Drills for concrete hammer drills: parameters and selection rules

A concrete hammer drill is a metal tool that can be successfully used for drilling holes in structures also made of brick, natural and artificial stone.

Concrete drills are used in construction and repair work and are classified according to various parameters: design, power of the equipment on which they are installed, type of shank, as well as the geometric parameters of their spiral part.

The right drill can be selected for each specific task

Important parameters

Without drilling holes in various surfaces, construction and repairs are impossible. And if a regular electric drill is quite suitable for making holes in a structure made of wood materials, brick and plasterboard, then only a hammer drill can cope with a concrete structure.

The peculiarity of this equipment is that it can not only drill the surface being processed, but also exert an impact load on it, that is, perform the function of a jackhammer. Naturally, to install it on a hammer drill you need to use a special tool - a drill.

It differs from a conventional metal drill in a number of parameters.

The drills differ from each other in their design features, among which the following should be highlighted:

- design of the spiral part;

- the presence of a special cavity in the inner part;

- material for manufacturing the working part, which can be a hard alloy;

- number and geometric parameters of cutting edges.

Main parts of the drill

Drills are also distinguished from ordinary drills by the design of the shank, which allows them to be securely fixed in the chuck of the equipment used. The most common types of concrete drill shanks and chucks used when working with rotary hammers are the following.

SDS+

SDS-plus drills, like cartridges in this category, are designed for installation on medium and light series rotary hammers. It is devices of this type that are most often used by home craftsmen to perform various repair and construction work. The diameter of the SDS-plus shank cannot exceed 18 mm.

Drills with this shank are designed for light construction hammer drills

SDS-max

Intended for concrete processing, drills with shanks of the SDS-max category (the diameter of their fastening part exceeds 18 mm) are used in the configuration of professional series rotary hammers.

The SDS-max system with an increased contact area of the wedges is designed for heavy hammer drills

The main manufacturers of SDS-plus concrete drills (the most popular category) are Chinese companies.

As a rule, the parameters of such products comply with the requirements set by GOST, so they can be installed on any rotary hammers.

Meanwhile, you should not try to insert a tool for working with concrete into a regular drill, since it will not be possible to do this even with considerable effort.

To choose the right drill for a hammer drill, you should take into account such parameters of the working part as:

- length, the size of which determines how deep the hole you can drill;

- diameter.

Operating parameters of the drill

Taking into account the fact that hammer drills are used to work with particularly durable materials (concrete, natural and artificial stone), their design has a reinforced design, and the working part is made in the form of a double spiral.

This is what allows you to use hammer drills when working with concrete and other materials for a long time, without worrying about their technical condition.

Many models of concrete drills for rotary hammers are equipped with a tip made of the strongest alloy of the VK8 brand, which allows them to be successfully used for processing materials of particularly high strength.

Selecting tools of this type is not difficult: all of their most significant parameters are indicated in the labeling. For example, if in front of you is a concrete drill marked 6x160, this means that it has the following dimensions: working diameter - 6 mm, length - 160 mm. It must be borne in mind that the marking of the tool indicates its working length, which is slightly smaller than the dimensions of the working part.

The diameter of the working part of concrete drills installed on a hammer drill can be in the range of 4–30 mm. The most popular sizes fall in the range of 6–10 mm. Using a concrete drill of this size, you can, in particular, make a hole for placing a dowel.

How to choose the right drill

The choice of drill to equip a hammer drill should take into account the strength of the material in which the hole needs to be made.

The degree of steepness of the spiral part is also of great importance: the larger it is, the deeper the hole can be drilled at a higher speed.

When using a tool with such characteristics, waste material is more efficiently removed from the processing area, which allows you to work very quickly.

How to choose a drill for concrete? It is advisable to rely on the advice of specialists with experience in construction and repair work.

- For drilling shallow holes in concrete, a tool with a flatter spiral is suitable, which is also stronger and more durable.

- It is always better to choose tools from trusted manufacturers, since products from little-known brands are not always of decent quality and may not be suitable for hammer drill cartridges.

Concrete structures are drilled with a perforator, not drilled. The main requirement for a drilling tool is reliability

When purchasing a drill for a hammer drill, you should take into account not only GOST, but also the price category of the tool. On the modern market, you can choose both expensive drills for professional use and cheap disposable ones that do a good job with the tasks. High quality at an affordable price for concrete drills produced under the Bosch, Sturm and Makita brands.

Depending on their purpose, drills for rotary hammers are divided into several categories. Screw

These tools, ideal for drilling holes of considerable depth with a hammer drill, due to their design features, create a minimal amount of dust during operation and do not put a large load on the hammer drill.

Auger drill with carbide inserts

With a significant inclination of the working groove

The use of tools of this type allows drilling to be performed at high speed, which significantly increases the productivity of this process. When deciding to choose a drill for a hammer drill of the specified type, you should keep in mind that such a tool creates a significantly greater load on the equipment used than an auger one.

With a slight inclination of the working groove

Tools of this type, provided they are used with light loads, have an increased service life.

Crowns

These tools are used to create large diameter holes in concrete. This can be either a diamond drill or a drill, the working part of which is equipped with cutting plates made of hard alloy.

Drill bit with carbide cutters

It is recommended to apply lubricant to the shanks of drills installed in a hammer drill, then the tool will last much longer and its use will be more efficient.

