05/07/2021 Author: VT-METALL

Issues discussed in the material:

- Pros and cons of gas and electric welding

- Gas welding technology

- 3 electric welding methods

Every professional welder knows which welding is better - gas or electric. This question is often asked by beginners who are just learning the basics of welding. However, there is no clear answer to this question. Each type of welding is designed to perform certain types of work and is suitable for processing certain metal workpieces.

If we talk about which welding is best to learn for beginners, then, definitely, electric welding. It does not require such high qualifications as gas, and the equipment and components themselves are simpler and cheaper. From our material you will learn about the advantages and disadvantages of gas and electric welding.

Which welding is best to use?

Which welding will produce less smoke?

Which welding is best to use in an apartment when replacing a steel cold water riser with steel. The pipe is leaking

I myself work in a housing office, no one has ever suffered from smoke when welding, there are pros and cons everywhere regarding materials.

I recently encountered in one company that often does work for wealthy private owners that acetylene welding is considered a priority (heating radiators - the seam is visible). With acetylene, they say, if you weld it, then in any case the seam looks flawless, but with electric arc - maybe it will be beautiful, maybe not. Everyone has their own standard of what “beautiful” is. Well, if they want to use gas welding, that’s up to the owner; in this case, there is no ban on using gas welding.

In this case, gas welding is better

It is believed that gas welding is more effective than electric welding when welding thicknesses from 0.2 to 5 mm. In other cases, electric welding is more economical.

Welder Joe is considered to be the worst type of welding in terms of quality and performance, and was excluded as a subject of study for vocational schools and technical schools in 1988.

I entered training as a general electric welder in 1989 in the city of Chisinau, and I didn’t care whether there was gas welding there or not, because I was a city boy, and the road to the plant was prepared for me. But the kids who came from the village to study didn’t like this arrangement at all, and they were given this activity as an elective.

Welder Joe is still suitable for non-responsible structures, gas welding greatly overheats the metal, and now she is prohibited from performing most metal structures

Post edited by LekhaKolyma: 03 April 2022 19:46

It is still suitable for non-responsible structures, gas welding greatly overheats the metal, currently it is prohibited from performing most metal structures

It is believed that in terms of quality and performance this is the most unsuitable type of welding

All this is true, but try using any other type of welding to weld it to an old rusty pipe somewhere where neither your hands nor your eyes can really go. For example, in the ceiling, under the floor of a neighbor who, due to infection, does not let him in. When installing gravity heating, it will give any other type a head start. But that's probably all. Tinsmiths have already forgotten about it, but before they cooked cars? Gas welding. And they drove and didn’t fall apart.

But, in general, of course, this type of welding is becoming a thing of the past. Because those types of work where it is not replaceable are disappearing.

Post edited by SergDemin: 03 April 2022 20:16

Source

What gases are used in welding

In order for gases to burn with maximum efficiency, oxygen without impurities is needed. Depending on the degree of purification, it can be:

- premium grade (concentration 99.5%);

- 2nd (99.2%);

- 3rd (98.5%).

Since gas welding is not done under sterile conditions, it should be taken into account that spontaneous combustion may occur when oxygen comes into contact with technical oils. Cylinders should be stored in a room where there are no sources of open fire in a place where the sun's rays do not reach.

Most often, acetylene is used in tandem with oxygen, since its combustion temperature reaches 3400⁰C. It is obtained from calcium carbide when dissolved in water.

Note!

At high pressure or temperature, acetylene explodes. Therefore, according to safety regulations, installing a water seal is mandatory.

Propane takes second place with a combustion temperature of up to 2800⁰C. Gas mixtures of oxygen with methane, hydrogen, kerosene vapor, and blaugas are significantly inferior in temperature to the leaders. Used only for working with non-ferrous metals with low melting points.

What is the difference between gas welding and electric welding?

Electric welding differs in many ways from gas welding. Scope of application, methods, process characteristics, economic feasibility, equipment, tools, efficiency, material to be welded, etc.

Electric arc welding is a process in which sections of metal to be joined are melted and then bonded together under the action of an electric arc. Welding is performed using an electrode, which melts or heats the surface.

