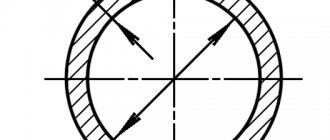

GOST 3262 75 applies to galvanized and non-galvanized welded steel pipes without threads and with rolled or cut cylindrical threads. Their scope of application is water and gas pipelines, heating systems, as well as the production of parts for water and gas pipeline structures.

Welded steel pipes are used for installation of water and gas pipelines

Range of water and gas pipes GOST 3262 75

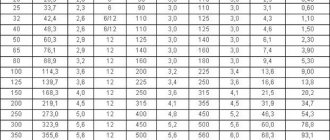

In accordance with the requirements of this regulatory document, pipes are produced according to the weight and dimensions indicated in Table No. 1. The unit of measurement of geometric dimensions is millimeters.

Table 1

| Outside diameter | Conditional passage | Weight of 1 meter of pipes, kg | Pipe wall thickness | ||||||||||

| Strengthened | Ordinary | Lungs | Strengthened | Ordinary | Lungs | ||||||||

| 10,2 | 6 | 0,47 | 0,4 | 0,37 | 2.50 | 2 | 1.8 | ||||||

| 13,5 | 8 | 0,74 | 0,61 | 0,57 | 2,8 | 2,20 | 2 | ||||||

| 17,0 | 10 | 0,98 | 0,8 | 0,74 | 2,8 | 2,20 | 2 | ||||||

| 21,3 | 15 | ˗˗˗˗ | ˗˗˗˗ | 1,1 | ˗˗˗˗ | ˗˗˗˗ | 2,35 | ||||||

| 21,3 | 15 | 1,43 | 1,28 | 1,16 | 3,2 | 2,80 | 2,5 | ||||||

| 26,8 | 20 | ˗˗˗˗ | ˗˗˗˗ | 1,42 | ˗˗˗˗ | ˗˗˗˗ | 2,35 | ||||||

| 26,8 | 20 | 1,86 | 1,66 | 1,5 | 3,2 | 2,80 | 2,5 | ||||||

| 33,5 | 25 | 2,91 | 2,39 | 2,12 | 4 | 3,20 | 2,8 | ||||||

| 42,3 | 32 | 3,78 | 3,09 | 2,73 | 4 | 3,20 | 2,8 | ||||||

| 48,0 | 40 | 4,34 | 3,84 | 3,33 | 4 | 3,50 | 3 | ||||||

| 60,0 | 50 | 6,16 | 4,88 | 4,22 | 4,50 | 3,5 | 3 | ||||||

| 75,5 | 65 | 7,88 | 7,05 | 5,71 | 4,50 | 4 | 3,2 | ||||||

| 88,5 | 80 | 9,32 | 8,34 | 7,34 | 4,50 | 4 | 3,50 | ||||||

| 101,3 | 90 | 10,74 | 9,60 | 8,44 | 4,50 | 4 | 3,50 | ||||||

| 114,0 | 100 | 13,44 | 12,15 | 10,85 | 5 | 4,50 | 4 | ||||||

| 140,0 | 125 | 18,24 | 15,04 | 13,42 | 5,50 | 4,50 | 4 | ||||||

| 165,0 | 150 | 21,63 | 17,81 | 15,88 | 5,50 | 4,50 | 4 | ||||||

When calculating the mass of 1 meter of products, the steel density value was taken as 7.85 g/cm³. Non-galvanized pipes are 3% lighter than galvanized water and gas pipes GOST 3262 75.

The maximum mass deviation at the customer's request should not exceed:

- for a separate pipe +10%;

- for the party +7.5%.

The production of steel water and gas pipes of the above range in accordance with GOST 3262 75 is carried out from steels in accordance with GOST 1050 and GOST 380 without standardization of chemical composition and mechanical properties. Pipes for parts of gas and water supply structures are produced in accordance with GOST 1050.

ACCEPTANCE RULES

3.1. Pipes are accepted in batches. The batch must consist of pipes of the same size, the same grade and be accompanied by one quality document in accordance with GOST 10692 with an addition for pipes intended for the manufacture of parts for water supply and gas pipeline structures, made of steel in accordance with GOST 1050: chemical composition and mechanical properties of steel in accordance with document on the quality of the workpiece manufacturer.

The batch weight is no more than 60 tons.

(Changed edition, Amendment No. 3, 4).

