GOST 30245-2003 Group B22

INTERSTATE STANDARD

BENT, CLOSED, WELDED, SQUARE AND RECTANGULAR STEEL PROFILES FOR BUILDING STRUCTURES

Specifications

Steel bent closed welded square and rectangular section for building. Specifications

_____________________________________________________________________ Text Comparison of GOST 30245-2003 with GOST 30245-2012, see the link. — Note from the database manufacturer. _____________________________________________________________________

MKS 77.140.70 OKP 526000

Date of introduction 2003-10-01

Preface

1 DEVELOPED by the Central Research and Design Institute of Building Metal Structures named after. N.P.Melnikova (CJSC "TsNIIPSK im.Melnikov")

2 ADOPTED by the interstate scientific and technical commission for standardization, technical regulation and certification in construction (MNTKS) on October 22, 2003. Voted for adoption

| State name | Name of the state construction management body |

| The Republic of Azerbaijan | State Construction Committee of the Azerbaijan Republic |

| Republic of Armenia | Ministry of Urban Development of the Republic of Armenia |

| Republic of Belarus | Ministry of Construction and Architecture of the Republic of Belarus |

| The Republic of Kazakhstan | Kazconstruction Committee of the Republic of Kazakhstan |

| Russian Federation | Gosstroy of Russia |

| The Republic of Tajikistan | Komarchstroy of the Republic of Tajikistan |

| The Republic of Uzbekistan | State Committee for Architecture and Construction of the Republic of Uzbekistan |

| Ukraine | Gosstroy of Ukraine |

3 INSTEAD GOST 30245-94

4 ENTERED INTO EFFECT from October 1, 2003 as a state standard of the Russian Federation by Decree of the State Construction Committee of Russia dated June 30, 2003 N 130, an amendment was made, published in the “Information Bulletin on normative, methodological and standard design documentation” N 10, 2004 Amendment entered by the database manufacturer

Application area

This standard applies to steel bent closed welded square and rectangular sections intended for structural steel structures.

Profiles are manufactured on specialized mills by forming a round tubular section with a longitudinal weld and subsequent compression by rollers into a square or rectangular profile.

Mandatory product quality requirements are set out in paragraphs 3.3 - 3.6, 4.3 - 4.5, 4.7, 4.11, 4.12, 5.2, 5.4, 5.5, 5.8 - 5.10, 5.12.

How to understand the markings

The marking of square steel pipes, the requirements for which are also specified in GOST, reflects the following characteristics.

At the top of the marking (numerator):

- geometric parameters of the products of the marked batch (height, width, wall thickness);

- number of the regulatory document in accordance with which the product is manufactured.

At the bottom of the marking (denominator):

- grade of steel from which the profile pipe is made;

- number of the regulatory document to which the material of manufacture of the product corresponds.

Marking of square pipes contains information about product parameters

As an example, let's look at how a square-section profile pipe with side dimensions of 100 mm and a wall thickness of 6 mm, made of S390K steel, is marked:

100x100x5 GOST 30245-2003/S390K GOST 2772-88.

Normative references

This standard uses references to the following standards:

GOST 166-89 Calipers. Specifications

GOST 427-75 Metal measuring rulers. Technical specifications GOST 1050-88 Long rolled products, calibrated, with special surface finishing, made of high-quality carbon structural steel. General technical conditions

GOST 3242-79 Welded joints. Quality control methods GOST 5264-80 Manual arc welding. Welded connections. Main types, structural elements and dimensions

GOST 5378-88 Protractors with vernier. Technical specifications GOST 7502-98 Metal measuring tapes. Technical specifications GOST 7566-94 Metal products. Reception, labeling, packaging, transportation and storage

GOST 8713-79 Submerged arc welding. Welded connections. Main types, structural elements and dimensions

GOST 14637-89 Rolled thick sheets of carbon steel of ordinary quality. Specifications

GOST 15150-69 Machines, instruments and other technical products. Versions for different climatic regions. Categories, operating, storage and transportation conditions regarding the impact of environmental climatic factors

