The entry into the market of compact machines for semi-automatic welding and their high popularity have contributed to the expansion of the use of welding in almost all spheres of human life. Thus, with the help of semi-automatic, various car body repairs are carried out. Welding is also used in industrial or private construction. They are used to produce various metal structures.

In the process of working with the device, some components tend to wear out and become unusable. One of these components of this equipment is a sleeve for a semi-automatic welding machine. During operation, elements are subject to various external factors:

- High temperatures during welding.

- Drops of molten metal.

- Scratches.

- Various bends.

Inside the sleeve, its guides are abraded by the wire, which is fed to the welding zone. Naturally, all these influences adversely affect the device and disable it. Often, the sleeve for a semi-automatic welding machine is the first to break.

Types

Modern manufacturers today offer two types of welding hoses. This could be a hose itself or a burner. However, the appearance of these products is no different from each other. Both of these names refer to the same accessory.

Thus, a semi-automatic welding torch-sleeve consists of three main elements. This is the burner itself, the hose, as well as connectors for connecting them. Unfortunately, it is now difficult to find sleeves for sale separately. But you can purchase almost all the components of the design or find analogues.

Classification

It will be easier to choose a hose for gas welding if you know in advance what types exist. There are only three types, each corresponding to its own class:

- The first class is useful for working with propane, butane and acetylene; such a hose will withstand a pressure of no more than 0.63 MPa.

- A second class welding hose is useful for liquid fuels, such as kerosene or gasoline, and even white spirit solvent.

- The third class allows the semi-automatic device to work with only one gas - oxygen.

To make the hoses easy to distinguish from each other, they are painted in different colors. First class is always red, second is yellow, and third is blue. There is also a fourth, universal type, it is designated black or any other color other than the three basic ones.

Types of hoses for gas welding according to GOST 9356-75

There are also limitations in operating conditions. Some gas welding hoses can be used at extreme ambient temperatures of +70 degrees, but it cannot fall below -35. If you plan to work in very cold climates, you can purchase a welding hose that can work at -55.

The temperature capabilities of welding hoses may vary depending on their manufacturer.

Device

So, the sleeve for a semi-automatic welding machine consists of a rubber shell. Underneath there is a rather complex filling. Since semi-automatic welding requires a special wire, a complex system is located in the welding sleeve. It is a guide channel that feeds a spiral. There may also be a Teflon tube inside. Companies that produce components for welding may have different sleeve designs for semi-automatic welding machines.

Also, the work process requires the presence of protective gas. A separate hose is used to supply it. Depending on the brand and model of the device, the process of transporting and supplying wire and gas to the work area may vary. Along with the coaxial type, there is also a parallel type.

A positive power cable from the welding machine to the transformer also runs inside the sleeve. This cord goes to the current tip located on the torch. There are also two thin wires. They are connected to the start button.

Technical features

For proper semi-automatic welding, the device will require three components:

- A welding gun called a torch.

- A hose called a “welding sleeve”.

- A connector that allows you to connect the hose to the burner.

When using a torch, the hose fails more often than other parts, as it is abraded by wire from the inside and is subject to the influence of the external environment and mechanical deformations. It's all about its design, since it is a kind of multilayer hose, which has an inner layer that is in direct contact with the gas, as well as an outer protective rubber one. There can be any number of layers, depending on the production technology; they are separated by a special thread frame, which gives strength to the entire welding hose. The frame can be made of wire thread or fiberglass.

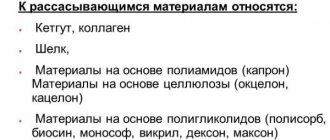

Consumables

A sleeve for a semi-automatic welding machine is a consumable material, or rather, a spiral responsible for feeding the wire. This part is also called a feed channel or a guide element.

The materials used for its production are wire or steel strip. However, the latter can also be made of plastic. The wire or tape is wound in the form of a spiral. Next, it is covered on the outside with insulating materials.

