Metal counterbore is used for secondary processing of holes in industrial equipment structures. This allows you to obtain a support or contact area with high mating accuracy. Treated holes are used for mounting various fasteners: bolts, screws or studs. Reliable fastening of structural elements is the basis for high-quality assembly, therefore countersinking is used in all industries with high technological requirements for the production process.

What is countersinking?

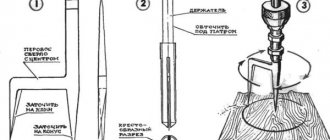

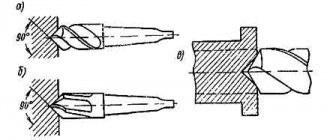

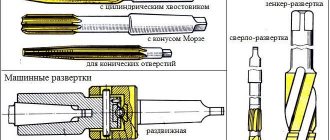

Countersinking is an expansion of the entrance part of a round hole for screws with cylindrical or conical (countersunk) heads. This technological process is carried out with a countersink of the appropriate shape. Conical ones create a supporting surface with a bevel angle of 60, 75, 90, 120 degrees. You can learn how to select a conical countersink according to the size of the fastener from the previous article.

Cylindrical countersinks form a cylinder-shaped recess for hexagon socket screws DIN 912 or for screws with semicircular and hexagonal heads, which, according to the design, must be recessed into the body of the part. The tool has teeth at the end and a guide pin for precise centering of the cutting part relative to the axis of the hole.

GOST requirements

Countering GOST 26258-87 is carried out in accordance with the requirements regulated by this standard.

According to the basic provisions, all tools with a contact plane cross-section not exceeding 8 mm must have a monolithic structure. This applies to devices with a cylindrical tail section. Counterbodies of larger diameter must be manufactured using welding joining technologies. In this case, the tail area and the working surface must be made of different grades of steel.

At enterprises engaged in the manufacture of this tool, there must be technical product control departments that check the quality of the product, including the integrity of the weld. For control, non-destructive testing methods of the connection are used. The presence of pores, cracks or other defects is unacceptable.

Control of the geometry of the finished product plays an important role. The permissible deviation of the counterbore diameter is 0.16 mm per 100 mm of length.

Countering plays an important role in the manufacture of parts for the needs of precision engineering. The vast majority of holes for fastening elements of modern devices were processed with this tool. Have you come across this device? Do you agree with the statement that countersinking and countersinking are the same process? Write your opinion in the comments.

What is counterlining?

Countering is the next stage of hole preparation, which consists of finishing (leveling, cleaning) the flat bottom of an already formed recess in the body of the part. The counterbore also has end teeth and a pin, and chip grooves on the side surface. The trunnion can be replaceable or permanent.

Countering allows you to obtain absolutely smooth, even supporting planes for thrust rings, flat washers or fastener heads, and also allows you to achieve perfect perpendicularity between the supporting plane and the axis of the hole.

Essentially, a counterbore for metal does the same job as a countersink, only the countersink processes the walls of the hole, and the counterbore processes the ends

. That is why it is often called a countersink. It is also used for turning valves, cutting and cleaning the ends of bosses for washers, thrust rings, and nuts. It can be used to trim recessed ledges formed as a result of drilling stepped holes.

Varieties

Steady rests are divided according to various factors: dimensions, methods of fastening the product on a lathe, additional structural elements, weight, number of fasteners.

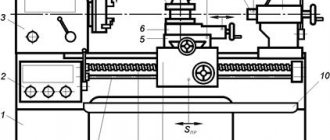

Fixed rest

A fixed steady rest is used to hold long parts. The part is secured to the equipment using mounting bolts that are screwed into the support plate.

The peculiarity of fixed structures is that it has three cams, one of which supports the top, the other two - the bottom. For fastening to workpieces, the fixed steady rest has a folding hinge, which simplifies this process.

Movable steady rest

The moving parts have several differences from the previous ones. The lathe has a longitudinal support on which the steady rests are attached. Thanks to this, the movement of the cutters with the additional part occurs simultaneously. This allows for more uniform processing. The cutting tool does not jam and maintains its integrity for a long period of time.

Another feature of the moving part is the presence of two cams to stop the part. One is located on the top of the structure, the other on the side. The role of the third stop is performed by the cutter.

Movable steady rest on the machine

What is the optimal cutting speed?

