Steel pipes are widely used in housing and communal services, oil, gas and chemical industries, mechanical engineering for the transmission of liquids or gases. Rolled tubular products are also used as a blank in the production of fasteners and other machine parts.

Basic methods for manufacturing steel pipes:

- Hot rolling and hot pressing;

- Cold rolling and drawing;

- Contact, manual electric arc, gas welding.

The range of pipes is regulated by regulatory documents: the dimensions of seamless products after hot deformation correspond to GOST 8732-78, cold deformation - GOST 8734-75, electric welded - GOST 10704-91. Capillary steel pipes with small diameters are also produced in accordance with GOST 14162-79. The main geometric parameters established in the standards are the outer diameter, the thickness of the pipe walls in millimeters and the weight of 1 meter of the product.

Correspondence table for pipe diameters in mm and inches

| Nominal diameter of the pipe (Dy), mm | Thread diameter (G), inch | Pipe outer diameter (Dн), mm | ||

| Steel water and gas pipe | Seamless steel pipe | Polymer | ||

| 10 | 3/8″ | 17 | 16 | 16 |

| 15 | 1/2″ | 21,3 | 20 | 20 |

| 20 | 3/4″ | 26,8 | 26 | 25 |

| 25 | 1″ | 33,5 | 32 | 32 |

| 32 | 1 1/4″ | 42,3 | 42 | 40 |

| 40 | 1 1/2″ | 48 | 45 | 50 |

| 50 | 2″ | 60 | 57 | 63 |

| 65 | 2 1/2″ | 75,5 | 76 | 75 |

| 80 | 3″ | 88,5 | 89 | 90 |

| 90 | 3 1/2″ | 101,3 | 102 | 110 |

| 100 | 4″ | 114 | 108 | 125 |

| 125 | 5″ | 140 | 133 | 140 |

| 150 | 6″ | 165 | 159 | 160 |

Rolled pipes according to GOST

Pipe diameter is the main characteristic of rolled pipes, thanks to which the necessary calculations are made. The diameter of metal pipes is regulated by GOST 10704-91, which divides products into several categories:

- Small - products that have the following value: no more than 114 mm.

- Medium diameter - rolled products ranging from 114 to 530 mm.

- Large diameter - a pipe whose size exceeds 508 mm. The classification is made according to the outer diameter of the pipe.

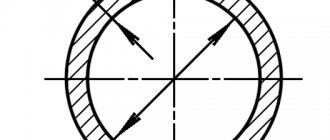

The diameter of a steel pipe is determined as follows:

- For seamless and electric-welded types of pipes - according to the outer diameter.

- For water and gas pressure pipes in accordance with the nominal diameter indicator - close to the values of the standard series of nominal sizes of the internal diameter. The nominal diameter of metal pipes is determined by the parameters set out in GOST 355-52.

The conditional diameter is a conditional value (Dy - in the past, DN - now), which is used when standardizing the diameter of rolled pipes, when, with the same outer diameter of the pipes, the internal size differs significantly. DN not only determines the throughput of rolled pipe, but also makes it possible to correctly select fittings and other fittings for pipe systems. GOST 28338-89 classifies pipes according to their DN value.

The relevance of using pipes of this category

The high popularity enjoyed by VGP pipes made from steel alloys can be explained very simply. No matter how exceptional the characteristics of today's popular pipes made of polymeric materials may be, their use in many cases is simply not possible. Such cases, in particular, include installation of a pipeline in the open air, where it will be affected by a lot of negative factors.

The demand for such products is also explained by the fact that, according to generally accepted requirements, pipelines for transporting gas and supplying it to consumers can only be made of steel pipes. That is why VGP pipes are simply an irreplaceable material in any gas industry.

Gas supply to a private home is a typical example of using VGP pipes

This is interesting: How to attach an anchor bolt: video, photos, nuances, tips

Connection method

As already mentioned, polypropylene is joined by welding. But despite the high level of plasticity, the minimum bending radius does not allow making turns even at an angle of 90°, not to mention steeper ones. All branches and turns are made using fittings. These are special elements for connecting plastic pipes. This is a whole range of different parts for each diameter.

Fittings for polypropylene pipes: types and varieties

The difference is that the marking indicates the diameter of the pipe for which these elements are intended. So you don't need any sizing. If you are using a pipe, say, with a diameter of 25 mm, then simply take fittings with the same marking. It is better to buy both from the same company. Then there will be no problems. If you had to take products from different companies, try them on to be sure. Take a piece of pipe to the store and check compatibility. It should fit in without any problems, but tightly, without gaps.

GOST 8732-78 Hot-deformed seamless steel pipes. Assortment.

STATE STANDARD OF THE USSR UNION

HOT FORMED SEAMLESS STEEL PIPES

Assortment

GOST 8732-78

STATE STANDARD OF THE USSR UNION

| HOT FORMED SEAMLESS STEEL PIPES Assortment Seamless hot-deformed steel pipes. Range of sizes | GOST 8732-78 |

Date of introduction

01/01/79

1. This standard applies to hot-deformed seamless steel pipes for general purposes, manufactured in outer diameter, wall thickness and length.

2. The dimensions and weight of 1 m of pipes must correspond to those given in the table. 1

Table 1

| Outer diameter, mm | Weight of 1 m of pipes, kg, with wall thickness, mm | ||||||||||||||

| 2,5 | 2,6* | 2,8 | 3 | 3,2* | 3,5 | 4 | 4,5 | 5 | 5,5 | 6 | (6,5) | 7 | (7,5) | 8 | |

| 20* | 1,08 | 1,12 | 1,19 | 1,26 | 1,33 | 1,42 | 1,58 | — | — | — | — | — | — | — | — |

| 21,3* | 1,16 | 1,20 | 1,22 | 1,35 | 1,43 | 1,54 | 1,71 | — | — | — | — | — | — | — | — |

| 22* | 1,20 | 1,24 | 1,33 | 1,41 | 1,48 | 1,60 | 1,78 | — | — | — | — | — | — | — | — |

| 25 | 1,39 | 1,44 | 1,53 | 1,63 | 1,72 | 1,86 | 2,07 | 2,28 | 2,47 | 2,65 | 2,81 | 2,97 | 3,11 | 3,24 | 3,35 |

| 26,9* | 1,50 | 1,56 | 1,66 | 1,77 | 1,87 | 2,02 | 2,26 | 2,49 | 2,70 | 2,90 | 3,09 | 3,27 | 3,43 | 3,59 | 3,83 |

| 28 | 1,57 | 1,63 | 1,74 | 1,85 | 1,96 | 2,11 | 2,37 | 2,62 | 2,84 | 3,05 | 3,26 | 3,45 | 3,63 | 3,79 | 3,95 |

| 30* | 1,70 | 1,76 | 1,88 | 2,00 | 2,12 | 2,29 | 2,57 | 2,83 | 3,08 | 3,32 | 3,55 | 3,77 | 3,97 | 4,16 | 4,34 |

