SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

The construction of load-bearing structures involves the use of reliable materials. It is to this list that U-shaped steel channels belong. In the manufacture of profiles, various technologies are used and different types of steel are used. The material is classified according to several characteristics, and their relationship determines such a thing as the assortment of channels. This article is devoted to this topic.

Channels are most widely used in construction, manufacturing and automotive industries

What is the difference between channel U and P?

What is the difference between channel U and P? Today it is no longer possible to imagine the construction or production of metal products or structures without shaped metal products.

This rental includes one of the most reliable profiles - channel. It is very popular where you need to add reliability for various designs. It is used to increase the strength of concrete.

This hot-rolled steel is used mainly in the field of construction. The channel is used in the construction of frames, industrial and residential structures, wiring of communications and to increase the strength of main structures. It is found as a separate profile on various sites, the foundations of building structures. The product is also used in the installation of bridges, finishing structures, and erecting industrial and residential buildings. What is the difference between channel U and P? Now it is impossible to imagine the construction of load-bearing columns without it. This product, with the help of its shape, can give even more strength and durability to the structure. Shaped products are able to withstand enormous axial loads and withstand additional bending forces. The area of use depends on its type, size and steel grade. Possessing the significant load-bearing capabilities of this product, it is used in almost all areas of industrial production.

“Important: in terms of resistance to downward loads, the channel is inferior only to an I-beam”

• Industry; • Automotive industry; • Car manufacturing; • Shipbuilding;

Due to its technical parameters, the channel is used in machine tool construction. Since it has excellent reliability, it can withstand vibration and high loads. What is the difference between channel U and P? They are used as part of the frame and attachments for units.

The economic benefit is that this product is lightweight and has excellent strength and resistance to axial pressure and bending. This factor makes it possible to build lightweight structures. The metal profile gives excellent fur. Processable and simply welded during assembly. What is the difference between channel U and P? The ease of installation makes for easy transportation.

The use of shaped steel increases the service life of the structure due to the resistance of the material to all loads. Ease of installation of structures at height, the low weight of the product allows you to lift large batches of profiles upward. Strictness in consistent dimensions allows use with virtually no alignment or straightening.

The product has a cross-sectional shape that allows it to withstand heavy loads over a long period of time. The profile withstands the influence of moisture, is unpretentious to mechanical stress and is not prone to deformation, because there are no weak points in the profile that are prone to breaking the section.

Markings and types

According to the manufacturing method, the channel is divided into several divisions:

— Hot rolled (I produce using the hot rolling technique); — Bent (produced using the cold rolling method);

These types of profiles are used in a variety of areas due to the difference in technical characteristics. In appearance they are distinguished by the difference in angles. In a bent channel they are rounded. In addition, all products are divided by size, the regulations of which are described in GOST. There are three more accuracy groups for product release:

"A" - high-precision; "B" - increased; "B" - normal;

The selection of a channel for certain buildings is determined by its length from the first flange to the second. According to technical regulations, this length can be from 32 to 115 millimeters. They are also divided by its length; as a rule, it ranges from 4 to 12 meters. The height of the shelf is usually 5 – 40 centimeters.

Shaped products and hot-rolled channels are divided into series:

1. “P” - the edges are parallel to each other; 2. “U” - edges with a slope; 3. “L” edges are parallel, but the product belongs to the light series; 4. “S” - the abbreviation means special channel;

Method and material for production

The product is produced in accordance with GOST 8240; the initial material for the production of rolled products is low-carbon steel, high-carbon steel and structural steel. They can also produce using steel with alloying components; the selection of steel is determined by the conditions for the technical parameters of the channel. When manufacturing a product, the workpiece is heated to a certain temperature and sent to a special rolling mill. In this installation, the process of rolling steel with rotating rollers takes place. The central part of the workpiece is the first to be processed, it becomes similar to the letter M. Then it is adjusted to size and fed to the unit for calibration. Then it is adjusted to the exact dimensions. Despite the simple production process, hot rolled products have high productivity and excellent quality. During the manufacture of the profile, heat treatment also occurs, a process in which recrystallization occurs in the crystal lattice of the steel. After annealing, this allows the internal stress to be reduced.

Advantages and disadvantages

One of the main advantages is the product parameters, thanks to which it is used wherever excellent rigidity characteristics are required. High probability of withstanding severe loads on the profile. Resistant to distortion and mechanical damage. Also highly resistant to corrosion. Among the disadvantages, poor susceptibility to welding should be noted.

What is the difference between channel U and P? The main difference is its shape, size and slope of the edges. P has maintained edges at an angle of 90 degrees, U has internally inclined edges.

