Silver and its properties. When is silver soldering necessary?

(function(w, d, n, s, t) { w[n] = w[n] || []; w[n].push(function() { Ya.Context.AdvManager.render({ blockId: "RA-805736-2", renderTo: "yandex_rtb_R-A-805736-2", async: true }); }); t = d.getElementsByTagName("script")[0]; s = d.createElement(" script"); s.type = "text/javascript"; s.src = "//an.yandex.ru/system/context.js"; s.async = true; t.parentNode.insertBefore(s, t) ; })(this, this.document, "yandexContextAsyncCallbacks");

Silver is a “white” precious metal that is actively used to create jewelry. Its sacred properties have been known since ancient times, but it was precisely its physical properties, such as softness, plasticity, and fusibility that made it popular in the jewelry industry.

When it is necessary to restore a broken piece of jewelry or correct a deformed area, silver soldering is used.

Soldering silver is used not only for repairing jewelry, but also for making new products or updating old ones. 925 standard is used as a basis.

Soldering a silver ring

The Importance of Silver in Ancient Times and Today

In ancient times, silver was considered a sacred metal. It was used to create amulets that protected people from dark forces and evil spirits. Gradually, this metal began to gain popularity as jewelry. In addition to making rings, earrings, pendants and chains, people made silverware.

Silver was often called lunar material and could only be worn by members of the nobility or people associated with religious teachings. This material was not available to ordinary peasants. Gradually money (coins) began to be made from silver. Now this metal is used for making jewelry, as well as in electrical engineering (silver plating, contacts).

Safety precautions for repair work

Since soldering is a process that involves the use of acids, a high-temperature soldering iron and a gas torch, it is necessary to follow basic safety rules:

- work is carried out only on a fire-resistant surface;

- When working with acid, you must use tight rubber gloves and safety glasses;

- the gas burner flame must be extinguished whenever work stops;

- A special stand is used for the soldering iron.

The action of the acid is neutralized by simple baking soda. You need to put it on a saucer next to you to remove the acid if it suddenly gets on your skin. Afterwards, the surface of the skin is washed with water.

Solder selection

The selection of the appropriate type of mixture when soldering steels is carried out in accordance with the structure of the raw material. Solders containing silver make it possible to produce strong seams with a uniform, dense cut. These types have increased anti-corrosion properties, which makes it possible to use them with substances exposed to aggressive environmental influences.

For home use and household needs, ordinary products are used, a mixture of which contains tin and a small amount of silver; soldering can be used for radio equipment and other household appliances.

To repair fittings, various pipes and other substances with a copper content of more than 57%, a structure marked PSR-12 is used. For structures with high requirements for reliability and strength, it is important to use more saturated materials. You need to know that there are products with a silver content of up to 70%.

Solder POS-40

POS-40 in packaging

As an alternative to tin soldering, silver-zinc is used. The price of such a product is high, but it pays off when used with steels of increased brittleness. Common solder in radio engineering is POS-40 solder, which contains 2.5% silver.

Do-it-yourself flux preparation

There are several ways to prepare flux at home. Basic tools and materials that may be needed during manufacture:

- A gas stove heats the substance to a liquid state.

- A spoon is used to dose the powder.

- A steel container or mortar is used to grind solid rosin into small particles.

- Sealed storage container.

After preparing the powder, it is necessary to prepare a solvent. The element is heated to the required temperature, usually a solution with proportions of 1 to 1 is used. The solution prepared at home is mixed with a spoon until all particles transform into a liquid state. During the process, the mixture acquires a yellowish tint.

Technique for soldering a silver chain with a soldering iron

In order to understand how to repair a silver chain using a soldering iron, you must complete the following steps at each stage:

- Surfaces are cleaned of dirt and degreased with acid, and then wiped with a flannel cloth. It is advisable to perform everything on a sterile surface. This means that the fireproof stand is also pre-wiped and degreased.

