Today, communications made of polymer materials have replaced most of their metal counterparts.

However, steel still remains a common alloy from which pipelines are made. One of the main characteristics of steel pipes that affects performance is diameter. This indicator is mandatory when drawing up construction plans. The diameters of steel pipes are regulated by the relevant GOSTs. I-beam: range, dimensions, technical characteristics (read more)

The diameter of a steel pipe is one of the most important parameters affecting the serviceability of the product.

Types of steel pipes according to their production method

Steel pipes are used for laying water supply systems and gas transportation communications. Such products have many positive qualities, among which are high strength and resistance to linear expansion. A significant disadvantage of such products is that they have poor resistance to corrosion. All steel pipes are classified according to their manufacturing method and purpose.

Steel pipes have a wide range of sizes, which determine their scope of application.

One of the most common types of steel pipes are electric welded products. They are also called straight-seam. Made from sheet steel. The use of electric welding equipment allows you to obtain a small, even seam. Such pipes are used when laying water supply lines and gas transmission systems. The diameters of pipelines of this type are quite easy to determine using regulatory documentation (GOST 10704-91). The range of section sizes in this case is 10-1420 mm.

The next type of steel pipes is spiral welded. Such products are made of steel, which is produced in rolls. Like the previous type, these parts have a seam, but it does not have a minimum width. Thus, spiral welded pipes are not able to withstand high pressures (unlike electric welded pipes). Because of this, they are not used for laying gas transmission systems. These products are regulated by GOST 8696-74.

Modern industry makes it possible to produce structures that do not have a seam at all. Seamless pipes are made from special blanks. It is worth noting that such products are made in two ways: hot and cold. In GOST standards, the diameters of steel pipes are prescribed in special tables containing other geometric characteristics of products, which simplifies the search. Seamless parts are regulated by GOST 8732-78 and GOST 8734-75.

Pipe diameters are specified in special GOST tables, along with other parameters.

The range of diameters of products that do not have a seam ranges from 10 to 550 mm. The absence of a seam significantly increases the strength characteristics of these pipes, which allows them to be used in critical communications.

On a note!

products, however, it only applies to parts whose diameter does not exceed 250 mm.

Production technology

The manufacturing process of electric-welded pipes consists of several stages, starting with the preparation of the strip (a roll of alloy steel of a specified width and thickness). Initially, rolled metal sheets are supplied in the same roll, but in “standard” dimensions. It is cut before installation on a bending machine, depending on the planned diameter of the pipe. Cutting and bending equipment is reconfigurable within a certain width-section range.

The following stages (using the example of manufacturing longitudinally welded pipes):

- straightening the metal by passing it through a system of paired horizontal shafts, thereby eliminating surface defects (waviness, bends);

- forming a pipe billet using a set of rolls with a gradual decrease in the radius of the billet until the opposite edges are as close as possible;

- welding of a longitudinal seam by compressing the structure with crimping rollers after heating its surface with high-frequency voltage.

The induction (non-contact) method involves passing the workpiece through an inductor, which receives high-frequency alternating current. The created electromagnetic field quickly heats the edges, which at the moment of compression turn out to be “melted”. The process takes no more than three seconds, taking into account this period the speed of metal movement through the machine is adjusted. If you run the equipment at increased productivity, the quality of the weld will decrease. In slow mode, the volume of products produced per shift decreases.

The contact welding method is carried out using fixed contacts. During operation, the pipe blank continuously moves along them at a speed sufficient to obtain a high-quality seam. Unlike the induction version, contact groups must be periodically replaced to maintain a tight connection with the surface being welded. The productivity rate in both cases reaches up to 50 linear meters per minute. The choice depends on the pipe diameter and wall thickness.

After welding, final processing is carried out. It includes:

- deburring – the procedure improves the appearance of the weld and allows you to identify areas where it is poorly welded;

- calibration – ovality is eliminated, accuracy of geometric dimensions and shapes is ensured (done after cooling with water);

- profiling - relates only to profile pipes, when a round billet is driven through forming rolls that create a square or rectangular cross-section;

- cutting – dividing solid rolled metal into segments of a specified length.

It remains to carry out quality control of the pipes. In this direction, three types of testing are used: non-destructive, hydrotesting, and flattening. The first option, according to GOST 10705-80, has four varieties - magnetic, ultrasonic, eddy current, x-ray. The second method is used more often. It is inexpensive but ineffective for detecting defects in welds. The flaw detector is usually installed on the line so that 100% of the pipe is tested.

Hydrotesting is carried out selectively, up to 15% of each new batch produced. The procedure itself is described in GOST 3845-75. It consists of a short-term increase in pressure (for 5 seconds) to 30 or 60 kgf/sq. cm. Pipes must withstand it without deformation, cracks or ruptures should not appear on the surface.

Flattening is carried out in accordance with GOST 8695-75. Two pipes from a batch are subjected to it, and the distance between the flattening points is set depending on the diameter of the pipes and the wall thickness. According to the test result, no tears or cracks should appear on the surface. Visual inspection is added to the technical methods, after which the pipe is packaged and shipped to the consumer.

Diameters of steel pipes: what are these indicators for and how are they determined

Knowing the exact diameter of a water or gas pipe, it becomes possible to calculate the volume of substance transported through communications. The use of such pipes in construction requires a clear definition of the dimensional characteristics necessary for calculations of economic systems.

