the use of cooling for diamond wheels, precision fixtures, the machine provides sharpening and finishing of cutters up to 25 in height mm. If necessary, the machine can sharpen and fine-tune the cutters. After installing the machine on the foundation, it is necessary to wash off the anti-corrosion coating from the treated surfaces with a rag moistened with gasoline or white spirit. Anti-corrosion coatings are applied to open, as well as closed with casings and covers, treated unpainted parts of the machine. Once cleaned, the surfaces are wiped dry and lightly oiled. Cleaning the machine with metal objects is not allowed.

Technical specifications

Thanks to the 3b634 grinding and sharpening machine, you can sharpen drills, metalwork tools and cutters. If you wish, you can familiarize yourself with the full list of operational parameters by reading the passport attached to it. If it is not available or it is not possible to purchase it due to the discontinuation and discontinuation of production of this grinding and grinding model, then the main technical characteristics are as follows:

- GOST machine – 8–82;

- power – 4 kW;

- grinding wheels (2 pcs.) PP size 400x40x203;

- distance between grinding wheels – 550 mm;

- equipment dimensions – 925x650x1440;

- equipment weight – 365 kg;

- height from the floor of the centers of the grinding wheels – 864 mm;

- voltage – 380 V, frequency 50 Hz;

- spindle speed – 1440 rpm;

- cutting speed – 30 m/s;

- sanding belt when installed, length – 300 cm, for sharpening it is recommended to use a height of up to 6 m.

If necessary, sharpen the drills, the frame can be installed at an angle at the top - 70-140 degrees, and at the rear - at an angle of 20 degrees.

The grinding machine is adapted to use cutters with different cutting edges, but their height should not be higher than 100 mm, and when using drills, the permissible diameter is 60 mm.

If you need to chamfer or polish a part, you need to take into account the diameter of the grinding wheels for installation and choose the optimal operating mode of the machine.

The 3B634 sharpening and grinding machine is more intended for repair work. The kit includes a special attachment necessary for sharpening drills. Taking into account the characteristics of the equipment, it is quite possible to make the nozzle yourself or buy it separately in the store.

Electrical equipment of sharpening machine 3E642

Supply system

The power supply to the machine is carried out with a copper wire with a cross-section of 2.5 mm².

The supply wires are entered through a flange elbow with a G1/2″ thread.

The following AC and DC voltages are used on the machine:

- power circuit 3 variable 50 (60) Hz, 380 (220, 230, 400, 415, 440) V

- control circuit 3 variable 50 (60) Hz, 110 V

- alarm and local lighting circuit – alternating 50 (60) Hz, 24 V

Initial launch

Before starting up the machine, it is necessary to carry out an external inspection of the electrical equipment.

ATTENTION! During EXTERNAL INSPECTION, THE INPUT SWITCH SHOULD BE SET IN THE “OFF” POSITION. During an external inspection of electrical equipment, it is necessary to check

During an external inspection of electrical equipment, it is necessary to check

- reliability of installation of electrical equipment and quality of electrical wiring;

- reliability of the grounding of the machine, as well as separate units and devices;

- condition and initial position of electrical equipment and mechanisms.

After inspection, disconnect by separating the connectors, and if they are missing, by disconnecting the power wires A6, B6, C6 (electric motor M6) of all electric motors at the terminal set in the electronic niche.

Set the QPI input switch to the “On” position. At the same time, the HLI signal lamp “Power connected” should light up on the control panel.

Using manual controls, check the precise operation of the magnetic starters.

When smooth operation of all electrical devices located on the control panel is achieved, connect the previously disconnected power wires of the M6 column drive electric motor to the terminals of the terminal block. Perform phasing of the network by correctly connecting the supply wires to the input terminal set, which is determined by the correspondence of the direction of movement of the column to the purpose of the push-button switches on the control panels that determined these movements. Next, connect the remaining electric motors.

Check the operation of electrical equipment in all modes without the product (idling).

Check the functionality of the emergency shutdown device (General Stop switch).