GOST 16523-97 Rolled thin-sheet carbon steel of high quality and ordinary quality for general purposes. Specifications

GOST 17066-94 Rolled thin sheets of high strength steel. Specifications

GOST 19281-89 Rolled products from high-strength steel. General technical conditions

GOST 19903-74 Hot-rolled sheet products. Assortment

GOST 27772-88 Rolled products for building steel structures. General technical conditions

GOST 30245-03: Steel bent closed welded square and rectangular profiles

Bent closed welded square and rectangular steel profiles for building structures. Specifications

1 area of use

This standard applies to steel bent closed welded square and rectangular sections intended for structural steel structures. Profiles are produced on specialized mills by forming a round tubular section with a longitudinal weld and subsequent compression by rollers into a square or rectangular profile. Mandatory product quality requirements are set out in paragraphs 3.3-3.6, 4.3-4.5, 4.7, 4.11, 5.2, 5.4, 5.5, 5.8-5.10, 5.12.

2. Normative references

This standard refers to the following standards and specifications.

GOST 166-89 Calipers. Technical specifications GOST 427-75 Metal measuring rulers. Technical specifications GOST 3242-79 Welded joints. Quality control methods GOST 5264-80 Manual arc welding. Welded connections. Main types, structural elements and dimensions GOST 5378-88 Protractors with vernier. Technical specifications GOST 7502-98 Metal measuring tapes. Technical specifications GOST 7566-94 Metal products. Reception, labeling, packaging, transportation and storage. GOST 8713-79 Submerged arc welding. Welded connections. Main types, structural elements and dimensions GOST 14637-89 Rolled thick sheets of carbon steel of ordinary quality. Technical specifications GOST 15150-69 Machines, instruments and other technical products. Versions for different climatic regions. Categories, conditions of operation, storage and transportation in terms of exposure to climatic factors of the external environment GOST 16523-97 Rolled thin sheet carbon steel of high quality and ordinary quality for general purpose. Technical specifications GOST 17066-94 Rolled thick sheets of high-strength steel. Technical specifications GOST 19903-74 Hot-rolled sheet products. Assortment GOST 19281-89 Rolled products made of high-strength steel. General technical conditions GOST 27772-88 Rolled products for building steel structures. General technical specifications STO MMK 220-99 Hot-rolled rolled products made of low-alloy steel grade 09FSB for electric-welded pipes. Technical conditions TU 39-0147016-109-00 Rolled products made of low-alloy steel of class K-48 - K-65 for cold-resistant and corrosion-resistant pipes. Technical specifications 3. Assortment

3.1 The cross-section of the profiles must comply with the standards

3.2 Profile dimensions, cross-sectional area, reference values for axes and weight for 1 m of profile must correspond to Table 1 for square profiles; for rectangular profiles - table 2

The maximum deviations in the wall thickness of the profiles must correspond to the maximum deviations in the thickness of the original workpiece with a width of 1250 mm of normal rolling accuracy B according to GOST 19903. The maximum deviations in thickness do not apply to bending areas.

The maximum deviations in the height and width of the profile must correspond to: - for a profile height (width) of up to 100 mm ... ±1.0, but not less - for a profile height (width) of over 100 mm ... ± 0.8.

3.5 Tolerances for the radii of external curvature must correspond to: - for t ≤ 6.0 mm …………….from 1.6t to 2.4t - for 6.0 < t ≤ 10.0 mm ……..from 2, 0t to 3.0t - at t ≥ 10.0 mm……………from 2.4t to 3.6t.

3.6 In the cross section of the profile, deviations from the angle of 90° should not exceed ± 1°30′.

3.7 Profiles are made with lengths from 4.0 to 12.2 m: - unmeasured length; — measured length; — a multiple of the measured length.

Maximum deviations along the length of profiles of measured and multiple measured lengths should not be more than + 60.0 mm.