An example is the heating system. The diameter of the pipes in such communications must be clearly calculated so that in winter the system ensures uniform heating of living quarters.

Calculating the diameter of a steel pipe allows you to determine its throughput.

Today, there are several common methods for calculating the diameter of steel pipes. The size table, which can be found in the regulatory documentation, is the simplest of them. You can also determine this parameter using online calculators. Such programs are located on specialized sites on the Internet, so finding them is not difficult.

Independent calculation of the diameter of the communication is carried out using mathematical expressions. The type of formula depends on the operational purpose of the communication. For example, to determine the diameter of a heating pipe, use the following equation:

D = sqrt ((3.14 x Q)/ (V x DT)), where:

D – diameter (internal); Q – heat flow indicator, calculated in kW; V is the speed of the substance transported through the pipeline (measured in m/s); DT – temperature difference at the initial and final points of the system (input/output); sqrt – square root.

Diagram of a steel pipe showing outside and inside diameter symbols.

This formula allows you to fairly accurately determine the diameter of the pipe. The designation of this indicator in the diagrams makes it possible to correctly calculate the required pressure and the amount of transported substance per unit of time.

Metal-polymer products

One of the popular types of pipes is metal-polymer. These are combined products, the main polymer body of which is reinforced with a metal frame or aluminum foil. The inner tube is made by extrusion. This is a heat-resistant polyethylene that is resistant to alkalis and acids, and can be used for transporting chemicals.

We recommend: Features of collet fittings for metal-plastic pipes

Advantages and disadvantages

Combined pipes have their advantages and disadvantages. This depends on the application and service conditions. Among the advantages it should be noted that:

- the presence of a metal frame significantly increases resistance to external loads. This allows you to maintain the shape of the polymer base and use pipes deep underground. They withstand the pressure of the earth's crust at a depth of more than 500 m;

- smooth surface of the polymer body;

- new technologies in the development of polymers have made it possible to increase resistance to mechanical damage;

- heat-resistant polymers are resistant to acid and alkaline substances;

- resistance to overgrowing;

- lack of electrical conductivity;

- polymer fiber is not susceptible to moisture and liquid;

- the aluminum frame is a barrier that does not allow oxygen to move between the layers of polymer pipes;

- the amount of metal in production has been reduced, which reduces the weight of the pipes;

- increased service life without repairs. The polymer body does not require additional anti-corrosion treatments;

- ease of transportation;

- low installation cost.

Among the disadvantages, it should be noted that polymers covered with aluminum foil are subject to mechanical stress, which violates the integrity of the surface. They are also susceptible to temperature changes. Each layer of the pipe has its own temperature regime. When constantly exposed to high temperatures of the flowing coolant, the pipe is subject to thermal deformation. As a result, its weakest part suffers, namely in the places where the fittings are attached. Over time, this can lead to leaks.

Application

Metal polymers are widely used in the housing sector. They are used for water supply systems, heating systems and utilities. The operating temperature range allows the use of metal-propylene pipes for both cold and hot water supply.

Pipes of larger diameter are used in laying pipelines for technical purposes. They can be successfully used as hydraulic transport and pneumatic transport.

Used as support systems in the marine industry.

Installation is carried out by ultrasonic welding, which ensures the quality of the seams.

Withstands a wide range of temperature changes.

Without much effort, you can change the shape of the pipe.

Metal-polymer products combine the strength of metal pipes and the resistance to chemicals of polymer pipes. This increases their service life. There is no need for additional processing of metal polymers.

What pipe diameters exist: their varieties

Today, diameters are divided into several types depending on what exactly this value characterizes. To use this parameter in calculations, it is recommended to study the types of diameters.

Nominal diameter of pipes (DN). Indicator of the internal space of the pipe. This parameter is calculated in mm or inches. In the second case, the value is rounded. Knowing this parameter allows you to select components (fittings) of the required size for the pipes.

Nominal diameter. This indicator is very similar to the previous type, but has some differences. For example, the main characteristic of a nominal parameter is its high accuracy, which does not tolerate rounding.

The diameter of a steel pipe is measured in millimeters or inches.

Inner diameter (Dу). This indicator is a physical quantity that is measured in mm. The internal diameter is used when calculating the permeability of a pipeline structure. This value should not be confused with the nominal pipe diameter.

On a note! To calculate this parameter there is a special formula: Dy = Dн - 2S.

Outer diameter (Dн). According to this parameter, all pipes made of steel are divided into 3 main groups: small, medium and large. Each group has its own size range and purpose. The easiest way to determine this indicator is from the table of steel pipes. GOSTs regulating such products can be easily found on the Internet using the search bar of your browser.

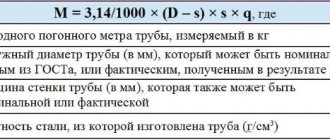

It is necessary to note such a parameter as wall thickness. This quantity is physical and affects the quality characteristics of the part. For example, the volume of the product and its weight depend on the thickness of the walls. The wall thickness is calculated in mm. To determine it, the following simple formula is often used:

t = Dн - Dу

There are special formulas for determining the pipe diameter.

Scope of application of electric-welded pipes

The prevalence of this type of pipe is due to its relatively low price compared to seamless ones. In this case, the diameter of electric welded products can be made to any size, regardless of the wall thickness. Thanks to this property, the finished product is light. But we also have to take into account a number of disadvantages. Thus, welded pipes are 25% less resistant to pressure from the inside; they are difficult to bend due to the risk of damage to the seam.