Drills installed on a hammer drill for concrete processing are divided into two main types:

- breaking (needed to make large diameter holes in concrete);

- walk-through (they have great power and allow you to make holes even in load-bearing concrete walls of building structures).

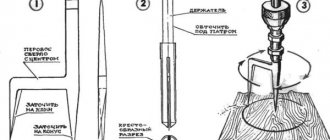

Heads of through-and-break drills provide precise punching due to the centering rod and rapid advancement due to chisel-shaped cutters

Drills and drills: differences

The main difference between a drill and a conventional drill is the design of the shank, which has a special groove. It is precisely because of the presence of such a groove that the drill cannot be inserted into the chuck of an electric drill. In addition, the distinctive features of the drills include:

- increased rigidity, which makes it possible to successfully drill even very durable materials;

- high productivity, which is achieved due to the fact that drilling is carried out with the simultaneous application of a shock load to the material being processed.

A shank with certain grooves is the visible and main difference between hammer drill bits and drill bits

To reliably fix the concrete drill in the hammer drill chuck, as well as to quickly replace it with the selected tool, the SDS fastening system (SDS), developed by Bosch specialists, is used.

Depending on the category of the hammer drill and the type of drill used, a fastening system of one of five types can be used to fix the latter. SDS

This system is used to hold tools with a shank diameter of 10 mm (this shank has two grooves).

SDS-plus

This is the most popular category of fastening devices, also used to secure tools with a shank diameter of 10 mm in a hammer drill. The SDS-plus shank has not two, but four grooves, two of which are closed.

SDS-top

This is a not very common category of fastening systems used to secure tools whose shank has a diameter of 14 mm. Devices of this type are used to complete rotary hammers of medium weight category.

SDS-max

Such devices are used to complete powerful rotary hammers of the professional series. They are equipped with drills with a shank diameter of 18 mm.

SDS-quick

This not very common category of fastening systems is notable for the fact that on the shank of the tools for which it is intended to secure, there are not grooves, but protrusions.

This type of shank was used in Bosch Uneo rotary hammers

When deciding which drills are best for equipping a rotary hammer, you must first focus on the tasks that you are going to solve. According to this, you can choose a drill:

- for drilling holes of small diameter (its cutting edges are slightly rounded, which makes it possible to give it higher strength);

- crown type, with the help of which large-diameter holes are created (for example, a diamond drill).

Adapters are used to install a drill with a non-native shank into a hammer drill.

Drill design features

What is the design of any concrete drill used to complete a hammer drill?

Shank

Using this structural element, the tool is fixed in the hammer drill chuck. Depending on the category of the fastening system, as mentioned above, drill shanks may have significant design differences.

Body

This structural part bears the main load. To ensure high reliability of the drill body, especially strong grades of steel are used for its manufacture.

Cutting part This element performs the main work of drilling holes. Depending on the purpose of the tool, its cutting part may have a different design and be made of different materials. Cutting parts are produced with diamond coating (diamond drill), as well as from carbide plates.

Diamond bit set for rotary hammer

Tool dimensions

To choose the right drill for a hammer drill, you should focus on three main parameters: the diameters of the shank and working part, and the working length. All sizes of drills are specified by the corresponding GOST, which greatly simplifies the choice.

When purchasing a tool of a certain diameter for a hammer drill, you can rely on the following recommendations.

- To perform housework, as a rule, drills with a diameter of 6, 8 and 10 mm are used.

- To drill holes for fastening massive and heavy objects, drills with a diameter of 10 and 20 mm are used.

Categories of concrete drills

Drills for concrete hammer drills, the dimensions of which are also regulated by GOST, consist of:

- spiral-shaped rod;

- cutting part;

- shank.

Drills for concrete work can be divided into three main categories:

- self-sharpening (specially designed for drilling deep holes with a hammer drill; when used, broken and crumbled concrete is well removed from the hole);

- spiral (highly efficient when dismantling massive concrete structures);

- with a flat arrangement of the spiral part (such drills, which require significant effort during use, are used for drilling shallow holes).

Concrete drill for professional use with double helix

You should also highlight a diamond drill, with which you can drill concrete structures reinforced with metal reinforcement. A diamond drill can significantly increase the productivity of work performed, but it must be taken into account that the cost of diamond drills for concrete is quite high.

There are also special types of drills, the requirements for the parameters of which are also specified by the corresponding GOST. These include, in particular:

- crowns;

- chisels;

- channel drills;

- flat chisels.

Drilling wood

In some cases, for drilling products made from wood materials, it is better to use not a standard drill, but a special wood drill. Using such a tool allows you to achieve the following advantages.

- Chips are removed from the processing area more efficiently.

- You don't need to put a lot of effort into forming a hole.

- The structure of the wood is not destroyed, since a clean drilling cutter is used as the tip of such a drill.

Source: https://met-all.org/oborudovanie/prochee/bur-dlya-perforatora-po-betonu-razmery-sds.html

Sds plus drills for rotary hammersSds plus drills are designed for drilling holes in stone, brick and concrete. SDS plus drills are made of high quality steel with a carbide tip at the end. The shank of the sds plus drills is made according to a standard hammer drill chuck. Sds plus drills are used with hammer drills that have the appropriate chuck.

All sds plus drills with carbide tips must not be cooled with water. Cooling of sds plus drills is carried out only in air.