3.2. Each pipe in the batch is subjected to inspection of the surface, dimensions and curvature.

It is allowed to use statistical control methods in accordance with GOST 18242* with a normal level. Control plans are established by agreement between the manufacturer and the consumer.

___________

* GOST R 50779.71-99 is in force on the territory of the Russian Federation.

The outer diameter of the pipes is checked at a distance of at least 15 mm from the end of the pipe.

(Changed edition, Amendment No. 3, 4, 5).

3.3. To control the parameters of the thread, to test for expansion, flattening, bending, the height of the internal burr, the remains of burrs, the right angle and the chamfer angle (for pipes with beveled edges), mechanical properties, no more than 1%, but not less than two pipes from the batch are selected, and for pipes manufactured by continuous furnace welding - two pipes per batch.

(Changed edition, Amendment No. 3, 4).

3.4. All pipes are subject to weight control.

(Changed edition, Amendment No. 3).

3.5. Each pipe is subjected to hydraulic pressure testing. With 100% quality control of the weld using non-destructive methods, hydraulic pressure testing may not be carried out. At the same time, the ability of the pipes to withstand the test hydraulic pressure is guaranteed.

(Changed edition, Amendment No. 6).

3.6. To check the thickness of the zinc coating on the outer surface and in accessible places on the inner surface, two pipes from the batch are selected.

(Changed edition, Amendment No. 2).

3.7. If unsatisfactory test results are obtained for at least one of the indicators, a repeat test is carried out on a double sample.

The results of repeated tests apply to the entire batch.

Technical characteristics of water and gas steel pipes GOST 3262 75

The length of steel water and gas pipes according to GOST 3262 75 is produced in the range of 4m ≤ L ≤12m.

Steel pipes come in regular and irregular lengths

If we use this parameter as a criterion, these products are:

- of unmeasured length. In a batch of pipes of this range, the presence of up to 5 percent of products with a length of 1.5 m ≤ L1 ≤ 4 m is allowed.

- multiple of measured or measured length. The magnitude of the longitudinal deviation in accordance with the requirements of GOST 3262 75 for the entire length can exceed the nominal value by 10 centimeters with a cut allowance of up to 5 millimeters.

All tolerances are strictly regulated by GOST and if there are deviations exceeding the permissible ones, the product is considered defective.

Important! If the thread is made by rolling, a reduction in the internal diameter of the steel water and gas pipe GOST 3262 75 is allowed by no more than 10 percent along the length of the thread.

The range of maximum deviations of pipe sizes is indicated in table No. 2.

table 2

| Pipe size | Maximum permissible deviation value | |

| Increased manufacturing accuracy | Manufacturing accuracy is normal | |

| Conditional diameter at outer diameter | ||

| Up to 40 millimeters inclusive | +/- 0.4 millimeters | plus 0.4 minus 0.5 millimeters |

| Over 40 millimeters | +/- 0,8 % | plus 0.8% minus 1% |

| Wall thickness | — 10% | — 15% |

The indicator “Pipe curvature” per 1 meter of length according to GOST 3262 75 does not exceed:

- 2 mm with nominal bore up to 20 mm;

- 1.5 mm if the nominal diameter is more than 20 mm.

One of the most significant technical characteristics of a water and gas pipe according to GOST 3262 75 is pressure resistance. Depending on the type, a product of this type can withstand:

- reinforced pipe – 3.1 MPa;

- the pipe is ordinary and light - 2.4 MPa.

TECHNICAL REQUIREMENTS

2.1. Pipes are manufactured in accordance with the requirements of this standard and according to technological regulations approved in the prescribed manner, from steels in accordance with GOST 380 and GOST 1050 without standardization of mechanical properties and chemical composition.

Pipes for parts of water supply and gas pipeline structures are made of steel in accordance with GOST 1050.

2.2. At the request of the consumer, the ends of pipes to be welded, with a wall thickness of 5 mm or more, must be chamfered at an angle of 35 - 40° to the end of the pipe. In this case, an end ring 1 - 3 mm wide should be left.

At the request of the consumer, on ordinary and reinforced pipes with a nominal bore of more than 10 mm, threads are applied to both ends of the pipe.

2.1; 2.2. (Changed edition, Amendment No. 3, 4).

2.3. At the request of the consumer, pipes are equipped with couplings manufactured in accordance with GOST 8944, GOST 8954, GOST 8965 and GOST 8966 at the rate of one coupling for each pipe.

(Changed edition, Amendment No. 3).