Types of loads and channels

View A.

"Canopy over the entrance." This type includes beams with rigid embeddings. The load is usually applied evenly. These could be canopies over entrances. Welding is used for their manufacture. They are made of two channels attached to the wall, and the space is filled with reinforced concrete.

View B.

“Interfloor slabs” Rigidly fixed single-span beams, the load on which is distributed evenly. Usually these are floor beams between floors.

Species C.

"Hinged balcony support." The beams have two supports with a cantilever, the load is distributed evenly between them, but they extend beyond the outer walls. This is necessary to create support for the balcony slabs.

View D.

"Under two jumpers." These are single-span hinged-supported beams on which two concentrated forces act. Usually these are lintels on which another pair of floor beams rests.

Species E.

"Under one jumper." These are single-span hinged-supported beams where one force is concentrated. Usually these are lintels on which one beam of another floor rests.

After it has been clarified what type of channel this channel belongs to and where the main load will go, a calculation formula is selected.

Main features and differences between channels “U” and “P”

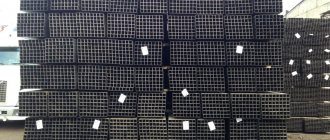

Channel

- This is a type of shaped metal product made from steel using special equipment. A distinctive feature of this profile is its U-shaped cross-section. The product is in demand in many areas of industry and construction.

Products are produced in two ways:

hot rolled (hot rolled channel);

cold rolled (rolled channel).

These types of profiles can be visually distinguished by the difference in the angles of the edges: rounded for the bent version and straight for the hot-rolled version.

In addition, bent steel channels are divided into equal-flange and different-flange options. And hot-rolled products are divided into several series depending on the type of edges:

“P” – the edges are parallel to each other;

“U” – the internal edges have a slope;

“L” – light series with parallel edges;

“C” – special channel;

"E" - economical series.

The range of channels includes products of various configurations; all features are indicated on the labeling.

There are three classes of products with varying degrees of strength:

B – increased accuracy;

Technical characteristics developed by Gosstandart:

The height of the shelf (a key marking parameter) ranges from 5 to 40 cm.

The distance between the edges (profile width) varies between 32 and 115 mm.

The wall thickness is from 4.4 to 8 mm, and the shelf thickness is from 7 to 13.5 mm.

The product itself can have a length from 4 to 12 m (more only by agreement between the manufacturer and the buyer).

The theoretical weight of one linear meter of a product is calculated in kilograms: from 4.84 to 48.3.

Note! The marking on the finished product has a digital and letter designation. The number indicates the size, which corresponds to the distance between the edges of the channel. And the letter indicates the type of profile (the angle of inclination at which the shelves are located).

Main characteristics of the assortment and compliance of channels with GOST

The assortment implies different characteristics of channels. In particular, the following are taken into account:

- slope of internal faces;

- thickness of walls and shelves;

- radius of curvature inside the channel;

- width;

- cross-sectional area;

- weight of the channel and linear meter.

- grade of steel on which almost all physical and mechanical qualities depend (hardness, resistance to loads and corrosion).

The widespread use of U-shaped channels in various fields of construction and production has led to the creation of a large number of standards for their production

A wide range of such profiles led to the development of a large number of GOSTs and other technical standards. The main condition for high quality is the compliance of the channels with these regulations.

Among the existing standards approved by Gosstandart, the following should be mentioned:

- GOST 8240-97. All channels made from hot-rolled steel correspond to it.

- GOST 19425-74. According to this regulation, I-beams and special channels are produced.

- GOST 8278-83. Bent channel, assortment includes requirements for equal flange profiles.

- GOST 8281-80. These are bent products with unequal shelves.

- GOST 5422-73. Channels made of hot rolled steel, manufactured specifically for tractors.

- GOST 5267.0-90. Hot-rolled U-shaped metal products for carriage building.

- GOST 21026-75. Hot-rolled steel profiles with bent flange for trolleys.

According to one GOST, different types of rolled metal are produced per channel. For example, a hot-rolled profile with a slope of flange edges from 4 to 10% is manufactured in accordance with GOST 8240-97. To distinguish it, it is marked with the letter “U” and the corresponding number, indicating the distance from shelf to shelf. According to the same GOST, a channel with parallel edges is also manufactured.

I-beam channels are most often used to create frame support structures that require increased loads

Channel grade: correspondence to letter and numeric data

To distinguish between types and subtypes of channels, not only GOST designations are used, but also markings with letters and numbers, which is called metal marking. This is primarily due to the wide range of sizes, different cross-sectional areas and, accordingly, the mass of the channel.