- Two surfaces for soldering are heated with a soldering iron. It is important that the temperature of the surfaces becomes higher than the reflow temperature of the solder, otherwise it will not be possible to solder the silver chain.

- Molten solder coated with a layer of flux is applied to the surfaces.

- The surface is additionally heated with a soldering iron until the flux melts. The soldering iron tip transfers the melt from one surface to another, forming a connection.

- After cooling, a small groove forms at the joints, which must be sanded to a smooth surface.

If the master solders 925 sterling silver, then the polishing is done with high-precision tools.

Soldering a silver chain with a soldering iron

Soldering tool

At home it is possible to repair any item, the main thing is desire. Silver parts are no exception; jewelry often breaks or develops cracks after mechanical stress. A trip to a jeweler can cost a pretty penny, and the quality of the work and the material used may be questionable.

Soldering iron

It’s not difficult to do it yourself; it’s important to carefully choose a tool. At home, you can use a soldering iron. It is important to note that not every electric heating equipment can heat the tip to a significant temperature. A regular soldering iron can heat the tip up to 350 ⁰C, which is not enough to melt parts.

Jewelry repair shops use a gas torch; it can heat the steel to the required level. It is possible to operate with heating equipment with increased power and a thin tip, however, such actions can only be performed with solders that do not have a high amount of mixture in the structure.

Preparation of materials

An electric soldering iron is included for soldering radio parts using solders containing silver in the structure. It will not be possible to connect a piece of jewelry with a soldering iron due to the lack of sufficient performance. For operations with such components, a thermal drill is used, as well as the following materials:

- high-temperature-resistant raw materials – brick;

- rosin;

- acid solution;

- tweezers, brush, nippers;

- copper tongs, a small piece of rag.

Silver Soldering Tools

Colophonium is used as a flux for production. The purpose is to form a film to avoid interaction of the substance with oxygen during operation. For jewelry crafts, a special compound is used; if stores do not offer appropriate options, it is possible to make rosin yourself. Borax and potash are mixed in one to one proportions, powdered borax crystals are ground with potash, the result is flux.

Non-silvered solders

During production, it is highly recommended not to use products that contain lead. This is due to the fact that traces of lead are difficult to remove, and reliable fastening is obtained in isolated cases. Lead is also toxic, and jewelry is usually worn in visible places on the body. With prolonged wear, the skin may react to toxic lead, which can be absorbed into the skin.

Soldering silver at home using tin

Tin wires are used extremely rarely when working with silver metals; it is possible to fasten parts, but there are negative factors:

- the seam is noticeable, different metals will give off a tint in sunlight;

- Tin darkens when in contact with water or exposed to a high humidity environment.

For silver parts of printed circuit boards, a soldering element of the POS-60 brand, which contains a large proportion of tin, can be used. The release form often looks like a wire with a flux composition.

Soldering process on a gas torch step by step

Action plan when working with a gas burner:

- Darkening and traces of oxidation are removed from the surface of silver.

- A layer of liquid flux is applied to the soldering area.

- A small piece of solder is applied to the soldering site. Its dimensions should be comparable to the dimensions of the faces being connected.

- A flame from a torch is supplied to the soldering site, but so that the solder is not blown away.

- Once the solder begins to melt, the torch flame is gradually increased until the solder becomes molten and forms a single edge joint.

- After cooling, the joint is cleaned and polished. It is necessary to smooth out all roughness and clean off the remaining flux.

How the process itself works

Silver jewelry should be placed on a suitable surface that has low thermal conductivity and will not be destroyed by exposure to high temperatures, such as brick.

Then the place where the weld will be located needs to be coated with flux and a piece of solder placed there.

Now you can take the burner and smoothly move it towards the product. The treated area should warm up evenly. And as soon as the flux has completely melted, the heat must be increased and soldering continued until a truly reliable seam is formed.

If the solder and flux suddenly run out, you need to carefully add new portions of them to the same place.