Technical specifications

Designation

| D diameter, mm | L total length, mm | B working length, mm | weight 1000 pieces, kg | |

| Drill sds plus 4x110 | 4,0 | 110,0 | 50,0 | 32,00 |

| Drill sds plus 5x110 | 5,0 | 110,0 | 50,0 | 36,00 |

| Drill sds plus 5x210 | 5,0 | 210,0 | 150,0 | 48,00 |

| Drill sds plus 6x110 | 6,0 | 110,0 | 50,0 | 38,00 |

| Drill sds plus 6x160 | 6,0 | 160,0 | 100,0 | 45,00 |

| Drill sds plus 6x210 | 6,0 | 210,0 | 150,0 | 54,00 |

| Drill sds plus 6x260 | 6,0 | 260,0 | 200,0 | 62,00 |

| Drill sds plus 6x310 | 6,0 | 310,0 | 250,0 | 70,00 |

| Drill sds plus 8x110 | 8,0 | 110,0 | 50,0 | 44,00 |

| Drill sds plus 8x160 | 8,0 | 160,0 | 100,0 | 56,00 |

| Drill sds plus 8x210 | 8,0 | 210,0 | 150,0 | 70,00 |

| Drill sds plus 8x260 | 8,0 | 260,0 | 200,0 | 80,00 |

| Drill sds plus 8x310 | 8,0 | 310,0 | 250,0 | 93,00 |

| Drill sds plus 8x400 | 8,0 | 400,0 | 340,0 | 124,00 |

| Drill sds plus 10x130 | 10,0 | 130,0 | 70,0 | 61,00 |

| Drill sds plus 10x160 | 10,0 | 160,0 | 100,0 | 72,00 |

| Drill sds plus 10x210 | 10,0 | 210,0 | 150,0 | 93,00 |

| Drill sds plus 10x260 | 10,0 | 260,0 | 200,0 | 108,00 |

| Drill sds plus 10x310 | 10,0 | 310,0 | 250,0 | 130,00 |

| Drill sds plus 10x450 | 10,0 | 450,0 | 390,0 | 205,00 |

| Drill sds plus 10x600 | 10,0 | 600,0 | 540,0 | 260,00 |

| Drill sds plus 12x160 | 12,0 | 160,0 | 100,0 | 92,00 |

| Drill sds plus 12x210 | 12,0 | 210,0 | 150,0 | 116,00 |

| Drill sds plus 12x260 | 12,0 | 260,0 | 200,0 | 137,00 |

| Drill sds plus 12x310 | 12,0 | 310,0 | 250,0 | 170,00 |

| Drill sds plus 12x450 | 12,0 | 450,0 | 390,0 | 248,00 |

| Drill sds plus 12x600 | 12,0 | 600,0 | 540,0 | 330,00 |

| Drill sds plus 13x160 | 13,0 | 160,0 | 100,0 | 94,00 |

| Drill sds plus 14x160 | 14,0 | 160,0 | 100,0 | 114,00 |

| Drill sds plus 14x210 | 14,0 | 210,0 | 150,0 | 116,00 |

| Drill sds plus 14x260 | 14,0 | 260,0 | 200,0 | 94,00 |

| Drill sds plus 14x310 | 14,0 | 310,0 | 250,0 | 210,00 |

| Drill sds plus 14x450 | 14,0 | 450,0 | 390,0 | 283,00 |

| Drill sds plus 15x160 | 15,0 | 160,0 | 100,0 | 130,00 |

| Drill sds plus 15x210 | 15,0 | 210,0 | 150,0 | 170,00 |

| Drill sds plus 15x260 | 15,0 | 260,0 | 200,0 | 210,00 |

| Drill sds plus 15x310 | 15,0 | 310,0 | 250,0 | 255,00 |

| Drill sds plus 15x450 | 15,0 | 450,0 | 390,0 | 374,00 |

| Drill sds plus 15x600 | 15,0 | 600,0 | 540,0 | 474,00 |

| Drill sds plus 16x160 | 16,0 | 160,0 | 100,0 | 133,00 |

| Drill sds plus 16x210 | 16,0 | 210,0 | 150,0 | 173,00 |

| Drill sds plus 16x260 | 16,0 | 260,0 | 200,0 | 215,00 |

| Drill sds plus 16x310 | 16,0 | 310,0 | 250,0 | 260,00 |

| Drill sds plus 16x450 | 16,0 | 450,0 | 390,0 | 380,00 |

| Drill sds plus 16x600 | 16,0 | 600,0 | 540,0 | 479,00 |

| Drill sds plus 16x800 | 16,0 | 800,0 | 740,0 | 640,00 |

| Drill sds plus 17x200 | 17,0 | 200,0 | 140,0 | 162,00 |

| Drill sds plus 18x200 | 18,0 | 200,0 | 140,0 | 200,00 |

| Drill sds plus 18x300 | 18,0 | 300,0 | 240,0 | 300,00 |

| Drill sds plus 18x450 | 18,0 | 450,0 | 390,0 | 440,00 |

| Drill sds plus 18x600 | 18,0 | 600,0 | 540,0 | 620,00 |

| Drill sds plus 18x800 | 18,0 | 800,0 | 740,0 | 824,00 |

| Drill sds plus 19x200 | 19,0 | 200,0 | 140,0 | 205,00 |

| Drill sds plus 20x200 | 20,0 | 200,0 | 140,0 | 255,00 |

| Drill sds plus 20x300 | 20,0 | 300,0 | 240,0 | 365,00 |

| Drill sds plus 20x450 | 20,0 | 450,0 | 390,0 | 520,00 |

| Drill sds plus 20x600 | 20,0 | 600,0 | 540,0 | 690,00 |

| Drill sds plus 20x800 | 20,0 | 800,0 | 740,0 | 920,00 |

| Drill sds plus 22x250 | 22,0 | 250,0 | 190,0 | 320,00 |

| Drill sds plus 22x450 | 22,0 | 450,0 | 390,0 | 630,00 |

| Drill sds plus 22x600 | 22,0 | 600,0 | 540,0 | 840,00 |

| Drill sds plus 22x800 | 22,0 | 800,0 | 740,0 | 1120,00 |

| Drill sds plus 24x250 | 24,0 | 250,0 | 190,0 | 410,00 |

| Drill sds plus 24x450 | 24,0 | 450,0 | 390,0 | 710,00 |

| Drill sds plus 25x250 | 25,0 | 250,0 | 190,0 | 410,00 |

| Drill sds plus 25x450 | 25,0 | 450,0 | 390,0 | 710,00 |

| Drill sds plus 25x600 | 25,0 | 600,0 | 540,0 | 950,00 |

| Drill sds plus 26x250 | 26,0 | 250,0 | 190,0 | 410,00 |

| Drill sds plus 26x450 | 26,0 | 450,0 | 390,0 | 710,00 |

Breakdowns of sds plus drills

| type of breakdown of sds plus drills | cause | warranty services |

| Head part, splitting or crushing (splitting) of a carbide plate, solder residues are visible, the base of the drill is often rounded | Overload, extreme load, force (reinforcement) | Not recognized |