2.4. Cracks, spots, swellings and declines are not allowed on the surface of the pipes.

Delamination is not allowed at the ends of the pipes.

Individual dents, rippling, scratches, traces of stripping and other defects caused by the production method are allowed, if they do not take the wall thickness beyond the minimum dimensions, as well as a layer of scale that does not interfere with inspection.

On pipes made by furnace welding, it is allowed to reduce the outer diameter to 0.5 mm at the seam if there is a gentle thickening in this place along the inner diameter of no more than 1.0 mm.

(Changed edition, Amendment No. 3, 4).

2.5. At the request of the consumer, on pipes with a nominal bore of 20 mm or more, the burr on the inner surface of the pipe seam must be cut off or flattened, and the height of the burr or its traces should not exceed 0.5 mm.

At the request of the consumer, on pipes with a nominal bore of more than 15 mm, manufactured by furnace welding and hot reduction, a gentle thickening with a height of no more than 0.5 mm is allowed on the inner surface of the pipes in the weld area.

(Changed edition, Amendment No. 2, 3, 4, 5, 6).

2.6. The ends of the pipes must be cut at right angles. The bevel of the end is allowed to be no more than 2°. The remaining burrs should not exceed 0.5 mm. When removing burrs, the formation of blunting (rounding) of the ends is allowed. It is allowed to cut pipes in the mill line.

By agreement between the manufacturer and the consumer, burrs up to 1 mm are allowed on pipes with a nominal bore of 6 - 25 mm, manufactured by furnace welding.

(Changed edition, Amendment No. 4, 6).

2.7. Galvanized pipes must have a continuous zinc coating over the entire surface with a thickness of at least 30 microns. The absence of zinc coating on the ends and threads of pipes is allowed.

On the surface of galvanized pipes, bubbles and foreign inclusions (hardzinc, oxides, sintered mixture), and peeling of the coating from the base metal are not allowed.

Individual flux spots and traces of pipes being caught by lifting devices, roughness and minor local deposits of zinc are allowed.

It is allowed to correct individual non-galvanized areas on 0.5% of the outer surface of the pipe in accordance with GOST 9.307.

(Changed edition, Amendment No. 3, 4).

2.8. Pipes must withstand hydraulic pressure:

2.4 MPa (25 kgf/cm2) - pipes, ordinary and light;

3.1 MPa (32 kgf/cm2) - reinforced pipes.

At the request of the consumer, the pipes must withstand hydraulic pressure of 4.9 MPa (50 kgf/cm2)

(Changed edition, Amendment No. 2, 3, 5).

2.9. Pipes with a nominal bore up to 40 mm inclusive must withstand the bend test around a mandrel with a radius equal to 2.5 outer diameters, and with a nominal bore of 50 mm - on a mandrel with a radius equal to 3.5 outer diameters.

At the request of the consumer, pipes must withstand the distribution test:

for pipes with a nominal bore from 15 to 50 mm - no less than 7%;

for pipes with a nominal bore of 65 or more - no less than 4%.

At the request of the consumer, pipes must withstand the flattening test to a distance between the flattened surfaces equal to 2/3 of the outer diameter of the pipes.

(Changed edition, Amendment No. 2, 3, 5).

2.10. At the request of the consumer, the mechanical properties of pipes for parts of water supply and gas pipeline structures must comply with GOST 1050.

2.11. Pipe threads must be clean, without flaws or burrs and comply with GOST 6357, accuracy class B.

Pipes with cylindrical threads are used when assembling with seals.

2.10; 2.11. (Changed edition, Amendment No. 3, 4).

2.12. At the seam, blackness on the threads is allowed if the reduction in the normal height of the thread profile does not exceed 15%, and at the request of the consumer does not exceed 10%.

Threads with torn (for cut) or incomplete (for rolled) threads are allowed on threads, provided that their total length does not exceed 10% of the required thread length, and at the request of the consumer does not exceed 5%.

(Changed edition, Amendment No. 2, 3, 5).

2.13. On a thread, it is allowed to reduce the useful length of the thread (without running) up to 15% compared to that indicated in the table. 4, and at the consumer’s request up to 10%.

(Changed edition, Amendment No. 2, 3, 5).

2.14. Threading on galvanized pipes is carried out after galvanizing.

2.15. (Deleted, Amendment No. 3).

2.16. At the request of the consumer, pipe welds are subjected to testing using non-destructive methods.

(Changed edition, Amendment No. 5).

