Properties of polypropylene

Although polypropylene is the least dense of all plastics, it is more resistant to abrasion, tolerates heat better, begins to soften only at 140°C, is chemically resistant, and almost does not crack as a result of corrosion. The material is plastic. Under loads not exceeding the maximum, it stretches and then returns to its previous shape without any changes in properties and characteristics. So it's a really good and safe option. Pipelines in food factories are made from polypropylene pipes.

An additional plus is that polypropylene pipes are easy to connect - they are welded. In general, not only water pipes and heating are made from polypropylene. This material can be used as a frame for greenhouses, country furniture and a bunch of other useful things.

As you can see, the diameters of polypropylene pipes are different. And that's not all. There is also up to 1600 mm

Polypropylene has two disadvantages: high thermal expansion and reaction to oxygen and ultraviolet radiation. We learned to deal with both. In order for polypropylene to tolerate UV rays and light, stabilizers are added. To reduce thermal expansion, reinforced pipes are made. But even with reinforcement, the increase remains large and compensators must be installed in pipelines.

Another disadvantage of polypropylene pipes is that they become brittle at low temperatures. Some types begin to crumble at -5°C, others at -15°C. So external pipelines made of polypropylene require UV protection and insulation. That's why they probably prefer to bury them.

Welding methods for straight-seam pipes

Pipe products, manufactured by bending a steel sheet (strip) into a circle and connecting its joints, are welded using several different technologies.

Furnace welding

The steel strip (strip) entering the rolling mill to give it a round shape is preheated in a tunnel furnace to a temperature of about 1300 °C. Approaching the rolling rollers, the side nozzles additionally heat the edges of the pipe with hot air to a temperature of about 1400 °C. Similar nozzles are installed in the roller zone of the forming mill and heat the edges of the strip to 1400 °C before directly bending the sheet into a circle with the extreme edges in contact.

After joining the edges, heated to high temperatures under pressure by rollers, a strong seam is formed, obtained by the method of mutual diffusion of molten metals. Next, the pipe is once again pulled through a furnace with forming rolls to give it the correct geometric shape. The technology refers to types of steel processing using hot deformation.

Rice. 5 Scheme of furnace and electric arc welding in a flux environment

Electric welding

Electric welding is more often used than other methods when welding round pipes; it allows you to obtain a high-quality seam on thin walls. Pipe products used for pipelines in the oil and gas industry are manufactured using submerged arc welding. To carry out welding work, a round-shaped pipe shell is formed in a forming rolling mill; if the diameter of the product is too large, the circle is assembled from two sheets, which are molded under a press until a semicircular shape is obtained.

Automatic electric welding is carried out simultaneously from both sides until a uniformly welded longitudinal seam is obtained; wire is used as an electrode. After removing the grand, ultrasonic testing and hydrotesting, the pipe is ready for use.

Rice. 6 Electric welding in inert gases - principle

Electric welding in shielding gas

The disadvantage of welding in air is the harmful effect of oxygen on the joint; as a result, air bubbles form in the seam strip, its chemical composition changes due to carbidization of alloying elements, and scale appears on the surface.

The use of inert shielding gases in the field of welding: carbon dioxide, argon and helium allows you to get rid of these harmful factors that arise due to the influence of environmental oxygen on the metal. During operation, neutral gases, being heavier than air, displace it from the working area, eliminating contact of the molten weld pool with atmospheric oxygen. Refractory tungsten products are used as electrodes.

Welding in an inert gas environment is more often used to connect parts made of stainless or high-alloy steel; the seams are characterized by homogeneity of the material, uniform thickness, high surface quality, and provide excellent tightness and strength of the joint.

Types and purpose

Polypropylene pipes can be single-layer or three-layer. Single-layer ones are used for water supply, sewerage, ventilation and other pipelines with the temperature of the transported medium not exceeding +45°C.

Three-layer PPR pipes are reinforced. Reinforcement is designed to reduce the amount of thermal expansion and nothing more. PPR pipes are reinforced with fiberglass and foil. Those with glass fiber are suitable for hot water supply, provided that the water temperature is not higher than 80°C. For heating and systems where water can heat up above 80°C, foil-reinforced polypropylene is used. The foiling may not be continuous. For such pipes, the permissible temperature of the transported medium is +95°C.

