Steel pipes are widely used in housing and communal services, oil, gas and chemical industries, mechanical engineering for the transmission of liquids or gases. Rolled tubular products are also used as a blank in the production of fasteners and other machine parts.

Basic methods for manufacturing steel pipes:

- Hot rolling and hot pressing;

- Cold rolling and drawing;

- Contact, manual electric arc, gas welding.

The range of pipes is regulated by regulatory documents: the dimensions of seamless products after hot deformation correspond to GOST 8732-78, cold deformation - GOST 8734-75, electric welded - GOST 10704-91. Capillary steel pipes with small diameters are also produced in accordance with GOST 14162-79. The main geometric parameters established in the standards are the outer diameter, the thickness of the pipe walls in millimeters and the weight of 1 meter of the product.

Correspondence table for pipe diameters in mm and inches

| Nominal diameter of the pipe (Dy), mm | Thread diameter (G), inch | Pipe outer diameter (Dн), mm | ||

| Steel water and gas pipe | Seamless steel pipe | Polymer | ||

| 10 | 3/8″ | 17 | 16 | 16 |

| 15 | 1/2″ | 21,3 | 20 | 20 |

| 20 | 3/4″ | 26,8 | 26 | 25 |

| 25 | 1″ | 33,5 | 32 | 32 |

| 32 | 1 1/4″ | 42,3 | 42 | 40 |

| 40 | 1 1/2″ | 48 | 45 | 50 |

| 50 | 2″ | 60 | 57 | 63 |

| 65 | 2 1/2″ | 75,5 | 76 | 75 |

| 80 | 3″ | 88,5 | 89 | 90 |

| 90 | 3 1/2″ | 101,3 | 102 | 110 |

| 100 | 4″ | 114 | 108 | 125 |

| 125 | 5″ | 140 | 133 | 140 |

| 150 | 6″ | 165 | 159 | 160 |

Seamless pipes: dimensions and characteristics

Seamless pipes are made by hot rolling from blanks called “sleeves”. To improve surface quality and increase dimensional accuracy, hot-rolled products are subjected to various types of cold deformation. The production of metal seamless hot-deformed pipes is carried out in accordance with GOST 8732-78, cold-deformed - with GOST R 54159-2010. The marking of rolled pipes indicates the outer diameter and wall thickness, expressed in millimeters.

Table of sizes and weights of hot- and cold-formed steel pipes of standard sizes

| Outer diameter, mm | thickness , mm | Weight 1 m, kg | Outer diameter, mm | Wall thickness, mm | Weight 1 m, kg |

| 3,5 | 2,46 | 108 | 6 | 15,09 | |

| 6 | 7,99 | 108 | 10 | 24,17 | |

| 60 | 8 | 10,26 | 114 | 5 | 13,44 |

| 4 | 5,82 | 133 | 5 | 15,78 | |

| 8 | 11,84 | 133 | 6 | 18,79 | |

| 9 | 14,21 | 140 | 5 | 16,65 | |

| 5 | 8,76 | 159 | 5 | 18,99 | |

| 76 | 6 | 10,36 | 159 | 6 | 22,64 |

| 8 | 15,98 | 159 | 8 | 29,79 | |

| 102 | 5 | 11,96 | 168 | 6 | 23,97 |

| 102 | 8 | 18,55 | 168 | 14 | 53,17 |

| 102 | 10 | 22,69 | 219 | 8 | 41,63 |

| 108 | 4 | 10,26 | 219 | 10 | 51,54 |

| 108 | 4,5 | 11,49 | 219 | 12 | 61,26 |

| 108 | 5 | 12,7 | 219 | 20 | 98,15 |

| 114 | 8 | 20,91 | 245 | 8 | 46,76 |

| 121 | 5 | 14,3 | 273 | 7 | 45,92 |

| 127 | 12 | 34,03 | 273 | 10 | 64,86 |

| 133 | 4 | 12,73 | 325 | 8 | 62,54 |

Stamp size

The height of the signs is from 5 to 30 mm, the width is from 3 to 12 mm - depending on the size of the pipe.