When countersinking or countersinking, the cutting speed is set depending on the material being processed. The optimal values are given below.

Source – “Encyclopedia of Mechanical Engineering XXL”.

| Steel HB ≤ 180 | 10-18 m/min |

| Steel HB ≥ 180 | 7-12 m/min |

| Cast iron, solid | 7-12 m/min |

| Medium hard cast iron, bronze | 12-23 m/min |

| Aluminum alloys | 40-65 m/min |

Note:

The lowest speed values correspond to a tool with a larger diameter, and the highest values correspond to a smaller diameter. When using carbide countersinks and counterbores, it is possible to increase the speed by 1.8-2 times.

Other parameters set on the processing machine, such as depth of cut, feed, correction factors, power, are calculated and determined from tabular data from regulatory documents in force in the industry.

Useful tips Updated: 11/16/2020 12:41:55

Tool material

Structural steel grades 45, 40X and 45X are used for the base counterbore rod. The cutting zone can be manufactured from the following materials:

Rod length

- The monolithic cutting area is made of high-speed alloy that meets the recommendations of GOST 19265.

- The material for carbide cutting inserts is selected from alloy VK8, VK6, VK6M, T15K6, T5K10.

- The properties of the material and the requirements for it are set out in GOST 3882. Compliance with geometry and dimensional parameters is controlled by GOST 25400.

Carbide plates are attached to the holder using solder MNMts 68-4-2, brass type L63 and L68. The solder thickness must be no less than 0.2 mm.

Wood, plastic and soft metals are processed with countersinks made of tool steel. Carbide countersinks have high durability and can withstand significant cutting forces that arise when machining strong steel parts on a machine.

The hardness of the cutting surface of countersinks made of tool steel is not lower than 62..66 HRC, the hardness of the shank is 36...45 HRC. The hardness on the body along the entire length of the countersink with carbide inserts is 35…46 HRC.

Scheme of the cutting surface of countersinks

Scraper conveyors TSC 50 tons per hour

This version is designed for transporting materials obtained from wood processing. An example is sawdust or wood chips of various fractions. The box is located in a horizontal plane and at an angle of up to 45 degrees. It is possible to install other angles.

A similar mechanism has been used in industry for quite a long period. The first model was already installed in 1988. The material is transported via the upper chute; it is also possible to use the lower chute. In the manufacture of the main part, stainless steel is used, which is coated with paint and varnish to increase the degree of protection. The minimum motor power is 4 kW.

Excerpt characterizing Tsekovka

Princess Marya was at first surprised, then frightened by this question. – ME?... Me?!... Is it hard for me?! - she said. – He has always been cool; and now it’s getting hard, I think,” said Prince Andrei, apparently on purpose to puzzle or test his sister, speaking so easily about his father. “You are good to everyone, Andre, but you have some kind of pride of thought,” said the princess, more following her own train of thought than the course of the conversation, “and this is a great sin.” Is it possible to judge a father? And even if it were possible, what other feeling than veneration could arouse such a person as mon pere? And I am so satisfied and happy with him. I only wish that you all were as happy as I am.

Application of scraper conveyors

The scope of application of the mechanism under consideration is very extensive. Often the mechanism is installed in the following cases:

- Transportation of rock. An example is the mining industry, in which it is necessary to transport material over long distances or carry out lifting.

- Acts as a support when moving the plow.

When considering the scope of application of a scraper, do not forget that it is limited. This is due to the fact that the scraper conveyor cannot be used to move fragile materials and parts. This is due to the significant impact that is exerted on the surface.

Scraper Rod Conveyor

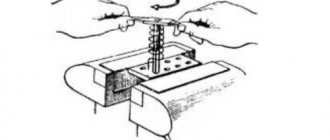

A special type of scraper conveyor can be called a rod structure. It is widely used in machining shops. Design features include the following:

- The base is represented by a metal gutter.

- Inside there is a rod, which is equipped with special spikes.

- To ensure the fixation of the rod when moving it, special guides are installed.

- A hydraulic pusher is installed as a drive, making a reciprocating movement.

Key features include simplicity of design, as well as the ability to perform repairs and maintenance yourself. A scraper conveyor is installed in production workshops. Loading areas are covered with hatches with bars. The disadvantage is increased wear, as well as the inability to transport fine substances.