Common building materials include profiled sheets. They are distinguished by their universal use and high technical characteristics. Let's figure out what kind of screws are used for corrugated sheet metal. We will tell you about their scope of application, varieties, design features, advantages and disadvantages. Read and learn how to calculate the required amount of hardware and how to choose high-quality fasteners.

Special hardware for securing profiled sheets Source nd-prime.by

Scope of application of self-tapping screws for profiled sheets

One of the main areas of application of profiled sheets is the construction of fences. A fence is erected on almost all plots with private houses to mark the boundaries of the territory. At the same time, homeowners are trying to build a fence that will emphasize their well-being. For this purpose, one of the suitable materials is precisely profiled sheet.

The modern design of sheet metal allows the construction of attractive fencing. After all, the material can have any color. Its fastening is carried out on the purlins between the pillars. In this case, fixation is carried out with special hardware.

Self-tapping screws for corrugated sheets on the fence allow you to securely fasten the sheet material. With their help, a strong enclosing structure of a private territory is created. This is important, because every homeowner strives to eliminate the possibility of unwanted persons entering the site.

Special hardware is also used when it is necessary to secure profiled sheets on the roofs of various buildings. After all, the material is often used as a roofing covering.

Special fasteners are used during installation of corrugated sheets on the roof Source 26357.ru

Self-tapping screws for metal profiles are also used when fixing sheet metal on the facades of buildings and during the construction of temporary or permanent partitions, for example, in utility blocks. Profiled sheets are used to create the walls of gazebos and other small architectural forms.

Important! Despite the possibility of using corrugated sheets as roofing, on facades and for the construction of partitions, more often such rolled metal is still used in the construction of fencing for private areas.

Preparation for installation

A roof made of corrugated sheets can have a slight slope, this is one of the positive aspects of this coating. Since the material is thin and light, it can be attached to a sparse sheathing in increments of five to ten centimeters.

To lay roofing material you will need:

- drill with attachment or screwdriver;

- electric scissors or hacksaw;

- self-tapping screws for roofing.

For information: laying corrugated sheets on a roof with two slopes begins from the end on the right, on a tent structure - from both sides at the top point of the slope.

The selection of sheets for installation should take into account their location, length and width of the roof surface. This way you can minimize losses when cutting material.

Basic requirements for installation conditions:

- taking into account the climatic characteristics of the region (reinforced fastening of the material in places with strong winds);

- Work in wet weather is not allowed;

- it is important to observe safety precautions when working at high-rise objects (use safety material, fences and soft, comfortable shoes)

Main mistakes when installing a profile:

Types of special screws

Hardware for fixing profiled sheets is a special fastener. These are specially designed devices in the form of self-tapping screws. Manufacturers make them in the form of a rod, which is equipped with a head. The special hardware is also distinguished by the presence of a triangular thread and a pointed tip to facilitate its screwing.

Special self-tapping screws with a sharp drill tip and hex head Source vashdom-kras.ru

The scope of application influences the classification of special screws. You need to know the types of hardware in order to use the appropriate fasteners for a specific job.

To use self-tapping screws for a fence made of corrugated sheets, you need to know that there is a similar fastener for fixing to wooden parts. It has a large thread pitch. It is designed specifically for wood. After all, its structure is less dense than that of metal.

Wood fasteners also have a sharp tip, which prevents splitting of wooden parts when connecting two elements of the same structure. Manufacturers produce galvanized, phosphated and yellow-passivated fasteners.

Special fasteners for corrugated sheets and wooden frames are also equipped with a sharp drill tip Source pro.zapodaj.net

There are also anti-vandal screws. They look like reinforced bolts. They are always welded to metal structures first. Only after this the sheet metal is fixed. This is one of the options for its reliable, strong and durable fastening.

Self-tapping screws for corrugated board fences are galvanized products. Such fasteners are available for use in different colors. Hardware is painted in accordance with the RAL catalogue. Their varied color range allows you to choose fasteners for a specific design solution.

