During the hot-dip galvanizing procedure, various types of electrolytes are used. This is due to the fact that on the cathode surface, electrolytic separation can occur from solutions with different compositions.

In this case, zinc itself can be present in them in the form of cations or anions.

It is necessary to pay attention to the fact that when using zinc, its standard potential is 0.76 V. At the same time, the use of electrolytes for galvanizing leads to the potential becoming negative. This feature should also be used during processing.

The industry also takes into account such a parameter as the potential for hydrogen evolution.

The galvanizing process is necessary to ensure proper deposition of zinc coatings. To achieve set production goals, the use of different electrolyte options is allowed.

The list of electrolytes is very extensive. These include acidic, ammoniacal, zincate, cyanide and others.

It is important to choose the correct electrolyte option, because this parameter will directly affect the quality of the zinc coating, electrolysis conditions and other central parameters.

Let's consider the main parameters of electrolytes, the use of which is common during the hot-dip galvanizing procedure.

Galvanizing electrolytes. Classification and types

Galvanizing electrolytes according to the nature of the medium are divided into

· acidic (chloride, sulfate, hydrofluorosilicic, hydrofluoric

· weakly acidic electrolytes (ammonium sulfate, ammonium chloride, ammonium-free chloride),

weakly alkaline or neutral (ammonia, pyrophosphate, amino complex),

· alkaline electrolytes (cyanide, zincate).

Electrolytes for galvanizing in composition can be

simple (these include acidic and weakly acidic electrolytes),

· complex.

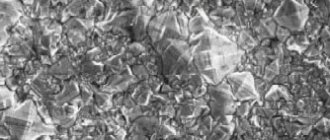

In simple galvanizing , the metal is in the form of cations (Zn^(2+)*mH_2 O). The mechanism of zinc discharge at the cathode is based on the reaction of adding two electrons to each zinc ion: Zn^(2+)*mH_2 O+2¯e=Zn+mH_2 O. Divalent zinc ions are discharged at low cathodic polarization (20-40 mV). Current efficiency in simple electrolytes reaches 98%. The dissipative ability of simple electrolytes is low. The structure of the deposited layer has an uneven, coarse-crystalline structure.

Complex galvanizing electrolytes are characterized by the presence of complex zinc anions in the working solution: [〖Zn(CN)〗_4 ]^(2-) , [〖Zn(OH)〗_4 ]^(2-), [〖Zn(CN)〗 _4 ]^(2-). The mechanism of zinc ion discharge can occur in two ways:

- [Zn〖(CN)〗_4 ]^(2- )= Zn^(2+)+ 4CN^-; Zn^(2+)+2¯e=Zn.

- [Zn〖(CN)〗_4 ]^(2-)+2¯e=Zn+4CN^-.

Zinc deposition on the cathode (discharge) occurs at high cathodic polarization. The current efficiency in complex electrolytes of different chemical compositions is significantly reduced compared to simple ones. Scattering power increases. The microstructure of the zinc coating has a fine-grained structure.

Features of the behavior of zinc when using different types of electrolytes

It is important to take into account such a property of the material as the divalency of zinc, regardless of the electrolyte in which it is currently present.

The density level of metallurgical zinc is at the level of 7.1 g/cm3. In this case, electrolytic density indicators can greatly depend on the structure of the substance. They should be taken into account so that galvanizing takes place without problems and an even, high-quality coating is obtained on the metal.

When using different types of electrolytes, the method of preparing the surface for applying the final zinc coating may differ. For example, if you use ammonia electrolytes, you should be prepared for special requirements for the quality of surface cleaning.

Particular care must be taken to remove any fatty contaminants from it, because they can negatively affect the quality of the finished result.

Return to articles Share article

Main technological parameters of electrolytes for galvanizing

The main distinguishing features of galvanizing in various electrolytes are:

· cathodic polarization – a change in the discharge at the cathode when the current density changes (with high cathodic polarization, the electrical conductivity of the electrolyte is high),

· polarizability of the electrolyte during zinc deposition (the higher the polarizability (potential) when the current density changes, the better the dissipating ability of the electrolyte),

· kinetics and mechanism of zinc electrodeposition.

The criteria for polarization and polarizability are actively influenced not only by the type of electrolyte (simple, complex), but also by the operating temperature range during galvanizing, chemical composition, concentration of constituent components, and brightening active additives. The highest polarizability rates are inherent in alkaline electrolytes (cyanide, zincate).