| 31,8* | 1,81 | 1,86 | 2,00 | 2,13 | 2,26 | 2,44 | 2,74 | 3,03 | 3,30 | 3,57 | 3,82 | 4,05 | 4,28 | 4,49 | 4,69 |

| 32 | 1,82 | 1,88 | 2,02 | 2,15 | 2,27 | 2,46 | 2,76 | 3,05 | 3,33 | 3,59 | 3,85 | 4,09 | 4,32 | 4,53 | 4,74 |

| 33,7* | 1,92 | 1,99 | 2,13 | 2,27 | 2,41 | 2,61 | 2,93 | 3,24 | 3,54 | 3,82 | 4,10 | 4,36 | 4,61 | 4,84 | 5,07 |

| 35* | 2,00 | 2,08 | 2,22 | 2,37 | 2,51 | 2,72 | 3,06 | 3,39 | 3,70 | 4,00 | 4,29 | 4,57 | 4,83 | 5,09 | 5,33 |

| 38 | 2,19 | 2,27 | 2,43 | 2,59 | 2,75 | 2,98 | 3,35 | 3,72 | 4,07 | 4,41 | 4,74 | 5,05 | 5,35 | 5,64 | 5,92 |

| 40* | 2,31 | 2,40 | 2,57 | 2,74 | 2,90 | 3,15 | 3,55 | 3,94 | 4,32 | 4,68 | 5,03 | 5,37 | 5,70 | 6,01 | 6,31 |

| 42 | 2,44 | 2,53 | 2,71 | 2,89 | 3,06 | 3,32 | 3,75 | 4,16 | 4,56 | 4,95 | 5,33 | 5,69 | 6,04 | 6,38 | 6,71 |

| 42,4* | 2,46 | 2,55 | 2,73 | 2,91 | 3,09 | 3,36 | 3,79 | 4,20 | 4,61 | 5,00 | 5,38 | 5,75 | 6,11 | 6,45 | 6,79 |

| 44,5* | 2,59 | 2,69 | 2,88 | 3,07 | 3,26 | 3,54 | 4,00 | 4,44 | 4,87 | 5,29 | 5,70 | 6,09 | 6,47 | 6,84 | 7,20 |

| 45 | 2,62 | 2,72 | 2,91 | 3,11 | 3,30 | 3,58 | 4,04 | 4,49 | 4,93 | 5,36 | 5,77 | 6,17 | 6,56 | 6,94 | 7,30 |

| 48,3* | 2,82 | 2,93 | 3,14 | 3,35 | 3,56 | 3,87 | 4,37 | 4,86 | 5,34 | 5,80 | 6,26 | 6,70 | 7,13 | 7,54 | 7,95 |

| 50 | 2,93 | 3,04 | 3,26 | 3,48 | 3,69 | 4,01 | 4,54 | 5,05 | 5,55 | 6,04 | 6,51 | 6,97 | 7,42 | 7,86 | 8,29 |

| 51* | — | — | — | 3,55 | 3,77 | 4,10 | 4,64 | 5,16 | 5,67 | 6,17 | 6,66 | 7,13 | 7,60 | 8,04 | 8,48 |

| 54 | — | — | — | 3,77 | 4,01 | 4,36 | 4,93 | 5,49 | 6,04 | 6,58 | 7,10 | 7,61 | 8,11 | 8,60 | 9,08 |

| 57 | — | — | — | 4,00 | 4,25 | 4,62 | 5,23 | 5,83 | 6,41 | 6,99 | 7,55 | 8,10 | 8,63 | 9,16 | 9,67 |

| 60* | — | — | — | 4,22 | 4,48 | 4,88 | 5,52 | 6,16 | 6,78 | 7,39 | 7,99 | 8,58 | 9,15 | 9,71 | 10,26 |

| 60,3* | — | — | — | 4,24 | 4,50 | 4,90 | 5,55 | 6,19 | 6,82 | 7,43 | 8,03 | 8,62 | 9,20 | 9,76 | 10,32 |

| 63,5 | — | — | — | 4,48 | 4,76 | 5,18 | 5,87 | 6,55 | 7,21 | 7,87 | 8,51 | 9,14 | 9,75 | 10,36 | 10,95 |

| 68 | — | — | — | 4,81 | 5,11 | 5,57 | 6,31 | 7,05 | 7,77 | 8,48 | 9,17 | 9,86 | 10,53 | 11,19 | 11,84 |

| 70 | — | — | — | 4,96 | 5,27 | 5,74 | 6,51 | 7,27 | 8,02 | 8,75 | 9,47 | 10,18 | 10,88 | 11,56 | 12,23 |

| 73 | — | — | — | 5,18 | 5,51 | 6,00 | 6,81 | 7,60 | 8,39 | 9,16 | 9,91 | 10,66 | 11,39 | 12,12 | 12,82 |

| 76 | — | — | — | 5,40 | 5,74 | 6,26 | 7,10 | 7,94 | 8,76 | 9,56 | 10,36 | 11,14 | 11,91 | 12,67 | 13,42 |

| 82,5* | — | — | — | — | — | 6,82 | 7,74 | 8,66 | 9,56 | 10,44 | 11,32 | 12,18 | 13,03 | 13,87 | 14,70 |

| 83 | — | — | — | — | — | 6,86 | 7,79 | 8,71 | 9,62 | 10,51 | 11,39 | 12,26 | 13,12 | 13,96 | 14,80 |

| 89 | — | — | — | — | — | 7,38 | 8,39 | 9,38 | 10,36 | 11,33 | 12,28 | 13,23 | 14,16 | 15,07 | 15,98 |

| 95 | — | — | — | — | — | 7,90 | 8,98 | 10,04 | 11,10 | 12,14 | 13,17 | 14,19 | 15,19 | 16,18 | 17,16 |

| 102 | — | — | — | — | — | 8,50 | 9,67 | 10,82 | 11,96 | 13,09 | 14,21 | 15,31 | 16,40 | 17,48 | 18,55 |

| 104* | — | — | — | — | — | — | 9,86 | 11,04 | 12,21 | 13,36 | 14,50 | 15,63 | 16,74 | 17,85 | 18,94 |

| 108 | — | — | — | — | — | — | 10,26 | 11,49 | 12,70 | 13,90 | 15,09 | 16,27 | 17,44 | 18,59 | 19,73 |

| 114 | — | — | — | — . | — | — | 10,85 | 12,15 | 13,44 | 14,72 | 15,98 | 17,23 | 18,47 | 19,70. | 20,91 |

| 121 | — | — | — | — | — . | — | 11,54 | 12,93 | 14,30 | 15,67 | 17,02 | 18,35 | 19,68 | 20,99. | 22,29 |

| 127 | — | — | — | — | — | — | 12,13 | 13,60 | 15,04 | 16,48 | 17,90 | 19,32 | 20,72 | 22,10 | 23,48 |

| 133 | — | — | — | — | — | — | 12,73 | 14,26 | 15,78 | 17,29 | 18,79 | 20,28 | 21,75 | 23,21 | 24,66 |