Upon completion of soldering, the product must be cleaned of flux and solder residues. Sandpaper is suitable for solving this problem. Additionally, the surface of silver can be treated with a solution of citric acid for brightening or with an iodine solution for blackening.

Do not forget that soldering must be carried out in a ventilated area, and the person performing this operation must be protected by a mask or goggles

Solder quality: how to fix it efficiently

Soldering efficiency directly depends on the quality of the solder . In workshops where they repair jewelry, high-quality alloys based on silver with the addition of purified copper or tin are mandatory.

To give the solder a silver shine, up to 20% zinc powder is added to it, which, when melted, forms the corresponding color.

You can make solder yourself, but for this you will need a muffle furnace and the starting elements: tin, silver or copper. If soldering is done at home yourself, then it is better to buy a ready-made rod or wire. In this case, you can count on the quality of the future connection .

High-quality solder has the following characteristics:

- it has a uniform shade; if the solder is made in powder form, then it has a uniform structure;

- When melted, the solder does not bubble or “splash,” as this means the presence of contaminants in the alloy.

To test, you can preheat and melt a small piece of solder.

Soldering iron for silver

Solder joint strength

It is worth noting that solders made from alloys of silver with copper and zinc are quite universal and can solder any metals. Silver solder has the advantages of high strength, flow rate, wettability and corrosion resistance. A soldered joint with tin containing silver is stronger than lead. The disadvantage of silver solder is its high melting point and significant cost, since silver is a precious metal.

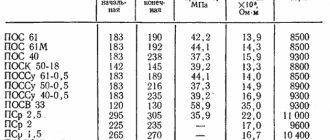

The strength characteristics of PSR-1.4 solder in comparison with other solders are shown in the table below. Even a 1.4% silver content in the solder significantly increases tensile strength while maintaining a low melting point.

The number in the name of the solder indicates the percentage of silver in it. Thus, alloys PSR-2.5, PSR-15 and PSR-25 can be used for soldering products that do not experience significant loads on the seam. To obtain a high-strength connection, PSR-45 solder is used, consisting of 45% silver, 30% copper and 25% zinc. It has high viscosity, malleability and fluidity. The solder joint will be resistant to corrosion, stretching, vibration and shock. Solders PSR-65 or PSR-80 have even higher strength properties, but have a high cost.

It must be said that silver solder is very difficult to find on sale, but you can make it yourself. How to make silver solder yourself and how to solder with a gas torch can be seen in the video.

Section question - answer

Is it possible to solder silver with a regular soldering iron?

Expert opinion

Grishanov Mikhail Petrovich

Jeweler, director of the Grishanov and Co. workshop

Unfortunately, soldering silver with tin is not possible due to the different densities of the metals. Tin is able to connect the edges, but even with the slightest mechanical force the decoration will collapse again.

How to repair a silver chain with your own hands at home, is it real?

Expert opinion

Pribrezhny Gennady Valentinovich

Jeweler 6th category

You need to buy special tools and accessories, ensure your workplace and work safety, use the manual and carry out the repairs yourself.

What kind of solders are used?

Silver additives are produced in different types and are used when soldering objects made of steel, as well as other alloys common in industry. Various parts contain other elements, the composition is reliable and has good quality indicators when connecting components. The main feature is the corrosion resistance of the connected components treated with silver.

In production, the most popular compounds are the PSR-10 and PSR-15 brands.

Soldering silver solution has different characteristics, the number at the end of the marking indicates the amount of precious metal in the composition. If there are high demands on the anti-corrosion resistance of the seam, grades PSR-70 and higher are used, however, such substances are expensive and are used by large industries. Soldering of silver is carried out according to various requirements, so the choice of composition before production must be approached competently.

Solder PSR-10

The form of release of material for soldering can be different, depending on the purpose and content of various alloys. It is sold in the form of powder or pieces of 2 mm or more; there are variations from a single sheet, which is easily cut with nippers to the required sizes. When working with wires, an element disguised as a wire is suitable; it is easy to transport and add in small proportions.