Areas of application of electric welded pipes:

- pipelines for cold and hot water;

- heating system of private housing, office premises;

- pipelines for supplying water, gas, and petroleum products.

The listed directions require the use of a pipe with a round cross-section and a diameter appropriate to the task. In the manufacture of metal structures and industrial furniture, profile products of square and rectangular shapes are usually used. They are also in demand in the production of sports equipment, installation of fences, railings, canopies, canopies, public transport stops, and street benches.

The strength and durability of the structure depends on the grade of steel. In the production of a pipe with a welded seam, a metal is used that is well welded, otherwise the strength of the finished product will not be sufficient. The resistance of products to high temperatures and aggressive environments (liquids, gases) also depends on the type of raw materials. In everyday life, such criteria are poorly taken into account; they are typical for industry.

Pipe diameter measurement systems: table (inches and millimeters)

Products whose diameter is measured in inches (for example, 5″) are used when laying water supply lines and gas transmission structures. On the Internet you can find tables containing this value in both millimeters and inches. Some of the schemes combine both measurement systems, which is very convenient. A five-inch pipe corresponds to a standard internal diameter of 125 mm.

Measuring the diameter of pipes in inches is used during the installation of water and gas transmission lines, as this simplifies the overall calculation. One inch is equal to 25.4 mm. It is important to remember that when measuring a pipe, 1 inch has a different size, namely 33.5 mm. This is explained quite simply: pipe dimensions are calculated by the internal diameter, and not by the external one. When drawing up the installation plan and diagram, it is necessary to take this discrepancy into account. Such information allows you to answer the question of how to measure the diameter of a pipe and avoid making mistakes.

Table 1. Dу in millimeters and inch system for designating the sizes of steel pipes:

| Dу, mm | Thread diameter, inches |

| 150 | 6″ |

| 40 | 1 1/2″ |

| 80 | 3″ |

| 15 | 1/2″ |

| 100 | 4″ |

| 32 | 1 1/4″ |

| 50 | 2″ |

| 125 | 5″ |

| 25 | 1″ |

On a note! As a rule, no problems arise when installing only steel products, since they are measured in inches. However, when it becomes necessary to replace the old steel communication with plastic, confusion can occur. Therefore, it is worth remembering that the actual and metric inch sizes are different.

In most cases, laying inch pipes does not cause any difficulties. The nature of the discrepancy lies in the designation of steel products (water and gas), which are sold and marked with a nominal diameter, while their actual cross-section has different dimensions. As an example, we can give a simple calculation of the dimensions of a pipe whose outer diameter is 140 mm and wall thickness is 5.5 mm.

To avoid mistakes when planning communications, it is necessary to take into account both the external and internal diameter of the pipes.

To determine the actual diameter, a simple equation is used:

D = Dн – t x 2

After introducing the required values, this formula takes on the following form: D = 140 – 5.5 x 2 = 129 mm. This indicator corresponds to the actual diameter of the pipe, whose outer wall cross-section is 140 mm. However, the nominal bore or internal diameter of an inch pipe (or millimeter) is the dominant value. In this case, this value is 125 mm, which is what most construction calculations are made on.

To connect steel and plastic pipes, special transition elements - fittings - are used. Such adapters allow you to connect two pipes with different cross-sections, made of different materials. In order not to make mistakes when installing communications or replacing them, it is recommended to take into account both the external and internal diameters of steel pipes.

Pipeline installation: useful information

Of course, no one assembles kilometer-long highways using one pipe, since this would take too much time. Yes, and organizing cutting, welding, and insulation in field conditions is not so easy. Therefore, specialized enterprises that install steel pipes for water supply assemble enlarged sections at their bases - or, as they are also called, pipe strings.

The finished sections are transported to the site by long vehicles, so that straight sections of the highway are installed at an accelerated pace.

Pipe carrier delivers finished sections to the site

How a pipe string is assembled

To assemble sections from individual pipes, special installations are used. The pipes laid on them are dried, cleaned of dirt, and the ends are welded. If there is no factory insulation, the outer surface of the section is primed and a protective coating is applied with heat-shrink tape, which we mentioned just above.

Each of these operations is carried out in its own zone, since the workshop has separate lines for welding and applying insulation. When performing this work, pipes or finished sections rotate around their own axis.

The types of installations used depend on the volume of work performed, the size of the pipes, the technology of their assembly and insulation. Shaped parts for large pipelines are also assembled in the workshop - on special assembly tables.

Table for assembly and welding of shaped parts of pipelines

Centralizer for joining pipe ends

Assembly of pipeline sections of complex configurations is also carried out in the workshop

So:

- Let us consider, as an example, the installation of a section on a type III installation - they assemble pipes with a diameter of 219 mm and above. They are placed using a lifting mechanism on a rack, from where they are moved to the alignment line. Sections of three lengths are assembled there: 18m, 24m, 36m. They are all multiples of 6, since this is the standard length of one pipe.

- Upon completion of assembly, a seam root is formed at all section joints. This is done either by semi-automatic welding or by installing a special gasket from the inside. Then, the “semi-finished product” of the section, through an intermediate rack, is fed to the automatic submerged arc welding line.