The magnitude of the discharge of complex ions at the cathode is higher than the cathodic polarization of hydrated ions. Consequently, the dispersing ability increases, the structure of the surface layer becomes uniformly fine-grained and dense. However, the current output decreases. The zinc at the anode dissolves through a galvanic process to form positively charged hydrated ions and complex anions.

09033 Seal SLOTOFIN 10

The SLOTOFIN 10 seal is used for finishing chromated or passivated surfaces of zinc and zinc alloys. If only SLOTOFIN 11 sealant concentrate is diluted in the solution, after drying, clean, transparent, organic layers are formed, increasing not only anti-corrosion protection, but also fingerprint resistance and the overall appearance of the coating. Blue chromated or passivated zinc surfaces and clear chromated or passivated zinc alloy surfaces are treated with SLOTOFIN 10 to obtain a uniform, colorless coating. On yellow chromed or passivated surfaces, the iridescent effect disappears, the coating becomes uniform and has a slight yellow tint. On black passivated or chromed layers, the color intensity is increased by adding black dye concentrate SLOTOFIN 13. In addition, minor color imperfections caused by black chromatization or passivation disappear. We recommend that the compaction of bulk processed parts be carried out outside the galvanizing line. This also includes suspension parts that are designed to be treated with the black paint seal SLOTOFIN 13. The SLOTOFIN protective film is applied both “wet on wet” and to pre-dried parts.

09064 Seal SLOTOFIN 40

The SLOTOFIN 40 seal is used for finishing chromated or passivated surfaces of zinc and zinc alloys. It is carried out using two compaction concentrates SLOTOFIN 41 and SLOTOFIN 42. It is based on a polymer base and contains nano-silicon compounds. After drying, a clean, colorless organic-inorganic protective film is formed, which not only increases corrosion protection, but also reduces the effect of fingerprints and improves the overall appearance of the coating. We recommend that the compaction of bulk processed parts be carried out outside the galvanizing line. Cleaning of galvanic installations or centrifuges is carried out using a degreasing solution at elevated temperatures.

09073 Seal SLOTOFIN GM 1610

SLOTOFIN GM 1610 is a seal used in suspension or drum lines for passivated or chromated layers of zinc and its alloys in order to create a certain coefficient of friction on screw threads. Depending on the use of individual concentrates, different friction values are achieved. Even when treated only with the SLOTOFIN GM 1610 seal, the anti-corrosion protection is improved. For particularly high requirements, parts can be first treated with another seal from our SLOTOFIN series and then, after drying, with an additional SLOTOFIN GM 1610. The resulting colorless layer is very durable. The coating is controlled using UV rays.

09067 Seal SLOTOFIN 70

The organic seal SLOTOFIN 70 is used for finishing chromated or passivated layers of zinc and its alloys. The seal forms an almost completely continuous film on parts of complex shapes, and is especially suitable for processing parts of window and door fittings. Once dry, it forms a clean, colorless, organic film that not only enhances corrosion protection, but also improves fingerprint resistance and the overall appearance of the finish. Blue and colorless chromated or passivated surfaces of zinc and zinc alloys are treated with a uniform colorless coating as a result of treatment in the SLOTOFIN 70 sealing solution. On yellow chromed or passivated surfaces, the iridescent effect disappears, the coating becomes uniform and has a slight yellow tint. Black passivated zinc-nickel surfaces cannot be treated with SLOTOFIN 70. We recommend sealing bulk parts outside the galvanizing line in special drum units. The seal is applied both “wet on wet” and to pre-dried parts. Cleaning of galvanizing units, drums or baskets is carried out using a combination of a potassium salt degreasing solution and suitable degreasing additives. We recommend products from our SLOTOCLEAN series for this.

Application areas of weakly acidic galvanizing electrolytes

Weakly acidic galvanizing electrolytes are used to produce bright and high-gloss zinc coatings on products with a simple configuration. However, weakly acidic galvanizing electrolytes have good covering ability, so they are actively used when galvanizing complex-profile cast iron parts, where dissipation ability is not so important.

Cast iron and high-carbon steels are the main materials for applying zinc coating from weakly acidic electrolytes. of weakly acidic galvanizing electrolytes is expanding .

galvanin chemistry"

, LT-2021 Vilnius, Lithuania

tel.: +, fax: +, E-mail: *****@***lt

2.6.

During operation of the electrolyte, carbonates may accumulate. When their concentration is more than (70 - 80) g/dm3, it is necessary to clean the electrolyte. This is achieved by cooling the electrolyte to a temperature of (5 – 10) °C. It is recommended to have a cooling device for this purpose.

