Profiled sheet is a building material that is made in the form of separate metal sheets that are specifically designed to cover any premises in order to protect them from precipitation, wind and other external factors.

This material is made from galvanized steel using the cold profiling method, after which the surface of the sheets takes on a wavy shape.

Corrugated sheet is one of the highest quality and durable materials and therefore the demand for its purchase and use in the construction process is gradually growing.

What is the difference between roofing sheets and corrugated sheets?

Profiled sheets are tougher, more durable than corrugated sheets, and their range is much larger.

Corrugated sheeting is characterized by a high degree of noise absorption, but when finishing the roof with corrugated sheets, it is necessary to additionally use soundproofing materials. Also, due to the fact that corrugated sheeting is a rigid structure with complex terrain, this allows it to be used during installation at any height, and it can withstand heavy loads.

In fact, corrugated sheets and corrugated sheets are the same material , only corrugated sheets are most often called roofing material, and corrugated sheets are a universal coating.

Corrugated sheeting - GOST (regulatory framework)

The fact that profiled flooring is a new material for the domestic market, but demonstrating rapid development, is evidenced by the adoption of regulatory conditions for its production in 2012. Today, manufacturers who have a reputation for the quality of corrugated sheets rely on the provisions of GOST 24045-2010 “Bent steel sheet profiles with trapezoidal corrugations for construction.”

Other standards include:

Advantages and disadvantages

Advantages of the material:

- The corrugated sheet has significant resistance to corrosion, ultraviolet radiation and precipitation.

- Due to the presence of sliding properties , snow or dirt does not remain on the roof, but immediately flows off it.

- The long shelf life of the material is about 50 years.

- You can easily and without problems install the coating without having much experience in construction.

- Versatility in use.

- Nice appearance .

- Environmental friendliness and safety of corrugated sheets. At high temperatures, toxic compounds are not released.

- The low weight simplifies the process of transporting the corrugated sheet to the construction site.

- The affordable price for purchasing profiled sheets allows you to purchase it at average costs.

- Provides reliability and protection against leakage .

Disadvantages of a professional sheet:

- becomes very hot in sunny weather .

- Poor sound insulation - pronounced sound from precipitation hitting the roof.

- If the installation of construction work is carried out unprofessionally, then the tightness of the roof may be compromised .

As you can see, the disadvantages are in the minority, and this allows us to talk about the versatility, high practicality and functionality of the material.

Methods for attaching lathing under profiled flooring

Roof options: single-pitch and gable.

The main component of the sheathing are beams that are laid at right angles to the slings.

Having chosen the desired step, the beams are secured with bolts, staples or, most often, nails. A properly designed sheathing will last your roof for a very long time.

Along the eaves there should be a board that is thicker than the main sheathing beams.

Additional strengthening is also required by roof features, for example, chimney, window, fire personnel, etc.

In this case, it is worth strengthening the perimeter of the exits with additional boards.

Fastening of the profiled flooring occurs only after the insulating sheet has been laid and the ventilation system has been installed.

The thickness should be calculated taking into account the height of the corrugated sheet and the length of the external fasteners that hold the profile.

It is recommended to choose a distance between steps of no more than thirty centimeters. And with a decrease in the angle of inclination, that is, the less steep the roof, the pitch of the sheathing should decrease.

It also takes into account how strong and thick the material is, how light the corrugated sheeting is and under what weather conditions it should hold up.

It is worth installing wind boards at the ends of the roof

They should rise above the frame enough to cover the corrugated sheeting.

The length of the step largely depends on the height of the roof, hail, snow and other precipitation, which place additional stress on the roof.

The longer the profile height has been chosen, the higher the roof load can be tolerated.

If the roof has a slope of no more than fifteen degrees, then type C20 corrugated sheeting is used (the use of continuous sheathing and laying of profiled sheets is done overlapping, in two waves).

When using sheets of type C35, the sheathing pitch is increased to thirty centimeters, and the sheets are laid in one wave. If with this type of installation you use a step of 55 - 65 centimeters, then you need to prepare for a decrease in the critical load.

Type C44 corrugated sheeting is installed at a sheathing pitch of sixty-five centimeters. With this step, you can also use the highest categories of profiled flooring.

The use of antiseptics and other substances that can protect the tree from pests and adverse conditions is desirable, but not necessary. They will help your roof last a very long time and not require additional repairs.

