Materials science: lecture notes Alekseev Viktor Sergeevich

7. Chemical-thermal treatment: nitriding, ion nitriding

Chemical-thermal treatment

– nitriding is used to increase the surface hardness of various parts - gears, sleeves, shafts, etc. made from steels 38ХМУА, 38ХВФУА, 18Х2Н4ВА, 40ХНВА, etc.

Nitriding

is the last operation in the technological process of manufacturing parts.

Before nitriding, complete thermal and mechanical treatment and even grinding are carried out; after nitriding, only finishing is allowed with metal removal up to 0.02 mm per side. Nitriding

is a chemical-thermal treatment in which diffusion saturation of the surface layer with nitrogen occurs. As a result of nitriding, the following are provided: high hardness of the surface layer (up to 72 HRC), high fatigue strength, heat resistance, minimal deformation, greater resistance to wear and corrosion. Nitriding is carried out at temperatures from +500 to +520 °C for 8–9 hours. The depth of the nitrided layer is 0.1–0.8 mm. At the end of the nitriding process, the parts are cooled to +200–300 °C together with the furnace in a stream of ammonia, and then in air.

The surface layer cannot be etched. Deeper than this is a sorbitol-like structure. The process of liquid nitriding in molten cyanide salts is widely used in industry. The thickness of the nitrided layer is 0.15-0.5 mm.

The nitrided layer is not prone to brittle fracture. The hardness of the nitrided layer of carbon steels is up to 350 HV, alloyed – up to 1100 HV. The disadvantages of the process are the toxicity and high cost of cyanide salts.

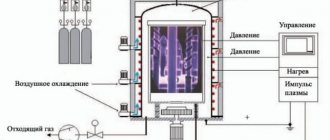

A number of industries use ion nitriding, which has a number of advantages over gas and liquid nitriding. Ionic nitriding is carried out in a sealed container in which a rarefied nitrogen-containing atmosphere is created. For this purpose, pure nitrogen, ammonia or a mixture of nitrogen and hydrogen are used. The parts placed inside the container are connected to the negative pole of a source of constant electromotive force. They act as a cathode. The container body serves as the anode. A high voltage (500-1000 V) is switched on between the anode and cathode - gas ionization occurs. The resulting positively charged nitrogen ions rush to the negative pole - the cathode. A high electric field intensity is created near the cathode. The high kinetic energy possessed by nitrogen ions turns into thermal energy. The part heats up to from +470 to +580 °C in a short time (15–30 minutes), nitrogen diffusion occurs deep into the metal, i.e. nitriding.

Compared to nitriding in furnaces, ion nitriding can reduce the total duration of the process by 2–3 times and reduce the deformation of parts due to uniform heating.

Ion nitriding of corrosion-resistant steels and alloys is achieved without additional depassivation treatment.

The thickness of the nitrided layer is 1 mm or more, surface hardness is 500-1500 HV. Parts of pumps, injectors, machine lead screws, shafts and much more are subjected to ion nitriding. This text is an introductory fragment.

From the author's book

Metal processing Metal processing includes a fairly large number of works of various types, but each of them begins with preparing the surface to be processed. What does it mean to machine a metal part? First of all, check its dimensions and

From the author's book

Hole processing Drilling metal It is perhaps difficult to imagine the manufacture and assembly of any mechanism without the need for drilling and further processing of holes. Yes, and in other areas of metalwork production, be it

From the author's book

Heat treatment of finished products Heat treatment is carried out on a finished forging and serves to change the structure of the metal. The quality of the product and its durability depend on its correct implementation. Hardening It is intended to impart

From the author's book

Signal Processing When choosing the type of sensor device used in a robot, it is necessary to decide on the issue of reading and processing the signal coming from it. Vjui Many sensors are resistive type sensors, meaning that their resistance varies according to

From the author's book

6. Chemical-thermal treatment: carburization, nitrocarburization To change the chemical composition, structure and properties of the surface layer of parts, they are heat treated in a chemically active environment, called chemical-thermal treatment. With her

From the author's book

1. Carbon and alloy structural steels: purpose, heat treatment, properties High-quality carbon structural steels are used to produce rolled products, forgings, calibrated steel, silver steel, long steel, stampings and ingots. These steels

From the author's book

Heat treatment Heat treatment is a heat treatment process, the essence of which is heating glass to a certain temperature, holding it at this temperature and then cooling it at a given speed in order to change either the properties of the glass or its shape.