2.7.

The anodes are made of sheet steel and hung on rods using steel hooks.

2.8.

The pendants are made of steel and insulated with material resistant to alkalis and acids. To insulate pendants, it is recommended to use polyvinyl chloride pastes [for example, plastisol D-2A (TU)]. Before applying plastisol, the pendants are coated with AK-091 (TU) primer or other similar primer. The hooks of the pendants must be steel. The contact hook holder of the suspension is made of brass. It is possible to use plastisols and primers of other brands, as well as other insulation methods.

3.

PROCESS STAGES

3.1.

Degreasing in organic solvents

3.2.

Chemical degreasing in alkaline solution

3.3.

Hot water rinsing

3.4.

Electrochemical anodic or cathodic degreasing in an alkaline solution

3.5

. Hot water rinsing

3.6.

Cold water rinsing

3.7.

Activation or etching

3.8.

Cold water rinsing

3.9.

Anodic desludge removal in alkaline solution (operation performed if necessary)

3.10

. Cold water rinsing

3.11.

Cold water rinsing

3.12.

Galvanizing

3.13.

Catching

3.14.

Cold water rinsing

3.15.

Clarification in (0.3 – 0.5)% nitric acid solution (can be excluded)

3.16.

Passivation

3.17.

Catching

3.18.

Cold water rinsing

3.19.

Washing in warm water (temperature no more than 40 °C)

3.20.

Drying (temperature no more than 60 °C)

Purification of spent weakly acidic ammonia electrolyte of galvanizing shop

Table 6.4

| Type of pollution | Nature of the problem | Cleaning method |

| 1 | 2 | 3 |

| Electropositive metals: copper >0.20 g/l lead >0.06 g/l antimony >0.10 g/l tin >0.4 g/l | The coating is dark, black, spotted after colorless or blue passivation, rough, pitting. | 1. Work the electrolyte at ik=0.2-0.3 A/dm2, volumetric amount of electricity 2-5 A-h/l, cathode – corrugated steel sheets. Work until a light coating is obtained. 2. Analyze the solution and, if necessary, adjust it |

| Iron > 0.05 g/l | Dark grey, black, brittle coating. | 1. Add 1-1.5 g/l sodium or potassium persulfate or 1-1.5 ml/l 30-33% hydrogen peroxide. 2. Let the electrolyte settle and filter or decant it. Purification from iron can be carried out similarly to purification from electropositive metals. |

| Chromium compounds. | coverage . | 1. Acidify the electrolyte with a 50% sulfuric acid solution to pH 1-1.5. 2. Heat the electrolyte to a boil. 3. Introduce 1 ml/l of 30-33% hydrogen peroxide or 0.5-1 g/l of sodium persulfate (potassium). 4. Cool the electrolyte to room temperature. 5. If a precipitate forms, filter the electrolyte. 6. Work the electrolyte at ik=0.2-0.3 A/dm2 and a volumetric amount of electricity of 2-4 A-h/l on corrugated steel cathodes until light coatings are obtained. To reduce the processing time, it is advisable to first (after step 5) introduce 1-2 g/l of zinc dust or zinc powder. 7. Adjust the pH to the working value with a solution of sodium hydroxide, bicarbonate of soda or zinc carbonate with continuous stirring until the solution becomes cloudy. 8. Filter the formed precipitate or let it settle and decant the solution. 9. Conduct an analysis for zinc content and adjust the electrolyte. |

| Organic compounds. | Fragile, dark gray coating. | 1. Introduce 1-1.5 ml/l of 30-33% hydrogen peroxide. 2. Work at ik=0.2-0.3 A/dm2 and a volumetric amount of electricity of 3-4 A-h/l on a cathode with a developed surface. 3. Adjust the electrolyte according to the content of organic components. |

A universal method for purifying spent weakly acidic ammonia electrolyte from galvanizing from harmful impurities includes the following operations:

- Acidify the electrolyte with a 50% solution of sulfuric or hydrochloric acid to pH 1-1.5.

- Heat the electrolyte to a boil.

- Add 1-1.5 ml/l 30-33% hydrogen peroxide.

- Cool the electrolyte to room temperature.

- Neutralize the electrolyte to pH 4-4.5 by adding a solution of ammonium hydroxide (ammonia water).

- Set aside and filter the electrolyte.

- Work the electrolyte under the following conditions: current density 0.2-0.3 A/dm2; volumetric amount of electricity 2-5 Ah/l; corrugated steel cathodes; zinc anodes. The end of the development is obtaining light coatings. To reduce the processing time, first add 1-2 g/l of zinc dust or powder.