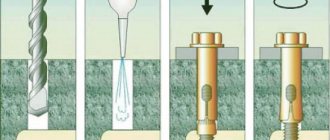

For the most convenient installation, you should use specialized screws. They have a drill at the end and a rubberized base under the cap. These screws are produced in all colors and patterns to suit your roof type.

Attach profiled sheets to self-tapping screws, nails or V-shaped fasteners. The use of nails is justified when cladding walls and constructing protection panels.

The profiled sheet is laid from the bottom rows to the top.

The sheets are attached to a wooden base in the recesses between the waves.

The edges of the bottom row of profiled sheets should protrude, creating a cornice, 15 - 20 centimeters from the walls of the building. This will protect the latter from damage and damage to the cladding.

The installation of sheathing under corrugated sheets requires the use of wooden beams or boards laid closely or spaced perpendicular to the rafters.

Advice. It is easier to treat the edges of the beams from splinters and chips on the ground, even before assembling the structure. Also, impregnation with an antiseptic is easier on a disassembled frame than on an assembled one.

Types of corrugated sheets for roofing and choosing the best

The load-bearing type is intended for creating partitions and finishing walls. It can be purchased at a low price, and you can also place an individual order when you need sheets of a certain size.

With its help, you can not only construct some elements of the building, but also easily repair the roof, finish the facade, its walls, ceiling, and even build durable fences.

When calculated per square meter, this material has low weight and good strength.

The wall profile sheet has a rectangular or trapezoidal profile with a polymer coating or can be galvanized. If you make walls from it, they will be much lighter in weight than buildings made of reinforced concrete. Wall corrugated sheets are convenient and easy to cut if you need to do façade cladding or cladding work, install load-bearing elements, and also make decorative metal structures.

IMPORTANT!

Which corrugated sheet is better for the roof of a house? Roofing profiled sheets (H series) are used for the construction of roofs and any fences that can withstand bad weather. It can withstand heavy loads.

Types of profiled sheets

Brands of corrugated sheets

Typically, corrugated sheets are made of sheet steel with zinc and aluminum-zinc coating. If they use an aluminum-zinc coating, they put AC in the marking, if they use zinc, they don’t put anything. If zinc is applied electrolytically, then EOTS is installed. The sheet can also be coated with a layer of aluminum (letters AL in the marking) or aluminum-silicon (AK). These coatings provide better protection, but are expensive.

Profiled steel sheet with a protective coating - this is corrugated sheeting

In addition to various “primary” coatings, rolled steel sheets are used in various thicknesses. In combination with different profiles, it has different load-bearing capacities, accordingly, it has different purposes and areas of application. According to their purpose, profiles are divided into types (GOST 24045-2016):

- N - for load-bearing covering decks that support the weight of the roof with insulation and the load of climatic influences;

- NS - for flooring and wall fences;

- C - for wall fences that perform load-bearing and enclosing functions.

Sometimes there is such a decoding of the designations of corrugated sheets, where type H is load-bearing (for load-bearing covering decks that bear the weight of the roof with insulation and the load of climatic influences). He is the heaviest, the toughest. Roofs with high snow and wind loads are made from this corrugated sheeting.

Brands of corrugated sheets and their purpose

NS - load-bearing wall. Another name is universal. Less “hardy”, but can be used on the roof with low loads on it. It is also possible to build load-bearing walls from it (with sufficient thickness and depth of the relief). He is often “allowed” onto fences that do not have crossbars between the posts.

C - wall profiled sheet. Used for cladding frame walls. It is used in the construction of garages from corrugated sheets and utility rooms. The same type, but of sufficient thickness, can be attached to the fence if there are crossbars between the posts. This material is not recommended for roofing. Unless there is almost no snow and wind. And then, the sheathing should be frequent, with small gaps.

Technical characteristics of the coating

Before purchasing materials from corrugated sheets, it is recommended to find out some details about the features of its use in construction for several reasons:

- To choose for yourself the best and most suitable type from all the profiled sheets for cladding a facade or for building a fence, and also to know what the requirements are regarding the size of the sheets used , since the possibilities of using the material depend on them.

- If you know the dimensions of the material, then you can calculate the required quantity to purchase and thereby save your time when choosing.