Related article:

I-beam: table of dimensions, weight and technical characteristics of profiles Weight and technical characteristics of the product. Product design features. Formulas for calculating I-beams. Price per linear meter of profile.

Profiles produced in accordance with GOST 8240-97 have additional both numeric and alphabetic codes. The number that comes first indicates the main characteristic, which emphasizes the size of the channel, determined by the distance between the shelves.

Helpful advice! The product is selected taking into account the expected loads on the future structure, the location and the purposes for which the material will be used.

The letter in the marking indicates the type of U-shaped product, indicating the structural features and location of the edges. Their decoding is given below:

- “P” – indicates parallelism;

- “U” – indicates the presence of a slope on the edges;

- “E” – indicates efficiency;

- “L” – implies lightness;

- “C” indicates the special purpose of the profile.

Types of U-shaped channels and their markings

To determine the remaining parameters of rolled metal of a particular brand, you can use a special table that shows GOST channels, dimensions and other data.

To make the information in the tables more compact, special symbols are used:

- h – indicates the height of the metal walls (basic value);

- b – indicates the width of the shelves;

- S – determines not the area, but the thickness of the main wall;

- R – indicates the radius of the rounded side of the shelf;

- t – indicates the thickness of the shelves;

- r – determines the overall radius of curvature of the shelves.

Differences between “U” and “P” type channels

The key difference between the “U” and “P” types, as already described above, lies in the structural features of the edges of the shelves.

Products from the “U” series:

have a smooth slope (4-10%) in the inner corners;

The thickness of the flanges along the section is non-uniform.

Products from the “P” series:

the edges are kept at an angle of 90 degrees;

The thickness of the shelves is the same throughout the entire section.

But at the same time, the weight per linear meter, cross-sectional area and other characteristics are the same in both cases.

The choice of the appropriate size and type of channel depends on the purpose of the potential structure, as well as on the expected level of loads that it will experience during operation

“U” type channel was considered standard

, its production began much earlier than

"P"

. This product is used as a supporting element in structures, and the peculiarity of its structure in the form of a slope allows it to evenly distribute the load.

Channel "P"

Ideal for mounting structures with fastenings. It is also convenient for mechanisms with moving elements and bolted connections, since the smooth edges of the shelves provide reliable grip.

In addition, the bending rigidity under high loads of this type of channel is an order of magnitude higher than that of the variety marked “U”

. But both types withstand pressure on the walls equally well.

Conventions in channel markings - how to understand them?

And since the main purpose of the channel is to withstand loads, from its markings it is first necessary to find out the parameters that will allow this load to be calculated, namely, the composition of the steel, its strength, rolling quality, and so on.

What can you learn from the labeling?

For example, before us is a package of hot-rolled channels, on which it is written: 30P-V GOST 8240-97/St3sp4-1 GOST 535-88

This means that we have a 30P channel - that is, with parallel edges and a section height of 30 cm. The letter B indicates the usual rolling accuracy B, made of steel St3, fourth category, first group.

The same channel, but only made of steel 09G2S with increased rolling precision will receive the designation 30P-B GOST 8240-97/345 GOST 19281-89

, in which 345 will mean the strength of steel corresponding to grade 09G2S.

But in the marking A 300x80x6 B GOST 8278-83/2-St3sp GOST 11474-76

the letter A will indicate high accuracy of profiling of a steel blank (strips) from the second category of steel St3sp, from which a bent equal-flange channel with dimensions of 300x80x6 is made (where 300 mm is the height of the section of the product, 80 mm is the width of the shelves, and 6 mm is the thickness of the shelves and walls)

Scope of application

In the construction industry, channels have gained significant popularity due to the safety, strength and reliability of the structure. the main task

This type of rolled metal consists of forming a strong support or frame that provides support for all components of the object being built.

The special shape of the profile section not only gives additional strength to the structure, but also has reliable axial bending, allowing it to withstand long-term high loads in any direction. The channel is also highly resistant to moisture, corrosion, vibration and mechanical damage, because there are no weak points in the body of the product that could cause a section failure.

Among other things, the low level of manganese and carbon content in the steel allows the finished product to be frost-resistant, which increases the service life of the structure. These and other positive characteristics make this type of rental almost irreplaceable.

In addition to construction, this type of shaped metal is used in many other areas:

in the architectural and decorative fields.

Channels are necessary for creating all kinds of structures: large-sized bridge structures, load-bearing columns, frames, foundations, roof purlins, ramps, as well as industrial buildings and residential buildings.