| 140 | — | — | — | — | — | — | — | 15,04 | 16,65 | 18,24 | 19,83 | 21,40 | 22,96 | 24,51 | 26,04 |

| 146 | — | — | — | — | — | — | — | 15,70 | 17,39 | 19,06 | 20,72 | 22,36 | 24,00 | 25,62 | 27,23 |

| 152 | — | — | — | — | — | — | — | 16,37 | 18,13 | 19,87 | 21,60 | 23,32 | 25,03 | 26,73 | 28,41 |

| 159 | — | — | — | — | — | — | — | 17,15 | 18,99 | 20,82 | 22,64 | 24,45 | 26,24 | 28,02 | 29,79 |

| 165* | — | — | — | — | — | — | — | — | 19,73 | 21,63 | 23,53 | 25,41 | 27,28 | 29,13 | 30,97 |

| 168 | — | — | — | — | — | — | — | — | 20,10 | 22,04 | 23,97 | 25,89 | 27,79 | 29,69 | 31,57 |

| 178* | — | — | — | — | — | — | — | — | 21,33 | 23,40 | 25,45 | 27,49 | 29,52 | 31,53 | 33,54 |

| 180 | — | — | — | — | — | — | — | — | 21,58 | 23,67 | 25,75 | 27,81 | 29,87 | 31,91 | 33,93 |

| 194 | — | — | — | — | — | — | — | — | 23,31 | 25,57 | 27,82 | 30,06 | 32,28 | 34,50 | 36,70 |

| 203 | — | — | — | — | — | — | — | — | — | — | 29,15 | 31,50 | 33,84 | 36,16 | 38,47 |

| 219 | — | — | — | — | — | — | — | — | — | — | 31.52 | 34.06 | 36,60 | 39,12 | 41,63 |

| 245 | — | — | — | — | — | — | — | — | — | — | — | 38,23 | 41,09 | 43,93 | 46,76 |

| 273 | — | — | — | — | — | — | — | — | — | — | — | 42,92 | 45,92 | 49,11 | 52,28 |

| 299 | — | — | — | — | — | — | — | — | — | — | — | — | — | 53,92 | 57,41 |

| 324* | — | — | — | — | — | — | — | — | — | — | — | — | -. | 58,54 | 62,34 |

| 325 | — | — | — | — | — | — | — | — | — | — | — | — | — | 58,73 | 62,54 |

| 351 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 67,67 |

| 356* | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 68,66 |

| 377 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 402 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 406* | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 426 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 450 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 457* | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| (465) | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 480 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 500 | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 508* | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 530 | . — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| (550) | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

Continuation of the table. 1

| Outside diameter, mm | Weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||||

| (8,5) | 9 | (9,5) | 10 | 11 | 12 | (13) | 14 | (15) | 16 | 17 | 18 | |

| 20* | — | — | — | — | — | — | — | — | — | — | — | — |

| 21,3* | — | — | — | — | — | — | — | — | — | — | — | — |

| 22* | — | — | — | — | — | — | — | — | — | — | — | — |

| 25 | — | — | — | — | — | — | — | — | -. | — | — | — |

| 26,9* | — | — | — | — | — | — | — | — | — | — | — | — |

| 28 | — | — | — | — | — | — | — | — | — | — | — | — |

| 30* | — | — | — | — | — | — | — | — | — | — | — | — |

| 31,8* | — | — | — | — | — | — | — | — | — | — | — | — |

| 32 | — | — | — | — | — | — | — | — | — | — | — | — |

| 33,7* | — | — | — | — | — | — | — | — | — | — | — | — |

| 35 | — | — | — | — | — | — | — | — | — | — | — | — |

| 38 | — | — | — | — | — | — | — | — | — | — | — | — |

| 40* | — | — | — | — | — | — | — | — | — | — | — | — |

| 42 | 7,02 | 7,32 | 7,61 | 7,89 | — | — | — | — | — | — | ||

| 42,4* | 7,10 | 7,41 | 7,71 | 7,99 | — | — | — | — | — | — | — | — |

| 44,5* | 7,54 | 7,88 | 8,20 | 8,51 | — | — | — | — | — | — | — | — |

| 45 | 7,65 | 7,99 | 8,32 | 8,63 | — | — | — | — | — | — | — | — |

| 48,3* | 8,34 | 8,72 | 9,09 | 9,44 | — | — | — | — | — | — | — | — |

| 50 | 8,70 | 9,11 | 9,49 | 9,87 | — | — | — | — | — | — | — | — |

| 51* | 8,91 | 9,32 | 9,72 | 10,11 | — | — | — | — | — | — | — | — |

| 54 | 9,54 | 9,99 | 10,43 | 10,85 | 11,67 | — | — | — | — | — | — | — |

| 57 | 10,17 | 10,65 | 11,13 | 11,59 | 12,48 | 13,32 | 14,11 | — | — | — | — | — |

| 60 | 10,80 | 11,32 | 11,83 | 12,33 | 13,29 | 14,21 | 15,07 | 15,88 | — | — | — | — |

| 60,3* | 10,86 | 11,38 | 11,90 | 12,40 | 13,37 | 14,29 | 15,16 | 15,98 | — | — | — | — |

| 63,5 | 11,53 | 12,10 | 12,65 | 13,19 | 14,24 | 15,24 | 16,19 | 17,09 | — | — | — | — |

| 68 | 12,47 | 13,10 | 13,71 | 14,30 | 15,46 | 16,57 | 17,63 | 18,64 | 19,61 | 20,52 | — | ~ |

| 70 | 12,89 | 13,54 | 14,17 | 14,80 | 16,01 | 17,16 | 18,27 | 19,33 | 20,35 | 21,31 | — | — |

| 73 | 13,52 | 14,21 | 14,88 | 15,54 | 16,82 | 18,05 | 19,24 | 20,37 | 21,46 | 22,49 | 23,48 | 24,42 |

| 76 | 14,15 | 14,87 | 15,58 | 16,28 | 17,63 | 18,94 | 20,20 | 21,41 | 22,57 | 23,68 | 24,74 | 25,75 |

| 82,5* | 15,51 | 16,31 | 17,10 | 17,88 | 19,40 | 20,86 | 22,28 | 23,65 | 24,97 | 26,24 | 27,46 | 28,63 |

| 83 | 15,62 | 16,43 | 17,22 | 18,00 | 19,53 | 21,01 | 22,44 | 23,82 | 25,16 | 26,44 | 27,67 | 28,85 |

| 89 | 16,88 | 17,76 | 18,63 | 19,48 | 21,16 | 22,70 | 24,37 | 25,90 | 27,37 | 28,81 | 30,19 | 31,52 |

| 95 | 18,13 | 19,09 | 20,03 | 20,96 | 22,79 | 24,56 | 26,29 | 27,97 | 29,59 | 31,17 | 32,70 | 34,18 |

| 102 | 19,60 | 20,64 | 21,67 | 22,69 | 24,69 | 26,63 | 28,53 | 30,38 | 32,18 | 33,93 | 35,64 | 37,29 |

