Soldering stainless steel is a rather labor-intensive procedure, but it will not cause any special problems if you know all the features of its implementation. With significantly less labor, it is possible to solder stainless steel alloys that contain no more than 25% chromium and nickel. Moreover, soldering stainless steel with such a chemical composition allows you to obtain reliable connections of products from dissimilar metals, excluding alloys with magnesium and aluminum.

Solder repaired bicycle frame

Soldering stainless steel, which contains a significant amount of nickel, can be difficult. This is due to the fact that in such alloys, when heated to a temperature of 500–700°, carbide compounds appear. The intensity of the formation of such connections depends on the duration of heating, so soldering should be performed as quickly as possible.

To minimize the risk of the formation of carbide compounds in the stainless steel structure during soldering, titanium is added to the alloy composition, and after the joint is formed, the product is subjected to heat treatment. You should be very careful when soldering cold-worked stainless steels, the surface of which may become cracked under the influence of heated solder. To avoid such consequences, it is necessary to eliminate the load on the parts being connected during the soldering process. In addition, it is possible to pre-anneal the products being joined.

Use a gas torch for annealing.

The choice of solder with which to solder stainless steel is influenced by both the chemical composition of the alloy and the process conditions. So, if this process is carried out at high ambient humidity, then silver alloys should be used, which contain a small amount of nickel. Soldering in an oven, as well as in a relatively dry atmosphere, is performed using chromium-nickel and silver-manganese solders.

The most common type of flux used when soldering stainless steel is borax, applied to the future joint in the form of a paste or powder. Melting borax on the surface of the parts being joined contributes to uniform and most accurate heating of the area of the future seam to the required temperature - 850°. Only after the required heating temperature has been reached, which can be determined by the color change of the future joint to light red, is solder introduced into the joint between the parts.

The flux is applied in an even layer over the entire surface, which must first be cleaned.

After soldering is completed, flux residues are present at the joint, which are removed by washing with water or sandblasting. To perform this procedure, you cannot use nitric or hydrochloric acids, which, although they effectively clean the flux remaining on the surface of the parts, have a negative effect on both the base metal and the used solder.

Features of stainless steel soldering

Using tin and compounds based on it, you can repair stainless steel products, as well as assemble homemade structures that are small in size and not subject to heavy loads. Kitchenware and other household items can be repaired with a regular soldering iron and tin solder.

Soldering of stainless steel in production is performed using a more complex technology. For soldering of critical structures, special industrial mixtures containing Cr < Ni, Mn, chromium, nickel, and manganese are used. You have to work with them in a protective gas atmosphere - argon with the addition of boron trifluoride. Pure copper is used as solder when soldering stainless steel.

Soldering of ferrous metals

The quality of fastening of steel products depends on several factors:

- steel grades;

- porosity of workpieces;

- level of cleanliness of the joining seam.

Tin or brass alloys are chosen as solder. They are used depending on the task at hand. An easier way is to use tin. It is easier to work with, however, the final seam will not have a high level of strength.

Brass-based solders are much stronger, but you will need special equipment to work with them.

The work process at the preparatory stage is practically the same. In both cases, the parts are cleaned of dirt and rust. Fix with clamps or a vice. Orthophosphoric acid is used as a flux. After this comes the soldering stage.

Soldering steel with tin

When soldering with tin, select a soldering iron with a power of 100 W or more. To obtain a high-quality seam, both parts are pre-tinned, after which tin solder is fed into the finished seam and soldering is completed.

Soldering steel with brass

Brass melts at temperatures above 900 °C, so to work with such solder you will need a gas torch. It is important to heat both elements evenly. Otherwise, the brass will quickly melt. It will only adhere well to the edges of steel workpieces (which can cause brittleness and stress failure), which will contribute to the formation of cracks in the final product.

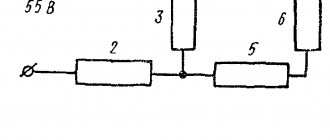

Equipment used

In order to properly repair products, you need to prepare materials, equipment and study technology. To solder stainless steel in a workshop at home, you will need:

- electric soldering iron with a power of 100 W (portable propane torch);

- flux;

- degreaser (solvent);

- abrasive paper, wire brush, needle file;

- tin solder;

- rags;

- protective equipment: gloves, respirator, safety glasses or transparent face shield.

Portable propane torch

In addition, for the initial heating of massive workpieces, a more powerful soldering iron may be needed. Phosphoric acid provides high-quality surface cleaning and rapid coagulation.

Useful tips

Soldering steel is a labor-intensive process, during which controversial issues may arise. In order not to get hung up on them, you need to take into account the advice and recommendations of other masters:

- An electric soldering iron with a power of 100 W is enough for home repair work. It is advisable to choose a model with a non-burning tip.

