Despite the abundance of new technologies in the production of materials, metal remains one of the most used and widespread to this day. Various types of metals, as well as their alloys, are used in all possible types of industry. Construction, electric power industry, mechanical engineering, defense industry, medicine... All areas of our lives are to one degree or another connected with this material. Naturally, quality indicators come first here.

The main indicator is the hardness of the metal . According to the definition, hardness is the ability of materials to resist elastic deformation, plastic deformation and (or) destruction in the surface layer from a harder embedded body (hardness tester indenter) that does not receive residual deformation.

For many test objects, sampling for the purpose of thorough laboratory testing is difficult or even impossible. The only qualitative indicator of the material available for measurement is hardness, which is determined by portable hardness testers.

In practice, measuring the hardness of metals makes it possible to study design features, options and subtleties of operation, analyze depreciation over time, obtain an idea of the results of temperature exposure, etc. This simple indicator will tell us how long a bridge will last, which pipeline to lay, whether this or that part will quickly wear out, what kind of sharpening a specific workpiece needs to be, how safe a car is, how long an implant will last, and much more. Thus, the hardness of metals is directly related to all the most important properties of the final product or structure.

Signs of metals

The following basic mechanical properties are distinguished:

- Hardness - determines the ability of one material to resist the penetration of another, harder one.

- Fatigue is the amount and time of cyclic impacts that a material can withstand without changing its integrity.

- Strength. It is as follows: if you apply a dynamic, static or alternating load, this will not lead to a change in shape, structure and dimensions, or damage to the internal and external integrity of the metal.

- Plasticity is the ability to maintain integrity and the resulting shape during deformation.

- Elasticity is deformation without violating integrity under the influence of certain forces, and also, after getting rid of the load, the ability to return to its original shape.

- Resistance to cracks - under the influence of external forces they do not form in the material, and external integrity is also maintained.

- Wear resistance – the ability to maintain external and internal integrity during prolonged friction.

- Viscosity – maintaining integrity under increasing physical stress.

- Heat resistance - resistance to change in size, shape and destruction when exposed to high temperatures.

What product characteristics are affected by hardness?

Specific criteria and indicators are important for each area. For example, wear resistance , which is the susceptibility of a metal to abrasion, surface destruction, and change in size during operation under certain conditions, is absolutely important in every area of use of this material. It is impossible to find an area where this indicator would not be just important, but even paramount, be it a children's construction set or a new viaduct, a surgical needle or a communications tower, a gas pipe or a wedding ring. Naturally, the higher the wear resistance, the longer the product will last, and the more expensive it will cost.

The next thing that hardness directly affects is the ability to process a particular metal or alloy and the type of processing. Here we can distinguish several large groups of processing methods:

- mechanical,

- casting,

- thermal,

- pressure,

- welding,

- electric,

- chemical

Of course, when choosing a method, several criteria must be taken into account (the main ones are the initial properties of the metal and the desired result), but the hardness of the starting material is one of the fundamental ones in this matter.

The hardness of metals also affects resistance to pressure and other forces. This is important, for example, for shafts or bearings that are subject to centrifugal and frictional forces.

The hardness of the material determines the possibility of using the product as a tool for working with other metal or non-metal products. Here we are talking about tool steel with a high carbon content (from 0.7% and above). Various tools are made from it for both industrial and home use: drills, cutters, hammers, pliers, files, surgical scissors, scalpels, etc.

The natural conclusion from all of the above is the recognition of the enormous importance of the hardness indicator of metals and the question of the likelihood of its increase.

!!! It is important to keep in mind that a certain hardness is expected for a certain product. There is no such thing as “the harder, the better.” Products with very high hardness are difficult to process and at the same time become brittle.

For example, the higher the hardness of the knife, the longer it will remain sharp, but problems with sharpening may arise, and with frequent use the blade will crumble and break.

Knives with a hardness below 60 HRC will serve a hunter or tourist for a long time, because... They are quite reliable: they withstand shock loads well, do not deform greatly, are resistant to corrosion, and are easy to sharpen.

Metal classification

Metals include materials that have a combination of mechanical, technological, operational, physical and chemical properties:

- mechanical confirm the ability to resist deformation and destruction;

- technological indicate the ability to perform different types of processing;

- operational ones reflect the nature of changes during operation;

- chemical ones show interaction with various substances;

- physical ones indicate how the material behaves in different fields - thermal, electromagnetic, gravitational.

