Channels and I-beams are types of metal products with high strength characteristics. They are popular in construction, in the production of medium and heavy equipment, and in the production of production lines. With the same height of the walls of the I-beam and channel and comparable dimensions of the flanges, the I-beam has greater strength and rigidity. However, much depends on the conditions of use of rolled metal, the direction of applied loads, and methods of fastening. Metal products with U- and H-shaped profiles are used precisely in those areas in which their technical characteristics are most fully used.

Main characteristics of the channel

This type of rolled metal is produced by hot rolling and bending of strip blanks. In accordance with the tables of GOST 8240, the wall height of a steel channel is 50-400 mm. Hot-rolled products with inclined inner edges of the flanges have an increased cross-sectional area and, in terms of strength characteristics, are close to analogues with an I-beam profile. To increase strength and resistance to low temperatures, rolled products are made from high-quality carbon and low-alloy steel grades.

The channel is convenient for installation on flat surfaces. Rolled steel is used for reinforcing concrete structures, creating frame buildings, and in the production of light machines and mechanisms. In private construction, the best choice is a channel rather than an I-beam, which is explained by the combination of sufficient strength and affordable cost of the U-shaped profile. The I-beam, due to its massiveness and high strength characteristics, is mainly used in large-scale industrial and civil construction.

Strengthening in case of emergency

It is necessary to install additional reinforcement if the openings in the brick wall have fallen into disrepair over time or under the influence of unfavorable factors, and the thickness of the wall itself differs from the standard one. The wall is mainly affected by temperature differences inside and outside the room.

In some cases, it is enough to supplement the frame with a second channel. Installation of such a structure is carried out in the same way as in a regular brick wall. The channels are fastened together with pins and also welded to metal plates that are installed around the doorway. The metal frame is reinforced on top with an I-beam and secured with anchor bolts. Corners can also be used.

Don't forget about wall treatment. This process is optimally performed with diamond tools.

Each case of redevelopment or repair and restoration work must be considered separately, based not only on the condition of the structure, but also taking into account the economic component. Do not forget that any opening in a brick wall weakens the strength of the structure. It will be very disappointing if in a newly renovated room the walls around doors or windows crack in a short period of time.

Main characteristics of an I-beam

The I-beam is produced with inclined edges of the shelves in accordance with GOST 8239-89, the range of products with parallel edges corresponds to the tables of GOST 26020 or STO ASChM 20-93. The products are characterized by high rigidity and strength, the value of which, in addition to the cross-sectional dimensions, is influenced by:

- grade of steel from which metal products are made; for operation under high loads and in difficult temperature conditions, low-alloy steels of type 09GS are used;

- span length - the larger this value, the lower the load-bearing capacity of the I-beam;

- method of securing the beam, direction and nature of the load.

When to strengthen wooden floor beams

- poor condition of the beam structure

. The result is wood damage. High humidity, temperature changes, the activity of various pests (bark beetles), cracking - all this leads to deformation of the floor beam;

- reduction in load-bearing capacity

. Under their own weight, constant and variable load, floor beams can bend. According to the standards, if the deflection is within 1:300, then there is nothing to worry about. For example, if a beam is 2500 mm long. bent by 10 mm. this corresponds to the normal deflection value. If the deflection is greater, it should be strengthened;

- the need to increase the load-bearing capacity of the beam

. Associated, for example, with the reconstruction of an attic into an attic or living space. Such a restructuring will lead to an increase in constant and variable loads on the floors of the second floor, which automatically requires a change in the cross-section of the installed wooden beams.

Within the article, several common methods of strengthening the ceiling (repair, reconstruction) will be given. But only a professional can accurately answer the question of how to strengthen wooden floor beams and only after analyzing the condition of the structure. After all, in each case the decision will be individual.

Using the table, you can get an idea of what cross-section a beam should have under a certain load.

Permissible cross-section of beams under load

Material prepared for the site moydomik.net

Comparison of I-beam and channel strength, depending on the applied load

The main difference between the properties of an I-beam and a channel is the different response to loads, in particular torsion, which is explained by the difference in the location of the center of gravity.

- I-beam . The maximum volume of metal, especially in products of the wide-flange and column series, is concentrated in the shelves. The I-beam flanges, symmetrical relative to the wall, absorb the main vertical loads and provide a high moment of inertia. The wall works mainly in compression. This symmetrical profile can only be subject to torsion in cases where a floor with an uneven load is laid on it. The I-beam, due to its massiveness, high cost and strength characteristics, is used mainly in large-scale construction to create floors that experience high loads.