The size of the channel is selected by a specialist strictly for the potential object. Calculations are carried out, the characteristics of the product are compared with the data of the standard version. If the differences are less than 5%, then the number is considered suitable. If the resulting value exceeds the threshold of 5%, then the next number is selected.

The low weight of the product allows the construction of lightweight structures, which is economically beneficial. This type of profile lends itself well to machining and welding. In addition, the straight surfaces of the edges fit perfectly together, which simplifies the installation process and allows you to build objects of any shape. Therefore, the channel type is from the “P”

is more versatile.

But for the manufacture of structures intended to operate under constant heavy loads (for example, as a supporting element of a structure), it is better to use products with inclined internal edges. In addition, the “U”

has an advantage in inertial characteristics.

Only a specialist can correctly calculate the volume of materials and correctly select the required type of channel and its number, depending on the purpose of the future object. Incorrect specifications can negatively affect the quality and reliability of the final design.

The use of this type of shaped steel significantly increases the service life of the structure due to the material’s immunity to loads and external influences. Low weight and ease of installation of structures at high altitudes make it possible to transport large quantities of channel upwards. In addition, the products require virtually no leveling or straightening due to their clear shape and precise dimensions.

“Hot-rolled steel channels. Assortment" - GOST 8240 97: description of the document

The main difference between a hot-rolled channel and a bent one is that it is produced by the hot rolling method. It is manufactured in accordance with several GOSTs, in accordance with the needs of a particular industry. The range of channels GOST 8240 97 was approved by Gosstandart back in 1997 and subsequently approved by almost all post-Soviet countries. On April 5, 2001, by decree of the State Committee of the Russian Federation for Standardization and Metrology, the document was put into effect on the territory of Russia.

Drawing of a standard 80 mm metal channel with dimensions

As a direct State Standard in the Russian Federation, it began to operate with some changes from the beginning of 2002, replacing the previously valid GOST 8240 89 “Hot-rolled steel channels. Assortment". The document indicates all the quality characteristics of rolled metal building materials produced by the hot-rolled method.

The current document indicates the scope of application of the products, establishes a range of hot-rolled steel channels with a height of 5-40 cm and a flange width of 32-115 mm. GOST includes various parameters of shapes and sizes, dividing products into different series:

- with sloped edges inside;

- with the edges of the shelves located parallel;

- economical models with parallel edges;

- lightweight products with shelf edges located parallel.

Each specific series, in accordance with the dimensions and qualities of the steel from which rolled metal is produced, provides its own extended table for the assortment of channels GOST 8240-97. In total, the document contains 7 tables, thanks to which you can choose the most suitable material for construction.

For each type of channel there is its own table of state standards, which indicates the main characteristics of the material

Channels 10P, 12P and 10U, corresponding to GOST 8240‒97

In the list of products that meet the requirements of GOST 8240-97, the most popular are channels with dimensions of 10 and 12 cm. All of them are produced by hot rolling. In this case, the number of rolling depends on the initial dimensions of the workpiece and the required accuracy of the product. The workpiece is subjected to heat treatment reaching 1250 °C.

Helpful advice! Considering that GOST tables indicate dimensions in millimeters, you can often find markings like channel 120, although this indicator indicates a U-shaped rolled metal product marked 12P or 12U.

Channel 10P has the following characteristics:

- the weight of a linear meter is 8.59 kg;

- 1 ton holds 116.4 m of channel;

- the height of the profile corresponds to its main dimension and is equal to 100 mm;

- channel width – 46 mm;

- profile walls have a thickness of 4.5 mm;

- The thickness of the channel shelves reaches 7 mm.

Depending on their purpose, channels are divided into light and reinforced profiles

Channel 10U, like 10P, has similar characteristics of a nominal height of 100 mm, a linear meter weight of 8.59 kg, a width of 46 mm and a thickness of 4.5 mm. One ton of material contains 116.4 m. The differences lie in the characteristics of the rounded shelves. In particular, the radius of the rounded side of the shelf is 7 mm, and the radius of the curvature of the shelves is no more than 3 mm.

Taking into account the differences in the main size, that is, in the height of the rolled metal, the 12P channel has significant differences in parameters. Its characteristics are as follows:

- the weight of a linear meter is 10.40 kg;

- 1 ton holds 96.15 m of channel;

- product height – 120 mm;

- channel width – 52 mm;

- profile walls have a thickness of 4.8 mm;

- The thickness of the channel flanges should not exceed 7.8 mm.