Color is just a dye. It does not affect the properties in any way.

Can polypropylene pipes be used in underfloor heating systems? I guess, yes. The coolant temperature does not rise above +45°C, which is quite acceptable even for single-layer ones. But due to high thermal expansion, PPR pipes for heated floors are not the best option, even those reinforced with foil. There are more stable options and not more expensive.

Why do you need a pipe range? A pipe is just a pipe

This is how you look at it. For example, steel pipes are products used in many industries: energy, chemical and oil industries, utilities: water pipes, heating pipes, etc. What about construction? There is no construction site without metal structures.

And each individual application requires its own parameters and performance characteristics, which are determined by the range of stainless steel pipes, or, for example, galvanized steel pipes. The same applies to other metal pipes.

Pressure classification

Since a certain pressure is created in the pipeline to transport the medium, polypropylene pipes have this classification. There are four categories:

- PN10. Working pressure 10 Bar (1 MPa), maximum temperature +45°C. For cold water and low pressure systems.

- PN16. Withstands pressure up to 15 Bar (1.5 MPa), temperature up to +60°C. Also for cold water, but can also be installed in high-rise buildings.

- PN20. Pressure 20 Bar (2 MPa) and heating up to +75°C. Usually these are reinforced pipes, but with a small wall thickness. Used for hot water supply.

- PN25. The most durable pipes. Working pressure 25 Bar or 2.5 MPa, long-term heating up to +95°C. These are exclusively reinforced, and with a thick wall. They are used for hot water supply with unstable pressure (in high-rise buildings) and for heating distribution.

The presence of reinforcement is visible on the cut.

To make the fiberglass visible, it is tinted. Color - any If we talk about which PPR pipes can withstand what pressure, then single-layer pipes (without reinforcement) can be used up to PN20. The difference is in the wall thickness and this can be seen in the table. The outer diameters of polypropylene pipes do not mean anything (first column). The same external dimension can be designed for different pressures. It depends on the wall thickness and the presence/absence of reinforcement. So pipe marking is mandatory. The pressure class is indicated there.

| Outer diameters of polypropylene pipes, mm | PN 10 | PN 20 | PN 25 | |||

| Inner diameter, mm | Wall thickness, mm | Inner diameter, mm | Wall thickness, mm | Inner diameter, mm | Wall thickness, mm | |

| 16 | — | — | 10,6 | 2,7 | — | — |

| 20 | 16,2 | 1,9 | 13,2 | 3,4 | 13,2 | 3,4 |

| 25 | 20,4 | 2,3 | 16,6 | 4,2 | 16,6 | 4,2 |

| 32 | 26,0 | 3,0 | 21,2 | 5,4 | 21,2 | 3,0 |

| 40 | 32,6 | 3,7 | 26,6 | 6,7 | 26,6 | 3,7 |

| 50 | 40,8 | 4,6 | 33,2 | 8,4 | 33,2 | 4,6 |

| 63 | 51,4 | 5,8 | 42,0 | 10,5 | 42,0 | 5,8 |

| 75 | 61,2 | 6,9 | 50,0 | 12,5 | 50,0 | 6,9 |

| 90 | 73,6 | 8,2 | 60,0 | 15,0 | — | — |

| 110 | 90,0 | 10,0 | 73,2 | 18,4 | — | — |

Please note that the wall thickness in the third column - PN25 - is less than in the previous ones, although the pipes are designed for higher pressure. It's not a mistake. It's just that the pipes here are only reinforced. And in the previous two categories the wall thickness and diameters of polypropylene pipes without a reinforcing layer are indicated.

Steel water and gas pipelines

Steel water and gas pipes are made in different assortments, characteristic of the category.

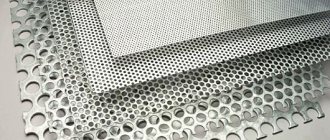

The standard specifies the following types of pipe products (see photo):

- light;

- ordinary;

- reinforced.

