Soldering, as a technology for creating permanent connections of metal products, has an ancient history. And today, despite the leading position of welding processes, soldering of steel, aluminum, copper, and many other metals and alloys continues to be successfully used in various branches of technology.

The process of soldering metal alloys of different compositions has its own characteristics. This is due to the different melting points and chemical composition of the alloys. Soldering does not apply to some grades of steel.

How to solder steel parts

Often there is a need to fasten steel parts without drilling and without welding. Soldering steel will help. But how to do it correctly, because there are special nuances here. A few recommendations from experts.

What kind of steel solders well?

Some grades of steel lend themselves well to soldering, while others are soldered with great difficulty and do not want to be combined with any solder or with any flux. As a rule, soft steels "for nails" are easy to solder. At the everyday level, this can also be explained by the fact that the material is dotted with microscopic craters and irregularities. But there are also electrical grades that are especially hard and elastic, and are used for shafts and precision mechanics. It depends on your luck here...

The question is that it is impossible for a home craftsman to determine the brand by eye. You can only find out how well a given part made of steel, or an alloy close to it, is soldered by experimentation.

How to make a tin connection - procedure

It all depends on how successfully the part can be tinned and how strong the contact of the tin solder with the steel is. In order for the contact to be satisfactory, if possible at all, the following must be done:

- steel stripping, chemical stripping under solder;

- heating the part to the melting temperature of the solder, keeping the solder on the part under flux for some time in a fluid state.

Cleaning the steel is first done mechanically, using sandpaper, to remove layers of rust and dirt. Then a composition that reacts well with iron oxides is used as a flux.

The most harmless to use, but effective in this case, is orthophosphoric acid, which can be easily purchased at a car store as a “rust cleaner.”

The required power of heating devices depends entirely on the mass of the parts.

The process of soldering two steel parts

If you need to solder two large nails, then the power of one soldering iron 100 W will not be enough. To heat up a large nail or a similar weight steel part clamped in a vice, you need to use a hair dryer. Or a gas burner.

You will also need cotton wool on a stick to supply flux to the heating zone, and a soldering iron of 50 W or more.

The sanded steel is heated with a burner.

As a rule, steel parts that can be soldered develop a very strong bond with tin, i.e. When the metal is coated, it is tinned.

The same is repeated with another detail. Then the two parts located together are heated, and additional solder is applied to the contact area with a soldering iron.

How strong is the soldering of steel, can it be made stronger?

The strength of such a connection will be determined by many factors:

- strength of bond between solder and metal,

But in any case, the strength of tin soldering cannot be compared with what is commonly understood as the strength characteristic of steel or “metal welding”.

You can strengthen it by using another solder - special strong and more refractory compounds containing silver, zinc, copper, etc.

Another direction for increasing strength is to cover with solder not only the plane, but also the sidewalls of the part - covering the part with solder. Then the pull-off resistance under multidirectional loads will be greater.

Extra strong soldering, special solders

To use compounds that provide a strong connection with steel, with its own melting point of about 800 - 900 degrees, you need to use a graphite crucible.

The work should only be carried out by specialists in metal smelting. It is necessary to know the basics of metal melting, the procedure for handling melts and safety precautions. In general, soldering of steel with heavy-duty solders is performed at specialized enterprises.

Possible solder composition:

- 55% zinc, 45% copper, some silicon to increase fluidity.

The composition is melted under a layer of coal in a graphite crucible. Steel parts to be soldered are heated with a gas burner. Phosphoric acid is used as a flux. The melt is fed to the parts. As a rule, tinning and soldering are carried out during one heating of both the parts and the solder. But such soldering of steel is more complex than simple welding...

But in everyday life, where you need to “patch”, “attach”, “join” two steel parts, you need to use solders with a low melting point, such as lead-tin.

Soldering iron with tin solder

The soldering process is the chemical joining of two metals using solder. Moreover, the crystal structure of the metal does not change. That is, the connected parts remain with their technical characteristics.

The connection itself is quite reliable, but much will depend on the type of solder and soldering technology. In addition, it should be noted that not all metals can be joined by this process. Basic metals, especially steel (iron), can be soldered together.

The essence of the process

The essence of the soldering process is that metals are joined together using an alloy that has a melting point lower than the melting point of the substances being joined.

During soldering, materials are heated to the melting temperature of the solder. This ensures very strong adhesion (sticking) - the property of materials to adhere to each other at the molecular level.