Design features of special self-tapping screws

Fasteners for profiled sheets are universal hardware. After all, they are used not only in the construction of fences, but also during the finishing of roofs and facades. For this reason, strict requirements are placed on them. Hardware for metal must provide durable, high-strength fastening of parts of the structure being built. However, they should not spoil the appearance of the structure.

Modern fasteners do not spoil the appearance of the corrugated sheet Source grs-nsk.ru

Regardless of the place of use, all self-tapping screws for the fence, which are also often called roofing hardware, consist of the following elements:

- The long part is the rod . Manufacturers apply metric threads to it. It may have different pitches. Moreover, during the production of hardware, their long parts are calculated in such a way that each rod is able to withstand breaking loads. This must be taken into account when selecting fasteners.

Important! The standard breaking force value is at least 102 kg/cm². However, many manufacturers who produce exceptionally high-quality fasteners increase the strength characteristics of their products. This parameter often reaches 170 kg/cm².

- Sealing gasket . Responsible fastener manufacturers produce hardware with neoprene gaskets. Such elements have improved characteristics. However, many manufacturers equip their products with simple rubber gaskets. Such elements have a shorter service life due to low reliability.

Sealing gaskets with washers for self-tapping screws Source tildacdn.com

- Convex washer . Such elements with a curved surface make it possible to ensure maximum tightness of holes in the sheet material.

- Heads . This screw element usually has a hexagonal shape. Thanks to this design, the hardware is tightened with a key. The self-tapping screw can also have a countersunk head. This design involves using a Phillips screwdriver to tighten the fasteners.

- The tip is in the form of a drill . This element has a special geometric shape. Her choice was influenced by the area of use of the fasteners. The tip in the form of a metal drill allows you to carry out work as quickly as possible when profiled sheets are fixed to wooden and even metal frames.

Self-tapping screws for profiled sheets with a drill tip Source shop-vershin.net

On a note! Drills for wood and steel have different designs. This feature must be taken into account when deciding how to attach the corrugated sheet to the metal.

See also: Catalog of companies that specialize in roofing work

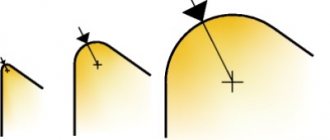

Corrugated sheet fastening scheme - for roofs

Corrugated sheet roofing is popular in private construction. It is lightweight, has a long service life, and an affordable price. But even here, unqualified installation can lead to fastening defects and roof failure. In order for the roof to serve for a long time, it is necessary to properly fix the building material. It is also important to know that the increased consumption of self-tapping screws during installation can reduce the tightness of the roof and lead to its deformation. So, it is advisable not to overdo it. On the other hand, if you are “greedy”, then the sheet will not be able to withstand standard loads. To avoid mistakes, experienced specialists have developed an optimal fastening scheme (see figure below).

Scheme of fastening sheets of material

- When fastening, the roofing screws are screwed down the waves, which is adjacent to the sheathing.

- When fixing the roof, the self-tapping screws are screwed in perpendicular to the batten slats.

- The maximum pitch between roofing screws should not exceed 50 centimeters.

- Along the edges of the profiled sheet, fasteners are screwed in every 2nd wave, in the middle we fasten them in a “checkerboard” version. We fix the end sheet to the sheathing slats without skipping in order to reduce the risk of exposure to wind and tearing.

- It is allowed to screw self-tapping screws into the upper ridges of the corrugated sheet waves only at the junction of 2 pieces.

- After installing the roof, it is necessary to periodically monitor the condition of the roof fastenings. Roofing screws should not be loose or untwisted. If this happens, quickly tighten the fasteners using a screwdriver. And if an outbreak of rye appears in any place, the fasteners are replaced (it is better to take galvanized ones).

Advantages and disadvantages of special fasteners

Like any other fasteners, special self-tapping screws for profiled sheet metal have certain pros and cons. Thanks to the presence of a drill tip in their design, the installation process is simplified. Indeed, in most cases there is no need to first create holes in the parts to be joined.

The hex head allows you to secure the hardware directly to the power tool. This could be a screwdriver or a drill. The use of electric tools also simplifies installation and reduces the time of planned work.

In addition, manufacturers use alloy steel to make special fasteners. Due to this, the hardware has high strength. They rarely break during installation of structures.