- Channel . Its main feature is the mismatch of the main axis of inertia with the wall. Such products work well with oblique bending. To create a light and durable metal structure, the channel is welded into a box with the seam reinforced with metal plates. Creating such metal products requires a lot of labor. The channel is most often used to create frame structures, make floors for small buildings - cottages, garages, outbuildings - as well as stairs.

Both the channel and the I-beam belong to profile rolled products, which are not designed to withstand serious forces directed perpendicular to the wall.

The calculator provides for the calculation of beams for bending and deflection, from hot-rolled and other rolled products of the following nomenclature:

- equal angle corner;

- unequal corner;

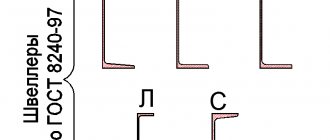

- channel with a slope and with parallel edges of the shelves;

- I-beams with sloped flanges and parallel. edges of shelves of various modifications, as well as T-beams (T-beams).

The dimensions of rolled corner profiles are specified by GOST 8509-93 and 8510-86; channels – 8240-97; I-beams – 26020-83; Tavrov - TU 14-2-685-86; (obtained by longitudinally cutting hot-rolled I-beams in half with parallel flange edges in accordance with GOST 26020-83) - see the I-beam weight calculator.

When calculating the mass of 1 meter of rolled stock, the steel density in these standards is taken to be 7.85 g/cm3 (7.85 kg/dm3 or 7850 kg/m3).

NOTE. The dimensions of the selected channel, I-beam and T-beam are indicated in the line “DIMENSIONS OF THE SELECTED PROFILE”; the dimensions of the corner shelves in their tables; The thickness of the corners is selected separately after the possible thicknesses of the selected corner number appear in the above line.

Design features

Channels 2 types:

- U-shaped hot-rolled products;

- U-shaped rolled products bent.

The design of the channel with 2 shelves in 1 direction places the main axis of inertia towards the wall with a displacement of the forces applied to the product. It works on an oblique bend. The channel frame will become light and durable when the channel is modernized. Make box racks out of it. Using electric arc welding with an intermittent seam, connect the channels with flanges inside the structure. Reinforcing the seam every 1.2-1.5 m strengthens the prefabricated product.

An I-beam does not require additional reinforcement. It can withstand loads.

Preliminary Considerations

The calculator provides calculations of beams for various schemes of their fastening and load. The load of beams can be distributed (“q” in diagrams 3,4,5,9,15, etc.) or concentrated (“P” in diagrams 1,2,6,7,8, etc.)

Read also: Installing a fitting on a pipeline

The fastening of beams can be: a) cantilever with rigid termination of one of the ends (for example, schemes 1,2,3 and others); b) “sealing - sealing”, when both ends of the beam are rigidly clamped (sealed), schemes 6,7,8,9; c) “hinge - hinge” (diagrams 12,13,14,15 and others), with the left hinge being fixed and the right hinge being movable; d) “sealing - hinge”, (diagrams 9,10,11 etc.)

Rigid embedding of the beam prevents the beam from turning and moving in any direction. A fixed hinge allows only rotation of the beam at the point of attachment in the vertical plane. The movable hinge allows the beam to rotate at the point of attachment in a vertical plane and move along its own axis.

These movements are very insignificant and are a consequence of the deformation of the beam under load. The main type of this deformation is its deflection, the magnitude of which, along with the load applied to the beam, also depends on the length of the beam, the dimensions of its cross section and the physical characteristics of the material, in this case, on its modulus of elasticity (“E”). The modulus of elasticity of carbon steel is (2-2.1)10^5 MPa; alloyed (2.1-2.2)10^5 MPa; therefore, the calculator uses an average value of 2.1*10^5 MPa, which is 2142000 kg/cm2.

From the dimensional characteristics of the cross section of the beam, the moment of inertia of the section (“I”) is used to calculate the deflection; the amount of deflection also depends on the position of the beam point being checked relative to the supports. The permissible amount of deflection of beams is determined by their purpose and place in building structures and is regulated by the relevant SNiP; in mild cases it should not exceed 1/120 - 1/250 of the length of the beam.

THEREFORE, IT IS STRONGLY RECOMMENDED TO CHECK THE CALCULATION RESULTS FOR ACCEPTANCE.

In the construction of critical objects and structures, channels are used that have high strength and are able to withstand significant loads, as well as the resulting shear and axial stresses without loss of load-bearing properties. However, situations may arise when the building was erected with errors in the calculations of the expected loads or they were changed during operation, as a result of which the limit of its strength was reached.

This means that further operation of the structure is impossible, since there is a high probability of creating an emergency situation. Therefore, the only way out of this situation without changing the loading conditions will be to strengthen the structure.