| Head part, chips on the edges of the carbide plate, most of the carbide plate remains firmly soldered | Extreme load when drilling, sds drill hitting reinforcement | Not recognized |

| Head part, splitting or crushing of carbide plate | Overload, extreme load (rebar) | Not recognized |

| Head part, splitting the carbide plate and the drill base, no visible remains of the carbide plate on the drill base | Bore soldering defect | Admitted |

| The head, carbide plates and drill bases are partially detached from the base, no traces of soldering material are visible | Bore soldering defect | Admitted |

| The head part, the carbide plate has a smooth split or fracture mark, no solder residue is visible | Bore soldering defect | Admitted |

| The spiral part and the carbide plate are completely worn out | The drill bit's service life has expired. Further drilling is possible, but it is not effective (stress on the machine) | Not recognized |

| Broken spiral part, the broken area is uneven, not at an angle of 90 relative to the longitudinal axis of the drill | Fracture when exposed to a single load | Not recognized |

| The spiral part is broken, the transition from the spiral to the shank is worn and shiny | The helical part of the drill is clogged with sintered drilling material, drilling outside the helical part, the removal of drilling material during drilling is blocked, failure due to overload | Not recognized |

| Shank fracture, the fracture surface of the drill parts is not smooth, not at a right angle relative to the longitudinal axis of the drill | Overload, extreme load | Not recognized |

| Shank rounding | Drill hammer clamping device is worn out | Not recognized |

| Severe shank groove wear and deformation | Drill hammer clamping device is worn out | Not recognized |

| The drill is fractured at the marking site, the fracture surface of the drill parts is smooth, at a right angle relative to the longitudinal axis of the drill | Stress concentration due to drill marking too deep | Admitted |

Any reproduction, copying, reprinting of materials from the site krepezi.ru is possible only with the written permission of the site owners.

Drill bit for concrete drill

A drill is a metal tool used to drill holes of the required size in concrete, brick and other stone materials. They are used with a hammer drill as its working part when performing construction and repair work. Drills vary in type, the power of the tool with which they are used, as well as the type of shank and the steepness of the thread.

Characteristics of drills for rotary hammers, dimensions

Every construction enterprise cannot do without drilling walls, floors, various furniture, ceilings and other materials.

If a drill is used for small tasks (hanging a picture, shelf, hanger) in a wooden or brick home, then when working in panel houses a hammer drill is needed.

In addition to drilling capabilities, it includes jackhammer functions. In the case of a hammer drill, a drill is used as an attachment.

Features of various drills for hammer drills are:

- special design of the spiral device;

- internal cavity inside the rod;

- manufacturing the main part from a durable alloy;

- There are many differences in the number of cutting edges.

The main difference between a drill and a drill is the presence of a shank, which allows it to be securely attached to a hammer drill. Thanks to all these features, dust and solid particles of the material being drilled are eliminated and do not interfere with the operation of the tool.

Also, drills have several differences in shanks.

They are used to work with different hammer drills:

- “SDS+” – used in conjunction with household rotary hammers. Its diameter reaches 18 mm.

- “SDS-max” - used by professionals, with a fastening part diameter of more than 18 mm.

Manufacturers of drills are mainly Chinese. Such drills have a standard parameters connector - SDS-plus. They fit any hammer drill. However, drills are not suitable for drilling, and it will not be possible to force them into the chuck.

The following characteristics of drills used for a hammer drill are very important for the buyer:

- length - reflects the ability of the drill to make holes of the required depth;

- diameter.