| 104* | 20,02 | 21,09 | 22,14 | 23,18 | 25,23 | 27,23 | 29,17 | 31,07 | 32,92 | 34,72 | 36,47 | 38,18 |

| 108 | 20,86 | 21,97 | 23,08 | 24,17 | 26,31 | 28,41 | 30,46 | 32,46 | 34,40 | 36,30 | 38,15 | 39,95 |

| 114 | 22,12 | 23,31 | 24,48 | 25,65 | 27,94 | 30,19 | 32,38 | 34,53 | 36,62 | 38,67 | 40,67 | 42,62 |

| 121 | 23,58 | 24,86 | 26,12 | 27,37 | 29,84 | 32,26 | 34,62 | 36,94 | 39,21 | 41,63 | 43,60 | 45,72 |

| 127 | 24,84 | 26,19 | 27,53 | 28,85 | 31,47 | 34,03 | 36,55 | 39,01 | 41,43 | 43,80 | 46,12 | 48,39 |

| 133 | 26,10 | 27,52 | 28,93 | 30,33 | 33,10 | 35,81 | 38,47 | 41,09 | 43,65 | 46,17 | 48,63 | 51,05 |

| 140 | 27,57 | 29,08 | 30,57 | 32,06 | 35,00 | 37,88 | 40,72 | 43,50 | 46,24 | 48,93 | 51,57 | 54,16 |

| 146 | 28,82 | 30,41 | 31,98 | 33,54 | 36,62 | 39,66 | 42,64 | 45,57 | 48,46 | 51,30 | 54,08 | 56,82 |

| 152 | 30,08 | 31,74 | 33,39 | 35,02 | 38,25 | 41,43 | 44,56 | 47,65 | 50,68 | 53,66 | 56,60 | 59,48 |

| 159 | 31,55 | 33,29 | 35,03 | 36,75 | 40,15 | 43,50 | 46,81 | 50,06 | 53,27 | 56,43 | 59,53 | 62,59 |

| 165* | 32,80 | 34,62 | 36,43 | 38,22 | 41,78 | 45,29 | 48,73 | 52,19 | 55,49 | 58,79 | 62,04 | 65,25 |

| 168 | 33,44 | 35,29 | 37,13 | 38,97 | 42,59 | 46,17 | 49,69 | 53,17 | 56,60 | 59,98 | 63,31 | 66,59 |

| 178* | 35,53 | 37,51 | 39,47 | 41,43 | 45,30 | 49,13 | 52,90 | 56,62 | 60,30 | 63,92 | 67,49 | 71,02 |

| 180 | 35,95 | 37,95 | 39,95 | 41,93 | 45,85 | 49,72 | 53,54 | 57,31 | 61,04 | 64,71 | 68,34 | 71,91 |

| 194 | 38,89 | 41,06 | 43,23 | 45,38 | 49,64 | 53,86 | 58,03 | 62,15 | 66,22 | 70,24 | 74,21 | 78,13 |

| 203 | 40,77 | 43,06 | 45,33 | 47,60 | 52,09 | 56,52 | 60,91 | 65,25 | 69,55 | 73,79 | 77,98 | 82,12 |

| 219 | 44,13 | 46,61 | 49,08 | 51,54 | 56,43 | 61,26 | 66,04 | 70,78 | 75,46 | 80,10 | 84,69 | 89,23 |

| 245 | 49,58 | 52,38 | 55,17 | 57,95 | 63,48 | 68,95 | 74,38 | 79,76 | 85,08 | 90,36 | 95,59 | 100,77 |

| 273 | 55,45 | 58,60 | 61,73 | 64,86 | 71,07 | 77,24 | 83,36 | 89,42 | 95,44 | 101,41 | 107,33 | 113,20 |

| 299 | 60,90 | 64,37 | 67,83 | 71,27 | 78,13 | 84,93 | 91,69 | 98,40 | 105,06 | 111,67 | 118,23 | 124,74 |

| 324* | 66,13 | 69,91 | 73,68 | 77,44 | 84,91 | 92,33 | 99,71 | 107,03 | 114,31 | 121,53 | 128,70 | 135,83 |

| 325 | 66,35 | 70,14 | 73,92 | 77,68 | 85,18 | 92,63 | 100,03 | 107,38 | 114,68 | 121,93 | 129,13 | 136,28 |

| 351 | 71,80 | 75,91 | 80,01 | 84,10 | 92,23 | 100,32 | 108,36 | 116,35 | 124,29 | 132,19 | 140,03 | 147,82 |

| 356* | — | 77,02 | 81,17 | 85,33 | 93,59 | 101,80 | 109,97 | 118,08 | 126,14 | 134,16 | 142,11 | 150,04 |

| 377 | — | 81,68 | 86,10 | 90,51 | 99,29 | 108,02 | 116,70 | 125,33 | 133,91 | 142,45 | 150,93 | 159,36 |

| 402 | — | 87,23 | 91,96 | 96,67 | 106,07 | 115,42 | 124,71 | 133,96 | 143,16 | 152,31 | 161,41 | 170,46 |

| 406* | — | 88,11 | 92,89 | 97,66 | 107,15 | 116,60 | 126,00 | 135,34 | 144,64 | 153,89 | 163,08 | 172,24 |

| 426 | — | 92,56 | 97,58 | 102,59 | 112,58 | 122,52 | 132,41 | 142,25 | 152,04 | 161,78 | 171,47 | 181,11 |

| 450 | — | 97,88 | 103,20 | 108,51 | 119,09 | 129,62 | 140,10 | 150,53 | 160,92 | 171,25 | 181,53 | 191,77 |

| 457* | — | 99,43 | 104,83 | 110,24 | 120,99 | 131,69 | 142,35 | 152,94 | 163,51 | 174,00 | 184,46 | 194,86 |

| (465) | — | 101,21 | 106,72 | 112,72 | 123,16 | 134,06 | 144,91 | 155,71 | 166,46 | — | — | — |

| 480 | — | 104,54 | 110,23 | 115,91 | 127,23 | 138,50 | 149,72 | 160,89 | 172,01 | — | — | — |

| 500 | — | 108,98 | 114,92 | 120,84 | 132,65 | 144,42 | 156,13 | 167,80 | 179,41 | — | — | — |

| 508* | — | 110,75 | 116,78 | 122,81 | 134,82 | 146,77 | 158,69 | 170,55 | 182,36 | 194,12 | 205,84 | 217,50 |

| 530 | — | 115,64 | 121,95 | 128,24 | 140,79 | 153,30 | 165,75 | 178,16 | 190,51 | — | — | — |

| (550) | — | 120,08 | 126,63 | 133,17 | 146,22 | 159,22 | 172,16 | 185,06 | 197,91 | — | — | — |