At the next stage, the finished whip is fed to the insulation line, where it is dried, coated with primer, and a protective coating is applied. All that remains is to load the whips onto a long transport vehicle, which is called a “lash carrier,” and deliver them to the installation site.

Outer diameter of pipes (Dн): classification of steel products

As mentioned above, the inner and outer diameters are different from each other. The first of them is used to designate individual elements of pipeline structures. Sales of steel products are also carried out by internal diameter. This indicator is important if it is necessary to carry out installation calculations for a water supply or gas line. In turn, the outer diameter is used to determine the strength characteristics of the pipeline and its resistance to mechanical loads.

The outer diameter allows you to determine the strength of the pipe and its resistance to damage.

The outer diameter of steel pipes is a characteristic by which all products made from this material are classified.

Depending on this parameter, there are three main types of pipelines:

- small;

- average;

- big.

Pipes that belong to the small group have a diameter range from 10 to 102 mm. Medium-sized products can have a cross-section from 102 to 426 mm. The diameter range of large steel pipes starts from 426 mm. In turn, it is recommended to determine the internal diameter using the table.

Small pipes are used when installing communications in residential buildings. Medium-sized products are used to lay urban water transportation lines, and they are also actively exploited by companies engaged in oil (crude) production. The main areas in which large steel products are used are oil and gas transportation areas. Trunk lines are assembled from large parts. The diameter of gas pipes can reach 1220 mm.

The range of steel pipes is quite wide, since these products are used in all areas where laying communications is required.

Advantages of galvanized metal pipes

Galvanized pipes are steel products coated inside or outside. The galvanizing process is carried out using different technologies:

- electroplating;

- thermal diffusion;

- hot galvanized.

The first method is the most expensive, but with its help you can obtain an even zinc coating with a thickness of 10 to 25 microns. The cheapest method is hot-dip galvanizing, but it does not always provide an even coating.

Thanks to the protective layer, a galvanized steel pipe receives additional positive qualities:

- increased strength;

- resistance to corrosion (compared to conventional pipes, rusts 10 times slower);

- ability to withstand mechanical damage;

- resistance to increased pressure inside (well suited for transporting gases and liquids under pressure);

- ease of installation.

An additional plus is that zinc coating creates unfavorable conditions for microorganisms. Therefore, the inner surface of the pipe will be clean from bacterial plaque even after many years of operation.

GOST galvanized pipes are presented in two options:

- water and gas pipeline – 3262;

- electric welded – 10704.

The applications of galvanized pipe are extensive:

- for laying pipelines;

- for installation of communications (water supply, sewerage, heating);

- for agricultural needs (in irrigation systems, for supplying fertilizers to fields, as a support for young trees, grapes);

- installation of outdoor lighting, advertising objects;

- construction (greenhouse frames, warehouses, repair shops, gyms, parking lots);

- to create drainage systems;

- when creating the frame of furniture and decorative products.

Galvanized pipes are an almost ideal option for use in any area, although they are more expensive than usual. But if you consider that the service life of galvanized material is about 50 years, the cost of purchasing this type of pipe is completely justified.

Standard diameters of steel pipes: table and description

When finding the internal diameter, the indicator corresponding to the dimensions of the nominal diameter is rounded to 0 or 5. Thus, when determining this characteristic, the size is standardized to the nearest parameter of the metric system.

Knowing this information, it is easier to calculate the pipe diameter. How this parameter is measured in millimeters and inches has already been mentioned above.

On a note! The most widespread, due to their operational suitability, are products with a diameter from 426 to 1220 mm. These steel pipes are used as main lines for gas and oil pipelines, sewers, as well as structures used for irrigation of fields.

In residential buildings, steel water pipes are used, the diameter of which is 15 or 20 mm (sometimes 32). For sewerage, larger products are used, which is due to the need to drain wastewater. Heating systems consist of small pipes.

Table 2. Influence of diameter on operational scope:

| Operational area | Diameter, mm |

| Water pipelines in residential buildings | 15-32 |

| Gas pipelines in residential buildings | |

| Sewage systems | 50-100 |

| Gas and oil transportation lines | 426-1220 |

Regulatory documents contain more detailed tables, which contain information not only about the section, but also about other geometric characteristics. Using them, it is easiest to determine the diameter of the pipes (in millimeters and inches). It is important to remember that by using special tables you can calculate the required cross-sectional indicator (internal or external) of both steel and other types of pipes.

Seamless tubes and their applications

Seamless tubes are widely used in various equipment and mechanisms, ensuring the movement of the working environment. Here are some examples:

- boilers in which coolant circulates (water, steam, antifreeze);

- devices working with steam, the same steam generators, superheaters, desuperheaters and other similar equipment;

- cooling circuits for liquids, such as motor oil in cars;

- heat exchange tubes of nuclear reactors;

- oil heaters.

Seamless tubes are widely used in other equipment, devices, units, and assemblies. They pointed out only a small fraction of what could be.

Finding the diameter of steel pipes: GOST table with thicknesses

The use of special tables located in the regulatory documentation allows you to very quickly determine the required parameter. This can be the internal or external diameter, and auxiliary geometric characteristics such as wall thickness, weight, etc. are also indicated.

It is worth noting that the difference between the outer diameter of metal pipes and Dу can reach 7 mm (depending on the type of rolled metal). For example, steel electric-welded parts used in the installation of utility communications may differ in these indicators by 5-10 mm.