When you need the help of a jeweler. Table: cost of services in your city

If you urgently need the help of a jeweler to repair silver jewelry, then it would be advisable to contact a workshop at the nearest address. A set price list is provided for each type of soldering.

Soldering prices vary depending on the type of work and region.

Krasnoyarsk:

| Type of soldering | Price |

| Soldering iron | from 800 rubles |

| Gas burner | from 1000 rubles |

Tyumen:

| Type of soldering | Price |

| Soldering iron | From 1000 rubles |

| Gas burner | From 1100 rubles |

SPB:

| Type of soldering | Price |

| Soldering iron | From 1000 rubles |

| Gas burner | From 1100 rubles |

Moscow:

| Type of soldering | Price |

| Soldering iron | From 600 rubles |

| Gas burner | From 900 rubles |

Novosibirsk:

| Type of soldering | Price |

| Soldering iron | From 700 rubles |

| Gas burner | From 900 rubles |

The price is also determined by the complexity of the decoration and the amount of work.

How to solder silver with a soldering iron

Jewelry items are repaired using a gas torch or an electric soldering iron. Before soldering silver at home, it is important to determine the sample. High-grade metals are not exposed to the temperature of a soldering iron. If you have funds or a complex product shape, it is better to contact specialists.

It is prohibited to solder jewelry items with enamel or blackening, or hard soldering elements.

Fixed gemstones must be removed before soldering, otherwise they may crumble and deteriorate when exposed to high temperatures.

It is impossible to melt solid silver substances with a mains-powered electric soldering iron. For reliable fastening, high rates of melting of the substance are required; heating equipment forms a surface fastening of the elements.

Soldering silver with a soldering iron

Using an electric soldering iron, it is possible to fasten massive parts with silver solder; the tool is often used to work with lead-tin substances.

What you need for soldering

To solder objects made of silver, preliminary technical preparation must be carried out. To do this, space is freed up for the products to be soldered, and the necessary components and devices are placed, which include:

- fire-resistant material (asbestos sheet or brick);

- wire cutters, tweezers, copper tongs;

- gas burner or soldering iron;

- small brush;

- textile;

- silver type solder with flux;

- sulfur liver;

- acid solution for etching.

Having prepared all the required substances and tools, proceed directly to work.

How to do soldering?

The information that, starting from the early Middle Ages and the emergence of the first production workshops, people used soldering to join (alloy) two parts of the same precious metal, came to us with preserved jewelry, on which a rough seam is clearly visible.

Gold jewelry of the Middle Ages was massive and, therefore, some unevenness of the seam was not noticeable.

As before, there and now the connection of two metal surfaces is carried out using a third, which melts at a much lower temperature.

By heating all three surfaces (using a torch or laser), the low-melting surface melts and spreads over the parts to be joined.

Once solidified, the soldering forms a hard bonding layer of alloy, which is then ground to make it invisible.

The low-melting alloy surface that creates the bonding layer is called solder and is usually produced in the form of rods.

Each metal requires its own solder and even several.

When the edges of the surfaces to be soldered heat up, an oxidizing strand appears on them - an oxide that interferes with the strong adhesion of the welded layer to the base.

Moreover, it not only worsens the connection, but can lead to an instant break after cooling.

To prevent this, flux is used - a substance that, when heated, neutralizes the acidic film.

The flux is not only selected for each metal or alloy, but also depending on the further use of the item, the load on the solder joint, solder and a number of other parts, the flux must be different.

If solder for melting gold can be purchased or made independently (for example, from silver, copper, brass and 880-grade dental crowns), then you only need to buy flux.

The solders, which were used back in Kievan Rus, contained mercury or cadmium.

Nowadays it is extremely rare to find such solders and, probably, it would be redundant to say that they are very toxic and it is better not to use them.