Taking into account the specific application of the tool, drills are created with a reinforced type of construction, double spiral shape, so they do not break and serve for a long time without any malfunctions. The drill tips are made of the strongest alloy - VK8. This allows you to work for a long time with materials of increased strength.

When designating the size and diameter of the drill, the following numerical designation is used - 5.5x110, or 6x160. This means that the diameter of the drill is 6 mm and the length is 160 mm.

The specifications also include the working length. It is smaller than the main one by about 130 mm.

The diameter of the drill can be as small as 4 mm or up to 30. The choice of each of them depends on the tasks assigned to the tool. Diameters of 6 and 10 mm are often used.

This is quite enough to hang a picture or install a small plinth. It must be remembered that the diameter of the hole drilled is the same diameter as the dowel.

How to choose a drill bit for a hammer drill?

When deciding on the purchase of the right drill for working with durable construction products, it is worth familiarizing yourself with some of the features of each type. For example, the steeper the spiral, the greater the drilling speed and the deeper the hole. This allows the waste material to be quickly removed from the working area.

You should also take into account the tasks facing the tool and the advice of professional builders:

- For drilling to shallow depths, you need to use products with a flatter spiral arrangement. Such tools are the most durable and durable.

- It is better to purchase exclusively branded products. After all, a tool from an unknown manufacturer may have shank grooves that do not coincide with the hammer drill holder.

Drills with brand names Sturm, Bosch and Makita have excellent quality indicators. In addition, their price is quite reasonable.

How to choose a nozzle for a specific hammer drill?

Depending on the purpose of use, drills can be divided into three types:

- Auger - ideal for drilling to great depths. Used to create multiple holes. Due to the design features, the drill removes dust well, reducing the load on the tool and reducing operating time.

- Flutes with a large angle of inclination allow maintaining high productivity and drilling speed. At the same time, the hammer drill itself accounts for a larger share of the load than when using auger drills.

- With a slight angle – suitable for long-term use with little effort. With their help, a large number of small depth holes are created.

- Crowns – used to create wider holes. For example, for pipes and electrical accessories. The design feature of such drills is that a glass with cutters is attached to their base.

In order for the hammer to serve for a long time and efficiently, it is necessary to use a special lubricant during operation. It is applied to the tool chuck and the drill itself.

Also, all hammer drills used for concrete materials are divided into two types:

- Breakthrough - used for making large diameter holes in concrete products.

- Pass-through drills are the most powerful and productive drills. They can be used to make holes in load-bearing walls of multi-story buildings, for example.

How is a drill different from a drill?

A drill can be called a drill that has one distinctive feature - its shank is equipped with a special groove. This means it cannot be used with a drill.

Also, the distinctive features of each drill are:

- high rigidity , allowing you to work with very durable materials;

- high productivity , because drilling is combined with striking.

For each material (concrete, brick, metal) different drills are used, which have specific characteristics.

Types of drill shanks for rotary hammers

Professional builders use drills with shanks that have a special fastening system. This ensures quick replacement of the old drill with a new one.

There are 5 such systems in total:

- SDS – located on drills with a diameter of 10 cm, and equipped with 2 grooves;

- SDS-plus is a more popular type of shank. It can have from 0.4 to 2.5 cm in diameter. Used for making holes in large building slabs.

- SDS-max - found on drills with a diameter of 20 to 80 cm. Popular and most often used with heavy-duty rotary hammers.

- SDS-top – has a diameter of 1.4 cm and 4 grooves. A drill with such a shank is used with medium-weight rotary hammers.

- SDS-quick - has one feature: there are protrusions in place of the grooves. Used in rare cases. The tip is made of a special alloy with high hardness. However, it can only be used once.

You can also divide the shanks depending on the purpose of the product:

- Drills for making small holes are equipped with a tip whose edge is slightly rounded. This increases the reliability of the tool.

- Products for drilling larger holes (for example, for sockets) have special crowns that allow waste material to linger in their internal cavity. They can be divided into two groups: those intended for dry drilling and diamond ones.

Basic parameters of the drill

To take a closer look at the main parameters of the drill, you must first understand its structure in more detail:

- The shank serves as a wear-resistant element and is made of high-strength steel. It is inserted into the part of the hammer drill called the chuck. It is the shank that serves as the main distinguishing feature of the drill. A professional can easily determine which shank is suitable for a particular hammer drill.

- The working part directly carries out the drilling process and has various shapes. It is made from a special alloy of metals that ensures high strength of the product.

- Soldering is the cutting element of the drill, which also affects the speed and quality of work. Made of hard alloy, and may have differences in the number of working edges. The service life of the drill depends entirely on the degree of wear of the soldering tip.

Dimensions of drill bits for rotary hammers

The sizes of drills are characterized mainly by three values - diameter, main and working length.

The choice of diameter depends on the planned task:

- For work at home – 6, 8 and 10 mm.

- For fastening large systems and structures - 10 and 20 mm. In the first case - for a dowel, in the second - for an anchor bolt.

An important note from professionals is a reminder: the diameter of the dowel should always match the diameter of the hole. The length of the drill can vary over a fairly wide range.

Concrete drill for rotary hammer

The components of the tool are:

- spiral rod;

- shank;

- cutting part.