High-strength self-tapping screw made of alloy steel Source vellmart.net

Most fasteners have a galvanic layer. To create it, white or yellow zinc is used. Thanks to this coating, high corrosion resistance of hardware is ensured.

On a note! If the fastener is black, this means that it is covered with a special film, whose characteristics are worse than those of galvanic coating.

When self-tapping screws for corrugated sheets on a fence are twisted and unscrewed several times, they wear out the threads and the drill tip. Therefore, each time it is possible to achieve a strong connection.

In addition, the installation of profiled sheet metal should be trusted to experienced craftsmen. Otherwise, a non-professional may cause distortion of both the hardware and the entire structure being created. As a result, the work will have to be redone, which will increase costs.

Professional installation of corrugated sheets on the fence frame Source mega-zabor.ru

Calculation of the number of special screws

Profiled sheets are mounted with an overlap. It is made by capturing one or two waves of material. A single sheet is fastened in the middle and around the perimeter. However, the number of hardware may vary in each specific situation. Their number is significantly influenced by the wind load.

On a note! If the fastening of sheet metal is carried out on the roof, then the snow cover and the slope of the roof are also taken into account. These factors influence the number of fasteners that must be used to secure the material.

The consumption of self-tapping screws increases with the increase in wind load and roof inclination angle. Usually the calculation of the number of hardware is carried out per 1 m². Their number per square area of profiled material is most often 4-8 pieces.

Approximately 4-8 self-tapping screws are required for 1 m² of corrugated sheet Source vsmete.ru

In the place where two sheets overlap, hardware is installed in each wave used to connect the rolled metal. When installing profiled material at an inclined angle, the pitch between fasteners is usually reduced. Therefore, the number of hardware used is increasing. The number of fasteners also increases at the corners of fences and other structures.

To determine the number of fixing elements, the step with which they will be placed in a specific location of the fence is first calculated. Only after this is their total number calculated.

On a note! When calculating, the number of screws for one sheet is multiplied by the total number of profiled material that will be used in the construction of the fence. After calculation, the resulting value is increased by approximately 10%.

Preparing more screws than the calculated number will allow you not to stop work if low-quality hardware is discovered. Additional fasteners may also be needed to more securely fix the sheets in certain places on the fence or any other structure being created.

Before installation, self-tapping screws are always prepared with a reserve Source distroy.ru

On a note! When deciding what screws are needed for corrugated sheeting on the fence, do not forget that hardware may be needed to secure other elements of the fence being built, for example, protective and decorative caps or a metal casting over the gate.

Where should the fastening screw be screwed into the profile sheet?

According to the manufacturers' recommendations, fastening with self-tapping screws must be done in the places of greatest contact between the sheet and the sheathing - in the lower part of the wave. This will help avoid deformation and achieve the tightest fit.

However, when quickly installing a low-quality, cheap roof, using fasteners not recommended for roofing, the “slate” technique of fastening to the upper parts of the waves may be justified. This will avoid massive water leakage in the event of depressurization of the joint.

Distinctive features of metal fasteners

Manufacturers produce self-tapping screws for corrugated sheets on wood and metal. The specific type of hardware depends on the material used to make the fencing frame or, for example, the sheathing that is created during roof construction.

On a note! Typically, the length of the metal fastener is 19 mm, and its diameter is 5.5 mm.

Dimensions and shape of the drill tip

One of the features of self-tapping screws for profiled sheets is the size and shape of the drill, which is the tip of the hardware. For metal fasteners, the so-called drill has a larger diameter and length. In this case, the cross-section of the thread and the drill is almost the same.

Hardware for profiled sheets and metal frames are distinguished by a longer tip and fine thread pitch Source ruftorg.bel

The drill tip for metal hardware is longer than the drill bit for wood fasteners, and has almost the same diameter with a similar thread size for the following reasons:

- The length of the drill for a metal screw must necessarily exceed the thickness of sheet or other rolled metal, including steel posts and purlins between them. Thanks to this design feature, all chips are removed when fastening parts. If this does not happen, then it will clog the thread. Therefore, the complexity of installation work will increase. The self-tapping screw may even jam.