For example, for an outer size of 10.2 mm, the parameter will vary in the following values: 1.8, 2.0, 2.5, respectively. The same dependence is typical for standard pipe products with an internal diameter of 20 mm, the metal thickness is 2.5, 2.8, 3.2 mm, respectively.

Size chart for thick-walled pipes

When purchasing, specify what kind of pipe you are interested in - light, ordinary or reinforced, and not just the standard internal diameter of 20mm. When this parameter changes, the strength of the metal of the water and gas pipe will change at the same diameter.

Marking of polypropylene pipes

As has already been said, it is impossible to determine by the outer diameter what pressure the pipe is designed for. Moreover, determining the type of material is also difficult. Therefore, all this information is indicated in the markings that are applied to the pipe. It repeats itself approximately every meter, so it’s simply impossible not to see it.

Marking of polypropylene pipes: let's look at an example

The first place is usually the name of the company or its logo. It is better not to buy unnamed pipes. But there is also a danger of falling for a fake if the company is well-known. You need to study the logo well and buy only if it matches completely. The following information is provided:

- The material from which the pipe is made. For polypropylene it is PP. A reinforcing material may also be specified. If it's aluminum it costs AL.

- Fiberglass - GF.

- Composite material with fiberglass - PPR-GF.

- PP-R100. These are pipes for pipelines with temperatures up to 100°C.

Decoding SDR for polypropylene pipes

So there is complete information that is necessary in order to decide where to use and under what conditions.

| Designation of the service class of PP pipes | Temperature of the transported medium (operating/maximum) in °C | Area of use |

| HV | up to 20 | Only for cold water supply. |

| 1 | 60/80 | For DHW with operating temperature 60°C. |

| 2 | 70/80 | For DHW with an operating temperature of 70°C. |

| 3 | 40/60 | For underfloor heating with coolant temperatures up to 40°C. |

| 4 | 60/70 | Heating and underfloor heating systems with an operating temperature not exceeding 60°C. |

| 5 | 80/90 | Heating and underfloor heating systems with an operating temperature not exceeding 800°C. |

Additionally, we recommend reading the article “How to choose the best polypropylene pipes.”

Varieties of pipe diameters

Over the years, rolled metal pipes have gained great popularity in the construction industry and other areas.

The distinctive differences of the product are the varieties of pipe diameters. Due to the extensive range, the use of rolled pipes is possible both in the biochemical, mechanical engineering, food and other industries. The internal and external parameters of pipe rolling often have a significant difference, and this is not surprising. Everything depends on the value of the wall thickness, which the manufacturers have set as a constant parameter.

Standard types of pipe diameters

Diameter is one of the established values in determining the parameters of rolled steel pipes according to GOST. If you know the exact value of the diameter and wall thickness, it is easily possible to carry out any financial and technical calculations for upcoming projects.

According to the established GOST standard, all types of pipe diameters are divided into products:

- Large size (more than 500 mm);

- Medium (115-500 mm);

- Small (up to 115 mm).

Steel pipes have good corrosion resistance, which increases the service life of pipe products.

Pipe rolling parameters are set based on the diameters of the products. The values themselves can be calculated either in millimeters or inches.

| Du | Inches | Du | Inches | Du | Inches |

| 6 | 1/8″ | 150 | 6″ | 900 | 36″ |

| 8 | 1/4″ | 175 | 7″ | 1000 | 40″ |

| 10 | 3/8″ | 200 | 8″ | 1050 | 42″ |

| 15 | 1/2″ | 225 | 9″ | 1100 | 44″ |

| 20 | 3/4″ | 250 | 10″ | 1200 | 48″ |

| 25 | 1″ | 275 | 11″ | 1300 | 52″ |

| 32 | 1(1/4)» | 300 | 12″ | 1400 | 56″ |

| 40 | 1(1/2)» | 350 | 14″ | 1500 | 60″ |

| 50 | 2″ | 400 | 16″ | 1600 | 64″ |

| 65 | 2(1/2)» | 450 | 18″ | 1700 | 68″ |

| 80 | 3″ | 500 | 20″ | 1800 | 72″ |

| 90 | 3(1/2)» | 600 | 24″ | 1900 | 76″ |

| 100 | 4″ | 700 | 28″ | 2000 | 80″ |

| 125 | 5″ | 800 | 32″ | 2200 | 88″ |

Sometimes users have a question about how to find out the diameter of a pipe. It's simple! Either look at the markings or use tape. Wrap it around the pipe and remember the size, then multiply by Pi 3.1415.