- The best type of solder are rods made from an alloy of lead and tin. If you need to repair a crack in a pot, you need to use tin solders.

- The ventilation system will protect the respiratory tract from diseases associated with inhalation of harmful impurities.

You need to practice on spoons, cups and old bowls. You can use waste from the production of galvanized castings.

Solder Types

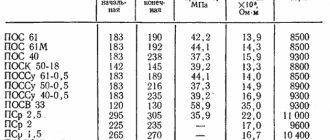

Solders for stainless steel are divided into two main groups:

- soft;

- solid.

Soft ones are the usual compositions based on Pb and Sn grades POS. Sufficient tin content increases ductility and fluidity, allowing it to penetrate into all micro-irregularities of the surface and significantly improving adhesion. In addition, tin is a good deoxidizer, which is especially important when working with stainless alloys. The disadvantage of such soldering compositions is the low strength of the resulting joint.

To obtain stronger solder joints on stainless steel, hard solders are used. They are used both in industrial conditions and in the home workshop. Up to 30% technical silver is added to solid compositions. They are produced in the form of thin rods and are designated by the letters PSR.

Solder HTS – 528

If you need to solder together dissimilar products made from materials such as stainless steel, copper alloys, nickel, cast iron, use the HTS-528 composition. It already contains flux, and the melting point is not less than 750 ° C

Connection with other metals

The connection of two different metals, for example, the soldering of copper and stainless steel, must be approached from the position of studying their properties. Metals have different melting points, so the soldering process is considered one of the most difficult.

Joining copper and stainless steel at home includes processing the workpieces, tinning the edges and the soldering process itself.

Read also: At what height from the floor to hang sconces

It should be noted that copper and stainless steel can be soldered with a soldering iron or torch. The first tool is low-power, so it cannot work with hard solders.

The soldering iron is also not used for soldering large contact areas due to the length of the process. In addition, the flux will oxidize even before it has time to fully warm up.

A burner is the best option. With its help you can solder not only stainless steel with copper, but also with brass.

By the way, when choosing solder, you need to pay attention to brass rods. It is primarily the most common material for soldering stainless steel and can even be used in a joint without flux.

It should be taken into account that brass is inferior to silver in many respects. But it is cheaper. It should only be used for soldering simple non-critical connections.

To obtain high-strength connections, it is better to use copper-phosphorus solder. It is more expensive, but this is a guarantee of high-quality soldering. But the best are silver alloys.

The process of soldering copper or brass to stainless steel is no different from others. It is necessary to clean the edges of the two metals, degrease them, and tinning each edge separately.

Next, you need to place two workpieces on the workbench so that there is a gap of no more than 3 mm between them. Flux is applied, heated, and then solder is fed into the soldering zone.

It should melt and spread along the border of the workpieces. As soon as the gap is completely filled, soldering stops. Metals cool naturally. The remaining flux is washed off with water.

Flux preparation

Corrosion-resistant alloys are very sensitive to soldering conditions, so the correct choice of flux for soldering stainless steel is extremely important.

The most widely used flux contains:

- 7 parts technical borax;

- 2 parts boric acid;

- 1 part calcium fluoride.

Making flux at home

For soldering small workpieces, the composition of the flux is simplified - equal parts of borax and boric acid are taken. The mixture is diluted in water and applied to the soldering area. Once it dries, it will provide excellent adhesion to the surface of the alloy.

Before applying flux, it is necessary to thoroughly mechanically treat the soldering area with sandpaper, a wire brush or a needle file.

Inventory

To carry out the work, you need to prepare all the necessary tools in advance. If soldering steel is carried out at home, you need the following equipment:

- Electric soldering iron. The optimal power of the equipment is 100W. As a similar option, you can use a hand-held propane torch.

- Solution for degreasing the working surface.

- Flux for soldering.

- Tin based solder.

- Rags.

We must not forget about personal protective equipment - safety glasses, gloves, a work suit and a respirator.

Solder Types

Solder for soldering stainless steel is considered the main consumable material when carrying out work. There are two groups of solders:

- Soft - mixtures made from lead and tin. These materials increase the ductility and fluidity of the consumable material for creating a connecting seam. The disadvantage of soft compositions is the low strength of the hardened material.

- Solid - used in workshops and enterprises. The compositions contain 30% technical silver, thanks to which the connection is strong and durable.

Flux preparation

Proper soldering of stainless steel requires a competent choice of flux. This is due to the fact that alloys that are resistant to corrosion processes are easily damaged during the welding process. To avoid mistakes when choosing a purchased mixture, you can prepare it yourself. Making flux:

- Take a portion of borax and the same amount of boric acid.

- Mix the ingredients together.

- Dilute with clean water.

- Stir until a homogeneous mass is formed.

The finished composition is applied to the adhesion site. After drying, the adhesion rate to the treated surface increases.