Due to the fact that the wire constantly rubs against the inner surface of the sleeve, the internal elements actively wear out. This is also facilitated by dust and dirt that gets inside along with the wire. The channel is especially susceptible to active wear if work is carried out with aluminum wire. For work with aluminum material, Teflon tubes are used.

These guide channels are “consumables” that must be changed periodically. The gas hose must also be replaced. It is prone to ruptures.

Construction of hoses for welding machines

A hose for argon welding, a gas torch or a cutter is a multilayer pipeline, the body of which is reinforced with a thread frame . That is, such a hose consists of an inner “pipe”, which is braided with threads of the load-bearing frame and covered with another, outer layer.

An elastic material with high resistance to pumped media (flammable gases, argon, helium and oxygen) is used as a structural material for the “inner” pipe and the outer layer. Typically, technical (black) rubber is chosen as such a material.

Moreover, the outer layer is made either of the same black rubber, or of vulcanized rubber with frost-resistant additives, to which a color is added that makes it easier to identify the hoses.

Thread or fiberglass is used as a reinforcing coating. Moreover, the coating is wound onto the “inner” black rubber pipe before applying the outer layer.

Welding Hose Classes

The classification of hoses is related to the characteristics of their operation. That is, the class of the hose is influenced by the type of welding machine to which such a “pipeline” is connected and the type of substance transported through it.

Based on these signs, there are:

- Oxygen hoses that can withstand high pressure (up to 20 atmospheres!). In the general classifier, oxygen hoses belong to the third class. Marking – blue color of the outer covering.

- Gas hoses that can withstand pressure up to six atmospheres. In the general catalog, such hoses belong to the first class. Moreover, this category should include hoses for gas welding or cutting, through which “fuels” are transported (acetylene, propane or butane), and hoses for argon-arc devices, through which inert gas is transported. Marking – black outer covering with a red stripe.

- Hoses for liquid fuel mixtures operating under pressure up to six atmospheres. This variety belongs to the second class, used in fuel lines supplying gasoline, kerosene and other flammable carbohydrates. Marking – black outer covering with a yellow stripe.

Moreover, the range of hoses is based on division by diameter and frost resistance class. Based on the first sign, hoses are divided into several varieties with diameters (internal) from 6 to 16 millimeters.

According to the second criterion, hoses are divided into two groups: the first is designed for operation in the range from – 30 to 70 degrees Celsius, the second – for operation in the range from – 55 to 70 degrees Celsius.

All varieties of the assortment go on sale in 100-meter bays. The price of welding hoses depends on their class, throughput diameter and is tied to the footage (length). Accordingly, the most expensive hose is oxygen (it is stronger), and “gasoline” and gas varieties are a little cheaper.

Reasons for element failure

If a semi-automatic welding sleeve with a mechanical valve has failed or the device has received mechanical damage, the part requires repair or replacement. In order not to spend extra money, you first need to diagnose the node.

If the welding seam turns out to be of poor quality, then this directly depends on the condition of the sleeve. A bad weld can be caused by wire jamming inside the element or by insufficient gas. Both reasons are grounds for replacing the hose separately or together with the burner. The last option is rarely used. More often they buy one new element, or make a welding sleeve for a semi-automatic machine with their own hands.

Marking

In order not to make a bad choice, in addition to the color, you need to pay attention to the markings that are applied to each gas welding hose. Usually it looks like this: III-9-2-HL GOST 9356-75. Here:

- III is a welding hose class, the third in this case. This can be understood by the blue coloring, but it is necessary to indicate the class on the labeling.

- 9 - diameter, in millimeters.

- 2 - design pressure, in MPa.

- HL is a designation confirming that the hose can be used in extremely cold climates.

Market offers and prices

The cost of the part from the kit together with the burner starts from one and a half thousand rubles. The most expensive device costs about 12 thousand. Channels for transporting wire will cost a maximum of 200-400 rubles.