From the author's book

6. Heat treatment of jewelry alloys. General provisions Heat treatment includes the following basic operations: annealing, hardening, aging and tempering (for ferrous metals). The use of one or another type of heat treatment is dictated by the requirements that

From the author's book

6.1. Heat treatment of cast alloys According to the classifier of jewelry alloys (Fig. 3.36), the main ones are noble alloys based on silver, gold and platinum, as well as copper, aluminum and zinc alloys. Advantageous heat treatment operations

From the author's book

13. Heat treatment of jewelry alloys The main type of heat treatment of jewelry alloys is recrystallization annealing. It is appointed either as an intermediate stage between cold plastic deformation operations, or as a final stage - in order to

From the author's book

13.1. Heat treatment of silver-based alloys Alloys of the Ag - Cu system are thermally treated, since copper is limitedly soluble in silver and its solubility changes with temperature. The heat treatment mode consists of quenching the alloy at a temperature of 700 °C in water with

From the author's book

13.2. Heat treatment of gold-based alloys Binary alloys gold - silver are not thermally hardened, since silver and gold are infinitely soluble in the solid state. Ternary alloys of the Au - Ag - Cu system are strengthened by heat treatment. Hardening effect

From the author's book

7.3.1. ELECTRICAL EROSION MACHINING Electrical erosion, i.e. The destruction of contacts under the influence of electrical discharges has been known for a long time. Much research has been devoted to eliminating or at least reducing the destruction of contacts. Research into the phenomenon of controlled

From the author's book

38. Chemical-thermal treatment of steel. Purpose, types and general patterns. Diffusion saturation of alloys with metals and non-metals Chemical-thermal treatment (CHT) - treatment with a combination of thermal and chemical effects to change the composition and structure

ION-PLASMA NITRIDING AS ONE OF THE MODERN METHODS FOR SURFACE HARDENING OF MATERIALS

,

, students;

, art. teacher

Improving the quality of metal and its mechanical properties is the main way to increase the durability of parts and one of the main sources of saving steel and alloys. The quality and durability of products are improved through a rational choice of materials and hardening methods while achieving high technical and economic efficiency. There are many different methods of surface hardening - hardening with high-frequency currents, plastic deformation, chemical-thermal treatment (CHT), laser and ion-plasma treatment.

The gas nitriding process, traditionally used in industry, as one of the types of chemical treatment, is the process of diffusion saturation of the surface layer of steel with nitrogen. Nitriding can be used with great effect to increase wear resistance, hardness, fatigue strength, corrosion and cavitation resistance of various materials (structural steels, heat-resistant steels and alloys, non-magnetic steels, etc.). It has a number of undeniable advantages, such as: relative simplicity of the process , the possibility of using universal equipment and devices for laying parts, the possibility of nitriding parts of any size and shape. At the same time, gas nitriding also has a number of disadvantages: a long process duration (20-30 hours) even when nitriding to small layer thicknesses (0.2-0.3 mm); the process is difficult to automate; local protection of surfaces that are not subject to nitriding is difficult; application of various galvanic coatings (copper plating, tinning, nickel plating, etc.) requires the organization of special production.

One of the areas of production intensification is the development and implementation at industrial enterprises of new promising processes and technologies that improve the quality of products, reduce labor costs for their production, increase labor productivity and improve sanitary and hygienic conditions in production.