- You will be able to purchase the profiled sheet that meets all the requirements established by GOST 24045-94 .

Determining the useful width of a profiled sheet

When a profiled sheet is found on trading floors, but all the necessary markings are not indicated on it, but only the general parameters of length and width are indicated, then buyers in such cases should know how to identify the useful width parameter and what needs to be considered for this.

All you need for this is two profiled sheets and a free area to place them. Arrange them so that the arrangement is identical to that of an overlapping installation. Having placed one wave of the first sheet tightly on the second building material, you need to take a tape measure and apply it from the freely lying edge to the place where the sheet is covered with the second product. The resulting parameter is the working width of the profiled sheet.

Corrugated sheet for roofing: dimensions and weight

Profiled sheets have a wide range of lengths and thicknesses. In accordance with the rules of GOST 24045-94, the length for all types of profiled sheets can be from 2.4 to 12.6 meters, and the width ranges from 600-1850 mm and is determined based on the manufacturer’s brand . The strength of corrugated sheets primarily depends on their thickness.

The standard thickness of corrugated sheets for roofing is 0.5 and 0.55 mm.

You can see the weight of the corrugated sheet in the table:

| Art. corrugated sheets | Thickness, mm | Length weight, kg/m | Weight, kg/m2 |

| Supporting corrugated sheeting | |||

| H57-750 | 0,7 | 6,5 | 8,67 |

| H57-750 | 0,8 | 7,4 | 9,87 |

| H60-845 | 0,7 | 7,4 | 8,76 |

| H60-845 | 0,8 | 8,4 | 9,94 |

| H60-845 | 0,9 | 9,3 | 11,01 |

| H75-750 | 0,7 | 7,4 | 9,87 |

| H75-750 | 0,8 | 8,4 | 11,2 |

| H75-750 | 0,9 | 9,3 | 12,4 |

| H114-600 | 0,8 | 8,4 | 14,0 |

| H114-600 | 0,9 | 9,3 | 15,5 |

| H114-600 | 1 | 10,3 | 17,17 |

| Profiled sheet type NS (universal roofing) | |||

| NS35-1000 | 0,5 | 5,4 | 5,4 |

| NS35-1000 | 0,55 | 5,9 | 5,9 |

| NS35-1000 | 0,7 | 7,4 | 7,4 |

| NS44-1000 | 0,5 | 5,4 | 5,4 |

| NS44-1000 | 0,55 | 5,9 | 5,9 |

| NS44-1000 | 0,7 | 7,4 | 7,4 |

It is also quite common to make sheets with a thickness of about 0.75, 0.8, 1 m. The dimensions of the corrugated sheets for the roof depend on the area where they are planned to be installed, purpose, loads and climate.

The width of the profiled sheet depends on its brand, for example, for the NS35 brand the width of the profiled sheet is 1060 mm and the height is 35 mm . Accordingly, the height will be from 0.5 to 0.8 mm. If you chose the H75 sheet grade, then the sheet width will be 800 mm, the profile height will be 75 mm and the metal thickness will be 0.7-0.8 mm.

Sheet sizes

Choice by quality

And now about how not to purchase a profile with a thickness of 0.5 mm, but to get 0.35 mm, which will corrode in the first year. What is the problem? In fakes.

When choosing a quality profile, pay attention to the following points:

- Sheet thickness. The finest items are clearly of dubious origin. Note that it is difficult to visually determine handicraft production, and even with a micrometer it will be possible to measure the thickness of the sheet together with the coating. So, for a roof, it is desirable that the thickness be 0.5 mm, zinc should be from 140 grams per square meter. What to do? Contact only trusted dealers or directly to the manufacturer.

- The quality of the raw materials used. For example, the Russian one produces profiles from metal of different origins. All raw materials have different degrees of galvanization, but within the limits of GOST. And you can require a quality certificate. And what the nameless profile with which the market is flooded is made from is a difficult question.

- Inner side of the sheet. There should be no streaks on it - only a uniform, pure color throughout the entire mass of the sheet. Coverage is very important! You don’t want the first hail to completely ruin the appearance of your roof, do you?

- Package. If the sheets are simply folded onto a regular block and hand-wrapped with film, this is not quality. When you bring (or will be delivered to you) such building material, you will find serious scratches due to improper protection, and you will end up rejecting at least one sheet from each package.