Continuation of the table. 1

| Outer diameter, mm | Weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||||

| (19) | 20 | 22 | (24) | 25 | (26) | 28 | 30 | 32 | (34) | (35) | 36 | |

| 20* | — | — | — | — | — | — | — | — | — | — | — | — |

| 21,3* | — | — | — | — | — | — | — | — | — | — | — | — |

| 22* | — | — | — | — | — | — | — | — | — | — | — | — |

| 25 | — | — | — | — | — | — | — | — | — | — | — | — |

| 26,9* | — | — | — | — | — | — | — | — | — | — | — | — |

| 28 | — | — | — | — | — | — | — | — | — | — | — | — |

| 30* | — | — | — | — | — | — | — | — | — | — | — | — |

| 31,8* | — | — | — | — | — | — | — | — | — | — | — | — |

| 32 | — | — | — | — | — | — | — | — | — | — | — | — |

| 33,7* | — | — | — | — | — | — | — | — | — | — | — | — |

| 35* | — | — | — | — | — | — | — | — | — | — | — | — |

| 38 | — | — | — | — | — | — | — | — | — | — | — | — |

| 40* | — | — | — | — | — | — | — | — | — | — | — | — |

| 42 | — | — | — | — | — | — | — | — | — | — | — | — |

| 42,4* | — | — | — | — | — | — | — | — | — | — | — | — |

| 44,5* | — | — | — | — | — | — | — | — | -. | — | — | — |

| 45 | — | — | — | — | — | — | — | — | — | — | — | — |

| 48,3* | — | — | — | — | — | — | — | — | — | — | — | — |

| 50 | — | — | — | — | — | — | — | — | — | — | — | — |

| 51* | — | — | — | — | — | — | — | — | — | — | — | — |

| 54 | — | — | — | — | — | — | — | — | — | — | — | — |

| 57 | — | — | — | — | — | — | — | — | ~ | — | — | — |

| 60 | — | — | — | — | — | — | — | — | — | — | — | — |

| 60,3* | — | — | — | — | — | — | — | — | — | — | — | — |

| 63,5 | — | — | — | — | — | — | — | — | — | . — | — | — |

| 68 | — | — | — | — | — | — | — | — | — | — | — | — |

| 70 | — | — | — | — | — | — | — | — | — | — | — | — |

| 73 | 25,30 | — | — | — | — | — | — | — | — | — | — | — |

| 76 | 26,71 | — | — | — | — | — | — | — | — | — | — | — |

| 82,5* | 29,75 | — | — | — | — | — | — | — | — | — | — | — |

| 83 | 29,99 | — | — | — | — | — | — | — | — | — | — | — |

| 89 | 32,80 | 34,03 | 36,35 | 38,47 | — | — | — | — | — | — | — | — |

| 95 | 35,61 | 36,99 | 39,61 | 42,02 | — | — | — | — | — | — | — | — |

| 102 | 38,89 | 40,45 | 43,40 | 46,17 | — | — | — | — | — | — | — | — |

| 104* | 39,82 | 41,43 | 44,49 | 47,35 | — | — | — | — | — | — | — | — |

| 108 | 41,70 | 43,40 | 46,66 | 49,72 | 51,17 | 52,58 | 55,24 | — | — | — | — | .- |

| 114 | 44,51 | 46,36 | 49,92 | 53,27 | 54,87 | 56,43 | 59,39 | — | — | — | — | — |

| 121 | 47,79 | 49,82 | 53,71 | 57,41 | 59,19 | 60,91 | 64,22 | — | — | — | — | — |

| 127 | 50,61 | 52,78 | 56,97 | 60,96 | 62,89 | 64,76 | 68,36 | 71,77 | — | — | — | — |

| 133 | 53,42 | 55,74 | 60,22 | 64,51 | 66,58 | 68,61 | 72,51 | 76,20 | 79,71 | — | — | — |

| 140 | 56,70 | 59,19 | 64,02 | 68,66 | 70,90 | 73,10 | 77,34 | 81,38 | 85,23 | .88,88 | 90,63 | 92,33 |

| 146 | 59,51 | 62,15 | 67,28 | 72,21 | 74,60 | 76,94 | 81,48 | 85,82 | 89,97 | 93,91 | 95,81 | 97,66 |

| 152 | 62,32 | 65,11 | 71,53 | 75,76 | 78,30 | 80,79 | 85,63 | 90,26 | 94,70 | 98,94 | 100,99 | 102,99 |

| 159 | 65,60 | 68,56 | 74,33 | 79,90 | 82,62 | 85,28 | 90,46 | 95,44 | 100,22 | 104,81 | 107,03 | 109,20 |

| 165* | 68,41 | 71,52 | 77,58 | 83,45 | 86,31 | 89,12 | 94,60 | 99,88 | 104,95 | 109,83 | 112,20 | 114,52 |

| 168 | 69,82 | 73,00 | 79,21 | 85,23 | 88,16 | 91,05 | 96,67 | 102,10 | 107,33 | 112,36 | 114,80 | 117,19 |

| 178* | 74,50 | 77,93 | 84,64 | 91,14 | 94,33 | 97,46 | 103,58 | 109,50 | 115,21 | 120,73 | 123,42 | 126,06 |

| 180 | 75,44 | 78,92 | 85,72 | 92,33 | 95,56 | 98,75 | 104,96 | 110,98 | 116,80 | 122,42 | 125,16 | 127,85 |

| 194 | 82,00 | 85,82 | 93,32 | 100,62 | 104,20 | 107,72 | 114,63 | 121,34 | 127,85 | 134,16 | 137,24 | 140,28 |

| 203 | 86,22 | 90,26 | 98,20 | 105,95 | 109,74 | 113,49 | 120,84 | 127,99 | 134,95 | 141,71 | 145,01 | 148,27 |

| 219 | 93,71 | 98,15 | 106,88 | 115,42 | 119,61 | 123,75 | 131,89 | 139,83 | 147,57 | 155,12 | 158,82 | 162,47 |

| 245 | 105,90 | 110,98 | 120,99 | 130,80 | 135,64 | 140,42 | 149,84 | 159,07 | 168,09 | 176,92 | 181,26 | 185,55 |

| 273 | 119,02 | 124,79 | 136,18 | 147,38 | 152,90 | 158,38 | 169,18 | 179,78 | 190,19 | 200,40 | 205,43 | 210,41 |

| 299 | 131,20 | 137,61 | 150,29 | 162,77 | 168,93 | 175,05 | 187,13 | 199,02 | 210,71 | 222,20 | 227,87 | 233,50 |

| 324* | 142,90 | 149,94 | 163,85 | 177,55 | 184,34 | 191,06 | 204,39 | 217,51 | 230,42 | 243,15 | 249,44 | 255,67 |

| 325 | 143,38 | 150,44 | 164,39 | 178,16 | 184,96 | 191,72 | 205,09 | 218,25 | 231,23 | 244,00 | 250,31 | 256,58 |

| 351 | 155,57 | 163,26 | 178,50 | 193,54 | 200,99 | 208,39 | 223,04 | 237,49 | 251,74 | 265,80 | 272,76 | 279,66 |

| 356* | 157,90 | 165,72 | 181,21 | 196,49 | 204,07 | 211,58 | 226,49 | 241,19 | 255,67 | 269,98 | 277,05 | 284,08 |