Table 3. Diameters and thickness of electric-welded steel pipes:

| Inner diameter (Dу), mm | Outer diameter, (Dн) mm | Wall thickness, mm |

| 80 | 89 | 3 |

| 15 | 20-22 | 1,5 |

| 50 | 57 | 3 |

| 100 | 108 | 3,5 |

| 32 | 42 | 2 |

| 20 | 25-28 | 1,5-2 |

| 40 | 48 | 3 |

| 25 | 30-32 | 2 |

The main indicator indicating the identity of the product is, of course, the internal diameter. Pipes are also designated by the external cross-sectional value, which is a necessary condition when calculating mechanical resistance.

On a note! The dimensions of products with inch markings are most easily determined using the tabular method. It is important to remember that when connecting lines made of steel with pipelines made of another material (for example, plastic), it is necessary to take into account not only Dу, but also Dн.

The popularity of the tabular method is due to the fact that combined pipeline structures are common in the modern world. Such systems contain steel pipes and polymer elements (fittings).

Large-diameter pipes are used to lay gas, sewer and oil pipelines.

Technical characteristics in accordance with GOST

The quality characteristics of steel pipes are always determined by the approved GOST. Special standards that require compliance are developed for ordinary and galvanized products that are used in the installation of water supply systems, heating systems, gas pipelines, etc. The state quality standard also determines the technological process in accordance with which production should be carried out.

When manufacturing their products, manufacturers often indicate dimensions in inches or millimeters. Galvanized pipes weigh approximately 3% more than conventional steel products. This feature must be taken into account in the design process of pipe structures. The zinc layer has its impact on installation and operating requirements. The layer applied to the surface must exceed 30 microns.

Labeling requires attention when choosing a product. On the pipe, the manufacturer indicates the material from which it is made, the weight, diameter of the product, as well as the thickness of the metal layer, the manufacturing plant, the batch number, and the date of actual production. All information provided must comply with current state standards.

Table of steel pipes: diameters, price per rolled meter

The cost of one meter of these products is determined by their weight. In this case, a certain relationship can be traced: the thicker the steel product, the greater its weight. On the Internet you can find many tables that contain information on the prices of various parts classified by internal diameter. Steel pipes belong to the middle price segment. They are more expensive than polymer ones, but surpass them in strength and pressure resistance.

It should be noted that various alloys and protective additives can be used for the production of steel pipes. This also affects the final cost of the products. For example, galvanized parts or stainless steel pipes have a higher price than elements made of ordinary steel.

Table 4. Cost of the most popular water and gas pipes made of steel:

| Dу, mm | price, rub. (per 1 m) |

| 50 | 80-170 |

| 15 | 32-70 |

| 40 | 80-108 |

| 32 | 53-95 |

| 20 | 40-50 |

Thus, the diameter of water pipes and gas transportation products affects their cost. Parts that have a cross-section over 100 mm are practically not used in everyday life. The cost of such pipes is quite high, since 1 m of a part can weigh more than 10 kg. The heaviest pipe has a diameter of 1220 mm and a wall thickness of 16 mm. The weight of a meter of such a part is approximately 475 kg.

Diameter is a necessary characteristic, without which it is impossible to lay a pipeline structure. When determining this parameter, it is necessary to clearly understand that there are several varieties of it. The tables that can be found in the relevant regulatory documentation most often indicate the internal diameter of steel products. If you decide to use a special formula to determine the cross section, it is recommended to pay attention to the examples

Pipes made of non-ferrous metals and their compounds

Along with steel, non-ferrous metals are also used in the production of pipe products.

Copper pipes have a number of advantages:

- bactericidal properties;

- high plasticity;

- not subject to corrosion;

- resistance to temperature changes;

- They do not crack when frozen and defrosted.

But they are susceptible to acids and mechanical damage, which significantly reduces the quality of the product and shortens its service life. It is impossible to connect them to galvanized and steel surfaces.

Cast iron pipe products are heavy, which narrows the scope of application. They are indispensable in a communication system. An excellent option when installing sewerage.

Pipe weight: calculation using formulas, tables and online calculator

Pipe weight is a parameter that determines the weight of 1 linear meter of a steel part. There are several ways in which this indicator can be calculated. These methods have some differences depending on the types of pipes that differ in cross-sectional shape. Determining the mass of pipes is a serious undertaking necessary for calculating transportation costs and construction nuances.

Calculation of the mass of a steel pipe is used in construction to determine the strength of a future structure.

Metal water pipes

Metal pipes have been used for decades. Despite the emergence of new materials, they still have not lost their relevance. Metal, like plastic, has its pros and cons.

The biggest advantage of metal water pipes is mechanical strength. However, its service life is only a few years . In addition, complex installation and welding work increases installation and maintenance costs.

During operation, growths form on the walls of a metal water pipeline, which lead to a drop in pressure and throughput.

Steel

Steel pipes are made both from ordinary carbon steel and galvanized. Installation of a water supply system from steel components is carried out using adapters, tees and couplings that connect the pipes into a single system.

Welded and seamless steel pipes can withstand enormous loads , high pressure and sudden temperature changes.

Which pipes to choose for water supply (video)

The disadvantages of such water pipes include heavy weight, complex installation and corrosion. However, modern manufacturers have learned to coat the inner surface with a non-metallic layer, which increases the service life of the product and avoids corrosion.