Such a progressive technology is ion plasma nitriding (IPA) - a type of chemical-thermal treatment of machine parts, tools, stamping and casting equipment, ensuring diffusion saturation of the surface layer of steel and cast iron with nitrogen (nitrogen and carbon) in a nitrogen-hydrogen plasma at a temperature of 400- 600ºС, titanium and titanium alloys at a temperature of 800-950 ºС in nitrogen-containing plasma. This process is currently widespread in all economically developed countries: the USA, Germany, Switzerland, Japan, England, France.

In many cases, ion nitriding is more appropriate than gas nitriding. The advantages of IPA in glow discharge plasma include the following: the ability to control the saturation process, which ensures the production of a high-quality coating with a given phase composition and structure; ensuring absolutely identical activity of the gaseous medium over the entire surface of the part covered by the glow discharge, this ultimately ensures the production of a nitrided layer of uniform thickness; reducing the labor intensity of local protection of surfaces that are not subject to nitriding, which is carried out with metal screens; a sharp reduction in the duration of nitriding of parts (2-2.5 times); reduction of parts deformation. The use of IPA instead of carburization, nitrocarburization, gas or liquid nitriding, volumetric or high-frequency hardening allows you to save capital equipment and production space, reduce machine tool and transportation costs, and reduce the consumption of electricity and active gaseous media.

The essence of the ion nitriding process is as follows. In a closed evacuated space between the part (cathode) and the furnace casing (anode), a glow discharge is excited. Nitriding is carried out with an anomalous glow discharge, at a high voltage of the order of W. Modern installations ensure the stability of a glow discharge at the boundary of its transition to normal and arc. The principle of operation of arc extinguishing devices is based on a short-term shutdown of the installation when a voltaic arc ignites.

Nitriding increases the corrosion resistance of parts made of carbon and low-alloy steels. Parts that are nitrided to increase surface strength and wear resistance simultaneously acquire properties against corrosion in steam, tap water, alkali solutions, crude oil, gasoline, and polluted atmospheres. Ion nitriding significantly increases the hardness of parts, which is due to highly dispersed nitride precipitation, the quantity and dispersion of which affects the achieved hardness. Nitriding increases the fatigue limit. This is explained, firstly, by an increase in the strength of the surface, and secondly, by the occurrence of residual compressive stresses in it.

The advantages of ion nitriding are most fully realized in large-scale and mass production, when strengthening large batches of similar parts. By varying the gas composition, pressure, temperature and holding time, layers of a given structure and phase composition can be obtained. The use of ion nitriding provides technical, economic and social effects.

The properties of a metal can be improved by changing its chemical composition. An example is steel nitriding, a relatively new technology for saturating the surface layer with nitrogen, which began to be used on an industrial scale about a century ago. The technology under consideration was proposed to improve certain qualities of products made from steel. Let's take a closer look at how steel is saturated with nitrogen.

Purpose of nitriding

Many people compare the process of cementing and nitriding because both are designed to significantly improve the performance of a part. The technology of introducing nitrogen has several advantages over carburization, among which there is no need to increase the temperature of the workpiece to the values at which the atomic lattice is attached. It is also noted that the technology of introducing nitrogen practically does not change the linear dimensions of the workpieces, due to which it can be used after finishing processing. On many production lines, parts that have been hardened and ground are subjected to nitriding and are almost ready for production, but some qualities need to be improved.

The purpose of nitriding is associated with a change in the basic performance qualities during the heating of the part in an environment characterized by a high concentration of ammonia. Due to this effect, the surface layer is saturated with nitrogen, and the part acquires the following performance qualities:

- The wear resistance of the surface is significantly increased due to the increased hardness index.

- The endurance value and resistance to increased fatigue of the metal structure are improved.

- In many industries, the use of nitriding is associated with the need to impart anti-corrosion resistance, which is maintained upon contact with water, steam or air with high humidity.