However, the main parts do not melt and mix with the solder material, as happens when welding using filler material.

Three technologies

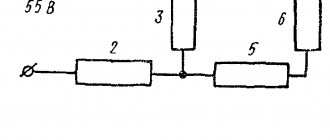

There are three technologies for soldering iron with tin:

- soldering iron To do this, you will have to use soft solders with a high lead content;

- blowtorch. This will require hard solders with a high tin content;

- electrical soldering of iron.

The first method is used if the iron will not be subjected to heavy loads during operation. The second is tinning of iron with tin, when tin solder is applied to the surface of a metal product and rubbed over its entire plane in a thin layer.

Constructive

This type of steel is characterized by the presence of chromium, used as an alloying additive. Thanks to chromium, steel acquires the necessary mechanical characteristics.

However, the presence of this alloying component significantly complicates the soldering process, since a fairly strong and difficult to destroy oxide film is formed on the surface of structural steels.

You can solder steel with the addition of chromium using an active flux containing acids. In addition, to obtain a high-quality result, special devices are used that create a protective atmosphere in the soldering area.

In addition, the steel surface prepared for soldering is coated with a layer of powder containing metal components. This protective layer prevents oxidation of the steel surface and burnout of alloying elements during heating.

Brazed joints on alloy steels are made using hard solders containing copper, silver or nickel.

Soldering sheet metal

Soldering tin (thin sheet iron) is a common process in the manufacture of metal containers. But often, even at home, it is necessary to fasten sheets of iron together, assembling sealed structures. Therefore, before soldering one sheet to another, you need to prepare everything you need.

For the process of soldering iron with tin, you will need solder with a small concentration of tin, for example, POS-40, flux, a soldering iron and an awl.

In the process of soldering iron, flux acts as a solvent and an oxidizing agent at the same time. That is, the metal is immediately wetted and protected from oxidative processes. Rosin and hydrochloric acid or zinc chloride and boric acid are used as fluxes.

As for the soldering iron, for high-quality tin soldering it is better to choose an electric tool with a power of more than 40 W. The old soldering tool, which is heated by the flame of a fire, is practically not used today, even at home.

How to solder iron

To solder iron at home, you will need tin solder with a small tin content, for example, POS-40, active flux, an awl and a soldering iron. When soldering metal, flux acts as an oxidizing agent and solvent, protecting the soldering area from oxides.

For these purposes, you can use both active fluxes and rosin, as well as zinc chloride, hydrochloric and boric acid. When soldering iron using active fluxes and acids, it is imperative to adhere to safety precautions. Have a well-ventilated area and protect your skin and eyes from exposure to harmful chemicals.

Sequencing

Here are the main stages of this process:

- cleaning of joined sheets;

- applying flux;

- heating up the soldering iron and tinning;

- soldering with tin;

- cleaning the joint with gasoline.

Cleaning is carried out mechanically with sandpaper. If the contamination is large, you will have to treat it with a solvent. If it is not possible to clean it using this method, then etching is carried out with sulfuric acid.

Two pieces of sheet iron are brought to each other at a distance of 0.3 mm. Their edges are treated with paste-like flux using a brush. The soldering iron tip is cleaned with sandpaper, and the tool itself is plugged into the electrical network through an outlet. To check whether it has heated up well, you need to place its tip in the ammonia mixture, which should boil.

Now the stage of tinning the iron is carried out. That is, using solder made of tin or its alloy, the edges of two sheets of tin are processed in order to cover them with a tin layer, which will perform protective functions against metal corrosion.

Everything is ready, all that remains is to solder the two ends of the sheets. The soldering iron tip is brought to the joint along with the tin solder, and they both move smoothly along the joint boundary.

In this case, the tip must be pressed not with a sharp end, but with a flat edge, due to which the parts being connected will warm up at the same time, which will affect the high quality of the iron soldering..

Application of flux

In order for the solder and the wire material to interact with each other, and the connection to be high-quality, the wires must be cleaned of the oxide film and only then soldered. For cleaning, you can use sandpaper, and for subsequent processing, use a special substance - flux.

Flux will not only clean copper wires, but will also create a thin protective film that prevents oxidation of the material.

It is allowed to use both solid flux - pine rosin, and liquid - various types of soldering acids or a homemade composition.