What is the difference between channels “U” and “P”

- Characteristics, classification and differences between channels

- Channel according to GOST

- Popular types of products (channel and what are the differences)

- Scope of application of the channel (what are the differences between channel and channel)

What is a channel? A channel is a small metal object, the cross section of which forms the letter “P”. The cross section of the wall is a jumper, and the legs are the letter “P”. The main purpose is to support the support mechanism in the building, in the production of metal structures in the field of construction and industrial production. Channel and what are the differences, how to distinguish them and what they are used for, let's take a closer look.

Channel p and u what are the differences

The design of the product allows for high strength to withstand vertical loads.

Numbers, letters and GOSTs

According to the production method, the channel can be bent or hot-rolled. It is easy to distinguish them even for a non-specialist - a hot-rolled channel has a clearly defined edge, while a bent channel it will be somewhat rounded. Other features of various types of channel are determined by their markings.

In particular, the letters A, B and C in relation to batches of hot-rolled channels will indicate that the rolling was carried out with high (A), increased (B) or normal accuracy (C).

Characteristics, classification and differences between channels

The channel is made by rolling metal blanks; special professional machines are used for this. Only high-quality steel is used to manufacture products. They are divided into special types:

- for carriage building;

- for the automotive industrial complex;

- ordinary.

According to their strength class they are divided into:

- high class A;

- increased accuracy class B;

- regular class B.

According to the manufacturing method, the product is divided into:

- hot rolled steel;

- bent steel equal flanges;

- unequal bent steel;

- steel special.

Depending on the precise rolling, the product is distinguished:

- U - with a slope along the inner edge of the shelf;

- P – parallel edge of the shelves;

- L – parallel shelf, light series;

- S – special.

Hot rolled steel channel - main characteristics and areas of use

Hot-rolled steel channel is a shaped rolled product capable of imparting special strength to building structures. The U-shape ensures the resistance of products to axial forces and lateral deformations, so such products are indispensable in bridge construction and other industries that experience severe loads.

According to the accuracy of dimensional parameters, three groups are distinguished:

Products of categories B and C belong to the highest quality category products.

Hot-rolled channels are made with shelves, the internal surfaces of which are parallel to each other or with a slope. In addition to conventional products with parallel internal edges, they produce products in light and economical series.

Attention!

For the manufacture of structures intended to operate under heavy loads, channels with inclined internal edges are used. The slope of the surfaces can be 4-10%.

A special channel is produced for the automotive industry and carriage production. Such products are divided into two classes: A - high strength and B - regular. The strength class is determined by the rolling accuracy.

The height of hot-rolled channels for regular and special purposes ranges from 50-400 mm, the width of the flange is 32-115 mm, the length of the product is 4-12 m. At customer request, sections longer than 12 m can be supplied.

Channel according to GOST

The difference between the “U” and “P” channels is the slope of the internal corners of the product. Product “U” has an internal angle, a smoothed slope equal to 90 degrees (most often it cannot withstand this value). Product “P” has an internal corner with a maintained angle of 90 degrees.

A hot rolled product is made using hot rolled metal. The product is manufactured in accordance with GOST 19425-74, it is carried out in the context of industries. Most often it is used in the field of carriage building, for example, for trolleys. The type and weight of products are different, the average weight of a P-product varies from 4.8 to 20 kg, weight is measured per 1 meter of product. The width of the product ranges from 5 to 10 centimeters, and the length - from 2 to 12 meters. In accordance with GOST, there may be weight deviations of no more than 5% of physical weight.

The size and type of the product is printed on the product, marked, and consists of a digital and alphabetic value. The number indicates the distance between the edges and the edge of the product, and the letter indicates the angle at which the shelves of the product are located. It is worth noting that the product itself contains a low content of carbon and manganese, which makes the product more stable and durable at low temperatures. These qualities give the product the opportunity not only to serve for a long time, but to save money and increase reliability in the operation of structures. When choosing the required product, experts advise studying the classification table. You can buy a new channel, or you can find used options in quite acceptable condition, for example, in online construction stores with delivery or on ad sites.

How much can a channel weigh?

| Channel number | Weight of 1 meter in kg | Meters per ton |

| 5 | 4,84 | 206,6 |

| 6,5 | 5,9 | 169,5 |

| 8 | 7,05 | 141,8 |

| 10 | 8,59 | 116,4 |

| 12 | 10,4 | 96,2 |

| 14 | 12,3 | 81,3 |

| 16 | 14,2 | 70,4 |

| 18 | 16,3 | 61,3 |

| 20 | 18,4 | 54,3 |

| 22 | 21 | 47,6 |

| 24 | 24 | 41,7 |

| 30 | 31,8 | 31,4 |

Popular types of products (channel and what are the differences)

Product type 10: widely used in construction and engineering fields; It has high mechanical qualities and is used for large rod structures, support and load-bearing mechanisms in the construction of various industrial facilities.