- Meeting the required criteria. We have already told you how to choose a specific profile to suit your needs - follow this. And under no circumstances trust unscrupulous sellers who will try to convince you to take a worse profile (after all, your neighbors supposedly bought the same one, and nothing happened). A wrong choice is also a bad profile!

Good luck with your purchase and successful installation!

Coating features

Profiled sheets are specially marked in order to indicate their differences between each other, including their purpose and their types. They are designated by Latin letters ( C – wall, N – load-bearing ).

NOTE!

The durability and strength of the entire structure is ensured by the fact that the profiled sheets have 8 protective layers.

Due to the fact that high-quality corrugated sheets are coated with a varnish coating (polyester, polyvinyl chloride) during their production, they look aesthetically pleasing. Their shelf life also increases.

The material has many positive properties:

- fluorescent;

- heat resistant;

- anti-corrosion;

The material can easily withstand any external influences and is environmentally friendly.

Marking

Universal profiled sheet "NS"

Metal sheets with a height of more than 44mm are suitable for roofs, walls and fences. In private construction, this brand of material is used most often, because all its indicators, such as the width of the corrugated sheet, the length of the corrugated sheet and its thickness, are average, as well as the price. Owners often purchase large quantities of identical sheets to use for all purposes.

Note!

Chipboard: what is it? Types, application features, photos, sizes, thickness, explanation, manufacturers

DIY houses made from shipping containers step by step: instructions, diagrams, pros and cons, photos, design

Working pressure in the heating system in a private house: what it should be, how to create it, instructions for adjusting it yourself

Where can corrugated sheets be used?

- During the construction of fences, both permanent and temporary, for the purpose of carrying out repair work.

- To create parking lots and parking lots for cars or sheds at places of sale of products.

- When permanent formwork is made during the construction process.

- To make sandwich panels using special European technology for arranging wall coverings.

Profiled sheets are used as insulation for facades of various types of premises:

- industrial;

- residential;

- commercial;

- for making roofs on roofs of various buildings.

If you need to make floors in buildings, ceiling and wall partitions are created from corrugated sheets.

Photo of a roof made of corrugated sheets

Calculation of materials for project implementation

Having learned all the parameters of the products, in particular the usable width, the question arises of how exactly to calculate the number of sheets required. You can carry out calculations in two ways:

- Along the length of the covered area. The length of the structure (fence) should be divided by the useful width parameter. Round the resulting value up, which will indicate the amount of material required.

- According to the area sheathed with corrugated sheets. A more complex calculation method, which is necessary in the process of roofing work and finishing the facades of buildings. It is important to take into account the fact that the overlap technology reduces the working width and length too. The value of the latter depends on the frame and the location of the beams from each other. We multiply the useful length by the working width to obtain the useful area covered by one sheet. We divide the entire area of construction work by the previously obtained parameter and obtain the amount of required material. If the value is not an integer, it should be rounded up.

With all this, it should be understood that the profiled sheet is selected individually for each case. So, for the construction of long fences, it should be noted that such building materials must be combined with strong posts and a frame. It is practical to use concrete or metal pillars as they do not deform under the influence of moisture and can easily withstand wind loads. It is better to avoid wooden supports, since their main drawback is the rapid rotting of the base. This inevitably leads to distortions of the fence and further destruction.

It is better to use metal corners or small wooden beams as a frame. This is due to the fact that it is much easier to attach corrugated sheets to them, and for this you only need to select the correct size of screws.

But in order to optimize costs, it is worth counting not only the number of profiled sheets, but also the posts, frame and fittings (fastening tools). To make the structure as stable as possible, the pillars should be placed as close to each other as possible. This will give the overall structure rigidity, even under storm wind loads.

Most popular markings

Today, there are a large number of materials made from corrugated sheets and, as a rule, only some of them are most actively used, which are much better and easier to use. The most popular markings of profiled sheets include:

- C8 . This marking of profiled sheets is most often used for decorative wall coverings . The performance characteristics of this brand have much in common with C10 sheets, which are ideal for building high fences whose dimensions reach more than 250 cm.

- H57 . Corrugated sheets are rigid and suitable for erecting various fences and have an attractive appearance.

- H75 . Corrugated sheets of this brand are suitable for absolutely any type of construction work and are stable if fencing in the form of walls is made from them.