Manufacturing method

Water and gas pipes are made from metal blanks, called strips, by special molding and further welding of the seam. For this purpose, ordinary carbon steel is used without further heat treatment. All water and gas pipes are manufactured using electric welding and mandatory quality control of the weld. It is the seam, as a source of increased danger to the integrity of the entire pipeline, that receives increased attention. To do this, an X-ray examination of its surface is carried out.

All products are manufactured in accordance with GOST. For ease of installation, cylindrical threads are applied to both ends of the pipe. The connection is made using special couplings or by welding./p>

During production, a distinction is made between products of normal precision and products with an increased level of precision. In the first case, we are talking about the installation of water supply or heating systems, and in the second case, about the use of pipes in the manufacture of various structures. When marking finished products, the letter “P” must be added, which means increased accuracy of the pipe diameter.

Manufacturing method

Water and gas pipes are made from metal blanks, called strips, by special molding and further welding of the seam. For this purpose, ordinary carbon steel is used without further heat treatment. All water and gas pipes are manufactured using electric welding and mandatory quality control of the weld. It is the seam, as a source of increased danger to the integrity of the entire pipeline, that receives increased attention. To do this, an X-ray examination of its surface is carried out.

All products are manufactured in accordance with GOST. For ease of installation, cylindrical threads are applied to both ends of the pipe. The connection is made using special couplings or by welding./p>

During production, a distinction is made between products of normal precision and products with an increased level of precision. In the first case, we are talking about the installation of water supply or heating systems, and in the second case, about the use of pipes in the manufacture of various structures. When marking finished products, the letter “P” must be added, which means increased accuracy of the pipe diameter.

Areas of use

The main and most extensive area of application of VGP pipes is the organization of pipeline systems for cold and hot water supply, heating, and distribution of low-pressure gas to consumers. The laying of pipelines is carried out by welding, on threaded connections, using additional fittings and fittings.

Due to the high reliability of the weld, this metal product is widely used to create metal structures, including those under heavy loads. Among them:

- scaffolding;

- small architectural forms - gazebos, canopies, pergolas;

- pieces of furniture - shelves, cabinets, racks;

- stands and frames for outdoor advertising elements;

- fences, gates, wickets.

Thanks to the high strength of the weld and modern methods of anti-corrosion treatment, the VGP pipe has a long working period. However, the specific service life largely depends on environmental conditions and the degree of aggressiveness of the liquid or gas transmitted through the pipeline system.

Production Features

Water and gas pipes are made from a pipe blank - strip, which is molded and then welded with a longitudinal seam using furnace or arc welding. The seam is usually located parallel to the longitudinal axis of the tubular product. At the welding site, the standard allows some thickening, leading to a slight decrease in the internal diameter. Each pipe undergoes a weld inspection using non-destructive testing methods, after which hydraulic testing becomes an optional activity.

Strips are produced by hot rolling from carbon steels of ordinary quality and high-quality structural ones. Ordinary quality steels are manufactured in accordance with GOST 380-2005. They combine affordable cost, good strength, and weldability without restrictions.

To increase corrosion resistance, pipe products are galvanized using the hot-dip galvanizing method. The thickness of the zinc coating must be at least 30 microns. There is no protective layer at the ends. Such products are used for laying in conditions of high humidity. There is another option for protecting a pipe product from corrosion damage - priming, and then coating with paints and varnishes for metal. Also used for coating are “two in one” enamels (primer + coloring composition) or “three in one” (rust converter + primer + paint).

Areas of application and individual parameters

The main areas of application of water and gas pipes, the geometric parameters and technical characteristics of which comply with standard 3262-75, are construction and repair. Pipes of this category are used for arranging gas and water communications and heating systems in cottages and multi-apartment buildings, administrative buildings, educational institutions, agricultural, industrial and any other facilities.

So, this type of rolled metal is used in:

- communications of cold and hot water supply;

- heating systems;

- gas pipeline networks.

Wall size is the criterion by which water and gas pipes are distinguished:

- ordinary;

- lungs;

- reinforced.

Reinforced VGP pipes are products (sometimes galvanized), the wall thickness of which is increased (accordingly, such products have more weight). They are used for installation of pipelines through which liquid or gaseous media are transported under high pressure.

If the technical characteristics and basic geometric parameters of water and gas pipes are regulated by a regulatory document, then the design option and cutting length are determined by the customer. Thus, the most popular are pipes whose ends are threaded during the production process. The reason for their high popularity is that they do not require welding to install them.