Equipment

for electric welding :

Gas welding requires the following equipment:

The differences in the components for welding may not be so significant, but when it comes to performing work in places remote from sources of electrical energy, gas welding is most often used. In addition, gas is often used for welding when it comes to utility repairs (residential, non-residential premises, heating mains, etc.) That is, gas is more convenient in field conditions. Oxygen and acetylene cylinders are much cheaper than a diesel generator.

Characteristics of the gas and electric welding process

Gas welding has the following main properties:

Electric welding has the following features:

Economic efficiency of welding

This indicator strongly depends on the thickness of the metals being welded - gas welding will be effective and economically justified up to a metal thickness of 6 mm. Thicker plates will require an unreasonably large amount of gas. On the other hand, for welding small, thin metal surfaces, the use of expensive tools and expensive electricity is also not economically feasible.

Materials to be welded

Metals such as copper, brass, lead, cast iron, etc., are easier to gas weld than electric arc welding. In addition, their rapid heating can lead to a change in strength.

Conclusion

Based on the above, when choosing a welding method, it is necessary to take into account many factors in order to obtain the maximum technological and economic effect.

Source

The essence of the fusion welding process

Fusion welding is a method of joining workpieces by melting contacting surfaces without compression. The energy source must provide sufficient power to melt the edges of parts and filler material. To form a weld pool, which is a mixture of liquid metals, the flame is concentrated on a small area of the joint. By moving the point of application of thermal energy along the joint line after cooling, a weld seam is created along the entire length.

Contaminants melt along with the metal, so slag forms on the surface of the bath. The upper layers are heated above the melting point, which leads to a change in the structure and mechanical characteristics of the seam after cooling. The advantages of fusion welding include versatility and the ability to join dissimilar metals.

What is the difference between argon welding and conventional welding?

Issues discussed in the material:

Not every novice welder knows how argon welding differs from conventional welding. First of all, it is necessary to understand the precise and free terminology. By “conventional” we most often mean the most common method of welding ferrous metals – electric arc. Argon, also known as argon-arc welding, is most often used when working with non-ferrous metal.

In addition to the working materials, both types of welding are fundamentally different in technological processes. From our material you will learn about the strengths and weaknesses of technologies, their main differences, and operating features.

Types of argon welding

Today, manual, mechanized, automatic and robotic technologies are used to join workpieces in a protective argon environment.

Is manual argon welding different from conventional welding? Apart from the difference mentioned above, there is no difference. In both cases, the process of joining the workpieces (moving the torch and feeding the filler wire) is performed manually. The technology is used both for welding simple parts and for working with complex structures. The disadvantage of manual welding (both argon and conventional) is low labor productivity. In addition, the welder needs quite a lot of experience to do the job well.

Otherwise, this technology is called semi-automatic, or semi-automatic welding. The welder operates the torch manually, and the filler wire is fed automatically. The productivity of this technology is three times higher than that of manual technology, and besides, a low-skilled specialist is enough to cope with the work. This type of joining of workpieces is widely used in shipbuilding.

Automatic argon welding is similar to conventional welding in that in both cases the parts are joined without the participation of a welder. Special equipment is used to weld workpieces. Its specificity directly affects the complexity of the work performed, the quality and configuration of the seam. The simplest seams are used to connect pipelines; automatic welding machines are used for their installation. This is the most productive technology with which it is possible to lay a pipeline even on the bottom of the sea.

Despite the fact that welders are not directly involved in the process of joining parts, highly qualified specialists set up the equipment, prepare it for work, and service and repair it.

Some time ago, another argon welding technology appeared - robotic, in which the connection of workpieces on conveyors is performed by robots. Its advantages include high productivity, as well as low cost.

The disadvantages of the technology are the high cost of equipment and the need to hire highly qualified specialists to configure and maintain robots. The installations are created by designers, and the software is developed by programmers. Both must have the highest qualifications. Robotic argon welding is used in the automotive industry. Economically, this technology is justified for large volumes of work.

Two methods of argon welding

How does argon welding with a consumable electrode differ from conventional welding? In this case, the welder, in addition to the current strength and electrode, selects the additive supply rate and the type of inert gas. The use of protective gases supplied to the work area from high-pressure cylinders increases the cost of work. The shielding gas is most often a mixture of 75% argon and 25% carbon dioxide. The wire wound on a coil acts as a consumable electrode.

Despite the difficulties that lie in the need to simultaneously control the supply of wire, gas, and current strength, the welds obtained in this case are characterized by high quality. In addition, the speed of work is higher than when using MMA.