If you need a Teflon tube, then it costs a maximum of 500-1000 rubles. Domestic sleeves can be purchased for 20-40 rubles. for each linear meter. The diameter of this hose is 6.3 mm. Therefore, it is not necessary to purchase the sleeve as a set. From purchased consumables you can make an excellent homemade sleeve for a semi-automatic welding machine.

Delivery of hoses for gas welding

Delivery cost in Moscow and the Moscow region: by courier - 500 rubles. (restrictions on courier delivery - no more than 50 kg and no further than 20 km from the Moscow Ring Road towards the region).

Delivery to other regions is carried out by transport companies. How to choose a transport company is described on our website in the Delivery in Russia section.

Contact number for receiving orders for delivery: +7 (495) 921-34-24 (accepted on weekdays from 9.00 to 17.00, on Saturdays from 10.00 to 14.00, and on the website - around the clock).

We do not divide orders into large and small; every customer is important to us. It's important that the next time you need something, you come back to our warehouse store.

How to choose

When purchasing semi-automatic welding kits, there are several important factors to consider. So, you need to know the model of the device and its functions. This can be work in environments of inert or active gases, argon arc welding or work with flux-cored wire. It is worth considering how the connecting elements are arranged. The most popular option is KZ-2. The ergonomic characteristics of the burner are also important. The handle should fit comfortably in the hand, and the button should be of sufficient size.

When choosing, you should pay attention to the diameter of the wire for which this or that device is intended. With ordinary welding devices, wire with a diameter of 0.6 to 1.6 mm is used. But specific devices can work with narrower size ranges - for example, 0.2-0.6 mm.

An important point when choosing is the maximum currents and sleeve thickness. Optimal for any welding work – 3 mm. But on sale you can find products of longer length.

How to choose a torch for a semi-automatic welding machine?

The semi-automatic welding sleeve is designed to transmit protective gas, wire and electric current that closes the arc. With use, the rubber shell cracks and gas begins to leak out. Possible cuts from sharp edges or melting from molten metal. The cable channel for feeding the wire becomes clogged with debris, which is why the wire feeds jerkily and with delays. In this case, it is necessary to replace the welding sleeve for the semi-automatic machine. Here we will look at the types of components, tips on selection and operation.

In this article:

It is difficult to find separate sleeves for a semi-automatic machine on sale. Most often they are sold complete with a burner and a connection connector, representing one whole. The sleeve itself consists of:

MIG torch disassembled

Compound:

| № | Description |

| 1 | Gas nozzle |

| 2 | Copper current collector |

| 3 | Copper diffuser |

| 4 | Spiral |

| 5 | Gander (Burner head) |

| 6 | Plastic nozzle |

| 7 | Sticker |

| 8 | Button |

| 9 | Screw |

| 10 | Burner handle |

| 11 | Plastic nozzle |

| 12 | Spring attachment |

| 13 | Coaxial cable |

| 14 | Spring attachment |

| 15 | Rear handle |

| 16 | Screw |

| 17 | Plastic nasa |

| 18 | Euro connector |

| 19 | screw |

| 20 | Key |

| 21 | Metal channel |

Some models use additional liquid cooling. At one end of the sleeve there is a connector that connects the supply of power current, gas, and wire from the drum. A chip comes from the connector for separate power supply of low-voltage control buttons.

The burner is fixed on the other side. It contains a mouthpiece for transmitting voltage to the wire, a nozzle that directs protective gas, a thermally insulating handle, and a control button. All this is a consumable material of the semi-automatic machine, wearing out with use.

Tips for choosing a PA welding sleeve

If only one element is mechanically damaged (channel, power wire, hose), it can be replaced separately. If all elements wear out naturally, it is advisable to immediately replace the entire burner with a sleeve or cable. Products are sold with a brief description of the characteristics, GOSTs and parameters, which we will now consider. Product codes and supplier articles (additional markings) are not important for selection, but are useful during repairs to select components.

