The reinforcement can be used either individually or as part of complex structures. To create complex structures, reinforcement parts are often connected to each other. The main connection method is welding. Welding is carried out using equipment that locally heats the edges of the parts, followed by melting and solidification. Welding of reinforcement can be carried out in various ways - overlapping, butt welding, hot welding, contact welding. But what electrodes should be used for welding reinforcement products? How to correctly determine the current strength? And how to control the quality of the work performed? In our article we will find out the answers to these questions.

Brief information

Reinforcement welding is the main method of connecting reinforcing bars. Using welding, you can connect rods of any length and shape. Welding can be carried out butt, overlap and crosswise. Spot resistance welding is also used in factory production. To carry out the work, standard welding equipment with automatic or semi-automatic supply of the electrode to the active zone is used. Welding of rods is recommended when inert gases are supplied to the core - this improves the quality of the weld and prevents corrosion in the core.

Welding helps to create a structure of any shape - mesh, squares, triangles, polygons. Welding of GOST fittings is carried out in protective clothing (suit, mask, gloves), which will protect a person from exposure to high temperatures. Welding work is recommended to be carried out in a dry, ventilated area, although if necessary, welding can be carried out at any time in the absence of strong wind and/or precipitation (rain, fog, snow). Welding work is regulated by domestic and international standards. The main governing law is GOST 14098-2014 (note that the old GOST 14098-91 was in force until 2014).

Technical requirements

5.1 When choosing rational types of welded joints and welding methods, you should be guided by the Appendix.

5.2 For the design of welded joints not provided for by this standard, working drawings should be developed with a technological description of welding conditions and a departmental regulatory document or enterprise standard that takes into account the requirements of current standards and approved in the prescribed manner.

5.3 When manufacturing reinforced concrete structures, it is allowed to replace the types of connections and methods of their welding with equivalent ones in terms of performance in accordance with the Appendix.

5.4 The chemical composition and carbon equivalent value of reinforcing steels of classes A240, A400S, A500S, A600S, Ap600S, A800S, A1000S welded according to this standard must comply with the requirements of GOST 34028;

(New edition, Amendment No. 1).

5.4.1 (Deleted, Amendment No. 1).

5.5 Cold-deformed reinforcement must meet the requirements:

— class B500С — current regulatory documents*;

__________

* GOST R 52544 is in force in the Russian Federation

— class Vr-1 — GOST 6727.

5.6 Reinforcement of unmeasured length of classes Ap600S, A800S and At1000S, as well as waste of this reinforcement, can be used in welded reinforcement products and embedded parts of reinforced concrete structures. In this case, the reinforcement is used as A400C class reinforcement without recalculating the cross-section.

Reinforcement of class A600C is allowed for use as anchors for embedded parts as reinforcement of class A500C without recalculating the cross-section.

(New edition, Amendment No. 1).

5.7 The designs of cross-shaped connections of reinforcement, their dimensions before and after welding must correspond to those shown in the figure and in the tables -.

| Figure 1 - Cross-shaped connection made by resistance spot welding |

5.8 The ratio of the diameters of the rods should be taken for connections of type K1 - from 0.25 to 1.00, type K3 - from 0.50 to 1.00.

5.9 For connections of type K1, the amount of precipitation (see figure) is determined by the formula

where: a is the total thickness of the rods after welding at the intersection, mm;

b - total size of dents (b' + b"), mm.

The relative precipitation values h/d'n for compounds of type K1 must correspond to those given in the table.

Welding techniques

Several technologies are used for welding reinforcement. The main techniques are bath welding of reinforcement, lap welding, creation of cross-shaped joints, contact technology. Below we will look at each technique in more detail.

Butt joint method

Bath welding of reinforcement is the optimal method for welding reinforcing bars. A pan is a U-shaped bracket to which steel rods will be welded. Bathroom technology allows you to obtain a high-quality, reliable seam that will not crack under the influence of mechanical shocks or chemically active substances. In addition, bath technology reduces the contact of the rods with the environment, so the risk of corrosion in this case will be minimal.

Welding work is carried out as follows:

- Using a metal brush, you need to clean the edges of the rods by 3-4 centimeters (a characteristic metallic sheen should appear at the ends). For better, faster processing, the brush must have a galvanized coating. After stripping, you need to rinse and degrease the edges so that they become clean.