It is easy for novice welders to work with semi-automatic MIG inverters, since during the welding process there is almost no spatter of molten metal, no slag is formed in the weld, and a small amount of smoke is generated. MIG technology is simpler than MMA when comparing labor costs and the quality of the resulting welds.

The additive gun design makes the job faster. MIG is optimal for welding thin sheet metals. It should be borne in mind that the surface of the workpieces must be thoroughly cleaned; this is why argon welding differs from conventional and MMA welding.

Argon welding differs from conventional welding in that it is difficult to use in open areas. This is due to the risk of wind blowing shielding gas out of the working area, which will negatively affect the quality of the seam. A special welding wire with a flux core allows you to cope with this disadvantage. Its properties are similar to a consumable electrode in a coating. This wire can be used instead of liquefied gas.

Argon TIG welding differs from conventional, MMA and MIG welding in a large number of conditions and elements used. This is a universal technology that allows you to work with almost any metal, including aluminum. However, it requires a higher qualification from the welder. In addition, the cost of work is also higher than with other types. Argon TIG welding is optimal for body work; it is also used to connect elements of artistic forging, and is used where, after completion of the welding work, the seams should not be visible. The seams obtained using TIG are distinguished by their visual appeal, especially for fans of the dieselpunk style.

Argon welding with a non-consumable electrode is performed using both alternating and direct current; the electrode itself does not burn out. This is due to the tungsten contained in it. Since the size of the electrode does not change during operation, it is easier for the welder to control the position of his hand. The current intensity is adjusted using a foot pedal, so the specialist needs to precisely coordinate his movements.

This technology allows you to work with low current values, which guarantees the safety of even very thin workpieces. When choosing low current settings, you must thoroughly clean the surfaces of the parts to be welded, and also be prepared for the fact that the work itself will take longer. Argon TIG welding is suitable for joining aluminum products that cannot be welded using other technologies.

Which welding is better

It is incorrect to say that semi-automatic welding is better than electric arc welding or vice versa. Each option has its own advantages and disadvantages that need to be considered before choosing a specific type of welding.

Pros and cons of manual arc welding

Advantages:

- Ease of operation and maintenance of equipment . Almost every person can master the basics of arc welding.

- Such welding can be carried out in different positions : both from below and from above, and at an angle and from the side.

- Thanks to the possibility of using a bent electrode, the seam can be laid in hard-to-reach areas of the product.

- The manual welding method allows you to work with a large number of metals.

Flaws:

- Electromagnetic radiation emitted during work is harmful to the health of the worker.

- The quality of seams depends, first of all, on the skills of the welder..

- Compared to other options, arc welding does not have the same efficiency and productivity.

Pros and cons of semi-automatic welding

Advantages:

- You can even work with metal products that are slightly corroded.

- The connection process does not require significant costs for consumables.

- The range of applications for semi-automatic machines is quite high ; they can be used for welding thin steel sheets up to 0.5 mm thick.

- Copper alloy wire can be used.

- During operation, the liquid metal is reliably protected from exposure to air.

- Oxide and slag do not appear on the seams.

- The connection is created faster than with manual welding.

Flaws:

- If there is no protective gas jet, the metal from the weld pool may splash heavily.

- Semi-automatic welding creates a brighter electric arc , so the issue of eye protection must be taken seriously.

The nuances of working with argon welding

Argon welding is similar to conventional welding in that both technologies, in addition to theoretical knowledge, require practical skills. And before you start practicing, it’s worth learning about the nuances of working in a protective environment of inert gases in order to avoid mistakes during the welding process that negatively affect the quality of the welded joint.

First of all, it is necessary to thoroughly clean and degrease the edges of the workpieces to be joined. In this regard, argon welding is also no different from conventional welding. Cleaning is necessary even if the metal surface does not visually contain any traces of dirt or corrosion. It is better to perform the welding itself with a short arc, since with a long arc the weld will be wide and shallow and, as a result, of low quality.

The arc when using argon welding should be short, the electrode rod should be as close as possible to the metal surface. To obtain a narrow, deep seam, the electrode should be moved longitudinally without sideways deviations and without transverse movements. Otherwise, the quality of the seam will be worse.