Threads on VGP pipes can be created during their production:

- rolling (a technology that allows you to obtain threads with the most accurate parameters, while it is possible that the internal diameter will be 10% smaller);

- slicing.

The thread on VGP pipes is cut or rolled at the request of the customer, and it can be either short or long.

Product parameters

The name speaks for itself - a pipe of this type can be used both in water supply systems and in gas pipelines. In principle, VGP pipe is considered a universal option for many applications.

Standard pipes have segment lengths from 4 m to 12 m. Moreover, there is a choice of material - without thread, or with cylindrical or knurled threads at the ends. Moreover, the pipe thread can be short or long - it all depends on the nuances of use.

Typically, a VGP pipe has three strength categories:

The strength category almost directly depends on the wall thickness of the pipe itself. The fact is that pipes of varying degrees of strength are used for different purposes.

For hot water supply, you will need a VGP pipe with thick walls; for cold water, you can use an option with average values.

For gas pipeline systems, pipes with a thin profile are perfect, since gas is not a substance that quickly destroys the systems that conduct it.

In general, pipes as a material are selected according to the application. Often, in an effort to save money, the user chooses the most inexpensive option. And, as a result, he pays twice for repairs or replacement of the line before its expected expiration date.

Main advantages

VGP pipes are in demand for the construction of main lines and domestic pipelines. They use gas or water as a working medium. The main advantages of such products are the following indicators:

- low coefficient of linear expansion, which prevents deformation of the structure under the influence of high and very low temperatures;

- high strength compared to polypropylene and many other materials;

- possibility of use in pressure-type structures;

- good thermal conductivity, which has a positive effect on maintaining the temperature of the transported working environment;

- tightness allows the delivery of volatile and gaseous substances, acids and many other chemically active substances through pipes.

A high thermal conductivity coefficient can lead to cooling of the transported working medium. To avoid this, VGP pipes are used with additional thermal insulation materials.

Advantages of VGP pipes

- Standard pipes VGP GOST 3262 75 are made of high quality steel.

- The so-called “black pipes” of the VGP have a reinforced weld.

- Pipes of this type have three categories convenient for the consumer - light, reinforced and ordinary. This allows you to choose the right option for the ideal design of the highway.

- The threads on the ends of the pipes can be long, short, or applied, depending on the customer’s wishes, on the desired side in the required parameters.

- Pipes of this category are supplied either with or without couplings.

- Pipe parameters can be indicated in inches, which is considered the norm.

- The pipes sold undergo mandatory hydro-vortex testing, so compliance with the standards can be considered almost perfect.

- Low cost with excellent product quality is a guarantee of the assigned standards and regulations.

- Versatility in use. Pipes of the required type are ideal for installation and repair work of almost any category.

- A huge range of types of pipes - from hot-rolled seamless, to cold-rolled and electric-welded options.

- Availability of component elements - flanges, couplings, tees, bends, transitions, etc., as well as the possibility of their easy use in installation work.

As you understand, standard VGP pipes GOST 3262 75 have a wide range of applications. The presence of at least three types of this type makes it possible to use them in almost all areas of pipelines. Moreover, it is possible to select a category for the type of main line, with a rich selection of pipe types for its installation.

Areas of application and individual parameters

The main areas of application of water and gas pipes, the geometric parameters and technical characteristics of which comply with standard 3262-75, are construction and repair.

Pipes of this category are used for arranging gas and water communications and heating systems in cottages and multi-apartment buildings, administrative buildings, educational institutions, agricultural, industrial and any other facilities. So, this type of rolled metal is used in:

- communications of cold and hot water supply;

- heating systems;

- gas pipeline networks.

Wall size is the criterion by which water and gas pipes are distinguished:

- ordinary;

- lungs;

- reinforced.

Reinforced VGP pipes are products (sometimes galvanized), the wall thickness of which is increased (accordingly, such products have more weight). They are used for installation of pipelines through which liquid or gaseous media are transported under high pressure.

If the technical characteristics and basic geometric parameters of water and gas pipes are regulated by a regulatory document, then the design option and cutting length are determined by the customer. Thus, the most popular are pipes whose ends are threaded during the production process. The reason for their high popularity is that they do not require welding to install them.

Threads on VGP pipes can be created during their production:

- rolling (a technology that allows you to obtain threads with the most accurate parameters, while it is possible that the internal diameter will be 10% smaller);

- slicing.

The thread on VGP pipes is cut or rolled at the request of the customer, and it can be either short or long.