An example of a symbol for a bent welded profile with a height of 180, a width of 100, a wall thickness of 5 mm, made of steel C245 according to GOST 27772:

180x100x5 GOST 30245-03 Profile———————————- C245 GOST 27772-88

4. Technical requirements

4.1 Profiles are manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

4.2 Profiles should be made from rolled sheets, supplied in rolls in accordance with GOST 19903, from steel: - general-purpose carbon and low-alloy steel with a thickness of 3 mm or more in accordance with GOST 27772 - general-purpose carbon with a thickness of 4 mm or more in accordance with GOST 14637; 3 mm thick - according to GOST 16523; — low-alloy thickness of 4 mm or more — according to GOST 19281; 3 mm thick - according to GOST 17066. Steel grade and delivery category are specified in the order for profiles; — low-alloy grades: Ch-20F; Ch-0.9SF; Ch-20ХМФА according to TU 39-0147016-109-00; 09FSB according to STO MMK 220-99.

4.3 Local curvature of profiles in the horizontal and vertical planes should not exceed 1 mm per 1 m of profile length. The total curvature should not exceed the product of the permissible local curvature (per 1 m of length) and the length of the profile in meters.

4.4 Twisting of profiles around the longitudinal axis should not exceed 2.0 mm plus 0.5 mm per meter of profile length.

4.5 The convexity and concavity of the profile walls should not exceed 0.01 of the profile size.

4.6 Profiles must be cut at right angles. Deviation from the perpendicularity of the cutting plane to the profile axis should not take the profile beyond the nominal length dimensions. Fire trimming of the ends of individual profiles is allowed in an amount of no more than 7% of the batch weight.

4.7 Cracks, sunsets, deep risks and other damage to the surface of profiles are not allowed. Minor roughness, nicks, dents, small scratches, a thin layer of scale and individual hairs should not interfere with the detection of surface defects and bring the wall thickness of the cross-section of the profile beyond the limits of permissible deviations.

4.8 Burrs on the ends of profiles must be removed mechanically at the request of the customer.

4.9 The longitudinal weld is performed by automatic high-frequency welding, and it must be located at a distance from the edge of the profile no closer than 4t.

4.10 The bead from the longitudinal seam is removed from the outer side of the profile, while the height of the bead protruding above the surface of the profile should not exceed: - with a profile wall thickness of up to 4 mm ... 0.5 mm; - with a profile wall thickness of more than 4 mm...1.0 mm.

4.11 Lack of penetration (lack of fusion) of the longitudinal seam should not exceed 50 mm per 1 m of profile length. The length of an individual local lack of penetration should not be more than 20 mm. Defective areas must be corrected using manual or semi-automatic welding in accordance with GOST 5264 and GOST 8713 using welding and filler materials corresponding to the mechanical properties of the profile steel. After correction, the seams must be cleaned.

4.12 For profiles made from low-alloy steels, the welded joint must be normalized.

4.13 Contents 4.13.1 The delivery set includes: profiles packed in packs according to standard sizes and batches and a quality document. 4.13.2 The quality document must contain the following data: - name of the manufacturer or its trademark; — name of the consumer; — profile designation; — heat number, chemical composition and mechanical properties of steel (according to the quality document with the quality control department stamp of the supplier of rolled sheet metal in coils); — profile length; — number of packs; -number of profiles; — order number and quality control stamp; — date of execution of the quality document.

4.14 Packaging 4.14.1 Profiles are tied into bundles taking into account the requirements of GOST 7566. Profiles in a bundle must be tightly packed and firmly tied in the transverse direction every 2-3 m of length. Profiles in a bundle up to 6 m long inclusive must be tied in at least two places. Profiles are supplied by theoretical weight. Pack weight - no more than 10 tons. 4.14.2 Packaging of profiles in bundles must ensure the ability to carry out loading and unloading operations using lifting mechanisms without damaging the profiles and in compliance with safety measures.

4.15 Marking 4.15.1 Marking of profiles in accordance with GOST 7566. 4.15.2 Marking must contain: - name or trademark of the manufacturer; — profile designation; — heat number; — profile length; — number of profiles; - weight and number of the pack; - OTK stamp.