Both the filler wire and the electrode must be placed exclusively in the working area, otherwise the protective properties of argon will be impaired, resulting in oxygen entering the weld pool. The additive must be supplied smoothly and evenly, without jerking. Violation of this requirement will lead to severe spattering of the metal and a decrease in the quality of the weld.

The essence of electric arc (conventional) welding

It will take time to learn how to properly perform argon welding. The welder will have to not only study the essence of the welding process, but also become familiar with its features and, of course, develop practical skills. It is important to understand the difference in the properties of various metals, understand welding machines, choosing the one that best meets the needs of a specialist, appropriately equip a workshop for the work, establish and justify their cost. After all, regardless of whether argon welding differs from conventional welding, both can bring profit to the welder. Of course, if he decides to do it professionally.

Let's take a closer look at the nuances of TIG, MIG and STICK technologies - knowing the features, advantages and disadvantages of each of them, it is easier to choose the most suitable option.

Argon welding differs from conventional welding in that in any case it uses an electrode, filler wire and inert gas, which performs a protective function and improves the quality of the weld. But these elements will vary depending on the technology used. Thus, in different versions of argon welding, consumable and non-consumable electrodes are used, the filler wire is made of different materials, and in addition, the inert gases used differ.

Requirements for the quality of welding seams

The list of requirements for welded joints is determined by the purpose of the finished product. However, there are mandatory requirements in accordance with which the weld must be made. In terms of hardness and strength, it should not be inferior to the metal of the workpieces.

For visual inspection, the seam is cleaned of slag and scale that are formed during fusion welding. The width of the seam should be the same along the entire length, the surface should be finely scaly. The presence of sagging, omissions, or narrowings is not allowed. If the metal has pores or cracks, the seam is rejected.

The type of fusion welding is chosen depending on the tasks being solved. When you often have to work outdoors, portable arc devices or a gas torch with cylinders will be more convenient. When working at one place, it is better to choose a semi-automatic option, and for mass production, an automatic one.

Types and nuances of electric arc welding

The simplest type is welding using a consumable electrode. In addition to simplicity, this is also the most affordable option from a financial point of view.

The simplicity of the process lies in the fact that it only requires the welder to select a suitable electrode and the required amperage. An electric arc melts the metal of the electrode, and a protective gas environment protects the weld pool from the penetration of oxygen formed during the combustion of the flux that covers the electrode. Protection is necessary, since oxygen, when reacting with the metal of the workpiece, causes its oxidation, which negatively affects the quality of the weld.

When developing certain skills, a welder can perform various types of welding work using a consumable electrode in a coating. It is suitable even for uncleaned surfaces or metals showing signs of oxidation. The main thing that a specialist must do is to choose the right electrode. The welding process can use both alternating and direct current.

Argon welding differs from conventional welding in that it is more difficult to control the process in this case. During operation, sparks are formed, the seam becomes clogged with slag, which reduces the strength of the welded joint. It takes a lot of effort to do a good weld. Also, this technology is not applicable when working with aluminum, sheet metals and thick massive workpieces.

Electric arc characteristics

An electric arc, which is formed using a welding machine, is, in fact, an electrical discharge flowing in a gas environment. The electric current that moves in it receives this opportunity due to the presence of an electric field in it. For the purpose of streamlining terminology, such an arc is usually called a welding arc.

The welding arc, which is the main element of the formed electrical circuit, is characterized by a decrease in voltage. If the welding electrode is connected to the positive terminal of the welding machine, it is called an anode, if it is connected to the negative terminal, it is called a cathode. When performing electric arc welding using alternating current, the cathodes and anodes alternate places.

The most important parameter of the welding arc is the distance between the interacting electrodes. Such a gap through which electric current flows is called an arc. The flow of electric current through such a gap is possible only if it contains charged particles - electrons and ions. Initially, naturally, such particles do not exist in this interval. For them to appear, the ionization process must be started.

Arc Welding Structure

Ionization of the arc gap occurs as follows: electrons begin to be emitted from the surface of the cathode, which charge the vapors and gases formed above the weld pool. The welding arc is:

- compressed type (its cross-section can be changed using the nozzle of the welding machine, the magnitude of the electromagnetic field, and gas flow parameters);

- free (it is also called a direct arc - the parameters of an arc of this type are not adjustable, they are unchanged).

Why should you contact us?

We treat all clients with respect and carry out tasks of any size equally scrupulously.