| 377 | 167,75 | 176,08 | 192,61 | 208,93 | 217,02 | 225,06 | 240,99 | 256,73 | 272,26 | 287,60 | 295,20 | 302,74 |

| 402 | 179,46 | 188,41 | 206,17 | 223,73 | 232,43 | 241,09 | 258,26 | 275,22 | 291,99 | 308,56 | 316,78 | 324,94 |

| 406* | 181,32 | 190,39 | 208,34 | 226,08 | 234,90 | 243,64 | 261,02 | 278,18 | 295,13 | 311,90 | 320,21 | 328,47 |

| 426 | 190,71 | 200,25 | 219,19 | 237,93 | 247,23 | 256,48 | 274,83 | 292,98 | 310,93 | 328,69 | 337,49 | 346,25 |

| 450 | 201,95 | 212,09 | 232,21 | 252,14 | 262,03 | 271,87 | 291,40 | 310,74 | 329,87 | 348,81 | 358,21 | 367,56 |

| 457* | — | 215,54 | 236,01 | 256,27 | 266,34 | 276,34 | 296,23 | 315,91 | 335,38 | 354,66 | 364,23 | 373,75 |

| (465) | — | 219,49 | 240,35 | 261,02 | 271,28 | 281,49 | 301,76 | 321,83 | 341,71 | 361,39 | 371,16 | 380,87 |

| 480 | — | — | — | — | 280,52 | 291,10 | 312,12 | 332,93 | 353,55 | 373,97 | 384,10 | 394,19 |

| 500 | — | — | — | — | 292,86 | 303,93 | 325,93 | 347,73 | 369,33 | 390,74 | 401,37 | 411,95 |

| 508* | — | 240,68 | 263,66 | 286,45 | 297,77 | 309,04 | 331,43 | 353,62 | 375,62 | 397,42 | 408,25 | 419,02 |

| 530 | — | — | — | — | 311,35 | 323,16 | 346,64 | 369,92 | 393,00 | 415,89 | 427,26 | 438,58 |

| (550). | — | — | — | — | 323,68 | 335,99 | 360,45 | 384,72 | 408,79 | 432,66 | 444,52 | 456,34 |

Continuation of the table. 1

| Outside diameter, mm | Weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||||

| (38) | 40 | (42) | 45 | (48) | 50 | 56 | 60 | 63 | (65) | 70 | 75 | |

| 20* | — | — | — | — | — | — | — | — | — | — | — | |

| 21,3* | — | — | — | — | — | — | — | — | — | — | — | — |

| 22* | — | — | — | — | — | — | — | — | — | — | — | — |

| 25 | — | — | — | — | — | — | — | — | — | — | — | — |

| 26,9* | — | — | — | — | — | — | — | — | — | — | — | — |

| 28 | — | — | — | — | — | — | — | — | — | — | — | — |

| 30* | — | — | — | — | — | — | — | — | — | — | — | — |

| 31,8* | — | — | — | — | — | — | — | — | — | — | — | — |

| 33,7* | — | — | — | — | — | — | — | — | — | — | — | — |

| 35* | — | — | — | — | — | — | — | — | — | — | — | — |

| 38 | — | — | — | — | — | — | — | — | — | — | — | — |

| 40* | — | — | — | — | — | — | — | — | — | — | — | — |

| 42 | — | — | — | — | — | — | — | — | — | — | — | — |

| 42,4* | — | — | — | — | — | — | — | — | — | — | — | — |

| 44,5* | — | — | — | — | — | — | — | — | — | — | — | — |

| 45 | — | — | — | — | — | — | — | — | — | — | — | — |

| 48,3* | — | — | — | — | — | — | — | — | — | — | — | — |

| 50 | — | — | — | — | — | — | — | — | — | — | — | — |

| 51* | — | — | — | — | — | — | — | — | — | — | — | — |

| 54 | — | — | — | — | — | — | — | — | — | — | — | — |

| 57 | — | — | — | — | — | — | — | — | — | — | — | — |

| 60 | — | — | — | — | — | — | — | — | — | — | — | — |

| 60,3* | — | — | — | — | — | — | — | — | — | — | — | — |

| 63,5 | — | — | — | — | — | — | — | — | — | — | — | — |

| 68 | — | — | — | — | — | — | — | — | — | — | — | — |

| 70 | — | — | — | — | — | — | — | — | — | — | — | — |

| 73 | — | — | — | — | — | — | — | — | — | — | — | — |

| 76 | — | — | — | — | — | — | — | — | — | — | — | — |

| 82,5* | — | — | — | — | — | — | — | — | — | — | — | — |

| 83 | — | — | — | — | — | — | — | — | — | — | — | — |

| S9 | — | — | — | — | — | — | — | — | — | — | — | — |

| 95 | — | — | — | — | — | — | — | — | — | — | — | — |

| 102 | — | — | — | — | — | — | — | — | — | — | — | — |

| 104* | — | — | — | — | — | — | — | — | — | — | — | — |

| 108 | — | — | — | — | — | — | — | — | — | — | — | — |

| 114 | — | — | — | — | — | — | — | — | — | — | — | — |

| 121 | — | — | — | — | — | — | — | — | — | — | — | — |

| 127 | — | — | — | — | — | — | — | — | — | — | — | — |

| 133 | — | — | — | — | — | — | — | — | — | — | — | — |

| 140 | — | — | — | — | — | — | — | — | — | — | — | — |

| 146 | — | — | — | — | — | — | — | — | — | — | — | — |

| 152 | — | — | — | — | — | — | — | — | — | — | — | — |

| 159 | — | — | — | — | — | — | — | — | — | — | — | — |

| 165* | — | — | — | — | — | — | — | — | — | — | — | — |

| 168 | 121,83 | 126,27 | 130,51 | 136,50 | — | — | — | — | — | — | — . | — |

| 178* | 131,19 | 136,12 | 140,86 | 147,59 | — | — | — | — | — | — | — | — |

| 180 | 133,07 | 138,10 | 142,94 | 149,82 | — | — | — | — | — | — | — | — |

| 194 | 146,19 | 151,92 | 157,44 | 165,36 | — | — | — | — | — | — | — | — |

| 203 | 154,63 | 160,79 | 166,76 | 175,34 | 183,48 | 188,66 | — | — | — | — | — | — |

| 2.19 | 169,62 | 176,58 | 183,33 | 193,10 | 202,42 | 208,39 | — | — | — | — | — | — |

| 245 | 193,99 | 202,22 | 210,26 | 221,95 | 233,20 | 240,45 | — | — | — | — | — | — |

| 273 | 220,23 | 229,85 | 239,27 | 253,03 | 266,34 | 274,98 | — | — | — | — | — | — |

| 299 | 244,59 | 255,49 | 266,20 | 281,88 | 297,12 | 307,04 | 335,59 | 353,65 | 366,67 | 375,10 | 395,32 | 414,31 |

| 324* | 268,00 | 280,14 | 292,07 | 309,61 | 326,69 | 337,84 | 370,10 | 390,61 | 405,48 | 415,15 | 438,45 | 460,52 |