- Adjust pH to working values.

- Analyze the electrolyte and adjust it if necessary.

- Apply a control coating to the corrugated cathode and, if necessary, work the electrolyte until light-colored coatings are obtained (see paragraph 7).

galvanin chemistry"

, LT-2021 Vilnius, Lithuania

tel.: +, fax: +, E-mail: *****@***lt

Workers involved in the use of the additive must be provided with cotton overalls, rubber gloves, safety glasses and observe personal hygiene measures. Additive and electrolyte analysis should be performed in a laboratory fume hood.

If the additive comes into contact with the skin or eyes, rinse thoroughly with plenty of water.

13.3.

Galvanizing baths and additive storage areas must be equipped with local and general supply and exhaust ventilation, ensuring clean air in the working area, in which the content of harmful substances should not exceed maximum permissible concentrations (MAC).

galvanin chemistry"

, LT-2021 Vilnius, Lithuania

tel.: +, fax: +, E-mail: *****@***lt

6.

PREPARATION OF ELECTROLYTE FOR WORK

6. 1. 1 method of preparing electrolyte

Table 3 Materials for preparing 1000 dm3 of electrolyte

| Name of material | Quantity |

| 1. Zinc oxide 3. Shine-forming additive A1-DE 5. Demineralized water or condensed water | 15 kg 135 kg 10 dm3 20 dm3 up to 1000 dm3 |

Approximately 250 dm3 of demineralized water or condensate water is poured into the bath for preparing the electrolyte. With vigorous stirring, add 135 kg of sodium hydroxide in portions until completely dissolved. In this case, the solution is heated. 15 kg of zinc oxide is slowly added to the hot solution while stirring and stirred until completely dissolved. The volume of the solution is adjusted to 1000 dm3 with water and allowed to stand for 24 hours. The solution is then decanted or filtered into a galvanizing bath and a sample of the electrolyte is taken to determine the concentrations of zinc and sodium hydroxide. Based on the results of the analysis, if necessary, the electrolyte is adjusted, and then 20 dm3 of the A1-EK cleaner and 10 dm3 of the A1-DE additive are added. After mixing, carry out the Hull cell test.

6.2. Method 2 for preparing electrolyte

Table 4 Materials for preparing 1000 dm3 of electrolyte

| Name of material | Quantity |

| 1. Zinc anodes 3. Shine-forming additive A1-DE 5. Demineralized water or condensed water | 135 kg 10 dm3 20 dm3 up to 1000 dm3 |

Approximately 500 dm3 of demineralized water or condensate water is poured into the bath for preparing the electrolyte. With vigorous stirring, add caustic soda until the temperature of the solution rises to 60 ºС. Zinc anodes in steel baskets are loaded into the hot solution. To maintain the temperature (60 ºС), caustic soda is constantly added. When the concentration of zinc in the electrolyte reaches (20 - 28) g/dm3 (the concentration is determined by titration), the baskets with anodes are removed from the bath. Then the volume of the solution is adjusted with water to ~95% of the required volume and caustic soda is added to a concentration of 135 g/dm3. When the electrolyte temperature drops to 30 ºС, 20 dm3 of A1-EK cleaner and 10 dm3 of A1-DE additive are added to the bath. The volume of the solution is adjusted to 1000 dm3 with water and after mixing, a test is carried out in a Hull cell.

galvanin chemistry"

, LT-2021 Vilnius, Lithuania

tel.: +, fax: +, E-mail: *****@***lt

7.2.2. Carrying out analysis

Place 2 cm3 of electrolyte in a conical flask with a capacity of 200 cm3, add 50 cm3 of distilled water, previously boiled to remove carbon dioxide, and 2-3 drops of phenolphthalein indicator. In another similar flask, pour 50 cm3 of an aqueous solution containing (0.3 - 0.4) g of sodium chloride and a small amount (about 0.02 g) of sodium carbonate and add 2-3 drops of phenolphthalein indicator. Then the analyzed solution is titrated until the color of the solution in both flasks becomes the same. After this, the consumed volume of hydrochloric acid (V1) is counted. Next, add 2-3 drops of methyl orange and continue titration until the solution turns reddish. Then a second reading of the volume of hydrochloric acid solution (V2) is made.

7.2.3. Processing the results

The content of sodium hydroxide C1 in g/dm3 is calculated using the formula:

C1 = 4 (2 V1 – V2)

The content of sodium carbonate C2 in g/dm3 is calculated using the formula:

C2 = 10.6 (V2 –V1)

7.3.

