Bearings are needed in any components that use rotational motion. There are many standard sizes, and the main types are ball, roller and conical roller. Bearings operate under different conditions, therefore the materials for their manufacture may differ in chemical composition and characteristics.

Bearings of different types and sizes

How bearings work

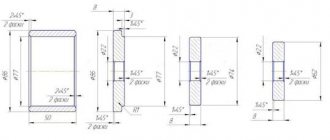

Bearings consist of a pair of rings (outer and inner), between which rolling elements are placed: rollers or balls. During operation, they move along raceways (grooves) made on the surface of the rings. To ensure that the rollers or balls do not move from the raceways and maintain the distance between them, the rolling bodies are placed in special cages (separators). Most bearings have this design, but some types operate without cages (they are characterized by a large number of rolling elements and a high load capacity, but a low maximum rotation speed).

The bearing consists of these parts: 1 – housing, 2 – rolling elements, 3 – cage (separator), 4 – groove for rolling elements, 5 – inner ring

Required material and tools

In addition to the bearing itself, in the process of making a knife you will need:

- wooden handles;

- brass pins for rivets;

- epoxy resin with hardener;

- oil, antiseptic impregnation for wood;

- consumables: paper, plastic tape, marker.

The oil for hardening is mineral or vegetable oil; old transformer oil or automotive waste oil is suitable. You will need copier paper in A4 or A3 format, wrapping paper for clamping the blade in a vice, and sanding paper of different grain sizes for sanding metal and wood.

It is necessary to have the appropriate equipment and tools available, as well as stock up on the following equipment:

- grinder with an abrasive disc and grinding wheel;

- an anvil or an analogue from an I-beam trim;

- hammer 4 kg, hammer 1 kg, blacksmith pliers and clamps;

- bench vise, chisel;

- furnace or forge;

- household oven;

- tabletop drilling machine;

- polishing machine;

- belt sander (grinder);

- Dremel;

- jigsaw and chisel.

Special requirements are placed on the stove; it must heat up to 1100 ºС, which is unattainable in the combustion zone of a conventional hearth. A thick-walled metal stove fired with charcoal is required. A conventional hood must be retrofitted with a supply fan.

It is best to use an abrasive disc to make it easier to cut the bearing race. A diamond coated bit will do. You should not try to use a milling cutter in the grinder - it will only slide along the surface of the hardened metal bearing.

Additionally, if you do not have sufficient experience working with forging tongs, electric welding will be required. With its help, reinforcement is welded to the workpiece, which will become a convenient holder for the knife workpiece when forging metal with a heavy hammer.

If you follow the recommendations of owners of bearing knives, it will not hurt to make or purchase a special device for sharpening the tool. It will allow you to maintain a high level of cutting properties of the knife during subsequent operation.

What are the general requirements for materials?

Cages, rings and rolling elements have different tasks, and therefore the requirements for them are different. Thus, separators must be durable, wear-resistant, able to withstand vibration and shock loads, have a low coefficient of friction and high dimensional stability. For their manufacture, low-carbon or stainless steels, brass or polymer materials are most often used.

Rings and rolling elements must be hard, durable, wear-resistant, maintain their dimensions during operation, have high dimensional stability, and withstand shock loads well. The material for their manufacture is selected taking into account operating conditions.

Annealing and forging of the workpiece

The steel is alloyed with chromium, so it must be annealed before forging. You must first heat the part red-hot in the oven and, without allowing it to cool, straighten it with a hammer on an anvil. The steel becomes ductile and, after cooling slowly in a furnace at a rate of 20–40 degrees per hour, is ready for forging.

The most critical stage of forging bearing steel should be carried out in the temperature range from 800 ºС, which corresponds to a cherry-red color of heat, and up to 1100 ºС, accompanied by a dark yellow glow. If you have a non-contact pyrometer, the temperature of the metal surface can be determined with an accuracy of ± 1.5 ºС.

You should first practice heating and forging metal on a regular rod. In order not to break the workpiece under hammer blows, it is better to heat the metal one more time than to continue processing it when it is cooled. It is easier to control the temperature by looking at the glow color; when a dull cherry glow appears, you should immediately place the part in the oven.