Stainless steel products are superior to conventional ones in all main characteristics, but their cost differs significantly , which leads to a significant increase in the cost of the entire water supply system.

Copper

The throughput of copper water supply is higher than that of others. This is achieved due to a smoother internal surface, so smaller diameter pipes can be used. Copper has disinfectant properties , due to which copper pipes are widely used for drinking water supply systems.

The undoubted advantages of copper products include their presentable appearance, resistance to corrosion and long service life, which can reach 70-100 years.

However, the high cost of copper pipes and installation work is not affordable for everyone. Such water pipes are usually found in luxury homes, where luxury is considered one of the important indicators.

For what purposes is the mass of steel pipes determined?

Steel pipes are widely used in the construction industry. In any project you can find information about the mass of the water supply system laid in the building. The same applies to other pipeline systems and structures made from rolled profiles. The weight of water and gas steel pipes is calculated in several ways. Why else is it necessary to calculate this parameter?

The weight of metal pipes is calculated before transporting the products.

The theoretical weight is necessary for sale, since the sale of pipes is carried out taking into account weight, not length. Thus, determining this indicator makes it possible to calculate the cost of a single batch.

Calculation of the mass of these products is used in construction to determine the strength of the future structure. This parameter allows you to find out what loads a frame made of pipes can bear.

On a note! Finding the specific gravity helps to increase the accuracy of calculations, since real values often do not coincide with GOST standards.

And finally, the weight of metal pipes is calculated before transporting the products. Transportation must be carried out using special cargo equipment, taking into account the possible load. When concluding a contract that specifies the number of products and their weight, you should be sure that transportation will be carried out in one trip.

Knowing the weight of pipes is necessary for sale, since the sale of material is carried out taking into account weight, not length.

Thus, knowledge of the weight of steel pipes is a necessary condition when purchasing them. Of course, when purchasing these parts individually, there is no need for such a calculation. Determining the weight in such a situation may be required only in order to calculate the real cost of the products.

Where are square electric welded pipes used?

Electric-welded square pipe is a relatively new product on the construction market. But, thanks to its strength characteristics, it is gradually gaining popularity. Today, square pipe (GOST 8639-83) is used in almost all types of construction.

Advantages of this type of product:

- Light weight and easy installation. It is convenient to connect metal pipes to each other using electric welding or metal screws (the choice of fastening method depends on the size of the corrugated pipe and the features of the structure being created).

- Versatility. Electric-welded pipes can be used as load-bearing supports and to create decorative elements.

- Simplicity in calculations. It is most convenient to calculate material consumption for products with a square cross-section.

- Good assortment. You can find a large assortment of square pipes on sale.

- Great strength. Electric welded pipes can withstand significant mechanical and static loads.

- Resistance to adverse external conditions. Thanks to special heat treatment, which eliminates the internal stress of the metal, square steel pipes (GOST 8639-83) do not require additional protection and can be installed outdoors. They will withstand temperature changes, heavy precipitation and other negative environmental influences.

Another advantage of this type of product is that steel square pipes are relatively inexpensive. This allows them to be used in almost all types of construction, to create various fences and decorative elements when landscaping a site.

Almost all profile square pipes presented on the construction market have an electric welded seam. But sometimes there are also handicrafts that are made from round pipes by pressing on a machine. Such a professional pipe does not have the GOST marking; the assortment in it is not observed. The only advantage is the low price, so such products are purchased for structures with low load (fences, decorative elements).

How to correctly calculate the weight of a pipe yourself: recommendations

You can calculate the mass of a steel part of this type yourself (without using government standards). First of all, it is necessary to determine the basic physical and geometric characteristics of rolled metal. Calculating the weight of round parts is somewhat different from calculating this parameter for profile pipes (rectangular and square).

To determine the weight of a meter of pipe having a circular cross-section, it is necessary to measure its internal and external diameters. For profile pipes, a mandatory step is to determine the width and height. If necessary, you can use regulatory documentation that is publicly available on the Internet. The corresponding GOSTs contain all the necessary information about pipes of any type. It is important to remember that for each type of these parts there is a corresponding document.

In order to determine the weight of a meter of round pipe, you need to measure its internal and external diameters.

Many indicators (for example, length) can be determined independently using a construction tape. In order for the calculation to be as accurate as possible, it is recommended to find out the type of material and its brand.

You can find out how much a pipe weighs without making complex calculations. GOST standards regulating metal pipe products contain special tables. They indicate the main indicators characterizing the part (including weight). You can also use an online calculator, which contains an algorithm for calculating mass.

Application of seamless pipes in construction

Seamless pipe is made from alloyed high-carbon steels. The absence of a weld seam gives the product increased strength.

Seamless steel pipe is manufactured using various technologies. The construction market offers seamless pipes produced using the following methods:

- drawing;

- pressing;

- forging;

- rolling.

Seamless pipe (GOST 8732), manufactured by rolling, can be:

- Cold rolled. Alloy steel heated to 500-600°C is first flattened under pressure and then rolled through rollers, giving the workpiece the desired shape.

- Hot rolled. The steel billet is heated to 1200°C, rolled through a press, and then cooled.

After creating the primary blank using a hot or cold method, the pipe is sent for further shaping. The heating and cooling process can be repeated several times until compliance with GOST standards is achieved.

Seamless steel pipes (GOST 8732) are used in aircraft construction and to create other vehicles. They are used in organizing pipelines for transporting gases and liquids under high pressure.

