Chemical composition of steel

AUS-8 alloy belongs to the category of high-alloy steels. Its key characteristic is hardness. It should be noted that the alloy was made by Japanese craftsmen. Chemical composition of AUS 8 steel:

| WITH,% | Si,% | Mg,% | Mo,% | V,% | Cr,% | S,% | P,% |

| 0,7-0,75 | 1-1,1 | 0,5-0,6 | 0,1 | 0,1 | 13-14,5 | 0,02 | 0,02 |

The alloy contains the optimal amount of carbon and iron. This ensures high performance properties of steel. But its ductility is not high, so processing it causes some trouble. A well-selected amount of chromium affects the corrosion properties of the metal.

| Chemical elements and their significance in the composition of knife steel: | |

| Carbon (C) | Without enough carbon it is very difficult to obtain a suitable hardness. This is the most important element in steel, it increases its strength. |

| Chromium (Cr) | gives the alloy increased anti-corrosion properties, chromium carbides increase wear resistance and hardenability. The high chromium content in the alloy affects its brittleness. |

| Manganese (Mn) | increases wear resistance and strength. Its content has a positive effect on the grain structure of the alloy and also contributes to excellent hardenability. |

| Molybdenum (Mo) | prevents steel from becoming brittle and allows it to maintain strength at high temperatures. Also increases corrosion resistance, strength, toughness. |

| Silicon (Si) | increases the strength and wear resistance of steel, like manganese, it makes steel more stable and reliable. |

| Vanadium (V) | forms the structure of carbides in such a way as to increase wear resistance, survivability and hardenability. |

| Nickel (Ni) | increases corrosion resistance and prevents steel from rotting. Increases the strength of steel. |

| Niobium (Nb) | the best carbide former, which provides corrosion resistance, ductility, and wear resistance. |

| Tungsten (W) | increases the wear resistance of steel, increases its stability during hardening and resistance to high temperatures. |

| Cobalt (Co) | enhances the effects of other individual elements in more complex alloys. Increases strength and hardness. |

| Sulfur (S) | is a harmful impurity, leading to the formation of cracks and tears. Typically, the sulfur content of high-quality steel is limited. The presence of sulfides is unacceptable for critical parts. |

| Phosphorus (P) | worsens the plastic properties of the alloy, causing the phenomenon of cold brittleness. In steels, phosphorus content is allowed in very small quantities. |

Characteristics of D2 steel

D-2 steel is a very popular brand worldwide. A large number of manufacturers use it in their production.

This brand was made in the United States of America. Its advantage lies in its production technology. In production, the so-called electroslag remelting technique is used, that is, before the molten material solidifies, it undergoes a special treatment that helps eliminate excess elements. The hardness is approximately 57-61 HRC .

D-2 includes:

- Approximately 11-13% Chrome, which is why it has the status of “semi-stainless”.

- Carbon – 1.45-1.65% , due to which it has high hardness.

- Manganese – 0,15-0,45%.

- Vanadium – 0,1-0,30%.

- Molybdenum – 0,4-0,6%.

- Silicon – 0,1-0,4%.

It has low strength, which distinguishes it from other steels of this class. Very hard. Due to the lack of chromium in its composition, it has a high tendency to rust. The disadvantage is that the surface is not prone to fully polishing the blade. It has analogues: Russian - X12MF , Japanese - SLD .

Mostly used for the production of knives (both hunting and household), shaving blades, and is also actively used in the creation of cars and metalworking.

physical characteristics

The high quality of the AUS 8 alloy demonstrates the good strength characteristics of the alloy. The metal melting process begins at a temperature of 1550 degrees. The complete transition of solid particles into a liquid state occurs at 1660 °C.