Product type 14: considered the most popular product in construction; widely used in the construction of various structures with heavy reinforcement of load-bearing parts; It is used in the construction and mechanical engineering sphere, it can be of normal and increased accuracy.

Product type 20: due to its high strength and reliability, it is used in complex structures with high dynamic, static and cyclic loads. Its main function is a load-bearing mechanism for strengthening bridges, complex reinforcement of floors in multi-storey buildings and in roofing mechanisms.

Marking and designation of channel in accordance with GOST 8240

The height of the channel profile is approximately 1.5-3.5 times greater than the width. The shape of its cross-section provides it with high levels of rigidity. This allows this type of rolled steel to be used in heavy engineering and construction, mainly for the manufacture of critical metal structures, as load-bearing elements of floors, frames of buildings and structures. In addition, many brands of channels are used in the automotive industry, carriage building, for the manufacture of supports, fences, gates, and for decorative purposes.

Scope of application of the channel (what are the differences between channel and channel)

Recently, this product has gained great popularity in use. And this is not surprising. In the construction industry, this product is simply irreplaceable; it provides not only the strength and reliability of the structure as a whole, but also safety. When commissioning any construction project, a school, an office building or your own home, a special metal corner or channel is always used. Directly in the design itself, its task is to provide powerful support for all complex parts. Experts advise using it in laying the foundation, which gives greater strength to the future object.

This product is also widely used for covering frames and for equipping ramps. Therefore, to ensure the rigidity and stability of the structure, one cannot do without it. In addition to the construction industry, it is used in the automotive and carriage manufacturing industries, in the architectural and machine tool industries. Due to the fact that the product has a strong axial bend, it has found its application in almost all sectors of the economy.

You can purchase such a product at any rolling mill or metal warehouse. Here is a more detailed description about channels.

Hot rolled channel and bent channel: differences

The channel belongs to the group of shaped rolled products. It has a U-shaped profile. This type of rolled metal is one of the main structural materials for industry and construction. It is used for the manufacture of highly loaded building structures and a wide variety of industrial products: for example, frames of trucks, cars. The industry produces bent or hot-rolled channels, which provides consumers with a wide choice of rolled products that are most suitable for their purposes.

Channel p and u what are the differences

- Source2

- Source3

- .. | Channel 24. Channel 24 assortment. Difference, dimensions, channel weight 1 meter and channel 24 characteristics.

The difference between a cold-formed channel and a hot-rolled one

A list of a number of distinctive points regarding the difference between a hot-rolled channel and a cold-rolled (bent) U-shaped profile.

The difference between a bent channel and a hot-rolled one:

1. Hot rolled has a more reinforced profile, because There are thickenings in the bend areas and flanges, which in turn are caused by the peculiarities of manufacturing the hot-rolled channel. Therefore, it is stiffer than a bent channel.

2. The bent one has clear internal radii, and therefore less rigidity.

3. The bent one has a lower specific gravity, thus, with the same product sizes, it weighs significantly less than the hot-rolled one, thereby reducing the cost of the metal structure.

4. A bent channel has a much wider range of products than a hot-rolled channel. You can calculate the required loads, set the required size of the bent channel, and the design will be cheaper, not inferior in reliability to a hot-rolled product.

5. The range of hot-rolled channels is limited and strictly regulated by the industry standard (GOST).

6. Equipment for the production of hot-rolled channels is bulky, and only metallurgical plants own them.

7. When profiling on rolling equipment, a bent product is freed from all workpiece defects. This eliminates the need for subsequent work on the product, such as chamfering.

8. The low specific weight of the bent channel allows not only to save on the purchase of the product, delivery and use of special equipment, but also during installation, namely, the installation speed increases, the design is lighter, and accordingly less funds will be required for the foundation.

will produce a bent U-shaped channel according to your dimensions or dimensions in accordance with GOST. More detailed information about the product:

Bent channel (U-profile)

How to calculate a beam for bending - wood + steel. Video from construction site #3. About the floor beam.

Bent channel - blanks for production and basic properties

This type of U-shaped profile is made from hot- or cold-rolled sheet steel of ordinary quality, high-quality structural steel, and low-alloy steel. Equipment – roll forming machines. The dimensions of a bent channel are determined in the same way as a hot-rolled one - by numbers. Product types: equal and unequal.