According to the metal classification system, all existing materials are divided into two volumetric groups: ferrous and non-ferrous.

Technological and mechanical properties are also closely related. For example, the strength of a metal can be the result of proper processing. For these purposes, so-called hardening and “aging” are used. Chemical, physical and mechanical properties are closely interrelated, since the composition of the material determines all its other parameters. For example, refractory metals are the strongest. Properties that appear at rest are called physical, and under external influence - mechanical. There are also tables for classifying metals by density - main component, manufacturing technology, melting point, and others.

Black metals

Materials belonging to this group have the same properties: impressive density, high melting point and dark gray color. The first large group of ferrous metals includes the following:

- Iron - cobalt, manganese, nickel, iron. They are used as a base or additives to alloys.

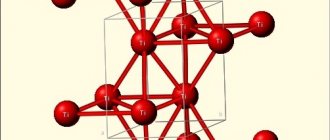

- Refractory - chromium, tungsten, molybdenum, titanium. All of them have a melting point higher than the level at which iron melts. Used as a base or additive for the production of alloy steels.

- Uranium – actinides and metals obtained as a result of synthesis. They are widely used in nuclear energy.

- Rare earths – neodymium, cerium, lanthanum. All metals have related chemical properties, but completely different physical parameters. They find their application as additives to alloys.

- Alkaline earth - calcium, sodium, lithium. In their free form they have no practical use.

The influence of chem. elements on the properties of steel.

Symbols of chemical elements:

| chromium (Cr) - X nickel (Ni) - H molybdenum (Mo) - M titanium (Ti) - T copper (Cu) - D vanadium (V) - F tungsten (W) - B | nitrogen (N) - A aluminum (Al) - Yu beryllium (Be) - L boron (B) - P bismuth (Bi) - Vi gallium (Ga) - Gl | iridium (Ir) - And cadmium (Cd) - Kd cobalt (Co) - K silicon (Si) - C magnesium (Mg) - Ш manganese (Mn) - G | lead (Pb) - AC niobium (Nb) - B selenium (Se) - E carbon (C) - U phosphorus (P) - P zirconium (Zr) - C |

INFLUENCE OF IMPURITIES ON STEEL AND ITS PROPERTIES

Carbon - found in steel usually in the form of a chemical compound Fe3C called cementite. With an increase in carbon content to 1.2%, the hardness, strength and elasticity of steel increase, but ductility and impact resistance decrease, and workability deteriorates, and weldability also deteriorates.

Silicon - if it is contained in steel in small quantities, it does not have a special effect on its properties. (Useful impurity; introduced as an active deoxidizer and remains in the steel in an amount of 0.4%)

Manganese , like silicon, is found in ordinary carbon steel in small quantities and does not have any particular effect on its properties. (A useful impurity; introduced into steel for deoxidation and remains in it in an amount of 0.3-0.8%. Manganese reduces the harmful effects of oxygen and sulfur.

Non-ferrous metals

The second largest group has low density, good ductility, low melting point, predominant colors (white, yellow, red) and consists of the following metals:

- Lungs – magnesium, strontium, cesium, calcium. In nature they are found only in strong compounds. They are used to produce light alloys for various purposes.

- Noble ones. Examples of metals: platinum, gold, silver. They have increased resistance to corrosion.

- Low-melting materials - cadmium, mercury, tin, zinc. They have a low melting point and are used in the production of various alloys.

The low strength of non-ferrous metals does not allow them to be used in their pure form, so in industry they are used in the form of alloys.

Copper and copper alloys

In its pure form it has a pinkish-red color, low resistivity, low density, good thermal conductivity, excellent ductility, and is resistant to corrosion. It is widely used as a conductor of electric current. For technical needs, two types of copper alloys are used: brass (copper with zinc) and bronze (copper with aluminum, tin, nickel and other metals). Brass is used for the manufacture of sheets, strips, pipes, wires, fittings, bushings, and bearings. Flat and round springs, membranes, various fittings, and worm pairs are made from bronze.