The above information determines that the results of nitriding are more significant than carburization. The advantages and disadvantages of the process largely depend on the technology chosen. In most cases, the transferred performance qualities are maintained even when the workpiece is heated to a temperature of 600 degrees Celsius; in the case of cementation, the surface layer loses hardness and strength after heating to 225 degrees Celsius.

Factors influencing nitridation

The main factors that influence nitriding are:

- the temperature at which such a technological operation is performed;

- gas pressure supplied to the muffle;

- duration of exposure of the part in the oven.

The efficiency of this process is also influenced by the degree of ammonia dissociation, which, as a rule, is in the range of 15–45%. As the nitriding temperature increases, the hardness of the formed layer decreases, but the process of diffusion of nitrogen into the metal structure accelerates. A decrease in the hardness of the surface layer of a metal during its nitriding occurs due to the coagulation of nitrides of alloying elements included in its composition.

The influence of temperature and alloying elements on the formation of a nitrided layer

To speed up the nitriding process and increase its efficiency, a two-stage scheme is used. The first stage of nitriding when using this scheme is performed at a temperature not exceeding 525°. This makes it possible to impart high hardness to the surface layer of the steel product. To perform the second stage of the procedure, the part is heated to a temperature of 600–620°, while the depth of the nitrided layer reaches the required values, and the process itself is almost doubled. The hardness of the surface layer of a steel product processed using this technology is no lower than a similar parameter for products processed using a single-stage method.

Nitriding process technology

In many ways, the process of steel nitriding is superior to other methods that involve changing the chemical composition of the metal. The nitriding technology for steel parts has the following features:

- In most cases, the procedure is performed at a temperature of about 600 degrees Celsius. The part is placed in a sealed iron muffle furnace, which is placed in the furnace.

- When considering nitriding modes, temperature and holding time should be taken into account. For different steels, these indicators will differ significantly. The choice also depends on what performance qualities need to be achieved.

- Ammonia is supplied from a cylinder into the created metal container. High temperatures cause ammonia to begin to decompose, causing nitrogen molecules to be released.

- Nitrogen molecules penetrate the metal due to the process of diffusion. Due to this, nitrides are actively formed on the surface, which are characterized by increased resistance to mechanical stress.

- The chemical-thermal treatment procedure in this case does not involve sudden cooling. As a rule, the nitriding furnace is cooled along with the ammonia flow and the part, due to which the surface does not oxidize. Therefore, the technology under consideration is suitable for changing the properties of parts that have already undergone finishing processing.

Ion-vacuum nitriding workshop

The classic process of obtaining the required product with nitriding involves several stages:

- Preparatory heat treatment, which consists of hardening and tempering. Due to the rearrangement of the atomic lattice under a given regime, the structure becomes more viscous and strength increases. Cooling can take place in water or oil, or another medium - it all depends on how high quality the product should be.

- Next, mechanical processing is performed to give the desired shape and size.

- In some cases, there is a need to protect certain parts of the product. Protection is carried out by applying liquid glass or tin in a layer about 0.015 mm thick. Due to this, a protective film is formed on the surface.

- Steel nitriding is carried out using one of the most suitable methods.

- Work is being carried out on finishing mechanical processing and removing the protective layer.

Steel nitriding modes

The resulting layer after nitriding, which is represented by nitride, ranges from 0.3 to 0.6 mm, which eliminates the need for a hardening procedure. As previously noted, nitriding has been carried out relatively recently, but the process of transforming the surface layer of the metal has already been almost completely studied, which has significantly increased the efficiency of the technology used.

Metals and alloys subjected to nitriding

There are certain requirements that apply to metals before carrying out the procedure in question. Typically, attention is paid to carbon concentration. The types of steels suitable for nitriding are very different, the main condition is a carbon fraction of 0.3-0.5%. Better results are achieved when using alloyed alloys, since additional impurities contribute to the formation of additional solid nitrites. An example of chemical processing of metal is the saturation of the surface layer of alloys, which contain impurities in the form of aluminum, chromium and others. The alloys under consideration are usually called nitralloys.