Sometimes, in order to correctly and firmly solder copper wires to each other or to any metal object, they use only liquid flux. You can prepare it by dissolving ordinary pine rosin in ethyl alcohol. Soldering acid is prepared independently by dissolving zinc granules in hydrochloric acid in the proportion of 412 grams of zinc per 1 liter of acid. But it’s better to buy ready-made flux that meets all quality standards, since bringing acidic compounds to copper wires is undesirable.

Features of working with galvanized products

Soldering galvanized tin in a purely technological process is no different from the previous one. But the technology has its own subtle nuances that affect the quality of the final result.

You cannot solder galvanized steel with solders that contain large amounts of antimony. This substance, when in contact with zinc coating, creates a weak seam.

It is better to use boric acid and zinc chloride as flux. If the products themselves have already been tinned with tin during the production process, then rosin can be used as a flux.

When a connection is made between galvanized iron (sheet) and wire, the latter must be bent at a right angle to increase the contact area of the two products.

The rest of the process is carried out exactly the same. By the way, it doesn’t matter whether the wire was made of galvanized or ordinary steel.

There are several more important points that must be taken into account in the process of soldering galvanized products. If solder rods based on tin and lead are used for soldering iron, then it is better to add flux based on zinc chloride and ammonium chloride. The ratio is 5:1 respectively.

Tin and cadmium based solder requires caustic soda as a flux additive.

If galvanized iron products, the protective layer of which contains more than 2% aluminum, are connected to each other, then solder based on tin and zinc is used. And hydrochloric acid and petroleum jelly (stearin) are used as flux.

Regardless of which parts or assemblies are connected by soldering, it is necessary, after the process is completed and the seam has cooled, to rinse the joint with water to remove any remaining flux.

What is the best way to solder steel products?

We must immediately make a reservation and say that steel can also be soldered with tin. However, if we want to obtain a sufficiently strong and reliable connection, then it is preferable to use refractory solders containing silver and copper.

When using such solders, steel is soldered at a fairly high temperature, starting from 450 degrees. Therefore, using a regular 100-watt soldering iron for these purposes is not entirely advisable here. Gas burners are mainly used.

Also, you should know that there are different fluxes for soldering. Some of them require washing off with soap and water, others do not. Fluxes based on hydrochloric and orthophosphoric acid must be washed off.

Safety precautions

Soldering iron with tin is an unsafe process. Therefore, precautions must be strictly observed. Protective gloves are put on your hands, and a stand must be installed under the soldering iron so that the heated tip does not touch the table and available materials. And the procedure itself must be carried out carefully.

Despite the apparent simplicity of the soldering operation, it is actually a serious procedure. And you need to treat it with great attention. Something was missed, they were even applied incorrectly, and we can assume that the quality of the joint has dropped sharply. Therefore, it is important to approach each stage responsibly, especially when it comes to cleaning two joined iron products.

How to solder metal correctly

Many people can solder wires and radio components, but not everyone can solder metal. In this article I will outline the principle of metal soldering as briefly as possible and with examples.

Introduction

Let's start with a general understanding of soldering. Soldering is a physical and chemical process of obtaining a connection as a result of the interaction of solder and the metal being soldered. It is similar to fusion welding, but there are still differences between them. When welding at the seam, the parts being welded melt, but when soldering, the material being soldered does not melt. Also, unlike welding, soldering is carried out at temperatures below the melting point of the metal being soldered. The formation of a seam during soldering occurs by filling the gap between the parts being connected with solder, i.e. the process occurs due to wetting and capillary effect.

Copper and aluminum connection

When connecting copper and aluminum wires by soldering, you can encounter many difficulties, which can only be overcome by using alternative connection methods.

The fact is that both aluminum and copper are covered with an oxide film in air. And if these films themselves do not affect the state of the conductor in any way and even provide fairly good conductivity, then when combined they contribute to the occurrence of a powerful chemical reaction. Under the influence of moisture contained in the air, at the point of contact between aluminum and copper oxides, the process of electrolysis begins, that is, an electric current is formed due to the fact that the ions of both materials have different electrical potentials.

Electric current is the movement of charged particles - ions, and during their movement, metals at the point of contact are destroyed. At the same time, aluminum is more destroyed. Destruction causes the contact to deteriorate, and subsequently the electrical resistance of the connection increases and it heats up. With severe corrosion, when direct contact between the two materials has already been lost, an electric arc occurs, which completes the destruction.

It is recommended to connect copper with aluminum only through a third, neutral material. Most often, steel terminal blocks or clamps are used for this.