- C21 . Materials made from corrugated sheets can be used for roofing, fencing and wall cladding .

- C18 . Profiled sheets are made in the form of ordinary galvanized products and coated with all sorts of polymer materials. They are intended for installation of roofs on pitched roofs and panel fences.

- NS44 . This brand can be used for any construction and installation work.

Content

First, let's answer the question why corrugated sheeting is so popular among other roofing materials. All because of such valuable qualities:

- Durability.

- Price.

- Light weight.

- Versatility of use - both as a roofing covering and as a basis for insulating a flat roof.

- Easy installation.

- Rigid and fixed joint with roof sheathing.

- Resistance to atmospheric and mechanical influences.

- Rich color range.

Modern corrugated sheets cover both industrial and industrial buildings of enormous area, as well as residential buildings with a wide variety of roof types - flat, semicircular, stepped and complex shapes.

Corrugated sheets are made of steel, with or without coating. For additional strength, profiled sheets are cold bent to form a specific profile. And depending on how the ribs were made, what height, frequency and shape they are, it depends on whether this or that type of corrugated sheet is suitable for you.

Roofing from corrugated sheets: calculation of the number of sheets

To calculate the material for the roof, you will definitely need information about the dimensions of the material used and the roof. To begin with, it is recommended to start by calculating the rafter system.

You also definitely need information about the expected weight of the finished structure, and the cross-sectional values of the beams, taking into account the coating material.

The main components of the rafter system are logs and beams , which are intended for the construction of the roof frame. The calculation of the pitch of laying the beams is done after calculating the load on the roof, which takes into account the weight of the roof, its covering and its own weight.

This is done to provide for all possible loads on the roof. In addition, the calculation of the load includes the weight of the workers who will be installing it and strong gusts of wind.

Attention!

To calculate the covering and rafter system, use our online calculator! After calculating the total load, the number of wooden beams is calculated, which are distributed in a certain direction at angles.

Calculations:

- In order to determine what load will be optimal for a linear meter of parts of the rafter system, you need to use tables with detailed calculations that are found in specialized literature on construction.

- The total footage is calculated.

- The total number of beams is calculated by measuring the length of one of them.

Quality criteria for corrugated sheets for roofs

A high-quality profiled sheet for roofing must meet several criteria:

- The packaging must bear the TU or GOST mark. The state's requirements for the quality of roofing materials are much stricter than those of the manufacturer itself.

- To prevent water from getting under the roof, I overlap the sheets. Be sure to check the symmetry of the waves on the profiled sheets. Each protruding wave must overlap the depression. When calculating the required number of sheets, order 20-30cm more, so you can definitely overlap at each joint.

- At the factory, the sheets are cut by a special guillotine machine. The jagged edges of the sheets indicate artisanal production. Rust will quickly begin to appear in place of the nicks.

- Each sheet must be packed in protective film. This will prevent the corrugated sheet from being damaged during transportation.

- Be sure to take into account the climatic features of your region. For areas where there is a lot of snow in winter, for example, it is worth choosing a more durable profiled sheet.

Roofing pie

A roofing pie is a structure consisting of several layers, which is made to create a roof . It consists of lathing and counter lathing, vapor barrier, waterproofing and roofing. The only thing that is not included is the rafter system.

Installation of the roofing pie is done in this way:

- Take the counter-lattice and install it on the surface of the rafter system. You can attach slab insulation between the beams if the roof is made of corrugated sheets, gable, hip or multi-gable.

- Waterproofing materials are placed on the insulation.

- For the profile sheet, you need to install the lathing, taking into account the gaps for ventilation.

- Roofing profiled sheets are laid out.

Roofing pie

The use of profiled sheets is quite diverse and ensures a long service life. Thanks to this material, it is possible to make both individual structures in the form of fences and install the roofing pie. Unlike corrugated sheeting, it has many advantages that make it indispensable in the construction process.

Wall profiled sheet “C”

The profile height of the wall profiled sheet is up to 44mm. If you don’t know which profiled sheet to choose for a fence, take type “C”. It is intended specifically for the construction of partitions and fences. For the fence, you should choose a sheet with a thickness of up to 0.6 mm. This type of sheet has a very low load-bearing capacity.