All drills can be divided into:

- Self-sharpening - sludge is removed very quickly. Designed for drilling holes of great depth. In most cases they fit perfectly with SDS-plus shanks. They are indispensable for the installation of medium-heavy structures.

- Spiral - have large drilling diameters. They are used when dismantling thick walls and in large-scale construction work.

- Flat - drill shallow holes. Also, during the work process they require a large amount of effort applied to the tool.

To increase the quality of construction work using a hammer drill, it is worth familiarizing yourself with some expert advice:

- Use the tool operating speed recommended by the manufacturer;

- Every 10 seconds the drill must be removed from the hole to avoid overheating;

- Before starting work, you should drop a little oil on the hammer drill chuck and shank;

- It is necessary to constantly monitor the precise alignment of the drilling axis, otherwise the tool may break;

- For concrete with a large amount of reinforcement, you need to use a diamond-coated drill.

Specific hammer drills for working on concrete

Specific drills used in certain types of work include:

- Crown – used when laying electrical wires;

- Chisel , shaped like a peak and easily destroys concrete;

- Flat chisel – used for spot chipping of concrete;

- Channel drill - greatly facilitates electrical wiring work.

Choice

When purchasing drills for a concrete hammer drill, it is worth remembering that this is a consumable item that cannot be repaired. That is why they are sold in sets.

Drill price categories

Depending on the price category, drills can be divided into:

- Cheap - do not have high quality and strength indicators, used for one-time work;

- Household - are representatives of the above-mentioned brands, which have fairly good reliability indicators;

- Professional – worthy of the highest evaluation criteria.

- Single-use products cost around 35 rubles . They are usually sold in sets of 10. For longer work, it is better to purchase expensive drills.

Wood drill for hammer drill

Drills are used to drill holes in wood products.

However, in some cases a more productive drill is used. In addition, it has a number of advantages:

- accelerated chip removal;

- the self-rotating screw tip does not require much effort;

- Thanks to the use of a clean drilling cutter, the wood being drilled is not destroyed.

The choice of a suitable drill for a concrete hammer drill must meet the requirements of strength, safety and reliability. This can guarantee high quality work. Also, in order not to make a mistake in your choice, you need to purchase products from trusted companies.

Source: https://poznaibeton.ru/instrumenty/bur-dlya-perforatora.html

A drill is a tool or consumable

Consumables in construction and repair, what are they?

A drill is a tool, or a consumable.

Consumables are materials that are consumed during repair and construction work, that is, not tools, but materials with a short service life.

These include various building mixtures (+ sand, cement, primers, putties, glue), as well as removable elements of power tools.

For example, cutting and grinding wheels for grinders (angle grinders), drills for rotary hammers, drill bits for electric drills, cutters, blades for various hacksaws, clorons, etc.

As well as cutting discs for saws (for example, circular saws), or files for an electric jigsaw.

Hardware is also consumables (self-tapping screws, nuts, bolts, screws, clamps, nails, various rivets, etc.).

Polyurethane foam, masking tape, sandpaper.

Drills (any kind, for metal, concrete, wood) are also consumables; in the process of performing work, they wear out and break.

From personal experience I can add that the cost of consumables is included in the cost of payment for the work performed.

That is, you need to immediately calculate how many circles you will need (this is for example) for an angle grinder, how many blades for a hacksaw for metal, or files for a jigsaw.

As a rule, all consumables are purchased by the person carrying out repairs or construction work, but the cost is paid by the customer.

Well, or the cost of consumables is immediately included in the estimate, not each individual consumable, but everything as a general line.

Read also: The chain on the chainsaw does not smear

Drills are used for impact drilling in concrete, brick and stone using a hammer drill. Drills vary in diameter, length and shank type. The length of the drill can be total - from tip to tip, and working - from the beginning of the spiral to the tip with a carbide plate.

Standard shanks – SDS-Plus and SDS-Max, SDS-Quick. The SDS-Plus and SDS-Max drill mounting system is used for rotary hammers and demolition hammers from BOSCH, AEG, DeWALT, Makita, HITACHI, Hilti, Ryobi, Kress, Skil, Milwaukee and others. There are less common and outdated systems:

- SDS-Top for old BOSCH rotary hammers;

- SDS square 9mm for Asian tools;

- HEX 13mm for Makita, HITACHI;

- HEX 19mm for Makita HK1800, HITACHI HK1810;

- HEX 21mm for Makita, HITACHI, Milwaukee, Kango;

- HEX 17mm for old rotary hammers Makita 8035NB, HR3510, HR3520, HR3850, HM0810, HM0810T, HITACHI;

- Spline (large spline shaft) for AEG, BOSCH, Atlas Copco, Milwaukee, Hilti, HITACHI, Kango, Makita, Metabo.

Each drill is designed for a specific type of drilling (light, medium and heavy) and is suitable for certain hammer drill models. If there is a discrepancy, the drill breaks. There are additional nuances: metal quality, soldering shape, fastening reliability, wear resistance and vibration level. According to extended criteria, drills are chosen by professionals for permanent and long-term work. At home, it is enough to have a set of drills of popular or required sizes of standard quality.

Types of drill spirals

Causes of drill failures - warranty cases

The carbide brazing and the drill body at the brazing point are broken. There are no traces of solder where the carbide brazing was located. The wear of the drill head is insignificant. The reason is a manufacturing defect, poor-quality soldering or a defect in the metal of the head part.