Our production facilities allow us to process various materials:

When completing an order, our specialists use all known methods of metal machining. Modern equipment of the latest generation makes it possible to achieve maximum compliance with the original drawings.

In order to bring the workpiece closer to the sketch submitted by the customer, our specialists use universal equipment designed for jewelry sharpening of tools for particularly complex operations. In our production workshops, metal becomes a plastic material from which any workpiece can be made.

The advantage of contacting our specialists is their compliance with GOST and all technological standards. Strict quality control is carried out at every stage of work, so we guarantee our customers a conscientiously completed product.

Thanks to the experience of our craftsmen, the output is an exemplary product that meets the most demanding requirements. At the same time, we start from a strong material base and focus on innovative technological developments.

We work with customers from all regions of Russia. If you want to place an order for metalworking, our managers are ready to listen to all the conditions. If necessary, the client is provided with free specialized consultation.

Source

What is the difference between gas welding and electric welding?

Gas welding requires the following equipment:

- a special gas burner; - flexible communication tubes; - a special filler wire (sometimes they do without it).

Electric welding requires the following components:

— electrical power source;

The differences in the components for welding may not be so significant, but when it comes to performing work in the steppe, forest, and places remote from sources of electrical energy, gas welding is most often used. In addition, gas is often used for welding when it comes to utility repairs (residential, non-residential premises, heating mains, etc.) That is, gas is more convenient in field conditions. Oxygen and acetylene cylinders are much cheaper than a diesel generator.

Characteristics of the gas and electric welding process

Gas welding has the following main properties:

— a large area is heated;

- automation of gas welding is difficult; - gradual heating of the metal; - with increasing metal thickness, the productivity of gas welding decreases.

Electric welding has the following features:

— a small area is heated;

- full automation of the electric welding process is possible; - the metal being welded heats up almost instantly; - productivity during electric welding practically does not depend on the thickness of the metal.

Economic efficiency of welding

Lead, copper, cast iron, brass, etc. Metals can be welded more easily by gas welding than by electric arc welding. In addition, their rapid heating can lead to deterioration in properties, for example, to a change in strength.

Thus, the choice of welding method depends on many factors that must be taken into account in order to obtain the maximum economic and technological effect.

Advantages and disadvantages

The advantages of gas welding include:

- low price of equipment;

- possibility of welding and cutting in field conditions;

- regulation of flame power over a wide range;

- welding of most types of metal and alloys - from aluminum to alloy steels;

- smooth heating, preventing the deformation of parts and the formation of cracks.

Flaws:

- Low efficiency due to high heat dissipation. For the same reason, the technology is not cost-effective when welding workpieces thicker than 5 mm due to excessive gas consumption.

- Heating a large area of areas adjacent to the seam contributes to the formation of residual stresses in the metal.

- When joining with an overlap, there is a high probability of deformation of the parts.

- Due to the peculiarities of the operating principle, the gas welding process is difficult to mechanize.

- The use of flammable gases is associated with a high explosion and fire hazard.

Gas or electric welding?

Today we want to figure out what the features of each method are. And is it possible to answer the question, which one is better? They differ significantly in operating principles, tools, scope of application and other parameters. Let's take a closer look at each type.

Electric

It is also called electric arc. It joins metals by melting and bonding parts under the influence of an electric arc. A special electrode helps with this, which, when melted, acts as glue.

When working with the popular argon, a tungsten electrode is used. Argon displaces oxygen from the working bath, that is, it protects the welding site from unwanted impurities and gases. Oxygen has a bad effect on the quality of the seam. Therefore, argon arc welding is used, since this gas is 38% heavier than air.

Electric welding can occur under the influence of alternating or direct currents. To work with alternating current, you need a welding transformer. It produces a powerful electric current to stabilize the arc.

Gas

Unlike electric welding, gas welding occurs due to a jet of burning gas from a special torch or cutter. To start cooking, connect 2 cylinders with different gases to the burner: the one that will burn (can be propane, butane or methane) and the oxidizer (oxygen). And sometimes it is better to use acetylene, which “works alone”.

Pros and cons of welding methods

Both options have their advantages and disadvantages. The features of electric welding include the following points:

To summarize, we can say that it is simply impossible to objectively determine which welding is better - gas or electric. They are both unsafe and require a highly qualified performer. Depending on the situation and the composition of the material being joined, one or another method is better.