Table of relationships between hardness numbers according to Brinell, Rockwell, Vickers, Shore

Rockwell, Vickers and Shore hardness values indicated correspond to Brinell hardness values determined using a 10 mm diameter ball.

| According to Rockwell | According to Brinell | Vickers (HV) | By Shore | |||

| H.R.C. | HRA | HRB | Imprint diameter | HB | ||

| 65 | 84,5 | – | 2,34 | 688 | 940 | 96 |

| 64 | 83,5 | – | 2,37 | 670 | 912 | 94 |

| 63 | 83 | – | 2,39 | 659 | 867 | 93 |

| 62 | 82,5 | – | 2,42 | 643 | 846 | 92 |

| 61 | 82 | – | 2,45 | 627 | 818 | 91 |

| 60 | 81,5 | – | 2,47 | 616 | – | – |

| 59 | 81 | – | 2,5 | 601 | 756 | 86 |

| 58 | 80,5 | – | 2,54 | 582 | 704 | 83 |

| 57 | 80 | – | 2,56 | 573 | 693 | – |

| 56 | 79 | – | 2,6 | 555 | 653 | 79,5 |

| 55 | 79 | – | 2,61 | 551 | 644 | – |

| 54 | 78,5 | – | 2,65 | 534 | 618 | 76,5 |

| 53 | 78 | – | 2,68 | 522 | 594 | – |

| 52 | 77,5 | – | 2,71 | 510 | 578 | – |

| 51 | 76 | – | 2,75 | 495 | 56 | 71 |

| 50 | 76 | – | 2,76 | 492 | 549 | – |

| 49 | 76 | – | 2,81 | 474 | 528 | – |

| 48 | 75 | – | 2,85 | 461 | 509 | 65,5 |

| 47 | 74 | – | 2,9 | 444 | 484 | 63,5 |

| 46 | 73,5 | – | 2,93 | 435 | 469 | – |

| 45 | 73 | – | 2,95 | 429 | 461 | 61,5 |

| 44 | 73 | – | 3 | 415 | 442 | 59,5 |

| 42 | 72 | – | 3,06 | 398 | 419 | – |

| 40 | 71 | – | 3,14 | 378 | 395 | 54 |

| 38 | 69 | – | 3,24 | 354 | 366 | 50 |

| 36 | 68 | – | 3,34 | 333 | 342 | – |

| 34 | 67 | – | 3,44 | 313 | 319 | 44 |

| 32 | 67 | – | 3,52 | 298 | 302 | – |

| 30 | 66 | – | 3,6 | 285 | 288 | 40,5 |

| 28 | 65 | – | 3,7 | 269 | 271 | 38,5 |

| 26 | 64 | – | 3,8 | 255 | 256 | 36,5 |

| 24 | 63 | 100 | 3,9 | 241 | 242 | 34,5 |

| 22 | 62 | 98 | 4 | 229 | 229 | 32,5 |

| 20 | 61 | 97 | 4,1 | 217 | 217 | 31 |

| 18 | 60 | 95 | 4,2 | 207 | 206 | 29,5 |

| – | 59 | 93 | 4,26 | 200 | 199 | – |

| – | 58 | – | 4,34 | 193 | 192 | 27,5 |

| – | 57 | 91 | 4,4 | 187 | 186 | 27 |

| – | 56 | 89 | 4,48 | 180 | 179 | 25 |

Threaded holes

Table of drills for holes for cutting cylindrical pipe threads.

Wrench nut sizes

Basic spanner dimensions for hex bolt heads and hex nuts.

Read also: How to check the density of electrolyte without a hydrometer

G and M codes

Examples, description and interpretation of L and M codes for creating control programs on CNC milling and lathes.

Thread types

Types and characteristics of metric, pipe, thrust, trapezoidal and round threads.

Drawing scales

Standard scales for images of parts on mechanical engineering and construction drawings.

Cutting modes

Online calculator for calculating cutting conditions during turning.

Threaded holes

Table of drills and holes for cutting metric threads with large (main) pitch.

CNC machines

Classification of CNC machines, CNC machines for metal for turning, milling, drilling, boring, threading, reaming, countersinking.

Cutting modes

Online calculator for calculating cutting conditions when milling.

Drawing formats

Table of side sizes of main and additional formats of drawing sheets.