The carbide brazing is completely absent; no traces of brazing on the main part of the drill are visible. The reason is a manufacturing defect, poor-quality soldering.

Read also: How to properly set up a torque wrench

The head of the drill is broken precisely under the carbide brazing, which seems to be cut at an angle of 90 degrees to the axis of the drill. The fracture surface is smooth. The reason is a manufacturing defect, a defect in the metal of the head part.

The drill is broken in the spiral area. The fracture surface is smooth, at an angle of 90 degrees to the longitudinal axis of the drill. The reason is a manufacturing defect, a metal defect.

Causes of drill failures – non-warranty cases

The carbide has been ground off or the edges have been rounded. There are significant signs of wear on the drill body. The reason is natural wear and tear.

The carbide solder is destroyed, part of the solder is still securely soldered to the main part of the drill. The drill head is partially rounded or damaged. The reason is getting into reinforcement or concrete.

The drill is broken in the spiral area. The shape of the fracture is uneven and is not located at an angle of 90 degrees to the drill axis. The reason is excessive bending or torsion load.

The drill spiral is clogged with foreign materials: fibers, paint, glue, etc. This causes poor sludge removal and overheating of the consumable. The drill may break and excessive wear on its body may occur. The reason is the use of the drill for other purposes.

Tips for using drills

When using long drills over 460mm, we recommend pre-drilling with a drill 210mm long.

Use special lubricants (gels or aerosols). They provide protection from moisture, have anti-corrosion and conservation properties, and therefore increase the service life of the hammer drill barrel.

Observe the drilling axis. The drill may break if it is skewed.

Select the nozzle specifically for the hammer drill, otherwise you will break the tool.

Basics of choosing pumping stations and five proven models

Because You are not logged in. To come in.

Because The topic is archived.

Childish question. ) Yes, the customer doesn’t give a damn what you include in the estimate - just include it in the price of a square meter, round meter or linear meter and that’s it.

Read also: How to replace a wood router

and if you start him separately, he will say dearly. When you order, you will only receive money, everything else must be included in the price in any way - ask, show the calculation, otherwise you cannot guarantee quality.

But the dressing gowns and other work clothes are yours, because the contractor doesn’t care whether he’s wearing shorts, he is not responsible for labor safety, in terms of protecting the contractor’s personnel. Or he simply won’t let you in without a robe. ¶

Drill bit for concrete hammer drill – SDS+ dimensions and price, drilling recommendations

An impact drill or hammer drill is used to make holes in hard rock-like materials.

The difference between the latter and a drill is:

- Availability of a special clamp for cutting tools.

- Higher power.

- The presence of additional functions - chiselling, just like a jackhammer.

For a hammer drill, a special cutting tool is used - a drill.

A drill is a highly specialized cutting tool used to create holes in concrete, brick, and stone products. It is the main equipment for a drilling tool - a hammer drill.

Design and types

The tool is a steel cylindrical rod, divided into several zones:

- Shank – used for securing in the hammer drill.

- The central part is made with spiral grooves designed to drain and remove drilling products.

- The cutting part is made of durable metal alloys capable of drilling with simultaneous impact on the material being processed.

Shank design

Two main sizes are used:

- SDS+ – 10 mm. Serves as the main device for performing household and semi-professional work. Used for making holes under light and medium loads:

- the diameter of the holes does not exceed 10-20 mm;

- the depth of the holes reaches 250-400 mm;

- SDS Max – 18 mm shank. Belongs to the category of professional. Used under heavily loaded conditions:

- the diameter of the holes being made is more than 20-25 mm;

- the size of the holes in depth can be one or more meters;

Purpose of the cutting tool

The drill is made with dust removal grooves of different designs:

- Auger inclination of grooves - has a spiral shape of the rod, which creates the most optimal conditions for the removal of drilling products. This allows you to relieve the drill from peak loads and create gentle drilling modes. This type of drill is designed to make a large number of holes with different depths.

- Small inclination of the grooves - this facilitates the making of a large number of shallow holes, without the need to create significant pressure on the drill itself.

- Large inclination angle of the working grooves - thanks to this design, the drilling speed increases and labor productivity increases, but this leads to an increase in the load on the hammer drill.

To reduce the load on the main drilling tool, drills can be made with several dust removal grooves.

Dimensions of concrete drills

Drills have three main dimensional parameters:

- The main drilling diameter is determined by the dimensions of the nose.

- The working size of the tool is the distance from the nose to the end of the spiral groove.

- The length of the drill is the total size of the rod.

Main dimensions for drills with SDS+ shank:

| Ø 4 mm | Ø 5 mm | Ø 6 mm | Ø 8 mm | Ø 10 mm | Ø 12 mm | Ø 14 mm | Ø 16 mm |

| 4x50x110 | 5x50x1 | 6x50x110 | 8x50x110 | 10x50x110 | 12×110 | 14x100x160 | 16x100x160 |

| 4x100x160 | 5x100x160 | 6x100x160 | 8x100x160 | 10x100x160 | 12x100x160 | 10×210 | 16×210 |

| 5×210 | 6×210 | 8×210 | 10×210 | 12×210 | 14×260 | 16×260 | |

| 5x210x310 | 6×260 | 8×260 | 10×260 | 12×260 | 14x210x310 | 16x210x310 | |

| 8x210x310 | 10x210x310 | 12x210x310 | 14×360 | 16×350 | |||

| 8×360 | 10×360 | 12×360 | 14×410 | 16×360 | |||

| 8×410 | 10×410 | 12×410 | 14×500 | 16×410 | |||

| 8×460 | 10×460 | 12×450 | 14×1000 | 16×460 | |||

| 8×500 | 10×500 | 12×460 | 16×500 | ||||

| 10×600 | 12×500 | 16×1000 | |||||

| 10×610 | 12×600 | ||||||

| 10×1000 | 12×610 | ||||||

| 12×800 | |||||||

| 12×1000 |

How to choose a rotary hammer?