After heating, the knife part is placed on an anvil and flattened with hammers to the required thickness. If you have no experience working in a forge, you can limit yourself to straightening the workpiece, replacing the forging operation with stripping the workpiece. A correct knife forging technique is considered to be one in which:

- forging is carried out by shifting the metal from the middle of the blade to the edge of the blade, gradually becoming thinner;

- rounding of the tip is carried out with simultaneous drawing of the knife blank along the length;

- After final rolling of the plate, an allowance of no more than 2 mm remains.

The workpiece is heating up

We saw the cooled workpiece along the grooves with a grinder

The straightened workpiece is heated and hammered to a flat shape.

We stretch the resulting tail in length so that at the end it measures 5 mm by 5 mm.

How bearings are made

The production of separators takes the least amount of time: up to 5 days. Different methods are used for this:

- Steel ones are most often produced by stamping (with the exception of cages for large-sized bearings, which are made by mechanical processing). To do this, blanks are cut out of the sheet, holes are punched in them for the rolling elements, then they are given the desired shape using a stamp and ground.

- Polymer separators are produced by injection molding. Their main advantage is the combination of elasticity and strength.

- Brass cages are obtained as a result of mechanical processing of the workpiece. Their advantages are the ability to work in difficult conditions or at high temperatures.

Depending on the precision of execution, rolling elements can be manufactured in up to 25 days. At the same time, balls are more difficult to produce than rollers. First, the steel rod is cut into pieces, then the blanks are processed using a press to give them a spherical shape, then they are ground and heat treated.

Rings can take up to 1 month to make. To do this, a steel pipe is first cut to obtain blanks, then they are formed, heat treated, ground and polished.

What degrades bearing performance?

The most noticeable deterioration of bearing performance is sulfur, phosphorus and oxygen. They can enter steel from ore or refractory materials in smelting furnaces and then remain in the material, reacting with metal components. To remove harmful inclusions, bearing steels are subjected to additional processing. In this regard, vacuum or electroslag remelting has performed well.

Bearing steels

A special group of structural steels includes bearing steels

used for the manufacture of rolling bearings (ball and roller). In terms of chemical composition and properties, these steels are close to hypereutectoid tool steels.

When bearings operate under load in the contact zone, compressive stresses arise in the surface layers of the parts. In the case of cyclic contact loads, stages of damage to the material develop successively: plastic deformation, exhaustion of the safety margin, the formation of microcracks in the surface layer, propagation of cracks deeper and chipping of metal particles (chipping). As a result of this process, a defect called pitting (the result of fatigue chipping) is formed on the surface of the part.

Contact fatigue

— the process of gradual damage to the surface layers of parts (chipping) operating under conditions of cyclic contact loads of high frequency.

The material's resistance to contact fatigue is called contact endurance.

, it is quantitatively assessed by the limit of contact endurance oR. Contact fatigue tests are varied, so they often use such a characteristic as contact stress ok, at which the sample can withstand a certain basic number of cycles: Nts = 10v6 (or 10v7).

Requirements for increased contact endurance are imposed on the materials of such parts as rolling bearings and gears - widely used critical parts: the performance of components and mechanisms, for example, metal-cutting machines, electric motors, cars, tractors, carriages and other structures, depends on their reliability and durability.

Bearing steels are intended for the manufacture of ball and roller bearings. These alloys have special markings: the first letter in the steel grade of this group is capital Ш, followed by the letter X, corresponding to chromium, and a number that indicates the percentage of chromium multiplied by 10. For example, steels P1Х15 and ШХ20СГ contain 1.5% and 2.0% Cr, respectively. The letters C and G indicate the presence of silicon and manganese.

Requirements for the properties and structure of bearing steels depend on the bearing design (ball, roller), operating conditions and dimensions. In table 14.12 shows data for ball bearings with a diameter of <60 mm operating without dynamic loads at temperatures of -60...+300 °C.

Steel grades ShKh15, ShKh15SG, ShKh4, ShKh20, ShKh20SG are intended for general purpose bearings; The chemical composition of steels is regulated by GOST 801-78. The carbon content in all steels is about 1%.