Homemade fluxes are not inferior to purchased compounds. To increase its effectiveness, before applying the substance it is necessary to treat the metal surface with sandpaper or a file.

Applying flux to the tube

Advantages of soldering stainless steel with tin

The use of soft tin-based compounds provides the following advantages:

- ease of soldering operations for small objects;

- short preparation;

- availability of soldering materials;

- Sufficient soldering quality for not the most critical parts.

Soldering stainless steel with tin

Soldering with soft tin compounds can be quickly mastered by a home craftsman.

How to work at home correctly?

Soldering stainless steel is considered a rather complex process, so work at home should be approached with special attention. Most solders, with the exception of tin, require a soldering iron of at least 100 watts .

Do not forget about preparing the surface for soldering. This procedure begins with mechanical processing of the plane and ending with its tinning.

The use of active fluxes requires special attention - after completion of work, it is necessary to rinse the connection with running water.

Preparation of equipment and necessary materials

When preparing equipment, it is important to pay attention to the characteristics and design features of the soldering iron. Its power is at least 80-110 watts; weaker devices will not be able to provide sufficient heating of the working area. The sting must be fireproof. You can work with a soldering iron using soft, low-melting solders - rods made of pure tin or from mixtures like POS. Pure tin will be needed when repairing kitchen utensils and vessels that come into contact with food or drinking water. It does not contain harmful components. The most suitable flux for such dishes is phosphoric acid.

For hard solders you will have to use a gas torch.

Is it possible to solder stainless steel to copper?

Soldering copper to stainless steel, although it is a rather complicated process, is still possible. The fact is that the connection of stainless steel to stainless steel and copper to copper occurs much more often, since the final quality of the connection is much better. But in various situations, when you need to make such a connection, you have to compromise on quality. Especially for such cases, special solders are produced that allow you to make a reliable connection that meets operational requirements. While for other types of soldering the use of flux is not always necessary, here it is necessary to carry out a full range of procedures, including tinning, and also to use all additional materials.

Selection of solder and auxiliary materials

The correct choice of composition allows high-quality soldering of stainless steel parts. Such a connection will be reliable and durable. The most common types of soldering compounds are tin-lead POS grades. For soldering work on stainless steel, experts recommend:

- POS50Kd18 (with the addition of cadmium);

- POS-61;

- POS-40.

Only clean tin should be used to repair items that come into contact with food. Not every flux is suitable for stainless steel.

Solder POS-61

Phosphoric and soldering acids

Commonly used:

- soldering acid;

- orthophosphoric acid ;

- zinc chloride.

It is necessary to apply flux immediately before soldering, so that the oxide film does not have time to re-form.

Interesting: Phosphoric acid is part of Coca-Cola. A good reason to think about whether you should drink it.

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

Soldering stainless steel is a rather labor-intensive procedure, but it will not cause any special problems if you know all the features of its implementation. With significantly less labor, it is possible to solder stainless steel alloys that contain no more than 25% chromium and nickel. Moreover, soldering stainless steel with such a chemical composition allows you to obtain reliable connections of products from dissimilar metals, excluding alloys with magnesium and aluminum.

Solder repaired bicycle frame

Soldering stainless steel, which contains a significant amount of nickel, can be difficult. This is due to the fact that in such alloys, when heated to a temperature of 500–700°, carbide compounds appear. The intensity of the formation of such connections depends on the duration of heating, so soldering should be performed as quickly as possible.

To minimize the risk of the formation of carbide compounds in the stainless steel structure during soldering, titanium is added to the alloy composition, and after the joint is formed, the product is subjected to heat treatment. You should be very careful when soldering cold-worked stainless steels, the surface of which may become cracked under the influence of heated solder. To avoid such consequences, it is necessary to eliminate the load on the parts being connected during the soldering process. In addition, it is possible to pre-anneal the products being joined.

Read also: How to read single line electrical diagrams

Use a gas torch for annealing.

The choice of solder with which to solder stainless steel is influenced by both the chemical composition of the alloy and the process conditions. So, if this process is carried out at high ambient humidity, then silver alloys should be used, which contain a small amount of nickel. Soldering in an oven, as well as in a relatively dry atmosphere, is performed using chromium-nickel and silver-manganese solders.

The most common type of flux used when soldering stainless steel is borax, applied to the future joint in the form of a paste or powder. Melting borax on the surface of the parts being joined contributes to uniform and most accurate heating of the area of the future seam to the required temperature - 850°. Only after the required heating temperature has been reached, which can be determined by the color change of the future joint to light red, is solder introduced into the joint between the parts.

The flux is applied in an even layer over the entire surface, which must first be cleaned.

After soldering is completed, flux residues are present at the joint, which are removed by washing with water or sandblasting. To perform this procedure, you cannot use nitric or hydrochloric acids, which, although they effectively clean the flux remaining on the surface of the parts, have a negative effect on both the base metal and the used solder.