Strengthening the channel for deflection and bending

One of the simplest ways to strengthen a channel is to install a support. It will allow you to significantly relieve the load-bearing beam without making significant changes to the finished structure. The connection method must fully correspond to the type of loading: in the case of constant shear force, you can make any connections of parts that can provide high reliability and strength, but in the case of dynamic ones, you should use riveted and bolted connections.

In some situations, installing a support is not possible due to the operating conditions of the facility. Consequently, you will have to increase the cross-section by welding steel plates or angles in the longitudinal direction, or weld another channel so that a symmetrical structure is obtained. Thanks to this, the main load will shift from the point of possible metal rupture and will be distributed evenly over the area of the new shaped beam.

Another way to strengthen the channel is to redistribute the load between the entire structure using structural changes to the frame or its elements. This will reduce the bending stresses that arise and provide the necessary margin of safety. However, you should not forget about carrying out new calculations of the object, as the problem may become more serious.

Strengthening the channel torsion

To strengthen the channel torsion, it is necessary to install a symmetrical structure by welding. It is believed that welds in the corners of the beam can weaken it, since when the metal is heated, it can become deformed, and the overlay metal, especially when installed locally, can take on the load. Therefore, special double-sided welding methods must be used.

The standard method of reinforcement is to weld a second channel parallel to the installed one to ultimately obtain an I-beam or box. Both options are approximately the same in effectiveness, but their implementation is only possible with full access to the entire surface of the steel frame, otherwise it will be necessary to destroy part of the finish, as well as install temporary safety supports.

The second way to increase torsional resistance is to perform concreting.

What load acts on the profile pipe?

This value must be accurately determined at the design stage of installation work. It is calculated by calculation methods, using reference information, the purpose of which is to help determine the necessary profile parameters: cross-section, metal thickness. The initial data in this case are the strength characteristics of the material and the types of upcoming loads.

and bend

,

an increase in the cross-section of the elements is achieved by attaching additional elements. The joint operation of additional reinforcement elements with the reinforced structure is ensured by welding

, as well as using

a bolted

or

riveted connection

.

How to strengthen a channel for deflection-bending and torsion

Concrete flooring of a private house using a channel

Modern construction cannot be imagined without various types of rolled metal, without such types of metal products as I-beams, steel channels, angles, and fittings. With the help of rolled metal products, high strength of building structures is achieved; with the help of beams and channels, bridges, ceilings, and various hangars are created. The metal is used in the construction of residential buildings and industrial buildings.

Read also: Shaped cutter for lathe

Channel in construction

Among all the structural elements that form the frame foundation of buildings, the channel has gained the most popularity. This metal product is a beam with a cross-section in the shape of the letter P. Depending on the size of the structure being built, different channel sizes and wall thicknesses can be used.

Channel for ceiling

In the construction of a private house, there is often a need to produce concrete floors. There are times when there is no financial opportunity or you don’t want to buy ready-made reinforced concrete structures.

How can you make concrete floors yourself?

Image from https://metinvestservice.ru/image/data/news_foto/shv.jpg

First of all, during installation, attention should be paid to the relationship between the length and width of the ceiling, to the layer of concrete being poured, to the shape and size of the load-bearing element being created.

Why are concrete floors chosen? This design will not allow any unnecessary sounds to pass through; there is another advantage - the base is strong, it will not sway or sag.

Of course, to strengthen the structure, you can use other rolled metal, for example, an I-beam. The channel is rightfully considered the most profitable, since it is cheaper, and in terms of strength it is in no way inferior to an I-beam.

Channel dimensions

For a concrete floor 5 m long, you need to take a channel with a cross section of 14 mm.

When to strengthen wooden floor beams

poor condition of the beam structure. The result is wood damage. High humidity, temperature changes, the activity of various pests (bark beetles), cracking - all this leads to deformation of the floor beam;

reduction in load-bearing capacity. Under their own weight, constant and variable load, floor beams can bend. According to the standards, if the deflection is within 1:300, then there is nothing to worry about. For example, if a beam is 2500 mm long. bent by 10 mm. this corresponds to the normal deflection value. If the deflection is greater, it should be strengthened;

the need to increase the load-bearing capacity of the beam. Associated, for example, with the reconstruction of an attic into an attic or living space. Such a restructuring will lead to an increase in constant and variable loads on the floors of the second floor, which automatically requires a change in the cross-section of the installed wooden beams.

Within the article, several common methods of strengthening the ceiling (repair, reconstruction) will be given. But only a professional can accurately answer the question of how to strengthen wooden floor beams and only after analyzing the condition of the structure. After all, in each case the decision will be individual.

Using the table, you can get an idea of what cross-section a beam should have under a certain load.