The use of alloying components in bearing steels is explained by the fact that:

• high carbon content (0.90...1.10%) ensures hardness after quenching and low tempering, the formation of a large amount of cementite;

• chromium (1.3...1.7%) increases hardness and, along with silicon and manganese, provides hardenability.

Heat treatment of bearing steels is typical for hypereutectoid steels and is carried out in several stages:

1) spheroidizing annealing;

2) hardening from temperatures 820...900 °C;

3) cold treatment at temperatures -70...-80 °C;

4) low tempering at 170…200 °C.

After this multi-stage heat treatment, the steels have fine grains, their phase composition includes tempered martensite with spherical cementite particles (granular). This structural-phase state of bearing steels ensures a hardness of 61...65 HRC and high contact endurance.

The hardenability of steels increases as the concentration of alloying components increases. Thus, steel ШХ15 is intended for the manufacture of ball bearings with a cross section of 10...20 mm; more alloyed steels ШХ15СГ, ШХ20СГ - for parts with a diameter of over 30 mm. For bearings of other shapes and sizes operating under different loads, special steels are used.

In the manufacture of high-speed bearings

Electroslag remelting (ESR) is mandatory to increase the purity of steel by minimizing non-metallic inclusions. In this case, in the marking of steels, the letter Ш is added after the hyphen, for example ШХ15-Ш.

Railway Roller Bearings

experience dynamic loads, so through hardening cannot be used for them. For such parts, steel with reduced hardenability has been developed - ШХ4. Parts made from this steel are subjected to high-frequency hardening, after which a highly hard surface layer 2...3 mm deep and a viscous core are obtained.

For the production of large roller bearings with a diameter of up to 2 m

Cemented low-carbon alloy steels are used (18KhGT, 20KhNMA, etc.): the hardness of the core is at least 35...45 HRC, which prevents punching of the cemented layer under contact loads during operation.

For bearings operating in aggressive environments, corrosion-resistant high-chromium steel 95X18 is used.

Preparation of overlays

The ergonomics and overall perception of the knife depend on the correct choice of material for making the handle. Metal alloys, plastics, genuine leather, and elastomers are used as the starting material for the manufacture of knife handles. Hard and valuable wood species are irreplaceable for this purpose.

The overhead handles, most suitable for the shank of the bearing knife, consist of 2 identical halves. You will need to stock up on scraps of metal rod for the knife handle pins. In the case of using wood, the following sequence should be followed:

- the antiseptic-treated block is clamped in a vice and sawn into 2 identical parts;

- to eliminate gaps, thoroughly sand the sides in contact with the metal;

- the contour of the knife handle is drawn, two dies are cut out with a jigsaw;

- the halves are placed on the shank, the holes for the pins are marked and drilled.

Handle preparation

Roughing and grinding the forging, transferring contours from the template

After this, the part is peeled using a sharpener or belt sander. During the processing process, excess layers of metal and unevenness are removed, and the surface becomes perfectly smooth and shiny.

At the next stage, a template of the cutting tool is prepared on paper on a scale of 1:1. A paper copy is cut out with scissors and traced with a marker on a sanded plate. It happens that the outline transferred to the workpiece is difficult to distinguish or is erased during subsequent cutting. In this case, you should duplicate the contours of the knife by scratching lines on the metal with a scriber. Instead, any bench tool with a tool steel tip will do.

The plate is clamped in a vice and cut using a grinder according to the template. In the most curved areas, many cuts are made, small fragments of metal are cut out in “steps”. In order to remove the remaining pieces and nicks, the semi-finished knife is ground with a grinding attachment.