Maximum current HideRead more

Maximum current strength is one of the most important parameters when choosing a welding hose with a torch for a semi-automatic machine. The characteristic varies from 150 to 550 A. The higher the indicator, the thicker the metal will be welded, provided that the semi-automatic machine is capable of delivering such a current.

If the maximum current strength of the torch is 200 A, and welding is carried out at 300 A, the welding sleeve will quickly overheat, the protective shell may melt, and the product will become unusable. When you often have to weld thick metal, choose a product with a rating of 350-450 A, such as a torch for a semi-automatic machine (Mig MAXI 450 Euro TW). For welding body metal with a semi-automatic machine, a sleeve with a torch up to 180 A is enough. A good option is BARSVELD MIG-15 (180 A, 4 m)

Sleeve length HideRead more

There are sizes from 3 to 5 m. It affects the maneuverability of the welder in order to move around a three-dimensional structure without dragging the semi-automatic device. If you often weld trusses, large containers, frames, you will need a 5 m welding hose. When work is carried out mainly at a welding table, a short torch of 3 m is sufficient.

Connection of the burner with the sleeve HideRead more

In budget versions, the sleeve goes inside the burner by rigidly fastening it. To avoid fracture, the manufacturer provides a small spring to prevent bending. Cooler versions, like the MIG welding torch, have a swivel joint. The sleeve rotates, but does not unscrew the burner. This is more convenient for making neat seams.

Channel diameter HideRead more

The channel through which the welding wire moves is made in the form of a rigid, dense spiral. It can be designed for diameters from 0.6 to 2.0 mm. When you often have to work with metals of different thicknesses, a large channel diameter will be a plus. You can alternate between installing spools of thin and thick wire, wasting minimal time. But if you only need to semi-automatically weld thin metal (1.0-2.0 mm), look for a sleeve with a channel of 0.8-1.0 mm. In it, the wire will dangle less and the feed will be noticeably smoother.

Frost resistance HideRead more

The parameter is prescribed in accordance with GOST 15150-69, indicating in which microclimate operation is permissible. Most products are produced with the “U” index, implying a temperate climate. If work is carried out outdoors in winter, choose hoses for semi-automatic machines with the “UHL” index. When welding on offshore oil platforms, torches marked “M” are used, which are resistant to cold, moisture and salts in the air.

Connector HideRead more

It can be Euro or regular pin. It does not affect the quality of welding, but only determines the method of connection to the semi-automatic machine. The connectors are not interchangeable, so check your owner's manual to see what type your welder has.

Ergonomics HideRead more

Good example of ergonomics

Very simple burners have a straight handle and a flat rectangular button. They are suitable for short-term welding from time to time. When you have to cook with a semi-automatic device every day for 4-8 hours, burners with ergonomic cutouts for fingers and a curved button are more convenient. Holding the torch requires less effort and makes your hand less tired.

Flexibility HideRead more

When working with a semi-automatic machine, the flexibility of the welding sleeve is important. This parameter is not specified anywhere, so you need to try it manually when purchasing in a store. Take the burner in your hand and lift it with your elbow bent to head level. If the sleeve does not form a vertical overhang from the bend, but sticks out further along the bias, this is a rigid option. It is only suitable for tabletop welding, and it will be inconvenient to crawl under large products or inside containers.

Cooling type HideRead more

Cooling can be air or water. In the first case, heat is removed naturally - it leaves the heated nozzle and mouthpiece into the air. This option is suitable for welding thin metals, as well as short-term welding of thick steels 10-20 mm.

For liquid cooling, two additional sealed tubes are provided in the welding sleeve of the semiautomatic machine. They reach the burner itself, and on the reverse side they are connected to the expansion tank. Ethylene glycol mixed with distilled water circulates through the system. The circuit contains a pump, a cooling radiator and a fan. Everything is very similar in principle to the engine cooling system in a car.