Classification

There is a conditional division into six classes:

1 - used for transporting low-pressure liquid and gaseous substances in irrigation systems. They make fences and supports, scaffolding, etc.

2 class - used in low and high pressure pipelines, for supplying petroleum products, gas and water.

3 class - works in conditions of high temperatures under pressure: heating boilers, petroleum cracking, nuclear technology.

4 class - thick-walled drill pipes that can withstand high torsional loads. They are used in the development of oil fields and other geological work.

5 The class is used in transport construction: carriages, cars, overhead cranes, drilling rigs and in furniture construction.

Class 6 – blanks used in mechanical engineering for the manufacture of: bearings, pump cylinders, receivers, etc.

Did you know that almost 90% of pipes manufactured in Russia are made of steel? Features of installing a pipeline made of steel pipes - read about methods of connecting pipes: soldering, fittings, couplings. Read about what is useful to know when soldering polypropylene water pipes here.

And here https://aquacomm.ru/vodosnabzenie/zagorodnyie-doma-v/avtonomnoe-vodosnabzhenie/trubyi/plastikovyie/press-kleshi.html you will find information about methods of connecting metal-plastic pipes - compression fitting, press fitting, press pliers.

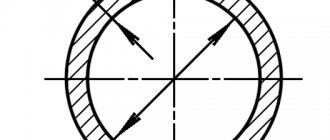

The diameter of the pipe is distinguished as follows:

- Up to 114 mm – small diameter pipes;

- From 114 mm to 480 mm – medium;

- From 480 mm – large.

Diameter of steel pipes according to GOST R

Small diameter (up to 114 mm.).

Small diameter pipes are not marked. An accompanying label with information is attached to them. The same applies to cold-deformed pipes up to 450 mm - they are transported in bags, and a label is attached to the entire bag.

The label contains the following information:

Small diameter pipes with information label

- Recipient's name;

- Order No.;

- Date/shift;

- Package No.;

- Batch number;

- Size;

- Standard (TU or GOST);

- Steel grade;

- Heat number;

- Pieces (number of units in the package);

- Theoretical weight kg. (if the order is in meters);

- Actual weight;

- Meters (total length);

- Recipient code.

Medium diameter (114 – 480 mm)

Pipes with a wall thickness of 3.5 mm and a diameter of 159 mm are marked each separately. Cold-deformed pipes from 159 – 450 mm, as a rule, three products from the entire package are marked and a label is attached.

Example of a steel pipe label

Large diameter (from 480 mm)

Marking with a diameter of 530 mm or more is allowed on the inner surface.

If the wall thickness is more than 10 mm, marking on the end of the pipe is possible.

The color of the paint may indicate the grade of steel from which the pipe is made.

Marking of a large diameter pipe on the inner surface

To make it easier to find the marking, it is usually marked with bright paint.

Example of boiler pipe marking colors:

Steel grade:

- 20 – green;

- 20PV – blue;

- 15GS – brown;

- 15ХМ – yellow;

- 12Х1МФ – red;

- 12Х1МФ-ПВ – orange;

- 15Х1М1Ф – white;

- 12Х2МФСФ – blue.

An example of paint marking of a seamless casing pipe with a threaded connection in accordance with GOST 632.

The combination of numbers “146 (E) 7.7 1083 304 OTTM A” means:

- 146 – diameter;

- (E) – strength group. “E” in brackets means that ultrasonic testing has been performed;

- 7.7 – wall thickness;

- 1083 – length (then there is an indentation of 30-35 mm);

- 304 – mass;

- OTTM – type of connection (short triangular thread is not indicated);

- A – execution (written only if option A);

- At the end is the plant's trademark.

Electric-welded pipes: range and technical characteristics

Electric-welded tubular products of round cross-section are metal products in demand for the transmission of liquid and gaseous media, in construction, for the creation of welded and prefabricated metal structures for various purposes. Available in spiral and straight seam. The assortment complies with GOST 10704-91.