CAD/CAM/CAE systems

CAD computer-aided design systems, 3D programs for design, modeling and creation of 3D models.

Magnesium, titanium and their alloys

Magnesium is not resistant to corrosion, but there is no lighter metal used for technical needs. Basically, it is added to alloys with other materials: zinc, manganese, aluminum, which are perfectly cut and are quite strong. Alloys with light metal magnesium are used to make housings for cameras, various devices and engines. Titanium has found its application in the rocket industry, as well as mechanical engineering for the chemical industry. Titanium-containing alloys have low density, excellent mechanical properties and corrosion resistance. They lend themselves well to pressure treatment.

Anti-friction alloys

Such alloys are specified to increase the service life of surfaces subject to friction. They combine the following characteristics of the metal - good thermal conductivity, low melting point, microporosity, low coefficient of friction. Antifriction alloys include those based on lead, aluminum, copper or tin. The most used include:

- babbitt. It is made from lead and tin. Used in the production of liners for bearings that operate at high speeds and under shock loads;

- aluminum alloys;

- bronze;

- metal-ceramic materials;

- cast iron.

Brinell method

The Brinell hardness value is determined by the diameter of the imprint left by a hardened steel ball on the surface of the metal being tested. The unit of measurement is kgf/mm2.

The method was proposed in 1900 by the Swedish engineer Johan August Brinell. The test is carried out as follows: first, the preliminary load of the indenter on the sample is set, and only then the main load. Moreover, the material is kept under this load for up to 30 seconds, after which the depth of indentation is measured. Brinell hardness (denoted as HB) is calculated as the ratio of the applied load to the surface area of the resulting indent.

Some hardness values for various materials (Brinell):

- Wood – 2.6-7.0 HB.

- Aluminum – 15 HB.

- Copper – 35 HB.

- Mild steel – 120 HB.

- Glass – 500 HB.

- Tool steel – 650-700 HB.

Soft metals

According to the metal classification system, these are gold, copper, silver, aluminum, but among the softest are cesium, sodium, potassium, rubidium and others. Gold is highly dispersed in nature. It is found in sea water, the human body, and can also be found in almost any fragment of granite. In its pure form, gold has a yellow color with a hint of red, since the metal is soft - it can even be scratched with a fingernail. Under the influence of the environment, gold is destroyed quite quickly. This metal is indispensable for electrical contacts. Although silver is twenty times more abundant than gold, it is also rare.

Used for the production of tableware and jewelry. The light metal sodium has also become widespread and is in demand in almost every industry, including the chemical industry for the production of fertilizers and antiseptics.

The metal is mercury, although it is in a liquid state, therefore it is considered one of the softest in the world. This material is used in the defense and chemical industries, agriculture, and electrical engineering.

Hard metals

The hardest metals practically do not exist in nature, so it is very difficult to obtain them. In most cases they are found in fallen meteorites. Chrome belongs to the refractory metals and is the hardest of the purest on our planet, and it is also easy to machine.

Tungsten is a chemical element. It is considered the hardest when compared with other metals. Has an extremely high melting point. Despite its hardness, any necessary parts can be forged from it. Due to its heat resistance and flexibility, it is the most suitable material for smelting small elements used in lighting fixtures. The refractory metal tungsten is the main substance of heavy alloys.

Vickers method

Vickers hardness is determined by pressing a diamond tip shaped like a regular quadrangular pyramid into the sample. After removing the load, measure the two diagonals formed on the surface of the material and calculate the arithmetic mean value d (in millimeters).

The Vickers hardness tester is quite compact (see photo below). The test is carried out at room temperature (+20 degrees). The hardness value of a body is indicated by the letters HV.

Metals in energy

Metals, which contain free electrons and positive ions, are considered good conductors. This is a rather popular material, characterized by plasticity, high electrical conductivity and the ability to easily donate electrons.

They are used to make power, radio frequency and special wires, parts for electrical installations, machines, and household electrical appliances. The leaders in the use of metals for the manufacture of cable products are:

- lead - for greater resistance to corrosion;

- copper - for high electrical conductivity, ease of processing, corrosion resistance and sufficient mechanical strength;

- aluminum - for low weight, vibration resistance, strength and melting point.