When the torch and hose heat up from welding, circulation starts, excess heat is picked up by the liquid and carried into the radiator. This allows you to work for a long time at high currents of 400-500 A without overheating and downtime. The purchase of a water-cooled welding hose is justified if such a function is present in the device itself. If it does not contain a block, then it can be purchased separately. A practical and reliable version of such a burner is Abicor Binzel RB 610 D WZ-2

Special configuration HideRead more

Most torches are made as thin as possible so as not to overload the welder's hand. But if you regularly have to cook in a ceiling position, molten metal and scale fall onto your hand. Even in leggings this is unpleasant, the threads of the seams quickly burn out and holes appear. In this case, choose a welding hose with a torch equipped with additional splash protection, such as the A-1231-5G3 torch

Tips for use and storage

In order for the welding hose to last longer, it is important to follow a number of simple rules during operation:

- Do not allow strong bends. During welding, this will complicate the wire feed from the drum and will affect the quality of the seam. When bent, you can permanently damage the supply channel and break the gas hose. Without shielding gas, the seam will become porous and weak. Sleeve bends with a radius of 30 cm or more are acceptable. It is best to place the hose package at a right angle.

- Try not to catch your sleeve on sharp corners or protrusions. They are capable of cutting the protective sheath, gas hose, and power wire insulation.

- If the welding sleeve of a semi-automatic machine gets into machine oil or fuel, immediately wipe it with a dry cloth. These substances can corrode the casing.

- Don't throw your sleeve under your feet. Other employees can easily trip over the hose package, step on it, drive a cart over it, or drop a heavy object on top of it.

- It is best to store the welding sleeve on the machine, hanging it on special hooks provided on the cart.

- When welding a seam in an overhead or vertical position, pay attention so that scale and liquid metal do not flow onto the sleeve. If necessary, cover the sleeve with a sheet of metal.

Summary table of the ratio of welding mode to material

To understand which welding hose is needed to work with certain welding currents, consider their ratio in the table.

| Plate thickness, mm | Current strength, A | Wire diameter, mm |

| 1.0-1.5 | 60-115 | 0.8-1.0 |

| 2.0-3.0 | 130-170 | 1.2 |

| 4.0-5.0 | 200-300 | 1.2-1.4 |

| 6.0 and higher | 300-400 | 1.6 |

In this case, the gas flow rate is adjusted within the range of 6-11 liters per minute so that the seam lies without pores. Each welder sets the wire feed speed individually within 30-45 m/min. Too high a speed will lead to a decrease in the electric arc, the wire will seem to pierce the weld pool. Low speed will cause the wire to melt far from the joint and cause a lot of spattering.

We recommend looking at a good selection of welding hoses for semi-automatic machines in the catalog of torches for semi-automatic welding machines (MIG-MAG). The catalog contains burners with hose packages of any characteristics described in the article. But popular models, popular among welders, are quickly dismantled. Hurry up to buy the one that suits your specific tasks.

Answers to questions: how to choose a welding sleeve for a semi-automatic machine?

Is it possible to lengthen the welding sleeve if it is not long enough? HideMore details

It is impossible to connect two sections of the wire feed channel. Crimping the power cable into the burner will create additional resistance. Therefore, it is not possible to extend the existing burner. “Lengthen” means replacing the burner with a sleeve with a new, longer one. The maximum size of a hose package for a semi-automatic machine is 5 m, but you can increase the length by installing an additional feed mechanism and connecting a welding torch to it.

Which connector is it better to buy a burner with? HideMore details

The connector is selected for a specific semiautomatic model. When choosing a machine for MIG welding, it is initially better to give preference to models with a Euro connector. When the welding sleeve is damaged or worn out, it will be easier to select a torch for it.