- Now you need to place the edges inside the bath. For a more secure fixation, some craftsmen tie the bath with wire, and during welding the wire is quickly removed from the active zone. It is not recommended for beginners to manipulate the wire, since there is a high risk of welding the wire to the surface of the bath.

- Welding should be carried out at high currents (the optimal current is 400 amperes with an electrode diameter of 5 millimeters) using automatic or semi-automatic equipment. First, the edge of one rod is melted, then the second. After this, the operation is repeated until the bath is completely covered with molten metal.

The main advantage of bath technology is the low consumption of consumables. Another big plus is the ability to carry out welding work at subzero temperatures (the current strength needs to be increased by 15-20%). Both steel staples and staples made of other metal alloys (copper, brass, duralumin, cast iron) can be used as a bath. The use of graphite baths is also allowed.

Overlapping reinforcement welding

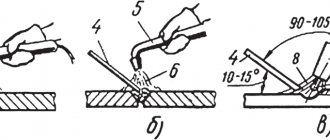

If the welded structure is not subjected to serious mechanical stress, then overlapping reinforcement welding can be used. The main advantages of the technology are simplicity, high speed of work, minimum consumables, and good reliability. The overlap of the reinforcement during welding must be complete to form a strong, large seam. It is recommended to carry out welding work from the lower rather than the upper position (this will ensure more active melting of the metal in the core). You can also perform side overlap welding at an angle of up to 15-20 degrees.

Optimal algorithm of actions:

- Clean the surface of the reinforcement using a wire brush or coarse sandpaper. It is also recommended to degrease the surface to obtain a high-quality weld in the core.

- Place the welded rods on top of each other. The optimal level of overlap is from 15 to 30 centimeters. It is not recommended to fasten parts with wire, since the wire will quickly melt when heated.

- Perform scalding on top in at least two places (at the edges). Then weld from below (in the center).

Cross welding

If you make a large volumetric lattice, you can perform cross-shaped welding of reinforcing bars. All work must be carried out in a strictly horizontal or vertical position so that the rods reliably press against each other. It is not recommended to weld at an angle, since it will be problematic to obtain a reliable, high-quality seam (the molten metal will actively drain or evaporate). The cross-shaped technology is also not recommended to be performed at negative ambient temperatures.

Features of cross-shaped technology:

- The optimal method for connecting rods is gas-shielded arc welding. The connection of the reinforcement should be made using short clamps with a short arc feed into the active zone.

- During feeding, the electrode should be at an angle of 30-45 degrees relative to the plane of the rods. Otherwise, melting will be less active, which will increase the work time and reduce the quality of the seam.

- To improve the fixation of the rods, tacks can be welded onto the reinforcement. It is recommended to apply them on both sides in order to fix the parts in both the lower and upper positions.

contact welding

Spot welding of reinforcement is a reliable method of connecting rods to each other. Welding requires the use of machine welding equipment, which is heavy. Therefore, in practice this technology has received little distribution, although it is often used in factory production. Contact spot welding looks like this:

- The rods are placed in a machine that looks like industrial pliers. Machine pliers securely fix the parts, and their position does not change during welding.

- Then the worker configures the machine using an electronic panel. The worker can choose all the technological features of the operation (current strength, processing depth, heating temperature).

- Then the worker starts the machine, which performs contact welding. During operation, the compressive surfaces are heated to high temperatures, which leads to melting of the reinforcement.

- During operation, it is possible to move the bars using a movable console. New machines can also move compression heaters, making them more versatile and easier to use.

Diameter and other parameters of fittings during welding

The main indicators of the modes during operation of the welding machine:

- electrode diameter;

- type, magnitude and polarity of electric current;

- arc voltage;

- speed of work;

- number of technicians.

With the contact method of welding reinforcement, one of the main indicators that affects the work as a whole, its quality and service life, is the strength of the current used.

The choice of electrode diameter depends on the thickness of the material used. It is important that the operating mode is based on the level of electrical current. If the electrode thickness is more than 4 mm, then it will be recommended to reduce the standard current by 10–15%. Reverse polarity mode is more in demand. When operating on direct electric current, thermal energy is actively generated, which increases the frequency of metal burns.