| 325 | 268,96 | 281,14 | 293,13 | 310,74 | 327,90 | 339,10 | 371,50 | 392,12 | 407,06 | 416,78 | 440,21 | 462,40 |

| 351 | 293,32 | 306,79 | 320,06 | 338,59 | 358,68 | 371,16 | 407,41 | 430,59 | 447,46 | 458,46 | 485,09 | 510,49 |

| 356* | 297,99 | 311,70 | 325,22 | 345,12 | 364,57 | 377,30 | 414,29 | 437,96 | 455,20 | 466,44 | 493,69 | 519,71 |

| 377 | 317,69 | 332,44 | 346,99 | 368,44 | 389,45 | 403,22 | 442,32 | 469,06 | 487,85 | 500,14 | 529,98 | 558,58 |

| 402 | 341,12 | 357,10 | 372,88 | 396,19 | 419,05 | 434,04 | 477,84 | 506,05 | 526,70 | 540,21 | 573,13 | 604,82 |

| 406* | 344,84 | 361,02 | 377,00 | 400,60 | 423,76 | 438,95 | 483,34 | 511,94 | 532,88 | 546,59 | 580,00 | 612,18 |

| 426 | 363,61 | 380,77 | 397,74 | 422,82 | 447,46 | 463,64 | 510,99 | 541,57 | 563,96 | 578,68 | 614,56 | 649,21 |

| 450 | 386,10 | 404,45 | 422,60 | 449,46 | 475,87 | 493,23 | 544,13 | 577,08 | 601,27 | 617,15 | 656,00 | 693,60 |

| 457* | 392,64 | 41G,33 | 429,82 | 457,20 | 484,12 | 501,33 | 553,76 | 587,40 | 612,11 | 628,34 | 668,04 | 706,51 |

| (465) | 400,16 | 419,25 | 438,14 | 466,10 | 493,62 | 511,73 | 564,85 | 599,27 | 624,58 | 641,20 | 681,89 | 721,35 |

| 480 | 414,21 | 436,04 | 453,67 | 482,75 | 511,38 | 530,22 | 585,56 | 621,47 | 6478 | 665,25 | 707,78 | 749,09 |

| 500 | 432,96 | 453,77 | 474,39 | 504,95 | 535,06 | 554,88 | 613,18 | 651,06 | 678,96 | 697,30 | 742,31 | 786,09 |

| 508* | 440,43 | 461,63 | 482,64 | 513,79 | 544,49 | 677,66 | 624,19 | 662,86 | 691,34 | 710,08 | 756,07 | 800,83 |

| 530 | 461,07 | 483,37 | 505,46 | 538,28 | 570,57 | 591,88 | 654,61 | 695,45 | 725,57 | 745,39 | 794,10 | 841,57 |

| (550) | 479,81 | 503,09 | 526,18 | 560,43 | 594,24 | 616,54 | 682,24 | 725,05 | 756,64 | 777,45 | 828,63 | 878,57 |

Notes: 1. Pipe dimensions taken in brackets should not be used when designing new equipment. 2. The mass of 1 m of pipes is calculated using the formula M =

0.02466

S ( D - S ),

where

D is

the outer diameter, mm;

S—

wall thickness, mm. The density of steel is taken to be 7.850 g/cm3. 3. Pipes, the mass of which is limited by a broken bold line, are manufactured by agreement between the manufacturer and the consumer. 4. Pipes with outer diameters and wall thicknesses marked with an asterisk are used in contractual legal relations for economic, scientific and technical cooperation.

1, 2. (Changed edition, Amendment No. 2).

3. According to the length of the pipe, the following should be made:

unmeasured length - ranging from 4 to 12.5 m;

measured length - within unmeasured length;

length, a multiple of the measured length - within the unmeasured length with an allowance for each cut of 5 mm;

approximate length - within an unmeasured length.

Notes:

1. By agreement between the manufacturer and the consumer, it is allowed to produce pipes with lengths beyond the limits specified for pipes of irregular length.

2. For pipes with a wall thickness of more than 16 mm, the length of the measuring pipes is established by agreement between the manufacturer and the consumer.

3. Pipes of approximate length are manufactured according to customer requirements.

4. Maximum deviations along the length of pipes of the measured length and lengths that are multiples of the measured length should not exceed: +10 mm - for a length of up to 6 m; +15 mm - with a length of more than 6 m or with an outer diameter of more than 152 mm; ±500mm is for approximate length.

3, 4.

(Changed edition, Amendment No. 1).

5. Maximum deviations in the outer diameter and wall thickness of pipes should not exceed those indicated in the table. 2 and .

table 2

| Outer diameter, mm | Limit deviations for manufacturing precision pipes | |

| Increased | ordinary | |

| Up to 50 incl. | ±0.5 mm | ±0.5 mm |

| St. 50 to 219 » | ±0,8% | ±1,0% |

| »219 | ±1,0% | ±1,25% |

Table 3

| Outer diameter, mm | Wall thickness, mm | Maximum deviations in pipe wall thickness for manufacturing accuracy, % | |

| increased | ordinary | ||

| Up to 219 | Up to 15 incl. | ±12,5 | +12,5 -15,0 |

| St. 15 to 30 | +10,0 -12,5 | ±12,5 | |

| 30 and above | ±10,0 | +10,0 -12,5 | |

| St. 219 | Up to 15 incl. | +12,5 -15,0 | |

| St. 15 to 30 | ±12,5 | ||

| 30 and above | +10,0 -12,5 | ||

6. By agreement between the manufacturer and the consumer, pipes can be manufactured with combined maximum deviations, for example: for the outer diameter of increased accuracy according to GOST 9567, and for wall thickness - normal accuracy, etc.

7. Ovality and variation in wall thickness of pipes should not take the size of the pipes beyond the maximum deviations in diameter and wall thickness.

8. The curvature of any pipe section per 1 m of length should not exceed: 1.5 mm - for pipes with a wall thickness of up to 20 mm; 2.0 mm - for pipes with a wall thickness of over 20 to 30 mm; 4.0 mm - for pipes with a wall thickness of over 30 mm.

9. At the consumer’s request, pipes must be supplied by internal diameter and wall thickness, as well as by external and internal diameters and by wall thickness.

Maximum deviations in the internal diameter for pipes with a diameter of 70-203 mm, a wall of 7-20 mm and a ratio of diameter to wall thickness equal to or less than 10 should not exceed the corresponding maximum deviations in the outer diameter indicated in Table. 2.

For other pipe sizes, maximum deviations in internal diameter are established by agreement between the manufacturer and the consumer.