Differences between a bent channel and a hot-rolled one:

- Visual characteristic – rounding of external corners.

- The advantage of bent products is the correction of workpiece defects when processed on profile bending machines. This eliminates the need for post-processing of the product, such as chamfering.

- Bent channel is a cheaper and lighter weight option compared to hot-rolled products.

Source2

- The young actor’s work is not flawless, but due to his penchant for creating a COMPLETE image, he was able to emphasize the hero’s ability to naturally respond to the requests of others.

- The play is quite SCENE and beautifully acted.

- The pendulum BACKED about sixty degrees.

- Our main DIFFERENCE from each other is not in appearance, but in the perception of the world as such.

- A new PRODUCTION plan has been approved for the coming month.

Selection of channel and I-beam. Sopromat

An approximate method for calculating the load on a channel

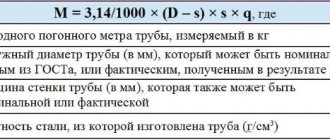

To make the calculation you need to do the following:

-First, determine the total load that will act on the beam - and multiply it by the standard safety factor for loads.

-Multiply the result obtained by the pitch of the beams (in this case this applies to channels).

Next, you need to calculate the maximum bending moment.

All data for the channel is taken according to GOST.

The formula is as follows: the bending moment Mmax will be equal to the design load multiplied by the length of the channel squared. The unit of measurement is kiloNewtons per meter. (1 kNm = 102 kgcm)

Then proceed to calculate the required moment of resistance of the beam.

The formula is as follows: the moment of resistance Wtr will be equal to Mmax, which is multiplied by the operating conditions coefficients and divided by 1.12 (this is a coefficient for taking into account plastic deformations).

What is the difference between U and P channels?

The construction of a garage, change house or high-rise building cannot be done without load-bearing elements. The most famous of them is the channel. The form factor is determined by GOST; types P and type U are distinguished. What is the difference between these profiles?

What is a channel

The structural beam is believed to have been invented in Germany. In any case, in Russia it is customary to call a U-shaped profile with the German word channel. The elements are available in various sizes, determined by the distance between the legs of the letter P (shelves).

Where is the channel used?

Wherever a rigid support or a durable frame is needed. A ramp for strollers, the frame of a construction house, a garage, prefabricated hangars - everything is made of channels. In industry, the U-profile is placed under the foundations of machine tools, and crane beams are mounted on them.

Engineers are attracted by the excellent combination of strength in all load directions (torsion, bending) with low weight. In addition, straight surfaces fit together like a children's construction set; you can assemble houses of any shape.

Channel assortment

Standardization is the basis of progress. There are GOST standards for channels that specify profile features and the distance between flanges. When designing a skyscraper or bridge, an engineer can select the required strength grade.

According to the standard, the channel is designated by a number and a letter. The number shows the distance between the shelves in centimeters. Despite the fact that the channel profile is always U-shaped, it may have features specified by the letter:

- P – channel with parallel flanges and right angles;

- U – channel with inclined internal walls;

- E – economical;

- L – lightweight.

Figure 1 shows the cross-sectional profiles of channels of various series.

To build a garage, 5P will be enough, 10P is suitable for floors, the most common size for building frames is 14P.

What is the difference between U and P channels?

For the production of channels of both series, hot rolling technology is used. The rolling mill of a metallurgical plant repeatedly pulls hot metal through rolls to form a profile. The surface of hot-rolled channels is not very smooth; during installation, you have to grind the planes, adjusting the elements to each other.

Channels of the P and U series differ in cross-sectional shape. For example, consider products 40P and 40U (position 1 and position 2 in Figure 1).

- For a 40P channel, the internal line of the flange is parallel to the outer one, that is, the thickness of the flange is the same over the entire section.

- In channel 40U, the inner part of the shelves is made with a slope, that is, the thickness of the shelf varies along the section. The thickness of the shelf is less at the edge and gradually increases towards the base. Typical deviation is 5-10%.

At the same time, the cross-sectional area of the U and P series channels is the same, the weight of 1 linear meter is also the same, the theoretical reference values characterizing the U and P channel are also close values.

The decision to use a particular series must be made by the designer, who has complete information about the purpose of the designed structure and the loads that it will experience.

Most often, hot-rolled channels are used in large projects - bridges, crossings, reinforcing structures. Where surface quality is not critical, where joining of internal planes is not required, but the margin of bending strength is important.

To summarize, what is the difference between channel U and P:

- The inner walls of the profile are inclined;

- The bending strength of the U assortment is higher than that of the same type P;

- Features of the form limit the application.