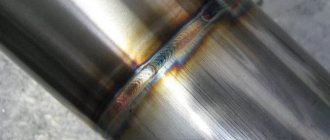

Microstructure of steels after nitriding

Nitrogen is added when using the following steel grades:

- If the part will be subject to significant mechanical impact during operation, then choose grade 38Х2МУА. It contains aluminum, which causes a decrease in deformation resistance.

- In the machine tool industry, the most widely used steels are 40X and 40HFA.

- In the manufacture of shafts that are often subjected to bending loads, grades 38ХГМ and 30ХЗМ are used.

- If during manufacturing it is necessary to obtain high accuracy of linear dimensions, for example, when creating parts for fuel units, then steel grade 30ХЗМФ1 is used. In order to significantly increase the strength of the surface and its hardness, alloying with silicon is first carried out.

When choosing the most suitable grade of steel, the main thing is to comply with the condition associated with the percentage of carbon, and also take into account the concentration of impurities, which also have a significant impact on the performance properties of the metal.

Types of Nitrided Steels

Both carbon and alloy steels, characterized by a carbon content in the range of 0.3–0.5%, can be processed using nitriding technology. The maximum effect when using such a technological operation can be achieved if steels are subjected to it, the chemical composition of which includes alloying elements that form hard and heat-resistant nitrides. Such elements, in particular, include molybdenum, aluminum, chromium and other metals with similar characteristics. Steels containing molybdenum are not subject to such a negative phenomenon as temper brittleness, which occurs when a steel product cools slowly. After nitriding, steels of various grades acquire the following hardness:

Hardness of steels after nitriding

Alloying elements found in the chemical composition of steel increase the hardness of the nitrided layer, but at the same time reduce its thickness. The thickness of the nitrided layer is most actively influenced by chemical elements such as tungsten, molybdenum, chromium and nickel.

Depending on the scope of application of the product that is subjected to the nitriding procedure, as well as on its operating conditions, it is recommended to use certain grades of steel to carry out such a technological operation. So, in accordance with the technological problem that needs to be solved, experts advise using products made from the following steel grades for nitriding.

38Х2МУА

This is steel, which, after nitriding, has a high hardness of the outer surface. Aluminum contained in the chemical composition of such steel reduces the deformation resistance of the product, but at the same time helps to increase the hardness and wear resistance of its outer surface. The exclusion of aluminum from the chemical composition of steel makes it possible to create products of more complex configurations from it.

40X, 40HFA

These alloy steels are used for the manufacture of parts used in the machine tool industry.

30Х3М, 38ХГМ, 38ХНММА, 38ХН3МА

These steels are used for the production of products that are subjected to frequent cyclic bending loads during their operation.

30Х3МФ1

Products are made from this steel alloy, the accuracy of whose geometric parameters is subject to high demands. To impart higher hardness to parts made of this steel (these are mainly parts of fuel equipment), silicon can be added to its chemical composition.

Characteristics of some steels after nitriding

Main types of nitriding

There are several technologies used to carry out nitriding of steel. Let's take the following list as an example:

- Ammonia-propane environment. Gas nitriding has become very widespread today. In this case, the mixture is represented by a combination of ammonia and propane, which are taken in a ratio of 1 to 1. As practice shows, gas nitriding when using such a medium requires heating to a temperature of 570 degrees Celsius and holding for 3 hours. The resulting layer of nitrides is characterized by a small thickness, but at the same time the wear resistance and hardness are much higher than when using classical technology. Nitriding of steel parts in this case makes it possible to increase the hardness of the metal surface to 600-1100 HV.

- Glow discharge is a technique that also involves the use of a nitrogen-containing environment. Its peculiarity lies in the connection of the nitrided parts to the cathode; the muffle acts as a positive charge. By connecting the cathode, it is possible to speed up the process several times.