- steel has high elasticity. Young's modulus is 2,000,000 kg/cm2. The metal tolerates shock loads well;

- the impact strength is 12-18 kJ/m2;

- the alloy retains heat well, the heat capacity coefficient is 485 J/kg*degree;

- temperature increase by 100 degrees, the linear size of steel changes by 11.8 microns;

- The electrical resistance of the metal is quite high and amounts to 250 MOhm*m, transmitting electric current through it is not a good idea.

Pros and cons of AUS 8 alloy

Steel products have many advantages. You should pay attention to the positive and negative characteristics of the alloy:

pros

- durable steel grade has high mechanical properties;

- grinding and polishing the product is not difficult;

- With proper heat treatment of the alloy, the cutting of knives turns out to be quite aggressive. Also, the products keep the cutting edge sharp for a long time;

- even under harsh operating conditions, the working part of the knife is maximally resistant to chipping;

- high impact strength allows the production of various products from the alloy. Such as: cleavers, hatchets, hoes and even machetes;

- with proper heat treatment, products are obtained with high hardness, they reach an average of 57-59 HRC;

- heat treatment does not require special conditions;

- the product can be sharpened without special skills and extensive experience;

- the products are not very expensive, the knives are quite competitive;

- wide range of alloy applications. It is used in industry, medicine, and cooking.

Minuses

- keeping the blade in a humid environment for a long time can lead to pitting corrosion;

- the hardness of steel varies greatly, it all depends on the manufacturer and the application of the technological process;

- Alloy products require little but constant care.

General information

AUS-8 steel is a high-alloy alloy with increased hardness. The chemical composition of steels is regulated by the Japanese standard. According to it, the chemical composition of the alloy contains the following elements:

- Carbon (0.7-0.75%). The task of this element is to bind free iron molecules, thereby strengthening them. Naturally, the greater the amount of carbon in the composition, the higher the hardness and strength. But after crossing a certain boundary, strength gradually begins to turn into fragility. In AUS-8 steel, this balance is maintained. But it is worth noting that such a large amount of carbon negatively affects the ductility and, accordingly, the manufacturability of the alloy.

- Silicon (1.0-1.1%). In AUS-8, silicon acts as a deoxidizer, i.e. it removes oxygen molecules from steels. Due to this, chemical segregation is reduced, which has a beneficial effect on the mechanical properties of steels. In addition, it is worth noting that with such an increase in strength, steel does not lose its ductile properties.

- Manganese (0.5-0.6%). Manganese, like silicon, cleans steel from harmful impurities: oxygen, sulfur and phosphorus. It improves the surface quality of steels and gives them additional resistance to mechanical stress.

- Molybdenum (0.1%) and vanadium (0.1%). These elements themselves belong to the group of refractory metals, which means they have a high melting point. For this reason, they have a positive effect on heat resistance, i.e. preservation of its mechanical characteristics with increasing temperature. But their quantity in AUS-8 is too small to significantly affect its properties.

- Chromium (13.0-14.5%). Chromium, as an alloying element, plays one of the main roles in steel. It increases such characteristics of the alloy as heat resistance, corrosion resistance and enhances the effect of heat treatment. Chromium also has a positive effect on the resistance of steel to abrasive wear.

- Sulfur (0.02%) and phosphorus (0.02%). These are harmful impurities. Their inclusion in the composition is extremely undesirable, but inevitable. The reason for this is the imperfection of the chemical composition of the alloys and the charge from which steel is smelted. Exceeding the permissible limits significantly harms the mechanical characteristics of stainless steel. This is especially true for sulfur. In addition, it contributes to the appearance of cracks during heat treatment of the alloy.

Analogs

As mentioned earlier, AUS-8 is a product of Japanese metallurgy. But in the world there are many analogues of this material, which have similar chemical composition and mechanical characteristics. Among them it is worth highlighting the following:

- 95X18 - Russia.

- Steel z100CD17 - France.

- Steel 440B - United States of America.

- 1.4125 - Germany.

- H18 - Poland.

Mechanical properties of steel

Forging of AUS 8 steel.