Main dimensions

So, let's first figure out what diameters there are.

- Nominal;

- Nominal diameter (DN) – nominal value set in millimeters;

- Interior;

- External – one of the main established parameters according to GOST;

- Wall thickness is the second established characteristic according to GOST.

OUTER DIAMETER OF PIPES

If we consider the external parameter, then there are these types of pipe diameters:

- Products with values of 424, 720, 530, 273, 3255, 920 are especially popular;

- Small sizes are used for water supply and heating systems of multi-storey and private buildings;

- Medium sizes are used when installing water pipelines and structures in the oil refining industry;

- Larger sizes are needed for leading oil, water and gas pipelines.

INNER DIAMETER

- If the external parameter does not change, the value of the internal parameter is often very different. When establishing standard dimensions of pipe products, the concept of “nominal diameter (DN)” is used;

- Conditional diameter is the nominal value of the internal parameter, rounded in any case to a larger value. DU – established by GOST 355-52 standard.

- Rolled pipe has an internal parameter value in the range of 6-200 mm.

In addition to millimeters, pipe sizes are measured in inches . 1 inch – 25.4 mm.

Pipe diameter correspondence table

Diameters of steel and water pipes (table)

There are only 4 types:

- Conditional (Nominal value of the internal diameter in mm);

- Nominal;

- External (Main indicator);

- Internal (Required to select the correct fitting).

An important parameter in rolled pipes is the wall thickness, which makes it possible to accurately determine the future load on the walls of the product even at the design stage.

The internal diameter must be known in order to correctly select fittings and additional products for the pipeline.

The external values of pipes with diameters of 17-165 mm have been established, which allow you to select the desired size of the product, focusing on the purpose of the structure being installed.

Pipe wall thickness depending on diameter

As mentioned earlier, the thickness of the walls will determine the design that can exert the appropriate pressure.

Why is standardization needed?

Standardization was created when polymer analogues appeared on the market. Due to the fact that it is possible to connect different materials, the scope of use of pipe rolling has expanded significantly.

Because of this, the dimensions of metal and polymer pipe products are basically always the same.

Established standards make it easier for experts to design and install pipelines. If an expert knows the value of the outer diameter of a steel pipe, then choosing connecting elements and creating a single structure will be easy and simple! Very often, metal structures are distinguished by the length of the product, external and internal values, and wall thickness.

Classification by indicators

All types of pipe diameters are divided among themselves according to two parameters^

By outer diameter

- Up to 115 mm – small;

- 115-500 mm – medium;

- 500-1420 mm – large.

According to the ratio of diameter to pipe wall thickness

- Particularly thin/thin walls;

- Normal;

- Thick/extra thick.

Varieties of pipe diameters are established for specific areas of application. For example, when installing cables for buildings, rolled pipes with a diameter of 10-30 millimeters are used.

Using Pipe Schedule

Rolled metal pipes with a diameter of 40-47 mm are often used in the design and installation of water supply and heating systems in apartments.

Pipes up to 149 mm are usually used for domestic and industrial purposes. Materials that have up to 272 mm are suitable for the oil refining, gas and chemical industries.

Products from 325 mm are used for installation of complex systems, such as heat pipelines and water supply lines. The product, with a diameter of 520-1030 mm, is used for transporting oil, gas, and installing sewers in housing and communal services.

Rolled pipes with an internal diameter of 630 mm are especially popular in construction and when installing road elements (supports, drains).

If you know about all the types of pipe diameters and their characteristics, installing or designing any elements will be quite simple!