Is it possible to install a Euro connector in the body of the semi-automatic machine to connect the corresponding burner? HideMore details

Yes, you can. Only this entails reworking the device; such work can be carried out by a specialized center. You will need to remove the existing connector, disconnect all communications from it and build in Euro. You can do this work yourself or order it from a service center. But changing the design entails losing the warranty for the semi-automatic device, therefore, if the equipment is still under warranty, we recommend waiting until the end of the warranty period.

Will a liquid-cooled torch heat your hand when welding with a current of 300-400 A? HideMore details

No, it will not. In it, the cable through which the operating current flows is placed inside a sealed hose with antifreeze. Heat is taken by the liquid directly from the cable and carried into the expansion tank through the radiator. It’s comfortable for your hand because only the nozzle heats up.

What happens if the liquid cooling channel is damaged? HideMore details

This happens when heavy metal objects with sharp edges are dropped onto the welding sleeve. If the channel shell is cut, coolant will leak out. In this case, turn off the antifreeze circulation so that the pump does not build up pressure. You can replace the tube with a sealed one without replacing the entire hose (disassembling the hose package will be required).

Why does a wire get stuck in the sleeve of a semi-automatic machine? HideMore details

The cable channel and current collector do not correspond to the diameter of the wire. It is also possible that the cable channel may get into the cable channel... Sometimes this happens when the channel is clogged with dirt. To do this, you need to periodically clean the channel with a wire of a larger diameter than the one that is being welded. If this does not help, the channel is replaced with a new one (sold separately).

There are still questions

Leave your contact details and we will contact you shortly

Feedback

Return to list

Burner design

There are many manufacturers of welding equipment, but the torch design is the same for everyone. They differ in materials, sizes, critical temperature and power, and mechanisms for supplying a protective medium (gas, flux).

Considering the design of the burner, it is worth noting that the main elements are:

- nozzle;

- holder;

- tip;

- insulating sleeve;

- base with handle.

Burner tips and nozzles are made from different materials and therefore have different service life. Copper is widely used, but the duration of work also depends on its quality. To increase service life, the nozzles are made of tungsten. But at the same time the price increases. The average operating time of such tips and nozzles is 200 hours.

Due to the frequent change of consumables, these elements are made quick-changeable so that the welder can replace them with his own hands in a short time.

The handle is made of heat-resistant insulating material that protects the welder from electric current. There is a button on the handle that turns on the supply of protective gas before igniting the arc.

The handle is connected to the welding machine through a supply hose, which contains the following:

- power cable;

- twisted wire feed channel;

- channel for supplying protective materials;

- cooling circuit;

- connector for connecting to the device and feed mechanisms.

The standardized hose length starts from 2.5 m and reaches 7 m. The length depends on the location and type of work performed. To reach the weld at a height without lifting the apparatus, the sleeve must be of maximum length.

But it is worth remembering that the excess, folded on the floor in rings, when voltage passes through them, works like inductive coils and gets very hot. As a result, a short circuit may occur.

Principle of operation

The included gas torch for the semi-automatic machine is an actuator for producing a welding seam in a shielding gas environment.

Gas burner for semi-automatic machine

The operating principle is as follows:

- The torch is placed to the base metal at the arc formation distance.

- Before the arc starts, shielding gas is supplied to the welding zone for a few seconds.

- Voltage is supplied to the current-carrying tip, and accordingly to the electrode wire.

- In the welding arc, the electrode wire melts and drops with the gas flow into the weld pool.

- When the torch moves along the elements being connected, a weld seam is formed.

- The protective gas environment ensures a high-quality and clean seam.

During welding work, torch elements are exposed to high temperatures. Particularly affected are the gas nozzle, the current carrying tip and the electrode holder, also called the diffuser and gas divider.

Burner device for semi-automatic machine

- burner base;

- insulating ring;

- electrode holder;

- current carrying tip;

- gas nozzle.

Failure of, for example, the current-carrying tip prevents the supply of welding wire to fill the pool.