5. Acceptance rules and control methods

5.1 Profiles are accepted in batches. A batch is considered to be profiles of the same profile size and one grade of steel, accompanied by one quality document. The number of profiles in a batch should be no more than 200 pieces.

5.2 If there is automatic control of welding of the longitudinal seam, 3% of the profiles from the batch are subject to inspection of the appearance. In the absence of automatic control, the profiles are subjected to continuous control in accordance with GOST 3242.

5.3 When checking the surface quality of profiles, a batch is considered to comply with the requirements of this standard if the mass of profiles with an unsatisfactory surface does not exceed 3% of the mass of the batch.

5.4 Sections of profiles with transverse seams must be cut out and discarded. It is permissible to weld transverse profile seams using semi-automatic welding, provided that the strength of the seam is equal to that of the base metal. The joint must be marked with indelible paint.

5.5 Dimensions that have maximum deviations must be checked on profiles selected every 1000 m of profiling.

5.6 If, when checking the selected profiles, there is at least one that does not meet the requirements of this standard, you should select twice the number of profiles from the same batch and re-check them. If the results of the re-inspection are unsatisfactory, piece-by-piece inspection is carried out.

5.7 The brand, chemical composition and mechanical properties of the profile material must be certified by a document on the quality of the supplier of sheet metal in rolls.

5.8 Geometric dimensions are checked during operational control with a measuring metal ruler in accordance with GOST 427, an MTs-3 caliper in accordance with GOST 166, a radius template, an angular template, an inclinometer in accordance with GOST 5378. The length of the profiles is measured with a tape measure RZ-20 in accordance with GOST 7502. The transverse geometric dimensions of the profiles are checked for distance from the end section of the profile is not less than the width of the larger section size. It is allowed to replace the specified measuring instruments with others, similar in purpose, with an accuracy class not lower than those provided for by the specified standards.

5.9 Local curvature is measured with a metal ruler in accordance with GOST 427. The overall curvature of the profile is measured using a string stretched across the ends of the profile and a ruler.

5.10 Twisting and deviation from perpendicularity of the cutting plane of profiles is determined by an inclinometer according to GOST 5378.

5.11 The quality of cutting profiles is checked by external inspection.

5.12 Welds are controlled in accordance with GOST 3242 without density tests.

5.13 Completeness is checked by comparing the batch of profiles prepared for shipment with the work order.

5.14 Packaging and marking of profiles is checked by external inspection for compliance with the requirements of this standard.

6. Transportation and storage

6.1 Profiles are transported by all types of transport in accordance with the transportation rules in force for this type of transport.

6.2 Transportation of profiles in terms of exposure to environmental climatic factors - according to conditions 7, storage - according to conditions 4 of GOST 15150.

7. Manufacturer's warranty

7.1 The manufacturer guarantees that the profiles comply with the requirements of this standard provided that the consumer complies with the conditions of transportation and storage.

7.2 The guaranteed shelf life of profiles is 24 months from the date of shipment from the manufacturer.

Assortment

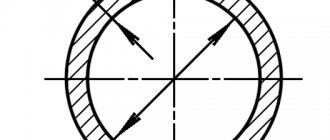

3.1 The cross-section of the profiles must correspond to that shown in Figure 1.

3.2 Profile dimensions, cross-sectional area, reference values for axes and weight for 1 m of profile must correspond to: for square profiles - table 1; for rectangular profiles - table 2.

Figure 1. h - height; b—width; t—wall thickness; R - radius of external curvature

3.3 Maximum deviations in the thickness of the wall of the profiles must correspond to the maximum deviations in the thickness of the initial workpiece with a width of 1250 mm of normal rolling accuracy B according to GOST 19903. Maximum deviations in thickness do not apply to bending areas.

3.4 Maximum deviations in height and width of the profile must correspond, %:

with a profile height (width) of up to 100 mm - ±1.0, but not less than ±0.5 mm;

»»»» St. 100 mm - ±0.8.