On a note! Typically, the pipes used to make the fence frame have a wall thickness of no more than 1 mm. However, even such rental allows you to build a durable fence. At the same time, it is not very difficult to fix profiled sheets on it with special self-tapping screws with a drill tip.

Special self-tapping screws with a drill tip allow you to quickly mount corrugated sheets even on a frame made of thick-walled pipes Source 24aul.ru

- The same diameter of the drill and thread makes the installation process easier. After all, it is almost impossible to screw a self-tapping screw without a drill tip into a pipe with thick walls. Usually, a hole is always first drilled in the steel frame and only then the hardware is screwed in. Moreover, sometimes special taps and dies are additionally used for cutting threads in thick metal.

Important! Attaching a profiled sheet to metal purlins using special threaded screws involves tightly pressing the rolled steel to a pre-created frame. The profiled material is retained due to the action of friction.

If a self-tapping screw for wood was created with a long drill tip, then during installation work the holes in the wood would constantly expand. Therefore, it would not be possible to securely fix the profiled sheet.

To secure the corrugated sheet on a steel frame, metal screws are used, and on a wooden frame, wood hardware is used Source brigadir35.ru

Important! Metal hardware is used when attaching profiled sheets if the thickness of the walls of the pipes from which the fence frame is created does not exceed 2.5 mm. However, even with this value, significant physical effort must be made. After all, pipes with a wall thickness of 2.5 mm are already very thick rolled products. It will not be possible to attach profiled sheets to it if unlicensed fasteners are used in the work.

Features of choosing metal hardware

When installing a fence or other structures, high strength of all connections must be ensured. In particular, a fixed fastening of the corrugated sheet with self-tapping screws to the metal purlins should be created. To ensure the required level of strength, you need to accurately select fasteners. When choosing, pay attention to the following nuances:

- Presence of markings on the head of the fastener. In its absence, high quality hardware cannot be guaranteed.

- The thickness of the rubber gasket must be at least 2 mm. In this case, the sealing element must be securely glued to the metal washer. In addition, the rubber gasket should not move freely along the rod of the fastener.

The rubber gasket of a special self-tapping screw is glued to the washer Source kd.market

- A protective zinc coating is required.

Important! It is unacceptable to use self-tapping screws during installation work, for the creation of which inexpensive non-ferrous alloys were used, even if they have anti-corrosion properties. Hardware must have a protective surface layer of zinc. It is this that prevents rust from occurring on fasteners.

When choosing self-tapping screws, take into account various characteristics of fasteners Source bouw.ru

- The dimensions of the hardware must correspond to the tasks being solved. Fasteners must be suitable for mounting specific fencing parts. Short hardware is used when profiled sheets are connected to each other. Long self-tapping screws for corrugated wood or metal are used when sheet material is fixed to a pre-created frame.

- The color of the fastening elements must match the color of the enclosing structure.

On a note! Often, when building a fence from profiled sheets, several types of metal hardware are used.

additional information

A few important tricks that will make the mount perfect:

- It should be placed only in places where the corrugated board is concave.

- The longest screws are needed for attaching skates. The photo shows how to attach corrugated sheeting to the roof with self-tapping screws:

- It is necessary to strictly observe the depth of screwing in the self-tapping screw. It is best to look at the rubber gasket: if it protrudes 1-2 mm from the roof surface, it means the self-tapping screw has been screwed in correctly.

If you work with other roofing materials, it is useful to read about the standard sizes of metal tile sheets.

Read also about which dowels to choose for drywall.

Not worth saving. Fastening is the key to long service life of the structure without the need for repairs. By choosing a product of low quality or the wrong size, the builder creates a risk that the structure will quickly become unusable. Ultimately, roof repairs will cost several times more money than the most expensive self-tapping screws. It is best to buy roofing screws in trusted stores, or in the store where the corrugated sheeting itself was purchased - this will significantly reduce the possibility that the screws are fake.

Dimensions of hardware for profiled sheets

To indicate the size of the screws with which profiled sheets are attached, only two numbers are used. The first of them allows you to find out the diameter of the hardware by the outer edge of the thread. The second number indicates the length of the fastener.