Using a marker, draw the shape of a knife on the workpiece and cut it out

We refine the corners and make a smoother line

Assembly

You need to dilute the epoxy glue. Marks should be applied to the dies being joined or shallow dents should be pressed for better adhesion of the epoxy layer. Be sure to degrease the metal part of the knife, which will be located inside the handle. Assembly is carried out in the following sequence:

- Epoxy glue is applied to the surface of the overlays from the scratch side;

- the halves are placed on both sides of the shank, pins are inserted into the holes, the assembled handle is wrapped in paper and tightly compressed with a clamp;

- after the epoxy has hardened, use a wood cutter to remove chamfers from the edges of the knife pads;

- Using sandpaper on a fabric base with a grit of 80, rough processing of the wooden dies of the knife handle is carried out;

- Polish the handle clean with strips of sandpaper.

The polished surface is covered with linseed oil heated to 50–60 degrees. After absorption, the procedure is repeated 2-3 times. There is no need to varnish the knife handle later. Under the influence of ultraviolet rays, the oil polymerizes, turning into a hard elastic substance. It fills the smallest pores of the wood, protecting the knife handle from moisture and external influences better than any varnish.

Cleaning and pickling

Unsightly scale and traces of burnt oil on the forged blade are removed with a grinder and a 240–320 grit sanding belt. Scratches remaining after machine processing are removed manually using 320-400 grit abrasive paper. Processing is carried out by straight-line movements of sandpaper directed at an angle of 90 relative to the direction of the grinder scratches.

From grinding with a P400 zero polish, they move on to polishing with a material with a grit of 600–800. Wetting the abrasive paper with water allows you to polish the product more effectively. A mirror shine appears after treatment with GOI paste or other polishing compound applied to a piece of leather.

In an additional etching operation, inscriptions, ornaments, and drawings are applied to the metal surface of the knife. Typically a technique is used in which a stencil is glued to the image area, and the surface around it is sealed with masking tape. Then a mordant is applied for a certain time, after which the knife is washed in water.

Blade hardening and tempering

Heat treatment is carried out in order for the steel to achieve the required parameters and is carried out in two stages. At the hardening stage, the metal acquires high hardness, strength and wear resistance. The blade should be heated in an oven to 830 ºС and immediately placed for one hour in a cuvette with oil heated to 50–60 ºС.

How to harden a knife from a bearing without a pyrometer? There are two ways to determine whether the product has reached the required temperature in the oven:

- sprinkle the instrument with table salt and note the moment of NaCl melting, it occurs when t = 800 ºС is reached;

- the magnet stops “sticking” to the metal at the temperature of the restructuring of the crystal lattice of the material, which occurs before melting.

Heating the oil is required to liquefy it so that it better envelops the homemade tool. During processing, the product should not be turned over; the hardening substance should not be added or shaken. You should be especially careful with oil. When hot metal is immersed, it tends to ignite.

At the tempering stage, an optimal combination of strength, ductility and toughness of steel is achieved. At the same time, the internal stress of the material is relieved. The instrument is placed in an oven heated to a temperature of 170–200 ºС, where it is kept for two hours.

Cooling of the handmade semi-finished product to ambient temperature occurs naturally in the switched off oven.

You can check the quality of hardening using a needle file. If, when running along the edges of the blade, it slides, hardening the knife from the bearing has achieved results. Also, the testing method involves trying to cut a glass bottle; the blade should leave scratches on the glass. This blade is used to shave the hair on a hand and plan a suspended sheet of paper.

After hardening, an interesting pattern appears on the blade

Sharpening and polishing the blade

Let's move on to such an important point as sharpening the knife. When doing this, symmetrical sharpening on both sides of the blade is important. It is also necessary to create the required bevel angle of the knife blade, which for ordinary knives is 15 - 25º. On razors, the smallest angle is 8–15 degrees, on tourist knives 25–30º. Manually sharpening a knife blade on a whetstone is unproductive. This is done simply and efficiently on a belt sanding machine called a grinder.

If you need to sharpen a knife to razor sharpness, special sharpening devices with replaceable abrasive bars are used. With the help of such equipment, it is not a problem to create any angle of descent from the butt of the knife or descent of the cutting edge of the knife.

Once the rough shaping and sharpening of the knife is complete, it's time to fine-tune the metal using a grinder and Dremel attachment. Through holes are drilled for the pins for attaching the knife handle. In order to better bond the wooden plates to the metal, about a dozen blind holes are made on both sides of the knife shank.