Check the operation of all locking devices according to section 5.

Check local lighting.

Description of work

Starting the grinding wheel, cooling pump (vacuum cleaner), and accessories is carried out by switches SB10, SB11, SB12, stopping by switches SB1, SB2, SB3 (“All stop”). The rotation direction and rotation speed of the grinding wheel are determined by switches SAI, SA2, respectively. The cooling pump (vacuum cleaner) can also be turned off autonomously using the SA3 switch. The choice of the direction of rotation and autonomous stop of devices P17, P51 can be carried out using switches SA4 and sA5, respectively.

Raising and lowering the column is carried out by switches SB4... SB6 and SB7... SB9, respectively.

Locks

The electrical circuit of the machine provides the following interlocks:

- impossibility of moving the column upward when the mechanism reaches the uppermost position - microswitch contact SQI (3.8);

- impossibility of moving the column down when the mechanism reaches its lowest position - microswitch contact SQ2 (3.9);

- inability to continue operation of the machine when switching switches SAI or SA2 or being in position “O” – contacts of switches SAI, SA2 (3.7).

Alarm system

The electrical circuit of the machine provides the following signaling: the “Power is connected” lamp is milky colored, located on the main console (HLI).

Design and equipment of the unit

The 3b634 sharpening machine has quite high functionality. The design includes:

- 2 working circles for performing rotational movements;

- electric motor with 2-speed modes, mounted in the inside of the head;

- a motor shaft with a protrusion on both sides of the cover, which acts as a spindle in the equipment.

The main features of this model include:

- the presence of a rotary table with a tool rest and 2 working surfaces (curvilinear, flat), for grinding parts;

- the ability to move the table horizontally to avoid rapid wear of the working circle;

- the right hand rest is equipped with a rotating mechanism and you can change the angle of inclination of the supporting surface if necessary;

- the presence of openings in the protective covers for better access to the workpiece and the surface of the working circle;

- moving the rotary table along curved guides to install the machine at an angle relative to the ends of the working circle.

Model features

On the sharpening and grinding machine 3b 634 you can not only sharpen products, but also carry out roughing and polishing work, and belt grinding. To ensure greater functionality, additional devices can be attached at any time by placing them on the trunnions mounted on the covers of the working head.

These are excellent assistants that not only firmly fix the sharpening machine casings, but also serve to secure the working head on the frame in the form of pins attached to the equipment.

It is worth noting that the electric motor of this brand of machine quickly overheats and therefore requires cooling. Although the design provides an air duct through which air circulates through the external cavity and unhindered penetration into the working head through a window in the supporting part.

One of the design features of the machine is the presence of built-in ball bearing supports, which provide stability to the protruding parts of the electric motor shaft and give them rotational accuracy. These are quite high-precision, persistent ball bearings with sealing elements, grease and axial labyrinth grooves placed on both sides.

Each element in the design of the sharpening machine is firmly fixed to a cast-iron frame, the inner part of which is hollow, where it is located in the electrical equipment. For unobstructed access, there is an opening in the front of the frame, as well as a sealed lid for closing.

Related video: Sharpening and grinding machine TCH-350

Location of controls for sharpening machine 3M642

Location of controls for sharpening machine 3M642

List of controls for the sharpening machine 3M642

- Main control panel

- Quick cross feed handwheels

- Fine cross feed switch handle

- Table hydraulic cylinder shutdown button (for 3M642E)

- Turntable Clamp Screws

- Central table fixing screw

- Grinding head bracket fixing screws

- Table stops

- Rigid table stop

- Handwheel for moving the table from the main workplace

- Pull handle for switching table speed

- Hydraulic power station control panel (for 3M642E)

- Electrical cabinet locks

- Duplicate control panel

- Quick cross feed handwheels

- Column Clamp Handle

- Handwheel for lifting the grinding head

- Handwheel for moving the table from the side workstations

- Table reverse lever (for 3M642E)

- Fine cross feed handwheel

- Introductory machine

- Socket for connecting devices