Source: https://metallservice24.com/raznovidnosti-diametrov-trub

Connection method

As already mentioned, polypropylene is joined by welding. But despite the high level of plasticity, the minimum bending radius does not allow making turns even at an angle of 90°, not to mention steeper ones. All branches and turns are made using fittings. These are special elements for connecting plastic pipes. This is a whole range of different parts for each diameter.

Fittings for polypropylene pipes: types and varieties

The difference is that the marking indicates the diameter of the pipe for which these elements are intended. So you don't need any sizing. If you are using a pipe, say, with a diameter of 25 mm, then simply take fittings with the same marking. It is better to buy both from the same company. Then there will be no problems. If you had to take products from different companies, try them on to be sure. Take a piece of pipe to the store and check compatibility. It should fit in without any problems, but tightly, without gaps.

Technical characteristics of steel water pipes

State VGP standards also concern such technical characteristics as length and weight.

According to GOST 3262 75, the length of the finished product can vary between 4-12 m. Taking this parameter into account, this type of product is divided into 2 categories:

- measured length or multiple of measured length - all products in the batch have the same size (a deviation of 10 cm is acceptable);

- unmeasured length - a batch may contain products of different lengths (from 2 to 12 m).

The cut of the product for water supply should be made at a right angle. An acceptable end bevel is a deviation of 2 degrees.

Special requirements apply to galvanized products. This zinc coating must be continuous with a thickness of at least 30 microns. There may be areas on the threads and ends of the finished product that are not coated with zinc. Places with bubble coating and various inclusions (oxides, hartzinc) are strictly prohibited - such products are considered defective.

Diameters corresponding to the standard

Table 1 shows the cross-sections of steel pipes that comply with the standard. Product parameters fully comply with GOST and TU pipe assortments. The standard range of diameters of steel pipes that are used when laying main pipelines starts with a value of 585 mm and reaches the extreme figure of 6975 mm. List of diameters for standard sizes of steel pipes: 585, 659, 685, 775, 875, 6575, 6775, 6975 mm.

| Nominal diameter (Dy) of the pipe, mm | Outer diameter (Dh) of the pipe, mm | ||

| Steel seam pipe, water and gas supply | Seamless steel pipe | Polymer pipe | |

| 10 | 17 | 16 | 16 |

| 15 | 21,3 | 20 | 20 |

| 20 | 26,8 | 26 | 25 |

| 25 | 33,5 | 32 | 32 |

| 32 | 42,3 | 42 | 40 |

| 40 | 48 | 45 | 50 |

| 50 | 60 | 57 | 63 |

| 65 | 75,5 | 76 | 75 |

| 80 | 88,5 | 89 | 90 |

| 90 | 101,3 | 102 | 110 |

| 100 | 114 | 108 | 125 |

| 125 | 140 | 133 | 140 |

| 150 | 165 | 159 | 160 |

Table 2. Outer diameters of steel pipes.

Differences in pipe sizes

Whether pipes are made of plastic, metal or ceramics, they have a list of characteristics that the buyer uses when choosing them.

The main indicators include the following:

- external section - if the pipe is round;

- internal section - considered to be the working diameter;

- wall thickness - usually characterizes the strength of the pipe.

The external section is formed from the internal section and the wall thickness multiplied by two. Often pipes are connected using a threaded method. The thread is applied to the outer part of the pipe, after which its diameter cannot be considered equal to the outer diameter of the pipe

And due to the fact that during installation it is necessary to start from the thread section, this value becomes more important, and, as a rule, is taken into account instead of the actual size of the pipe

Which pipe is considered small - medium - large?

Even in serious sources I have seen phrases like: “We take any pipe of average diameter and...”, but no one indicates what this average diameter is.

To figure it out, you should first understand what diameter you need to focus on: it can be internal or external. The first is important when calculating the transport capacity of water or gas, and the second is important for determining the ability to withstand mechanical loads.

External diameters:

- From 426 mm is considered large;

- 102-246 is called average;

- 5-102 is classified as small.

As for the internal diameter, it is better to look at the special table (see above).