The range of seamless pipes is the same for all methods of product formation. The GOST R 54159-2010 regulation specifies standards for internal and external sections, as well as wall thickness.

Seamless steel pipe can be used in everyday life. It is used to create wells in the private sector. Increased wall strength ensures a long service life for the source of drinking water.

Seamless steel pipe is also used in construction. With its help, bridges are erected, high-rise buildings and other structures are built where high resistance to mechanical and static loads is required.

Advantages and disadvantages of rolled steel pipes

Steel products have many advantages that we recommend you pay attention to. First of all, it is worth noting that parts made from this alloy have high strength characteristics. It is this fact that determines their widespread use in the construction industry, where the strength of products is one of the main indicators. A wide range of parts is also considered an important advantage, as it allows you to expand their operational scope. On the construction market, you can easily select parts that are suitable in shape and technical characteristics.

On a note! The production and sale of these products are carried out in linear meters. The weight of the pipes is the main characteristic that affects the cost.

Metal pipes have high strength characteristics.

All steel pipes can be divided into three categories:

- round;

- profiled (square and rectangular);

- non-standard (multifaceted).

A serious advantage inherent in these products is that they have high resistance to mechanical stress. Steel pipes withstand pressure and shock well. It is worth noting that they have an acceptable cost and belong to the middle price segment.

A wide variety of types of parts allows them to be used in various fields: construction, household, etc. Steel products have a small linear expansion rate. This is a very important advantage, since many pipes expand when heated, and if they are placed in a screed, this can lead to cracks.

In order to answer the question of how to calculate the weight of a pipe, it is necessary to become more familiar with all the methods that allow this calculation to be made. Knowledge of the weight of steel products is required at all stages, from their acquisition to installation.

A wide variety of steel pipes allows them to be used in various spheres of life.

Galvanizing of pipes

Galvanized pipes are highly reliable and reasonably priced. Thanks to a special protective zinc layer, resistance to corrosion increases. Damage to the protective layer may occur after deformation at the impact site, after which rust may form on the pipe. These products are used when equipment with a high-strength design is required, in which pressure and temperature changes will not occur. Zinc-coated steel pipes are excellent for temporary structures used in difficult environments.

Rules for calculating the weight of a steel pipe

Many people may think that determining the mass of pipes is a simple matter. However, such a calculation has many nuances that need to be paid attention to. First of all, it is important to remember that when purchasing a batch of steel pipes, it is necessary to check the weight. Any discrepancies in the calculations may lead to the fact that there is simply not enough material.

Excess weight may affect the construction characteristics of the future structure. The load exerted on the structure must be within the limits previously calculated and indicated in the corresponding drawing. The weight of 1 meter of pipe is calculated taking into account the grade of steel from which the product is made.

It often happens that the actual weight of the pipe does not correspond to the specific gravity prescribed in the regulatory documentation. This happens due to the nature of production. It is almost impossible to produce a product that perfectly matches the documentation. Therefore, GOSTs indicate permissible dimensional deviations.

When determining the weight of a meter of steel pipe, it is recommended to use several methods at once. This will reduce calculation errors to a minimum. If a formula is used to determine the mass, then it is recommended to double-check the reliability of the final results several times.

When purchasing a batch of steel pipes, you must check the weight.

Where is the VGP pipe used?

Water and gas pipes are made from high carbon steel using special technologies. Thanks to this, the VGP pipe receives additional qualities:

- high mechanical strength and impact resistance;

- resistance to pressure changes inside the pipe;

- immunity to sudden temperature changes and unfavorable external conditions.

Thanks to these characteristics, the use of VGP pipes is possible in various fields:

- laying a gas pipeline;

- installation of water supply systems (centralized or for a private home);

- creation of a heating system;

- construction of various structures (greenhouses, sheds, fences);

- production of furniture frames;

- construction of auxiliary structures (stairs, scaffolding).

VGP pipe in accordance with GOST 3262-75 is produced with different sections and wall thicknesses. This affects the areas of its use.

The outer diameter of the VGP pipe ranges from 10.2-165 mm.

Based on pipe wall thickness, HSV pipes are divided into 3 groups:

- Thin-walled. It is light in weight and has a wall thickness of up to 2 mm. Used to create small structures and in the construction of fences. Can be used to supply liquid under pressure not exceeding 25 kgf/cm2. Used to organize water supply in a private house.

- Average. The most commonly used option for various types of construction, for the installation of centralized water supply and heating systems. Wall thickness varies from 2.0 to 4.5 mm.

- Thick-walled. They have increased strength. Depending on the diameter, the wall can be from 4.5 to 5.5 mm thick. These products are able to withstand pressures of 32 kgf/cm2 and higher.

The use of thick-walled pipes is usually limited to the creation of large pipelines for transporting gases and liquids under high pressure. This is due to the fact that thick-walled pipes, due to the nature of their production, are more expensive.

For domestic purposes, VGP with medium and thin walls is usually used. They are cheaper, and their strength characteristics are sufficient for the construction of various structures on a suburban area.

Pipe weight: how to calculate weight when purchasing

Most often, manufacturers who produce various types of metal pipes sell their products in wholesale quantities. Individual parts are also sold, but the percentage is much lower compared to large orders placed by developers and individuals.