- The liquid medium is used a little less frequently, but is also highly effective. An example is a technology that involves the use of a molten cyanide layer. Heating is carried out to a temperature of 600 degrees, the holding period is from 30 minutes to 3 hours.

Ionic nitriding

In industry, the gas medium has become most widespread due to the ability to process large batches at once.

Processing Media Options

Currently, nitrogen treatment of steel billets in an ammonia-propane environment . In this case, metallurgists have the opportunity to expose raw materials to 570 degrees for three hours. The carbonitride layer formed under such conditions has a minimum thickness, but the strength and wear resistance are much higher than those of those options that were invented using the usual method. The hardness of this layer is in the range of 600−1100 HV.

The technology is particularly indispensable when choosing products made from alloy alloys or steel, which are subject to high requirements for operational endurance.

Also, an equally popular solution is the use of glow discharge technology, when the material is strengthened in a nitrogen-containing discharged environment, connecting metal products to the cathode. As a result, the workpiece acquires a negatively charged electrode, while the muffle has a positively charged one.

The technology makes it possible to reduce the duration of action several times. A discharge appears between plus and minus, and gas ions act on the surface of the cathode, heating it. This effect is carried out in several stages:

- initially cathode sputtering occurs;

- then cleaning the surface;

- then saturation.

At the first stage of spraying, a pressure of 0.2 millimeters of mercury and a voltage of 1400 volts are maintained for 5-60 minutes. In this case, the surface heats up to 250 degrees Celsius. The second stage involves using a pressure of 1-10 millimeters of mercury at a voltage of 400-1100 V. The procedure requires 1-24 hours.

Another very effective processing method is the tenifer process, which involves nitriding in a liquid based on molten cyanide under the influence of a temperature of 570 degrees Celsius.

Catalytic gas nitriding

This type of chemical treatment involves creating a special atmosphere in the stove. Dissociated ammonia is pre-treated on a special catalytic element, which significantly increases the number of ionized radicals. Features of the technology include the following points:

- Preliminary preparation of ammonia makes it possible to increase the proportion of solid solution diffusion, which reduces the proportion of reaction chemical processes during the transition of the active substance from the environment to iron.

- Provides for the use of special equipment that provides the most favorable conditions for chemical processing.

Steel nitriding process

This method has been used for several decades and allows changing the properties of not only metals, but also titanium alloys. The high costs of installing equipment and preparing the environment determine the applicability of the technology to the production of critical parts that must have precise dimensions and increased wear resistance.

Scope of application of steel nitriding

Nitriding of steel is one of the frequently used methods for processing alloy products to achieve maximum hardness and durability. Steel parts are not subject to deformation because they do not require subsequent hardening. Corrosion resistance increases significantly, which is important when operating mechanisms in humid environments.

Engineering steels

The use of nitrided steels is relevant not only in the engineering and machine tool industries, but also in the creation of household appliances - after all, consumers are becoming more demanding of the quality of purchased products every year.

This technique allows you to change the characteristics of not only steel, but also titanium alloys. The high cost of equipment and the difficulty of creating the required environment are compensated by the exact dimensions of the output parts and increased wear resistance. But there are also strength indicators that cannot be achieved by nitriding. Then the steel is alloyed, carrying out deep processing of its structure. The disadvantage of this method is the appearance of harmful impurities.

Video on the topic: Chemical-thermal treatment of steel

Properties of nitrided metal surfaces

Quite important is the question of what hardness of the nitrided layer is achieved. When considering hardness, the type of steel being processed is taken into account:

- Carbon steel can have a hardness in the range of 200-250HV.

- Alloy alloys after nitriding acquire a hardness in the range of 600-800HV.

- Nitralloins, which contain aluminum, chromium and other metals, can achieve a hardness of up to 1200HV.

Other properties of steel also change. For example, the corrosion resistance of steel increases, making it possible to use it in aggressive environments. The process of introducing nitrogen itself does not lead to the appearance of defects, since heating is carried out to a temperature that does not change the atomic lattice.