3.5 Tolerances for external rounding radii must comply with:

at t

at 6.0

at t > 10.0 mm - from 2.4t to 3.6t.

3.6 In the cross section of the profile, deviations from an angle of 90° should not exceed ±1°30′.

3.7 Profiles are made with lengths from 6.0 to 12.0 m, and by agreement between the consumer and the manufacturer - with lengths from 4.0 to 13.0 m:

- unmeasured length;

— measured length;

— a multiple of the measured length.

3.8 Maximum deviations along the length of profiles of measured and multiple measured lengths should not be more than +60.0 mm.

3.9 An example of a symbol for a bent welded profile with a height of 180, a width of 100, a wall thickness of 5 mm, made of steel C245 according to GOST 27772:

Table 1.

Table 2.

Notes on tables 1 and 2

1 I—moment of inertia; W is the moment of resistance; i is the radius of gyration.

2 Radius of external corner rounding R = 2.0/ at t 10.0 mm.

3 The mass of 1 m of profile length is determined by the cross-sectional area, with a steel density of 7.85 g/cm3.

4 By agreement between the consumer and the manufacturer, it is possible to produce profiles of other sizes.

Production of square profile pipes according to GOST

GOST 30245-2003 is an official regulatory document that specifies not only the dimensions of square pipes, but also the technological features of their production. Naturally, profile pipes that are produced by handicraft methods are strictly prohibited from being used in capital construction. Such products most often do not comply with GOST requirements not only in terms of geometric parameters, but also in terms of strength characteristics. In addition, they are not marked and are not considered goods admitted for public sale.

Line for the production of profile pipes

Technical requirements

4.1 Profiles are manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

4.2 Profiles should be made from rolled sheets supplied in rolls according to GOST 19903, from steel:

— carbon general purpose and low-alloy with a thickness of 3 mm or more — according to GOST 27772;

- carbon general purpose with a thickness of 4 mm and more - according to GOST 14637; with a thickness of 3 mm - according to GOST 16523;

— carbon quality grades 10, 15 and 20 — according to GOST 1050;

— low-alloy thickness of 4 mm or more — according to GOST 19281; 3 mm thick - according to GOST 17066.

The steel grade and delivery category are indicated in the order for profiles.

4.3 Local curvature of profiles in the horizontal and vertical planes should not exceed 1 mm per 1 m of profile length.

The total curvature should not exceed the product of the permissible local curvature (per 1 m of length) and the length of the profile in meters.

4.4 Twisting of profiles around the longitudinal axis should not exceed 2.0 mm plus 0.5 mm per meter of profile length.

4.5 The convexity and concavity of the profile walls should not exceed 0.01 of the profile size.

4.6 Profiles must be cut at right angles. Deviation from the perpendicularity of the cutting plane to the profile axis should not cause the profile to have abnormal length dimensions.

Fire trimming of the ends of individual profiles is allowed in an amount of no more than 7% of the batch weight.

4.7 Cracks, sunsets, deep risks and other damage to the surface of profiles are not allowed. Minor roughness, nicks, dents, small scratches, a thin layer of scale and individual hairs should not interfere with the detection of surface defects and bring the wall thickness of the cross-section of the profile beyond the limits of permissible deviations.

4.8 Burrs on the ends of the profiles must be removed mechanically at the request of the customer.

4.9 The longitudinal weld is performed by automatic high-frequency welding, and it must be located at a distance from the edge of the profile no closer than 4t.

4.10 The bead from the longitudinal seam is removed from the outer side of the profile, and the height of the bead protruding above the surface of the profile should not exceed:

— for profile wall thickness up to 4 mm — 0.5 mm;

- """" more than 4 mm - 1.0 mm.

4.11 Lack of penetration (lack of fusion) of the longitudinal seam should not exceed 50 mm per 1 m of profile length. The length of an individual local lack of penetration should not be more than 20 mm.