What is better to choose for your home - an inverter or a semi-automatic machine?

The design of the inverter and the semi-automatic device are different, as is the scope of application. To weld with an inverter, you need electrodes with coating; for a semi-automatic machine, a special wire and gas, which will act as a protective medium.

It goes without saying that for semi-automatic welding you will need gas cylinders. Plus, they need to be refueled from time to time. Consequently, such equipment, like the semi-automatic device itself, is characterized by large dimensions and weight.

In the case of a conventional welding inverter, none of this is required. For welding, you only need coated electrodes and welding tools. However, as mentioned above, the scope of application and solution of welding problems for a semi-automatic machine and a conventional inverter are completely different.

Gas and electric welding

Most connections of metal elements and parts are made by welding. The two most common types are gas and electric. In any case, welding is the process of forming a strong connection between metal surfaces as a result of heating their edges to a high temperature and forming interatomic bonds along the joint line.

In order to understand what gas and electric welding is, we will consider the main features and principles of their operation.

Operating principle of electric welding

If metal welding is carried out using an electric arc, then it is classified as electric arc. The metal parts are connected by means of an electrode, which can either melt to form a bonding seam, or be used solely to heat the contact surface, while remaining inert.

Electric arc welding with alternating current requires a welding transformer that provides high currents of 200-500 amperes on the secondary winding, which is necessary to stabilize the arc discharge. When welding on direct current, you will need a rectifier unit that ensures a uniform load on the electrical network.

Operating principle of gas welding

When gas welding a metal, its surface is heated by a hot stream of burning gas flowing from the torch nozzle. As a rule, the co-combustion of two different gases is required - the original fuel (propane, methane or butane), mixed with an oxidizer, which is most often oxygen. However, when acetylene is used, a sufficient amount of oxidizing agent is already contained in the surrounding air.

Electric arc welding is used in places with a reliable power supply, where the network is able to withstand its starting and operating currents. It is lighter and more compact than gas analogues. Gas welding is preferable in field conditions, away from electrical networks.

Source

Gas welding technology

Gas welding is a method of joining metals that involves the use of gases that create high temperatures, most often acetylene and oxygen, but there may be others. The main role in this process is played by the flame, on which, firstly, the heating temperature depends, and secondly, the possibility of melting a particular metal. It itself consists of a core in which acetylene decomposes, a reduction zone where the oxidation of hydrogen and carbon occurs, and a torch where the gas finally burns.

Depending on the ratio of oxygen and acetylene, there are three types of flame:

- Normal - in this case, gases are supplied in equal proportions. All zones in such a flame are blue, but the recovery zone is slightly brighter.

- Carburizing - has a bright yellow color and indicates a lack of oxygen.

- Oxidative - occurs when there is a lack of acetylene. Such flames are usually pale and short.

During welding, the worker regulates the supply of gases depending on the flame, focusing on their color. In addition, the temperature at which the metal will be exposed depends on its type. As a rule, it is at least +3,000 °C, which makes it possible to cut and melt different types of products.

Most often, a normal flame is used for melting and cutting metal, that is, when gases (oxygen and acetylene) are supplied in equal proportions. However, if the color of the fire begins to change, the settings should be adjusted.

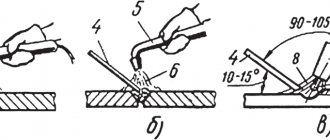

Methods for implementing gas welding can be as follows:

- gas-flame - a special filler wire is used, which melts together with the metal and fills the gap formed between them;

- gas press - in this case, the parts are fastened by tightly connecting pre-melted edges (filler wire is not used).

It should be noted that not all metals can be joined by flame welding. Most often it is used in relation to:

- tin and sheet steel no more than 5 mm thick;

- cast iron;

- non-ferrous metals;

- tool steel.

The above metals are similar in that only smooth and soft heating can be applied to them, and only gas welding can provide it.

Cutting and welding of metals with gas is used both in everyday life and in many industries. Since the part is heated gradually, this eliminates its deformation, therefore for thin metals this method is one of the most suitable. In order for the work to be carried out efficiently, it is necessary to adjust the flame and adjust the gas supply. This is done like this: the oxygen and acetylene valves are opened completely, after which the burner is ignited using a match or lighter. Next, only the acetylene valve is adjusted, while the oxygen valve still remains fully open.