Examples of symbols

A pipe with an outer diameter of 70 mm, a wall thickness of 3.5 mm, a length that is a multiple of 1250 mm, of normal manufacturing precision, from steel grade 10, is manufactured according to group B of GOST 8731:

A pipe with an outer diameter of 70 mm, a wall thickness of 3.5 mm, a length of 6000 mm (measured length), increased manufacturing precision, from steel grade 40X, is manufactured according to group B of GOST 8731:

The same thing, of unmeasured length, is manufactured according to group D of GOST 8731:

A pipe with an outer diameter of 219 mm, a wall thickness of 10 mm, of unmeasured length, normal manufacturing precision, made of steel grade St4sp, steel category 1, manufactured according to group B of GOST 8731 from an ingot:

A pipe with an internal diameter of 70 mm, a wall thickness of 3.5 mm, a length of 6000 mm (measurement length), of normal manufacturing precision, from steel grade 10, is manufactured according to group B of GOST 8731:

A pipe with an outer diameter of 95 mm, an inner diameter of 76 mm, permissible variations in thickness of unmeasured length, normal manufacturing accuracy, from steel grade 10, is manufactured according to group B of GOST 8731:

(Changed edition, Amendment No. 2).

10. Technical requirements - according to GOST 8731.

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the USSR Ministry of Ferrous Metallurgy

DEVELOPERS

A. A. Shevchenko, Doctor of Engineering. sciences; V. P. Sokurenko, Ph.D. tech. sciences; V. N. Rovensky

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the State Committee of Standards of the Council of Ministers of the USSR dated March 22, 1978 No. 757

3. INSTEAD GOST 8732-70

4. The standard fully complies with ST SEV 1481-78

5. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 8731-74 | , |

| GOST 9567-75 |

6. The validity period was lifted according to Protocol No. 3-93 of the Interstate Council for Standardization, Metrology and Certification (IUS 5-6-93)

7. REISSUE with Amendments No. 1, 2, approved in February 1982, September 1988 (IUS 5-82, 1-89)

Scope of application

The primary purpose of VGP pipes is to transport water (both hot and cold) and household gas to the end consumer. When installing a network of water and gas steel pipes, either welding, threaded adapters, or other additional parts and segments are used for connection. Most often, these products are present in household communications. A huge percentage of modern and private housing constructions and high-rises built in the past are equipped with VGP steel pipes for consumers to receive gas, heat and water.

In addition to their direct purpose, pipes are widely used for the construction of metal structures of various types and sizes: shelving and cabinets, scaffolding, fences and small architectural forms. But this is already a separate area of their application, into which we will not delve too deeply.

For gas pipeline

How to find out the dimensions of a product yourself

The standards for external diameters and wall thicknesses used in the water and gas pipeline system are established by GOST Z262-75, for electric welded pipes - standard 10705-80/10704-91. The value of the internal diameter can be found by looking at the product labeling. However, if it is necessary to repair communication systems, and data on the internal diameter of already installed pipes is unknown, the formula can be used to calculate the diameter:

- d = D - 2*S

- Where d is the pipe diameter indicator (inner part)

- D – outer diameter indicator

- 2S – double wall thickness

So, in order to independently calculate the parameters, you need to measure the thickness of the pipe wall and its circumference with a centimeter or tape measure.

TEST METHODS

4.1. For quality control, one sample is cut from each selected pipe for each type of test.

The tensile test is carried out according to GOST 10006-80. Instead of tensile testing, it is allowed to control mechanical properties using non-destructive methods.

(Changed edition, Amendment No. 3, 6).

4.2. The surface of the pipes is inspected visually.

4.3. Hydraulic testing is carried out in accordance with GOST 3845-75 with exposure under test pressure for at least 5 s.

4.4. The bend test is carried out according to GOST 3728-78. Galvanized pipes are tested before coating.

(Changed edition, Amendment No. 3).

4.4a. The expansion test is carried out according to GOST 8694-75 on a conical mandrel with a cone angle of 6°.

It is permissible to test on a mandrel with a taper angle of 30°.

(Changed edition, Amendment No. 3, 4).

4.4b. The flattening test is carried out according to GOST 8695-75.

(Changed edition, Amendment No. 3).

4.4v. Weld inspection is carried out using non-destructive methods according to regulatory and technical documentation.

(Introduced additionally, Amendment No. 3).

4.5. The thickness of the zinc coating on the outer surface and in accessible places on the inner surface is controlled according to GOST 9.301-86 and GOST 9.302-88, as well as with devices of the MT-41NTs, MTZON or Impulse type according to the normative and technical documentation.

4.6. The thread is checked using thread ring gauges in accordance with GOST 2533-88 (third accuracy class).

In this case, the screw-in of the no-go ring gauge onto the thread should be no more than three turns.

(Changed edition, Amendment No. 3, 4).

4.7. The curvature of the pipes is controlled using a straight edge in accordance with GOST 8026-92 and a set of probes in accordance with TU 2-034-225-87.

(Changed edition, Amendment No. 3, 5).

4.8. The right angle of the pipe ends is controlled with a 90° square measuring 160x100 mm, class 3 GOST 3749-77, plate probes set 4 TU 2-034-225-87 or an inclinometer GOST 5378-88. The bevel angle of the chamfer is controlled with a protractor according to GOST 5378-88.

(Changed edition, Amendment No. 3, 6).

4.9. The outer diameter is checked using smooth micrometers in accordance with GOST 6507-90, clamp gauges in accordance with GOST 2216-84 or GOST 18360-93.

The wall thickness, the height of the internal burr and the height of the burrs are measured with a micrometer according to GOST 6507-90 or a wall gauge according to GOST 11358-89 from both ends of the pipe.

The length of the pipes is measured with a tape measure according to GOST 7502-98. Threads are controlled with gauges in accordance with GOST 2533-88.

The mass of a batch of pipes is controlled on scales of no more than 10 tons with a division value of no more than 20 kg.

(Changed edition, Amendment No. 3, 4, 5, 6).

4.10. Weld inspection is carried out using non-destructive methods according to technical documentation.

(Introduced additionally, Amendment No. 4).

Advantages and disadvantages

The water and gas pipe is characterized by high strength and good wear resistance.

The rigidity indicators of such products are equal to the quality characteristics of solid metal timber with similar diameter parameters.

The use of VGP pipes is in demand when constructing not only main lines, but also household pipelines, for example, when replacing polypropylene water supply pipes reinforced with fiberglass (the characteristics are written here), where gas or water is used as the working medium.

The main advantages of water and gas pipelines are presented:

- low coefficient of linear expansion, which prevents deformation of the structure under the influence of high temperatures and as a result of freezing of the working environment;

- high strength compared to polypropylene and other materials, as well as the possibility of use in creating pressure-type structures;

- good thermal conductivity , which has a positive effect on the long-term preservation of temperature indicators of the transported working medium (read reviews about a hot water meter with a temperature sensor on this page);

- tightness , allowing the delivery of gaseous and volatile substances, as well as acids and other chemically active components.

It is important to remember that high thermal conductivity can cause cooling of the transported working medium, therefore the use of VGP pipelines with the additional use of thermal insulation materials is considered optimal.

What do you know about the design and repair of a water ball valve? Read this useful article for instructions on how to disassemble and restore the tightness of shut-off valves for water supply inside buildings.

Watch a video on how to make a heat accumulator for heating boilers with your own hands on this page.