The main cutting tool is selected in accordance with the fastening system provided in each specific hammer drill. The most common is SDS+.

To determine the necessary device, you need to answer a number of questions:

- Types of work performed – what diameter and how deep the holes need to be drilled:

- for a large number of holes with small dimensions, it is advisable to opt for a drill with a small inclination of the grooves;

- It is more convenient to make deep holes with drills with screw-inclined grooves;

- The intensity of use of a tool affects its strength and service life. A drill on which the rod has several spiral grooves to remove drilling products will help reduce the load.

- Material to be processed - for concrete you should choose a more durable drill, with carbide tipping, than for brick products. With a large volume of operations, you can consider the option of semi-professional products with cross-shaped soldering made of carbide steels.

Criterias of choice

Few doubt that a good tool is the key to successful work.

Here are several criteria by which you can determine the quality of a product with sufficient accuracy:

- Appearance of the packaging - a good product will not be sold in bulk; it must be placed in individual packaging;

- The packaging must indicate the main parameters of the tool , the date and place of production, and the manufacturer’s trademark;

- The name, brand of the manufacturer - a company that values its reputation will not supply low-quality products to the market.

Additionally, you need to pay attention to the appearance of the drill itself.

Quality products have:

- Flat, smooth surface.

- There are no irregularities, scuffs, or burrs on the surface of the product.

- The carbide bit must be located exactly in the middle, relative to the axis of the drill.

- The spiral groove is made with smooth, even contours.

The best companies and prices

Chinese drill “Ermak” - reliability and quality make it possible to use it in domestic conditions.

Reliable suppliers include a number of European, Japanese and American companies, for example:

- Alpen (Austria);

- Drebo (Germany);

- Diager (France);

- Bosch (Germany);

Among domestic productions, we can highlight products under the Zubr brand, the range of which includes household, semi- and professional products.

Due to the unstable economic situation in the world and our country, only approximate prices can be indicated:

- Short drills Ø 6-10 mm with a working part up to 50 mm cost 45-115 rubles/piece.

- An average tool Ø 6-12 mm, length up to 160 mm fits into the price of up to 150 rubles/piece.

- Branded products or those with larger sizes have prices starting from 200 rubles/piece.

Recommendations for drilling concrete

For a sufficiently long service life of the main equipment, a number of rules must be observed:

- Start drilling with low engine speeds, gradually increasing them during operation;

- When the hole depth is more than 50-100 mm, it is advisable to perform two or more passes and periodically remove the drill from the hole in order to remove crushing products.

- The drill is not intended for working on metal - therefore, when reaching a metal barrier, for example, reinforcement, it is necessary to stop work; To drill out steel products, use a metal drill, and then continue drilling further.

- When performing a large amount of work, it is advisable to take breaks so that the drill cools down - overheating will be noticeable by a change in the color of the cutting part, it will turn blue-violet.

- When performing work, it is necessary to monitor the general direction of drilling; deviation from the axis of the hole and the tool leads to an increased load on it and rapid failure of the drill and hammer drill.

- You should not immerse the drill deeper than the outlet grooves end - this can lead to jamming and breakage of the tool, and a “reverse strike” is also possible, that is, the unit can be pulled out of your hands.

Note! Under no circumstances should you resort to artificial cooling in a medium of water, oil or other liquids - this will lead to a loss of strength, hardness and other important performance characteristics.

Adviсe:

- For reliable operation of the hammer-drill combination, it is necessary to periodically lubricate the shank with a special lubricant.

- When working, you should use personal protective equipment - work gloves. This will protect the worker’s hands from possible burns in case of contact with a hot part.

0.00, (ratings: 0) Loading…

Source: https://househill.ru/steny/bloki/bur-dlya-perforatora.html

Concrete drills for rotary hammers: structure, types, purpose, selection criteria

Making a hole in a solid surface is no easy task. Metal drilling tools - concrete drills for a rotary hammer - can successfully cope with this task.

They are used during repairs or construction of objects.

They differ in several characteristics: purpose, power of the tool on which it is installed, type of base, features of the spiral part.

Design Features

Concrete drills for rotary hammers have a specific structure and consist of the following parts:

- The shank is a structural element by which the tool is secured in the hammer drill chuck. They are not always the same type. The structure of the shank depends on the design differences between the cartridges of products from different manufacturers.

- The body is the part of the drill that is subject to the greatest load during operation. It is made of hard metal alloys, which ensures the reliability and durability of the drill.

- The cutting section is the basis of the drilling element, aimed directly at making holes. The design of this part directly depends on the functionality. It should be the strongest part of the drill, so it is made with diamond coating or from hard alloy plates.