Table of diameters, thicknesses and weights of electric-welded metal pipes according to GOST 10704-91

| Outer diameter, mm | Wall thickness, mm | Weight 1 m, kg | Outer diameter, mm | Wall thickness, mm | Weight 1 m, kg |

| 1,5 | 0,54 | 89 | 3,5 | 7,38 | |

| 1,5 | 0,61 | 89 | 4 | 8,38 | |

| 1,5 | 0,68 | 102 | 4 | 9,67 | |

| 1,5 | 0,87 | 108 | 3,5 | 9,02 | |

| 2 | 1,18 | 108 | 4 | 10,26 | |

| 1,5 | 1,13 | 114 | 4 | 10,85 | |

| 32 | 2 | 1,48 | 127 | 4 | 12,13 |

| 1,5 | 1,42 | 133 | 4 | 12,73 | |

| 3 | 2,89 | 133 | 5 | 14,26 | |

| 1,5 | 1,61 | 159 | 4 | 15,29 | |

| 45 | 2 | 2,12 | 159 | 4,5 | 17,15 |

| 1,5 | 1,72 | 159 | 5 | 18,99 | |

| 48 | 2 | 2,27 | 159 | 6 | 22,64 |

| 3 | 3,55 | 219 | 5 | 26,39 | |

| 57 | 2,5 | 2,97 | 219 | 6 | 31,52 |

| 57 | 3 | 4,00 | 219 | 8 | 41,63 |

| 57 | 3,5 | 4,62 | 273 | 8 | 52,28 |

| 3 | 5,4 | 426 | 10 | 102,59 | |

| 76 | 3,5 | 6,26 | 1020 | 12 | 298,31 |

| 3 | 6,36 |

Marking of water pipes

The marking of gas supply pipes contains information about the diameter of the pipe, the presence of insulation, the presence and type of thread, as well as other necessary information.

Labeled water and gas pipes

Let's look at an example of branding Ts-R-25×2.8:

- C – galvanized surface;

- P – thread;

- 25×2.8 – (inner diameter) x (wall thickness).

Some technical requirements

All steel water and gas supply materials are manufactured according to technical standards and have GOST 3262-75, as noted earlier. Production is carried out from types of steel (GOST 380 and GOST 1050) without standardization of the chemical composition and all mechanical qualities.

If necessary, the ends of the pipes can be chamfered at an angle of 40 degrees at the manufacturer's factory. With this type of work, an end ring is left, the width of which lies in the range from 1 to 3 mm.

It must be said that chamfers are removed from products whose wall thickness is more than 5 mm.

In addition, at the customer's request, threads can be applied to both ends. The condition is a conditional passage, which should not be less than 1 cm.

Among other things, individual water and gas supply elements can be equipped with couplings (GOST 8944,8954,8965 or 8966). In this case, each water and gas steel pipe must be equipped with one coupling.

The surface of the products must not have cracks, blisters or dents. There should be no delamination, chips or burrs at the ends.

The following defects are allowed:

- Risks;

- Individual dents;

- Traces of stripping;

- A layer of scale that does not interfere with inspection;

- Some manufacturing defects, but only if they do not reduce the wall thickness to the minimum value in some places.

Below is a table of correspondence of some parameters of water and gas products.

Range of water and gas pipes GOST 3262 75

GOST is a standard or sample recognized by the state. This set of rules and requirements controls the quality and characteristics of manufactured products, including long rolled metal products.

GOST 3262 75 includes the standards and requirements that a welded steel pipe (both galvanized and non-galvanized) must meet. Such products may have no thread or be present (cylindrical threaded or knurled).

These types of metal products have become widespread:

- in laying gas and water pipelines;

- in the production of individual parts used in the installation of water supply structures.

The range of steel water pipes must meet standards for several characteristics. In this list:

- outside diameter;

- conditional pass;

- wall thickness indicator (parameter measured in mm);

- weight of 1 m of product (measured in kg).