According to the method of creating the connecting layer, laser soldering of the alloy and soldering, which uses a gas burner at home, stand out.

How the burner works:

- We prepare or purchase solder depending on the gold standard;

- Apply flux and wait until the flux spreads along the edge of the surface. Choose only the appropriate flux. Distribute the flux beyond the soldering area. This is done so that the prepared area is slightly larger than the soldering itself - it may have to be expanded during the soldering process;

- It will take feka. It is a bent tube with a hole at the end through which the burner supplies a thin stream of gas flame. Compressed air is supplied through the inner surface of the faucet;

- We join the two broken parts, heat them with a blowpipe, add solder until it stops shining, and leave it to cool, after which we clean it with a file.

Gas soldering helps restore gold; if soldering is done carefully, the seam will not be visible. Soldering, which uses a torch, can be done independently.

There are also professional methods for repairing gold that are used in jewelry workshops, for example, laser soldering.

It will allow you to repair a torn piece of jewelry completely unnoticed, regardless of the complexity and location of the break, gold standard and other conditions.

Laser soldering is performed using a laser beam directed by special equipment.

It is quite expensive and there is no need to purchase it for one-time soldering of gold.

Laser soldering has a number of advantages over gas soldering:

- Spot heating of the surface;

- No need to use flux;

- Inability to overheat the place where parts are soldered. Overheating is often a critical error when soldering gold. As a result, the adhesive seam will change color and it will not be possible to restore the original color using chemical methods. If this happens, then the entire product must be coated with an additional layer of gold using the electrochemical method;

- Soldering is possible for areas of several hundredths of a millimeter;

- There is no mechanical damage to surfaces, the laser acts accurately, precisely and without contact with the surface;

- The method allows you to prevent foreign particles from entering the soldering area.

Laser soldering is performed without changing tools; all necessary settings are adjusted on the control device.

It is imperative to use it when the decoration has a complex design, a complex break, or when it is not possible to do gas soldering yourself.

Why does the chain around your neck break?

If you believe superstitions, this sign has a dual explanation.

- If the chain with a cross breaks, God gives you the right to choose your own path.

- Another explanation says that people with negative energy have appeared in the environment, who wish evil, cause damage, and the sacred symbol neutralizes this effect.

- If the chain with the cross breaks, but you managed to catch the cross, health problems lie ahead.

If we discard all signs and superstitions, the breaking of the chain is explained either by careless handling or poor quality of the product.

“Close my love around your neck, I live to adorn you - you are my jewel,” said Grace Livingston-Hill (American writer). Careful and careful handling of jewelry will prolong the joy of “communication” with it for many years.

Selection of material for joining metal products

Solder for soldering silver can be purchased at any hardware store. It is better to give preference to refractory substances whose melting point is at least 240 °C. In this case, it is advisable to use specialized soldering paste or alloys marked PSR-2.

You can make your own solder for joining silver products. It must include the following metals:

These components can be melted in a submerged muffle furnace. The resulting mixture must be poured onto a substrate, and then passed through a rolling machine to create plates about 0.5 mm thick.

To create permanent connections between parts, strips with a width of about 1-3 mm are used. Pieces of the required length are cut from them. During soldering, air is exposed to the area being joined. To prevent oxidation and other negative reactions, it is necessary to use flux (colophonium). When the solder is heated, it is moderately distributed throughout the metal, isolating the welding area.

What to do if the chain is stretched

Since silver and gold are soft metals, the weave can stretch out if not handled carefully. First of all, this applies to products made from low-quality alloys or with complex filigree weave. Under severe external influence, a stretched silver chain or gold weave becomes irreversibly deformed.

Heavy gold chains in the Sunlight catalog

If a gold chain of simple weaving has stretched, you can independently remove some of the “extra” links to the previous length. If the weaving is complex and multifaceted, then regardless of the material, it is better to seek the help of a specialist.