For example, threaded hardware 4.8×35 has a diameter of 4.8 mm. Moreover, its length is 35 mm. The second size does not take into account the height of the screw head. In addition, the net length of the hardware to the head is indicated. In other words, the thickness of the rubber gasket and metal washer is not taken into account. This must be taken into account when selecting fasteners. After all, the gasket and washer reduce the length of the screw by about 4 mm.

Diameter and length of special fasteners Source kreptech.com

Important! The actual working length of the hardware is calculated by subtracting the longitudinal size of the tip, the thickness of the washer and the rubber sealing material.

When determining which screws are needed for a fence made of corrugated sheets, then they must take into account the characteristics of the specific place where they will be twisted. To be honest, take into account the thickness of the sheet material and the walls of the pipes from which the fencing purlins are made.

Now manufacturers produce fasteners with lengths from 19 to 250 mm. Moreover, their diameter can range from 4.8 to 6.3 mm.

Calculation of fastening material consumption

Before you start working on the roof, you need to calculate the consumption of roofing material and screws. There is a simple rule dictated by practice: a square meter of corrugated sheet is secured with at least nine self-tapping screws. This expense is considered standard.

Taking into account the fact that the corrugated sheeting is laid overlapping, the number of fastening elements is reduced. In addition, when purchasing self-tapping screws, you need to take into account accidental losses that always occur during construction work. The easiest way is to multiply the square footage of the roof by nine and get the required amount of fasteners. Self-tapping screws are usually sold in packages with the number of parts written on them.

For your information: in three and a half kilograms of the smallest roofing screws, 2.5 centimeters long, there are 1000 pieces.

Self-tapping screws are packaged in standard packages from 100 to 6000 pieces. Large fasteners are packaged in boxes of a thousand pieces.

Signs of high-quality self-tapping screws

One of the main signs of high-quality fasteners is the high hardness of the hardware. That is why they are made from low alloy steels. At the same time, the strength of the self-tapping screws must exceed the similar characteristics of rolled metal, which is used in the construction of the fence frame. After all, the hardware must provide the ability to drill a hole in the metal.

Fasteners for corrugated sheets are high-hard hardware Source vashdom-kras.ru

Fasteners for profiled sheets must be purchased in neat packaging. The manufacturer indicates its contact information on it. Product information is also indicated on the packaging. From it you can always find out the batch number and series, as well as when the fastener was manufactured. In this case, each of the hardware must have a marking on the end of the head. The mark is placed directly by the fastener manufacturer.

Self-tapping screws must be equipped with more than just a rubber gasket. For its manufacture, a responsible manufacturer uses EPDM. Such sealing material in high-quality products is glued to the washer. EPDM rubber has plasticity and allows you to compensate for the linear expansion of the sheet material.

On a note! If the self-tapping screw is dismantled, then the rubber seal is replaced with a new gasket. To check its quality, I use pliers. They press on the seal. If it is of high quality, then cracks will not form on it. After pressing, the rubber should also quickly return to its original shape.

Defects do not appear on rubber gaskets after squeezing with pliers Source dinmark.com.ua

Another sign of high-quality hardware is the presence of a zinc layer, the minimum thickness of which should be 12 microns. In this case, paint can be applied to the fastening element. However, it is used by manufacturers exclusively as an additional decorative coating. Paint is never used to create a basic protective layer.

Briefly about the main thing

Special self-tapping screws for fastening profiled sheets are used not only during the construction of fences, but also when covering roofs, finishing facades, and constructing partitions. Such hardware is made mainly with a hexagonal head. Their design also includes a sharp drill tip and a washer with a high-quality rubber gasket.

Fastening elements are durable self-tapping screws made of alloy steel. They simplify the installation process; they can be tightened with a power tool or a wrench. The fasteners are made with galvanic coating. Only experienced craftsmen can screw it in quickly and correctly.

To secure 1 m² of corrugated sheeting, approximately 4 to 8 hardware are required. It is recommended to use only fasteners with markings and an EPDM gasket no thinner than 2 mm.