Defective areas must be corrected using manual or semi-automatic welding in accordance with GOST 5264 and GOST 8713 using welding and filler materials that correspond to the mechanical properties of the profile steel. After correction, the seams must be cleaned.

4.12 The tensile strength of the longitudinal weld must be no less than 0.95 of the tensile strength of the base metal.

Side dimensions and wall thickness of a square pipe

According to GOST requirements, the dimensions of the sides of profile pipes with a square cross-section can vary in the range of 50–300 mm. In the range of these products, each profile size corresponds to a certain wall thickness: the larger the dimensions of the sides of the steel square pipe, the greater the wall thickness (this parameter varies in the range of 2–14 mm) they are produced.

All parameters that square pipes must comply with are given in the table.

Basic parameters of square pipes

Steel profile pipes with a square cross-section can be produced not only according to GOST, but also according to TU - these are specially developed Technical Conditions. In accordance with the requirements of this document, which is approved by the state regulatory body, pipes with a square profile can be produced in non-standard sizes (length, wall dimensions and thickness). Such products, the marking of which contains the abbreviation TU, are produced mainly on special orders.

When reviewing and approving the Technical Specifications, the state regulatory body assesses the degree of safety of products with non-standard sizes, provides for their mandatory testing, and also determines whether it is possible to produce it on the equipment with which the enterprise is equipped.

4.13. Completeness

4.13.1 The delivery set includes: profiles packed in packs according to standard batch sizes, and a quality document.

4.13.2 The quality document must contain the following data:

— name of the manufacturer or its trademark;

— name of the consumer;

— profile designation;

- heat number, chemical composition and mechanical properties of steel (according to the quality document with the quality control department stamp of the plant - supplier of sheet rolled coils);

— profile length;

— number of packs;

— number of profiles;

— order number and quality control stamp;

— date of execution of the quality document.

MATERIAL AND PRODUCTION

Profiles for drywall and the necessary additional elements for it are produced on special machines. The production uses galvanized steel in accordance with GOST 14918 of different thicknesses. The thicker the steel, the stronger the frame and the more durable the structure. Guide profiles began to be produced from steel 0.3 mm to 1 mm. Prices for such profiles may differ several times. Therefore, when choosing a profile, in addition to the price for the product, it is necessary to clarify what steel the profile is made from. When purchasing a profile, it is advisable to use a special device for determining the thickness of steel - a micrometer.

4.14. Package

4.14.1 Profiles are bundled in accordance with the requirements of GOST 7566.

The profiles in the bundle must be tightly laid and tightly tied in the transverse direction every 2 - 3 m of length.

Profiles in a bundle up to 6 m long inclusive must be tied in at least two places.

Profiles are supplied by theoretical weight.

Package weight: no more than 10 tons.

4.14.2 Packaging of profiles in bundles must ensure the ability to carry out loading and unloading operations using lifting mechanisms without damaging the profiles and in compliance with safety measures.

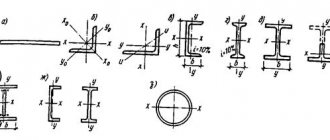

TYPES OF PROFILES

Profiles for drywall come in several types:

- Guide profile (PN) - serves as a direction for installing the rack profile and ceiling profile.

- Ceiling guide profile (PNP) - similar in purpose to PN, but is used for installation of ceilings, indispensable when installing suspended ceilings of various structures and designs.

- Ceiling profile (PP) - is usually installed to the ceiling and serves as a frame. The PCB is installed using special hangers with the ability to adjust the reach.

- Rack profile (PS) - installed in the guide profile and serves as the basis for plasterboard partitions.

- Beacon profile (PM) - used to level the base of walls when using plaster.

- Corner profile (PU) - the profile is used to design the corners of walls.