Technology of soldering stainless steel with tin

It is very important to carry out the preparatory operations correctly and carefully. Their purpose is to remove oxide film and other contaminants from the surface of the stainless steel that prevent the formation of a strong and durable solder joint. First, the surface is protected with sandpaper, a wire brush or a file. Next, after removing sawdust and abrasive particles, degreasing is carried out. To do this, take a special degreaser. It can be successfully replaced by any organic solvent - acetone, white spirit, numbered solvents (646, 657), etc.

Immediately after degreasing, the soldering area is coated with a flux compound. (If flux is included in the solder rod, this step is not performed.)

Now the actual tin soldering begins. First, the soldering area is heated using a soldering iron tip or a gas torch. When soldering with a torch, the oxygen content should be monitored, since if it is in excess, oxidation processes will begin, deteriorating the quality of the connection. When the permissible oxygen concentration is exceeded, the flame acquires a light blue tint.

The principle of soldering stainless steel

The entire soldering area should be heated to the melting temperature of the solder.

Important! The solder should melt not from the tip of a soldering iron or the torch of a gas burner, but from the heat stored in the parts being soldered.

Solder must be supplied to the working area until it begins to appear from the working gaps between the workpieces. This will ensure optimal adhesion.

Basic mistakes during soldering

Common mistakes that prevent you from achieving a positive result:

- Wrong choice of solvents. Aggressive substances are necessary to remove oxide from the prepared surface. Hydrochloric acid based pastes should be avoided as corrosion will make cleaning more difficult.

- Overheating of the connection point.

- Dirty soldering iron tip.

- Non-compliance. The choice of alloy must match the expected service conditions (mechanical load, color matching, food or water contact).

- Lost time. The paste is removed immediately after work to avoid discoloration and prevent corrosion.

- The heating temperature does not correspond to melting.

- Violation of soldered seams. This occurs as a result of movement as the alloy solidifies.

- Cold rallying. As a result of insufficient heating, cold welds are often characterized by stiffness, roughness and unevenness. This soldering error creates unreliable seams that are susceptible to cracking and failure.

The connection will be strong if you use the appropriate solder and do not skimp on flux.

Soldering stainless steel at home

It often happens that a home handyman needs to repair household utensils and stainless steel dishes. To do this, it is necessary to prepare a certain set of equipment, as well as working and auxiliary materials. In order to quickly and efficiently repair stainless steel products, you will also need to acquire a certain skill. Therefore, you should not immediately take on the repair of complex or large-sized products. To get better at “feeling metal and fire,” it’s better to practice on spoons, mugs, or just scraps of stainless steel.

Soldering stainless steel at home

To work, you will need to equip a workplace. The work table must be metal or have a non-flammable coating. Exhaust ventilation must be equipped - both the fumes from the soldering compound and the flux and degreaser are harmful to the respiratory system. The parts to be soldered must be securely fastened with inventory fastening devices - vices, clamps, clamps, spacers.

The work area should not be cluttered; only parts to be soldered may be contained in it.

Containers with working fluids should be tightly closed immediately after use and stored in a cabinet or bedside table.

It is necessary to carefully follow the technology for performing the work. If the processing is carried out poorly and the solder does not stick to the surface of the parts, it is necessary to stop soldering and repeat mechanical processing and degreasing. After degreasing, you can handle parts only with thick gloves - even a small sweat stain left by your fingers can ruin the work.

You can make your own wire brush for stripping. To do this, wires obtained from a piece of metal cable must be tightly inserted into a piece of pipe with a diameter of 5-10 millimeters and a length of about 10 cm. They should protrude from the tube by a few millimeters. For small soldering areas of stainless steel, and especially in narrow and hard-to-reach places, such a homemade product is much more convenient and effective than purchased brushes with a wooden handle.

This brush can be used to work in close proximity to a soldering iron or burner flame, minimizing the time between stripping and the start of soldering.

Soldering with a gas torch

The burner is moved smoothly, heating the metal evenly. The solder rod should melt not from the flame of the burner, but from the heat of the workpiece - only then will a strong and reliable connection be obtained. After applying the rod to the joint area, it is necessary to further heat the workpieces so that it completely penetrates into all the gaps and fills them. Heating is continued until excess soldering compound begins to flow out of the joint.

The most common mistakes

There are a number of mistakes that a person can make when carrying out work:

- Solder may not adhere to the material due to poor cleaning of the work surface.

- Contamination of the part with greasy fingers before applying flux.

- Insufficient heating. Solder does not always have time to fill the seam for reliable bonding.

It is important to remember to clean the soldering iron tip.

It is advisable to refrain from using solders with a high percentage of lead. Soldering stainless steel is a difficult process, but it can be done. To successfully connect parts, you need to choose the right consumables and use high-quality tools.