In the manufacture of steel pipes, several grades of steel specified in the requirements are used. This:

- carbon steel, made according to GOST 380;

- steel according to GOST 1050 - such raw materials are used for the production of parts necessary for gas and water supply structures.

International standard GOST R ISO 3183-1-2007

Pipes with a diameter of up to 48.3 mm inclusive are transported in bags, and the marking is applied with a stamp on a bandage or an attached metal label. The total length is indicated in meters and centimeters.

Requirements for pipes for pipelines according to GOST R ISO 3183-1-2007

Next, with a diameter of up to 406.4 mm, each pipe is marked with paint using a stencil on the outer surface. The length is indicated anywhere at the discretion of the manufacturer.

With a diameter of 406.4 mm inclusive and more, by default they are marked from the inside, unless the customer has specified another option. Apply using a stencil at a distance of 152.4 mm or more from the end of the pipe.

Marking of thick steel pipes at the end of the product

The stamp is not used to mark pipes closer than 25.4 mm from the weld:

- Steel strength groups above L175 without subsequent hardening;

- With a wall thickness of less than 4 mm.

Marking contains

- Manufacturer's trademark or name;

- Designation of the GOST R ISO 3183-1 standard (applied if the product fully complies);

- If it meets several standards, then all may be indicated;

- Designation of mass per linear meter;

- Steel class and strength group;

- Pipe forming method (S, W, F);

- Performed heat treatment;

- Test pressure (if tested above the standard pressure, this number is indicated in Pascals, after the word TESTED);

- There may be additional requirements.

Water supply systems made from steel pipes are used quite often, so you need to know about their properties and classification. Steel water supply pipes - sizes, diameters, materials, quality classes. You will learn about the technical characteristics of polyethylene pipes in this article.

Steel strength group

L320 and higher, with niobium content the letter C is indicated, vanadium - V, titanium - T.

Mechanical properties of materials for the manufacture of pipes - steel strength groups

The formation method or production process is indicated by:

S – seamless pipe; W – welded, except those made with a continuous seam; F – pipe made with a continuous weld.

Heat treatment is indicated by the following signs:

- Tempered and/or normalized pipe – N;

- Subcritical stress relief – HS;

- Subcritically cured – HA;

- Quenched and Tempered – Q.

The supplement includes

A paint spot with a diameter of 50 mm can be applied, which corresponds to the steel strength group, this applies to pipes over 114.3 mm in diameter, strength group L320 and higher.

Used color combinations for pipeline markings

Table of correspondence:

Pipes L415

- L320 - Black color;

- L360 - Green;

- L390 - Blue;

- L415 - Red;

- L450 - White;

- L485 - Violet;

- L555 - Yellow.

Reading example

"X GOST R ISO 3183-1-2007 14 54 57 L245 S"

Let's decipher:

- “X” – trademark;

- "GOST R ISO 3183-1-2007" - GOST;

- "14" - size;

- “54, 57” - mass;

- “L245” - steel strength group;

- "S" - seamless.

If the pipes have been subjected to treatment, such as heat treatment, then any markings that no longer correspond to the condition must be removed.

Couplings for products are also marked in accordance with standards and contain:

- Manufacturer's name;

- Steel strength group;

- Standard designation.

The threads on pipes are marked with a stamp or paint next to the thread; if the manufacturer of the pipe and thread are the same, then the trademark may be omitted.

Example of pipe marking with explanation

Thread marking according to GOST is carried out separately and does not give the right to claim that the entire product meets the same standard.

It can be quite difficult to understand all the intricacies of marking, but once you have mastered this “literacy”, one look at a steel pipe will be enough for you to learn everything, or almost everything, about it!

What can be used for marking?

For marking the following can be used:

- Indelible paint.

- Electrographs.

- Electric inkjet printing devices.

- Branding.

No data is applied to some types of pipe products, and for those that must have markings, the marking method is selected depending on the grade and main parameters of the pipe.