Profile for gypsum boards

PROFILE FOR GYPSUM CARDBOARD DIMENSIONS AND TYPES

Table of profile sizes and schematic representation of profiles for gypsum plasterboards

| Profile, sketch | Dimensions, mm | Length, mm |

| PN (guide profile) | 50*40, 65*40, 75*40, 100*40 | from 2800 to 5000 |

| PS (rack profile) | 50*50, 65*50, 75*50, 100*50 | from 2800 to 5000 |

| PP (ceiling profile) | 60*27 | from 2800 to 5000 |

| PNP (ceiling guide profile) | 28*27 | from 2800 to 5000 |

| PU (angular profile) | 31*31 | from 2800 to 5000 |

Acceptance rules and control methods

5.1 Profiles are accepted in batches. A batch is considered to be profiles of the same profile size and one grade of steel, accompanied by one quality document. The number of profiles in a batch should be no more than 200 pieces.

5.2 If there is automatic control of welding of the longitudinal seam, 3% of the profiles from the batch are subject to inspection of the external appearance.

In the absence of automatic control, the profiles are subjected to continuous control in accordance with GOST 3242.

5.3 When checking the surface quality of profiles, a batch is considered to comply with the requirements of this standard if the mass of profiles with an unsatisfactory surface does not exceed 3% of the mass of the batch.

5.4 Sections of profiles with transverse seams must be cut out and discarded. Welding of profile transverse seams by semi-automatic welding is allowed, provided that the weld is equal in strength to the base metal. The joint must be marked with indelible paint.

5.5 Dimensions that have maximum deviations must be checked on profiles selected every 1000 m of profiling.

5.6 If, when checking the selected profiles, there is at least one that does not meet the requirements of this standard, you should select twice the number of profiles from the same batch and re-check them.

If the results of the re-inspection are unsatisfactory, piece-by-piece inspection is carried out.

5.7 The brand, chemical composition and mechanical properties of the profile material must be certified by a document on the quality of the enterprise - supplier of sheet metal in rolls.

5.8 Geometric dimensions are checked during operational control with a metal measuring ruler in accordance with GOST 427, an MTs-3 caliper in accordance with GOST 166, a radius template, an angular template, an inclinometer in accordance with GOST 5378. The length of the profiles

measured with a tape measure RZ-20 according to GOST 7502.

The geometric dimensions of the profile section are checked at a distance of at least the larger section size from the end of the profile.

It is allowed to replace the specified measuring instruments with others, similar in purpose, with an accuracy class not lower than those provided for by the specified standards.

5.9 Local curvature is measured with a metal ruler in accordance with GOST 427. The general curvature of the profile is measured using a string stretched across the ends of the profile and a ruler.

5.10 Twisting and deviation from perpendicularity of the cutting plane of profiles is determined by an inclinometer according to GOST 5378.

5.11 The quality of profile cutting is checked by external inspection.

5.12 Welds are controlled in accordance with GOST 3242 without testing for tightness.

5.13 Completeness is checked by comparing the batch of profiles prepared for shipment with the work order.

5.14 Packaging and marking of profiles is checked by external inspection for compliance with the requirements of this standard.

Performance characteristics and applications of square pipes

The performance characteristics of steel pipes with a square profile are determined both by the material of their manufacture and by the features of their design, which is a closed profile formed from a metal strip. The result is a pipe that is lightweight but can withstand significant bending and torsion loads. The requirements for its strength characteristics, as well as the test methods by which they are controlled, are also specified in GOST.

Profile pipes are often used in load-bearing frames of various structures

Due to their exceptional strength characteristics, low weight and manufacturability, profiled metal pipes with a square cross-section have found wide application in many branches of human activity. So, these products are most actively used for:

- construction of buildings for various purposes (such pipes are used to construct lightweight load-bearing structures for warehouses, shops, greenhouses, winter gardens, farms, sheds, etc.);

- reconstruction of construction sites (with the help of square steel pipes, frames of roofing structures and ceilings, entrance lobbies, etc. are created);

- furniture production (cabinets, racks, shelves, tables, chairs, etc.);

- production of various mechanisms and devices in mechanical engineering;

- creation and installation of advertising structures.

Unlike pipes with a round cross-section, which, when exposed to significant bending loads, can not only bend but also collapse, products with a square profile under the same value and direction of the load only bend, and when it is removed they return to their original state.