On a note! Measuring the length of products that make up one batch is not a convenient solution. In order to simplify implementation, the cost is calculated taking into account the mass of the batch, which is determined based on the mass of the part. To calculate it, you need to know the weight of 1 meter of pipe. This is the fastest calculation method, but it is not the best for the customer. This is due to the fact that after using steel pipes, as a rule, a certain percentage of surplus remains.

To determine the mass of a batch in production, two methods are used. The first of them takes into account the use of an online calculator. This program allows you to quickly calculate the weight of steel parts. Often, an online calculator is posted on the website of a company that produces steel products. Thus, each buyer can determine the required batch weight in a matter of minutes and immediately place an order.

To determine the mass of a batch of pipes in production, you can use several different methods.

The second method to calculate the weight of steel pipe for purchase is weighing. It is produced using special cargo equipment. This operation is performed in 2 stages. First of all, the car (or trailer) is placed on the scales, which allows you to determine its weight. Next, a batch of metal parts is loaded into it. The initial weight of the vehicle is subtracted from the resulting figure to obtain the total mass of the batch.

Each buyer can come to production if it is necessary to determine other characteristics of the batch. For example, you may need to calculate the number of pipes in one order. It is also very often necessary to know the length of products. As a result, carrying out such calculations will allow you to place an order not by weight, but by the number of packages.

Read the continuation of the article on the next page. To move to the next part of the article, use the page navigation numbers.

Materials for making pipes

The demand for tubular products in various industries allows them to be produced from a variety of materials. The raw materials for their production are:

1. Metals and their alloys:

- steel;

- cast iron;

- copper and its derivatives such as bronze and brass.

2. Polymer compounds:

- PVC compounds with chlorine;

- PVDF fluoride compounds;

- polyethylene;

- cross-linked polyethylene of several types, differing in the method of stitching;

- fiberglass;

- polypropylene;

- polybutene compounds.

3. Combined materials:

- metal-polymer products containing aluminum: the use of an aluminum intermediate load-bearing layer between two layers of heat-resistant polyethylene, connected with a special adhesive;

- copper metal-polymer pipes: copper is used as the working layer, the protective layer is made of a polymer material. No adhesive is used;

- steel with an inner layer of cement. To enhance their protective properties, they are waterproofed. For these purposes, you can use enamel;

- metal-polymer have a metal frame and a polymer body.

4. Concrete based:

- ceramic;

- asbestos-cement is used as a case for telephone lines located underground;

- concrete;

- reinforced concrete ones are used for drainage of waste and storm water.

Classification by shape and surface

Based on the type of cross-section, production method, and the presence or absence of a weld, pipes are divided into different types. round in cross-sectional shape

and

profile

. The latter are mainly square or rectangular, but when molded they can be given other configurations. The scope of their application is wide: from the construction of warehouse terminals to furniture. For example, from a square pipe you can make a frame for a wardrobe or a door frame for the front door.

According to the manufacturing technique, pipes are divided into extruded, centrifugally cast, forged, rolled, and deformed. The surface of the pipe can be polished, galvanized, ground or turned. The final stage of rolled metal production is mechanical or temperature treatment to give the finished product the necessary physical properties.

Classification of pipes by purpose

Pipes are produced in two categories: general

and

special

purpose. The former are used when laying water pipes, pipelines, risers, gas and hydraulic lines. They are used for pumping gaseous and liquid products into tanks. The classes of steel pipes - and there are six of them - show in which area a particular product can be used.

For example, class I pipes are used in cases where there is no need for specific properties of the product. From them you can mount scaffolding or an irrigation system, build a fence with strong posts or a fence from a wall, load-bearing or universal profile. But special-purpose pipes have a narrow specialization. Their areas of application include geological exploration, hydrocarbon production, construction, and mechanical engineering.

Galvanized pipes

Both sides of the pipe are coated with a thin layer of zinc, which does not interact with water. With this coating, corrosion occurs very slowly, which is why products last longer than non-galvanized ones and are more durable.

They have also found application in laying water pipes and for outdoor use.

Nowadays, several types of galvanized pipes are used:

- Hot galvanizing. The most popular method of galvanizing finished products. Disadvantages: uneven coverage and the possibility of sagging. The advantages include speed, low price and processing of products up to 12 m in length.

- Hot galvanizing of steel sheets. This method is suitable for processing pipes with thin walls; it is suitable for galvanizing steel up to 3 mm thick. The steel sheet is driven in a special solution and dried. The output has a uniform thin coating and reliable adhesion. One of the disadvantages is the additional work on the weld that appears during the manufacturing process.

- Thermal diffusion galvanizing. A new processing method that involves placing zinc particles with opposite charges on steel. Often, finished small pipes are subjected to this treatment. The advantage of this method is a high-quality coating without peeling, even in hard-to-reach places. Disadvantages include high cost, limited length and difficulty in processing.

- Galvanic coating. One of the most expensive processing methods, used mainly for coating small pipes, which are used in the manufacture of furniture frames, railings, etc. In addition to zinc, nickel, chromium and copper are applied in this way. Finished pipes are protected from rust for a long time and look nice. The disadvantages of coating include increased requests for material samples and high processing costs.

Galvanized pipes are divided into several types:

- Water and gas pipelines. Widely used when laying pipelines in buildings.

- Electric welded. Used when laying external pipelines and building various structures.

- Profile. Mainly used for the manufacture of metal structures in buildings and outside.