In many cases, hot-rolled channels of all series can be replaced by bent channels of similar dimensions. The issue of possible replacement is also decided by the designer.

What common

In addition to the fact that both profiles belong to the same type of product, there are many common features between them. For example, both types of channels are made from the same steels under similar production conditions. Related to both types of construction is the scope of their application: construction.

Both brands of products are used to increase the strength of erected structures. The presence of the main “jumper” in this case can also be considered their common feature.

Channel: marking profiles with U-shaped shelf edges

This common participant in a great variety of prefabricated structures undoubtedly needs no further introduction or annotation for true master builders. And yet: sometimes “communication” with channels presents some difficulties regarding determining the markings and choosing the product necessary for the most clear implementation of the tasks assigned to the building material. For example, what is better to use in a particular situation: a profile with parallel edges of the shelves or one with slopes? What is the correct way to select a hot-rolled steel U-shaped profile and its dimensions? Let's find out!

Geometric parameters of the U-shaped profile

The dimensional parameters of the channel are determined by a number that is equal to the height (the distance between the outer edges), defined in centimeters. Other sizes are established by GOST and are presented in reference tables.

Attention!

There is a general condition for choosing a channel (and other beam sections) for a specific engineering problem. If the calculated parameters of a product are inferior to the properties of the nearest standard option by less than 5%, then this particular number is chosen. If more than 5%, then preference is given to the next number.

The U-shaped profile is made in two ways - hot rolling and flexible.

Main settings

Roughly speaking, a channel is an all-metal profile with a U-shaped section of shelves (in appearance it resembles the letter of the same name - hence the name). It can be made of different types of steel and stainless steel. This rental product differs in dimensions and dimensions (all information is in the special tables below), and in its technological characteristics and parameters: height, width, thickness, shelf inclination, as well as resistance and inertia, and some other data. The height of the product is greater than its width, as a rule, one and a half times or more (up to 3.5). And the cross-sectional shape of the channel provides a high level of structural rigidity. This type of rolled metal is also used in the construction of buildings, structures of various sizes, as well as in mechanical engineering, as a rule, for the manufacture of metal structures. The product is used as a load-bearing element of floors and frames of various structures. In addition, some brands are used in automobile and carriage construction, as well as for decorative purposes. To understand all this in detail, let’s carefully read the materials below.

Prices for channel 16 in Moscow

Attention! The prices given here for channel 16 should be understood as indicative only. In many cases, prices are actually negotiable and may depend on delivery and other delivery conditions, as well as lot sizes. In retail trade, goods can be sold at a price per piece.

To review prices for channel 16, the largest electronic trading platforms were used: “Price Pulse” and “Tiu.ru”. For an objective analysis, offers with prices from the categories “by rating”, “cheap” and “expensive” were taken. Here are prices per kilogram (usually for retail and small wholesale) and per ton. It should be noted that the lowest prices are usually offered for large quantities of channel bars.

Prices for "Tiu"

Rating section:

- 25 rub/kg. Channel 30 U

- RUB 26,638/ton

Road section e:

Data from "Price Pulse"

- 22,880 rub./t — 34,105 rub./t

- from 21 to 26.80 rub. — 33 rub./kg

Rating: 0/5 — 0 votes

Production technologies

There are cold-rolled (bent) and hot-rolled technologies for the production of these products. In the first case, the channel is obtained by cold profiling from appropriate blanks. In the second - using hot rolled profiles.

Also, U-shaped channels are different in their design. For example, there are products with parallel edges of shelves (brand P) and with inclined edges (brand U). Regardless of the options used, the range of profiles determines their low weight and excellent rigidity. It is these properties that make it possible to use channels of different sizes for the manufacture of structures with increased loads for construction and other purposes. Among the advantages of profiles is the ability to withstand bending, as well as various types of loads: for example, rupture or compression.

Areas of use of bent channel

The strength characteristics of U-shaped products obtained by bending are inferior to similar parameters of hot-rolled products. Therefore, a bent channel is not used in the construction of load-bearing elements planned for operation under conditions of severe loads.

In what situations is a bent channel used:

- In steel frames as additional reinforcing parts.

- In activities for the reconstruction of residential and industrial facilities. Such products reduce the load on the foundation.

- In finishing works. For example, to create partitions in residential buildings, offices, industrial premises.

- In the production of frame structures in automobile and carriage building. Most often - for the manufacture of load-bearing frames of trucks, construction and road equipment.

The channel type and its number are determined only based on the results of calculations made by a specialist. An incorrect choice of dimensional and strength characteristics can cause a decrease in the reliability of the structure.