When choosing a square profile pipe to solve a specific problem, you must first make all the necessary calculations. As a result, it will become clear which product with what geometric profile parameters will be able to withstand the loads that will fall on it.

PRICE FOR PROFILE FOR GYPSUM CARDBOARD

Retail prices for profiles for gypsum boards:

| Profile view | Thickness 0.4 mm | Thickness 0.6 mm |

| Profile 28*27 mm, Russia - 3 meters | 50 RUR/pcs. | 54 RUR/pcs. |

| Profile 60*27 mm, Russia - 3 meters | 85 RUR/pcs. | 125 RUR/pcs. |

| Profile 50*40 mm, Russia - 3 meters | 92 RUR/pcs. | 120 RUR/pcs. |

| Profile 75*40 mm, Russia - 3 meters | 132 RUR/pcs. | |

| Profile 75*50 mm, Russia - 3 meters | 140 RUR/pcs. | |

| Profile 100*40 mm, Russia - 3 meters | 148 RUR/pcs. | |

| Profile 100*50 mm, Russia - 3 meters | 162 RUR/pcs. | |

| Beacon profile M6 - 3 meters | 30 rub/piece | |

| Beacon profile M10 - 3 meters | 32 RUR/pcs. |

Prices for stamping (fasteners) for gypsum plasterboard profiles:

| Fasteners | Price |

| Straight suspension 60*27 mm | 9.5 rub/piece |

| Profile extension 60*27 mm | 7.5 rub/piece |

| Crab (single-level connector) | 12 RUR/pcs. |

| Two-level suspension | 12 RUR/pcs. |

| Suspension with clip | 15 RUR/pcs. |

Depending on the volume, discounts from 2 to 8% on profiles for gypsum plasterboards. Free delivery is possible using StroyOPT Group’s own transport - Far East. The cost of delivery to Sakhalin, Kamchatka, Magadan and other regions of the Far East is calculated based on volume and ranges from approximately 2200 to 2800 rubles per 1 cubic meter. Detailed calculation on request. Sending by consolidated cargo or container.

Finishing with plasterboard has recently become widespread. When working with this material, in most cases you cannot do without a frame. The frame consists of different types of profiles, the differences between them often raise questions. In this article we will look at the main types of profiles and other structural elements for installing drywall.

Types of profiles

guides are attached to walls, floors and ceilings when framing partitions and when covering walls. It is designated by the letter combination UW or in the Russian classification – PN. The profile is U-shaped; a rack profile or other guide profile is inserted into it when adjacent to the walls.

The guide profile for the ceiling performs the same function as the UD profile, only it is used to create suspended ceiling structures. It is designated by the letters UD, in Russian markings - PPN. The profile is also used to create frame structures or for wall cladding.

Fasteners

Direct suspension is the most common fastening element. It is used for installing a suspended ceiling and for attaching gypsum board cladding to the wall in cases where a ceiling profile is used for the racks. The length of the suspension usually does not exceed 12 - 12.5 cm, so the thickness of the ceiling or cladding should not be more than this value.

An anchor suspension is used in situations where the thickness of the ceiling or cladding exceeds 12.5 cm. Sometimes an anchor suspension is called a suspension with a rod, because it consists of two elements, the fastener itself and a rod, the movement of which along the vertical axis allows you to change the height of the ceiling.

Anchor suspension (suspension on traction)

Changing the height of the anchor suspension allows you to change the height of the ceiling.

The extension allows you to increase the length of the ceiling profile; it is inserted at the end of one element and at the beginning of another.

Connecting element extending the ceiling profile.

Extending the ceiling profile

The single-level connector was given the name “crab” by its builders due to its shape. This element combines load-bearing ceiling profiles with auxiliary ones.

Single-level connector (crab).

Using a single-level connector for ceiling structures.

A two-level connector is also used to combine ceiling profiles, and it connects them not at one level, but at two, because of this the thickness of the ceiling increases, but fewer cut elements are obtained.