Welding and soldering of metals are permanent connections. However, there is an important difference between these methods. When welding, metals are joined due to local heating of the part to a temperature where it begins to melt. The result is a connection of two parts into one whole. Soldering operation involves obtaining a strong connection between different parts or structures.

Metal welding diagram.

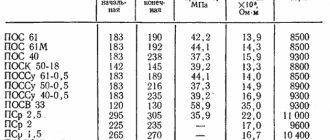

Solder selection

The correct solder for soldering stainless steel is the key to the quality of the connection. The following factors influence the choice of suitable material:

- metal composition;

- working conditions.

Under standard conditions, soldering is performed with silver solder - it has excellent anti-corrosion properties, and the nickel in its composition increases the strength of the connection. Visually, the connection will not differ from the main surface. Craftsmen consider silver compounds to be the best material for soldering stainless steel. However, it is prohibited to use silver without additives. To improve the quality of the connection, copper or zinc is added to it.

Features of tin soldering

Solders based on tin-lead mixtures are distinguished by high quality connections at an affordable price . This is the main reason for the popularity of soldering stainless steel with tin at home. The method has proven itself best when sealing small cracks or connecting small parts. Products subject to temperature loads during operation are recommended to be soldered using silver compounds. An example is distillation tubes, which are operated at high temperatures under pressure.

The use of tin as a filler material when soldering stainless steel is not widespread in industry due to the low temperature threshold of the connection.

Advantages

The use of low-melting solders has the following advantages:

- easy procedure for soldering small parts;

- preparatory procedures do not take much time;

- low cost of consumables;

- You can use either a household electric soldering iron or a gas burner.

Flaws

The method has the following disadvantages:

- low connection strength;

- the low melting point of tin reduces the scope of application of sealed parts;

- competent use of molten tin requires certain professional skills from the master.

Modes

Tin-lead solders are used with the following parameters:

- the maximum burner temperature is 240 Cº;

- minimum power of the soldering device – 40 W;

- surface exposure interval – no more than 10 seconds;

- The thickness of the solder, regardless of the form of manufacture, should not exceed 4 mm.

How to work at home correctly?

Soldering stainless steel is considered a rather complex process, so work at home should be approached with special attention. Most solders, with the exception of tin, require a soldering iron of at least 100 watts .

Do not forget about preparing the surface for soldering. This procedure begins with mechanical processing of the plane and ending with its tinning.

The use of active fluxes requires special attention - after completion of work, it is necessary to rinse the connection with running water.

Connection with other metals

When soldering dissimilar compositions, for example, soldering stainless steel with copper or bronze, it is necessary to carefully study the properties of the metals being joined . The main problem is the selection of temperature parameters, since the workpieces have different melting conditions.

Regardless of the type of metal, the contact area must be thoroughly cleaned.

As a working tool, you can use a soldering iron or a torch.

If silver solder is not available, brass-based compounds can be used. This will reduce the quality characteristics of the connection, but will allow you to save on consumables, since brass is cheaper than silver.

Tips for proper and strong soldering of metals

When working with steel or other metals, you must adhere to basic safety rules and also know some of the nuances of soldering.

How to heat and cool metal

An important step before starting work is preparing the workpieces. And here you need to know for sure which alloy you will solder or check it yourself:

- See how a metal workpiece reacts to heating with a soldering iron or torch. How quickly an oxide film forms on the surface. It’s better to know this in advance and for sure, otherwise subsequent work will be done in a hurry.

- It is best to warm up the prepared and secured parts gradually. Make sure that no overheated spots appear on the metal. The soldering area must be heated evenly over the entire area.

- Do not heat only the butt seam; also work on the area near the joint. Most often, you need to warm up 0.5 - 2 cm, depending on the purpose of soldering and the dimensions of the elements being connected.

- Use only soldering irons or torches that produce solder at operating melting temperature.

- Do not cool the finished seam with cold water or other liquids. Let the metal “rest” and cool evenly for several minutes in the open air.

- Remove soldered workpieces from a vice or clamps only after the solder has completely cooled.

Basic mistakes

The slightest mistake can lead to a significant decrease in the quality of the connection. The following tips will reduce the likelihood of errors:

- When doing homework, the optimal soldering iron power is 100 W. Using a more powerful device will lead to overheating of consumables, and a less powerful one will lead to incomplete heating of the metal.

- Use a soldering iron with a non-burnt tip.

- It is better to solder food utensils with pure tin, since lead has toxic properties.

- Experienced craftsmen recommend using active compounds as flux. Orthophosphoric acid has proven itself best.