Rules for selecting electrodes

For welding reinforcing bars, it is recommended to use electrodes of the brands E42, SM-11, ANO-5, ANO-6, VSC-4, UONI-13. Advantages - high quality of the weld, minimal consumption during welding, good temperature stability, no corrosion risk. Electrodes of these brands can operate at low ambient temperatures, which will be very useful in winter. To weld standard fittings with a diameter of 5-10 millimeters, electrodes with a diameter of 2-4 millimeters are used. For larger spare parts, electrode parts with a diameter of 4-6 millimeters are used.

Also, do not forget to check the strength of the welding current:

- To work with popular electrodes with a diameter of 3 mm of the E42 or SM-11 brand, it is better to use a current of 100 to 150 amperes. For thicker electrodes, the current must be increased to 150-220 amperes (4 mm) or to 180-290 amperes (5 mm).

- Electrodes ANO-5 and ANO-6 with a diameter of 4 mm are welded using a current whose strength is 170-220 amperes. If the diameter is 5 mm, then the current must be increased by 40-60 amperes.

- Low-power electrodes VSC-4 are welded using a small current - 90-100 amperes (diameter 3 millimeters) or 120-150 amperes (diameter 4 millimeters).

- Also on the market you can find new electrodes of the UONI-13 brand. They should be cooked with a weak current - for devices with a diameter of 2 millimeters, a current of 30-50 amperes should be used. For every additional millimeter of diameter, you need to increase the current strength by 50-70 amperes.

Types of metal fittings

According to GOST 5781-82, rods are divided into the following classes: from A-I (A240) to A-VI (A1000). The most commonly used are:

- A-I (A240). Smooth rods of this class are made of steel grade St3. The steel can be hot-rolled, calm, semi-calm, or boiling.

- A-II (A-300). This reinforcement has the advantage of protrusions, due to which the adhesion strength to concrete only increases. For the manufacture of rods whose diameter does not exceed 40 mm, St5 steel (quiet or semi-quiet) is chosen. If the diameter of the rods is 40 mm or more, then 18G2S is preferred.

- A-III (A400). They have the same coupling advantage as the previous class. The choice is made on steel 35GS and 25G2S. The latter is considered an improved option, so the ends of the rods made of 25G2S steel are marked with white paint. This steel can be used for electric welding, since the rods acquire increased strength due to cold drawing.

This class of reinforcement is the most common; it is used in critical structures, including those where stress is artificially created during manufacturing.

According to GOST R 52544-2006, there are three more classes of reinforcement subjected to thermomechanical hardening:

- A500C. Hot rolled rods. Currently, this steel is often used instead of A-III. Its advantages: there are no alloying additives and can be used in arc welding.

- B500C. Cold rolled steel.

- At800. Hot rolled steel.

In reinforced concrete structures, two types of reinforcement are used:

- Longitudinal. This is the main type. Holds the design load.

- Transverse. Used to combine longitudinal reinforcement belts into a three-dimensional frame. Connects compressed concrete and stretched rods, takes on the forces from thermal expansion.

The diameter of the longitudinal reinforcement is larger than that of the transverse reinforcement.

Quality of work

After welding work, it is recommended to check the quality of the resulting seam. GOST rules do not provide precise instructions regarding the conduct of inspection work. Please note that this should be done after the connection has cooled completely (ideally the test should be carried out the next day). Most masters in practice use the following verification methods:

- Light blows with a hammer on the seam. Using a metal hammer, the structure is tapped at the seams. The blows should be light, but accurate. Before tapping, it is advisable to wash and wipe dry the striking part of the hammer (debris or water particles can negatively affect the quality of the blow). During inspection, the weld should not crack or peel; otherwise, the welding procedure must be repeated.

- Dropping the resulting structure from a height of 1-2 meters. If the welding work was carried out efficiently, then a fall from a small height should not cause any damage to the structure. It is advisable to dump the structure onto a flat, level surface that is free of debris. It is recommended to reset the structure 2 times - this will improve the quality of the test.

- X-ray examination. If the welding was carried out poorly, then all the microcracks and irregularities will be visible on the x-ray. X-ray examination is very accurate, reliable, and with its help you can obtain accurate information about the quality of the seam. The method has many disadvantages - additional costs for purchasing equipment, research cannot be carried out frequently, and difficulty when working with large structures.