Use of high-quality structural carbon steel

The scope of application is quite wide. The main consumers of alloys are the engineering and construction industries. One of the advantages is considered to be good weldability.

As the name suggests, “structural” means used for building metal structures. Another name is reinforcing steel.

Considering the main grades of quality steel used by industrial enterprises, they can be divided by purpose.

- High-quality low-carbon steels 05-10. Their main purpose is the production of responsible and high-quality structures using welding (increasing the amount of carbon helps to reduce weldability). A small amount of carbon after welding does not provoke the formation of cracks in both hot and cold conditions.

- High-quality low-carbon steels 12-20. Their main purpose is the production of structural elements and parts that are not critical, lightly loaded, and subsequently cemented. Processed by cutting, cold stamping, complex drawing. Surface requirements: wear resistance, high hardness with a soft core. We manufacture mechanical engineering elements (shaft, axle, bolt, coupling, fork, lever, flanges and others), as well as elements of boiler equipment operating at high pressure and temperatures from -40°C to 450°C (pipeline, tee, connecting flange and others).

- High-quality medium carbon steels 25-35. Parts made from this material operate under medium loads and low stresses. After chemical-thermal exposure, they have high strength of the surface layer, wear resistance, but with insignificant strength of the core of the part (nut, screw, pawl, hook, cam, sprocket, etc.).

- High-quality medium carbon steels 40-45. After heat treatment, products made from this material can withstand medium loads (shaft, gear, connecting rod, etc.) well. To obtain blanks, the method of hot die stamping is used. Subject to all methods of heat treatment. In all medium-carbon steels, after quenching and subsequent high tempering, the internal structure becomes tempered sorbitol. In connection with this, viscosity increases with plasticity, and this means low sensitivity of stress concentrators. As the diameter of the product increases, its hardenability decreases.

- High-quality medium carbon steels 50-55. Parts made from these steels are highly loaded elements of mechanisms and assemblies (clutch, gear, spring ring, etc.).

- High-quality high-carbon steels 60-80 (G). Parts are manufactured that are subjected to constant compression stresses, which are operated under friction conditions (eccentric, spring, spring, etc.), as well as those operating under heavy dynamic and static loads (torsion bar, cross).

- High-quality boiler steel 12K-22K. They are used in the manufacture of parts whose operation involves elevated temperatures and high pressure. To improve weldability, titanium is introduced into the composition, and deoxidation is carried out by aluminum. Vessels and boilers that work with turbines, combustion chambers on ships and steam units are made from it.

- Automatic steel. Widely used in the industrial production of fasteners for automobiles and assemblies operating under static loads (bolt, nut, stud).

Categories of Ferrous Secondary Metals

There are certain requirements for ferrous metal waste. To send alloys to steel furnaces, certain processing operations will be required. Before submitting an application for waste transportation, you must familiarize yourself with the GOST ferrous metals to determine its cost. Black secondary scrap is classified into steel and cast iron. If the composition contains alloying additives, then it is classified as category “B”. Category “A” includes carbon materials: steel, cast iron, additives.

Metallurgists and foundry workers, due to the limited primary raw material base, are showing an active interest in secondary raw materials. Using scrap ferrous metals instead of metal ore is a resource-saving as well as energy-saving solution. Recycled ferrous metal is used as a coolant for converter smelting.

The range of applications of metals is incredibly wide. Black and colored are used indefinitely in the construction and machinery industries. The energy industry cannot do without non-ferrous metals. Rare and precious ones are used to make jewelry. Both non-ferrous and ferrous metals are used in art and medicine. It is impossible to imagine a person’s life without them, from household supplies to unique instruments and apparatus.

Shore method

This method of measuring hardness was proposed by the American inventor Albert Shore. It is also often called the “rebound method”. In Shore hardness testing, a striker of standard size and weight is dropped from a specific height onto the surface of the material being tested. The key value of this experiment is the height of the striker’s rebound, measured in conventional units.

Shore hardness is measured in the range from 20 to 140 units. One hundred units corresponds to a rebound height of 13.6 mm (± 0.5 mm). According to the standard, this value is the hardness of hardened carbon steel. A modern device for measuring the Shore hardness of materials is called a scleroscope or durometer (it can be seen in the photo below).