It cannot be used as a load-bearing structure, so it is almost never used for roofs, unless the roof consists of very strong rafters and a thin frame.

Dimensions of metal profile sheets

The length of the corrugated sheet varies from 500 mm to 12 m. Theoretically, its maximum value can be many times greater, but the longer the sheet, the more difficult its transportation and loading and unloading operations.

The width of the metal profile can be overall (full) and installation (useful). The fact is that during assembly, part of one sheet, as a rule, overlaps with a nearby sheet, resulting in an overlap. The useful width is less than the full width by the amount of this overlap. This must be taken into account to determine the useful and total area of the ordered material. The dimensions of corrugated sheets in overall width range from 1200 to 800 mm.

The original rolled steel sheet determines the thickness of the metal profile. It takes values from 0.35 to 1 mm and determines the weight, stiffness and durability of the material.

It is important to consider the dimensions of the corrugated sheet when planning the building

Types of protective and decorative coating

In addition to the zinc coating, corrugated sheets of corrugated sheets are often coated with a layer of polymer material. It provides both additional protection of the metal from corrosion and a wide variety of color characteristics. Thanks to this, the scope of application of corrugated sheets as a means of implementing the most original design ideas has expanded significantly.

If previously they used mainly simple tones: red, blue, green, now chocolate, ash-black, terracotta, purple and gray are in fashion.

Among the polymer coating types, the following can be noted:

- Polyester - can be glossy or matte, the most economical and common type. Combines sufficient resistance to fading and corrosion. Wear resistance is low.

- Pural — it is practically not affected by either ultraviolet rays or precipitation with a high content of aggressive components. When processed, it does not produce microcracks, is resistant to scratches and temperature changes. Thickness is about 50 microns.

Profiled polycarbonate sheet has high strength, but is not resistant to UV rays - Plastisol - has a layer thickness of 200 microns, due to which it allows you to create convex decorative patterns on the surface. It has maximum scratch resistance and high durability.

- Polydifluorionad is extremely resistant to fading and has excellent dirt-repellent properties. This is one of the most expensive coatings and is used for cladding structures whose appearance is subject to increased demands.

Paint and varnish coatings allow you to save money in cases where color and design conditions come to the fore, and the operating circumstances are more delicate.

Profiled sheet - advanced material

It is believed that the metal profile was invented by the English engineer Henry Palmer in 1820. Like everything new, his profile bending machine turned out to be quite primitive from the perspective of our time. However, this was a truly revolutionary technical event. Thanks to the transformation of shape, the sheet of metal acquires completely different mechanical characteristics. Moreover, by changing the size and shape of the profile, you can change these properties in a very wide range.

For example, of the dimensions of a metal profile sheet for a roof, the most important is the height of the corrugation. Its shape is also significant. It is most often trapezoidal, wavy or cassette, that is, in the shape of the letter P.

The main advantages of metal profiles: affordability, long service life (up to 50 years), excellent combination of lightness, rigidity, strength and flexibility, versatility, rich color palette, fire safety, ease of installation.

This is interesting: how to calculate a linear meter.

At the same time, there are some restrictions in its use. For example, it is not recommended to use corrugated sheets on low-slope roofs with a slope angle of less than 10 degrees. In this case, on the roof in places where moisture stagnates, there is an increased risk of material corrosion.

In addition, some care must be taken when working so as not to damage the protective polymer coating.

Also, the surface of the metal profile has strong resonating properties, which loudly “make themselves known” during rain and hail, so sound insulation is needed. And the high thermal conductivity of corrugated board requires good thermal insulation when used as a roof in attic-type residential buildings.

Application area

Galvanized corrugated sheeting is a popular building element that is widely used in the construction of various objects. It is used:

- As an interfloor ceiling or load-bearing structure.

- For roofs of structures with high requirements for relative loads.

- When pouring a foundation in the form of a temporary structure.

- In the form of a permanent or temporary fence of a building.

If budget savings are your top priority during construction, you should choose a profiled sheet to solve your problems.

Corrugated sheeting with varnish or polymer coating is used:

- When installing kiosks or pavilions for trade.

- Installation of gas stations, industrial premises.

- During the construction of cottages, dachas, country houses.

- For cladding the exterior of a building.

- As interior decoration.

- For the construction of gates and fences.

- When performing roofing work in buildings with large spans.