Determination of the content of shine-forming additive Al-DE

7.3.1. Reagents, solutions and instruments:

Hull cell, made according to drawing 1 (section 14) from organic glass according to GOST with a thickness of (3 - 5) mm or other materials that do not interact with the electrolyte;

cathode - a polished plate made of steel grade 10 according to GOST 1050-88 with a length of (b0.0 ± 1.5) mm, a width of (45.0 ± 1.5) mm and a thickness of (0.4 ± 0.1) mm;

anode - a zinc plate of the TsO grade according to GOST 3640-79 with a length of (45.0 ± 1.5) mm, a width of (38.0 ± 1.0) mm and a thickness of (7.5 ± 2.0) mm. On the working side of the plate, in order to increase the surface, grooves with a depth of (1 - 2) mm are milled;

stabilizing rectifier, output voltage (0 – 30) V, current up to 2A;

stopwatch;

laboratory filter paper according to GOST;

distilled water according to GOST 6709-72;

hydrochloric acid according to GOST 3118-77, diluted 1:2;

nitric acid according to GOST 4461-77, solution with a mass fraction of 0.5%;

Viennese lime;

cylinders, beakers and measuring flasks according to GOST 1770-74;

pipettes according to GOST.

7.3.2. Carrying out analysis

Electrolysis equipment is connected in series. 40 cm3 of electrolyte, corrected for the main components, is placed in a Hull cell. The cathode is degreased with Vienna lime, activated in a solution of hydrochloric acid and electrolysis is carried out for 10 minutes at a current of 0.4 A. Then the cathode is washed with water, the lower half of the coating is clarified in a solution of nitric acid, washed again with water and dried with filter paper. The appearance of the zinc coating must meet the following requirements:

Galvanizing at home

Process theory.

Galvanic galvanizing (zinc plating) is the process of depositing metal cations on the anode. The reaction takes place in an electrolytic bath under the influence of electric current.

Electrolyte.

Any solution of zinc salt can serve as an electrolyte. The most common in everyday life is a solution of ZnCl (zinc chloride) and HCl (hydrochloric acid), which is called soldering acid. You can also obtain a ZnSO4 solution by etching zinc in a H2SO4 solution (sulfuric acid is a battery electrolyte). When etching zinc, you should be extremely careful, since the reaction occurs with the release of heat and explosive hydrogen H2.

Zinc.

Where can I get zinc? There are several options:

— salt batteries (these are the cheapest!!! index L);

— fuses from the USSR;

— parts with zinc coating;

— purchase of pure zinc in chemical stores. reagents and at radio markets.

Preparation for galvanizing (galvanizing).

- First of all, you need to prepare the galvanic bath itself. You can use glass or plastic containers as a bath. It is necessary to install stands for the cathode and anode.

- The electrolyte should not contain undissolved salt crystals. To reduce the salt concentration, you can add distilled water to the solution until the individual crystals at the bottom of the bath completely disappear.

- Anode. The anode is a zinc plate to which the “plus” from the power source is connected. The larger the zinc anode area, the more uniform coating you will have on the cathode. The use of several zinc anodes makes it possible to obtain a coating on the entire surface of the cathode at once.

- The cathode (we add a “minus”) is the part on which zinc will be deposited. The surface of the cathode must be thoroughly cleaned of oxides (rust), degreased and “activated”. To activate the surface of the cathode, you need to dip it in an acid solution. In the bath, the cathode should be placed at the same distance from any anode to obtain a uniform layer of zinc on all sides.

- The power source can be any power supply with a constant output voltage or a battery. The stronger the current and voltage, the faster the process will take place and the looser the surface you will get as a result. For domestic use, you can use a car battery, BUT you will need to include an incandescent light bulb (10 to 20 watts) in the circuit to reduce the current.

Galvanizing.

After all the preliminary procedures, all you have to do is plug in the power supply (or secure the terminals on the battery) and dip the cathode into the galvanic bath.

The process should proceed without violent boiling; if this is observed, this means you have a very high current strength and it should be reduced by adding consumers to the electrical circuit.

A zinc coating appears on the surface of the cathode; the longer the cathode is in the bath, the thicker the layer you will end up with.

ATTENTION!!! The process of galvanic galvanizing (galvanizing) takes place using acid solutions and electric current sources. To avoid injury, we recommend following safety rules when working with acids and electrical safety rules when working with household electrical appliances.