The most important indicator of the AUS 8 alloy is its hardness. With the right manufacturing process, steel can reach 60 HRC or, under special conditions, 65 HRC. The alloy tolerates a load of 770 MPa well, which indicates its high strength.

One of the competitive advantages is the absence of deformation at 600 MPa. Steel also performs well under alternating cyclic loads. It can withstand up to 6 million cycles under a load of 700 MPa.

But these strength characteristics affect the ductility of the metal. Relative compression and elongation under a certain impact are 30 and 15%, respectively.

Technological features

The high carbon content makes AUS-8 steel completely non-weldable. Welded seams are much inferior in strength properties to solid metal and crack when exposed to impact loads. Also, steel is floc sensitive and prone to temper brittleness.

AUS-8 is processed only by pressure at fairly high temperatures, which range from 950-1100 ºС. In this way, rolled products in the form of sheets and strips are obtained from the material.

The highest value of mechanical properties corresponds to heat treatment, including hardening and tempering. Hardening consists of heating to a temperature of 1050 ºС followed by rapid cooling in oil. The hardness in such conditions reaches a value of 65 HRC.

Although such steel has high hardness, it has internal uneven tension. To level it, low tempering is used. The hardness decreases slightly, but the resistance of the alloy to impact loads increases. Tempering involves heating to 150 ºС with further cooling in air.

Application area

Steel is in high demand. It is made by different manufacturers. Even with some differences in production, the alloy retains its main characteristics. Products made from AUS 8 steel are widely used.

Japanese alloy parts can be found everywhere. Of course, the most popular niche is knife making. But besides it, there are other directions where the alloy is found.

Steel AUS 8 in everyday life

You can find many items made of AUS 8 steel in the kitchen. The products are reliable, safe, and do not emit harmful oxides. Kitchen utensils such as forks, spoons and knives are made from it. Alloy blades are available to both ordinary consumers and professional hunters and tourists.

When purchasing a product for yourself, you need to know its future purpose. But we can say with confidence that a blade made of AUS-8 steel will serve its owner for a long time. The alloy can be seen in furniture decorative elements. Razor blades are made from it.

The internal cavities of household appliances, meat grinders, washing machines, microwave ovens are often lined with stainless steel. Door and window fittings can also be made from this alloy.

It is used in elevator parts, street lighting structures, and billboards. Steel is also used for interior and exterior decoration of cars. Many individual components may consist of this alloy.

AUS 8 steel in surgery

Sharp surgical knives, scalpels and saws are made from AUS 8 steel. Reusable and disposable scalpels are often made from this steel. They are subject to ISO standards: 7153/1-88, GOST R503281.1-92, GOST 21240-89.

Surgical knives used for amputations contain large amounts of chromium. Such objects are distinguished by complex alloying. Surgical instruments are made in special ovens. The tool is tested for hardness and corrosion resistance.

AUS 8 steel in collectible weapons

A collector's item.

When making collectible items, craftsmen use hardened steel AUS 8. The weapons are made in an exquisite design, with good cutting properties and reliable handles. You can hang a saber, dirk, dagger, samurai saber or Cossack saber on the wall. The range of products is quite extensive:

- army, camping, boot and Finnish knives;

- special and national;

- pen, throwing, pocket and souvenir items.

Blades and handles are decorated with gilded designs or personalized engravings. The owners of such products keep them in a place of honor. But sometimes they take it with them hunting, fishing or on a simple picnic. This way you can show your friends all the beauty of the product.

Application

As already stated at the beginning of the article, the main purpose of AUS-8 steel is the production of knife blades. Blades from AUS-8 have proven themselves well among fans of edged weapons, surgeons and ordinary people who use knives in everyday life.

Knives made from AUS-8 have the following properties and advantages:

- Light sanding and polishing. To carry out these operations, no special skills or extensive experience are required.

- The advantage is that, subject to the required operating conditions, a knife made from AUS-8 can hold an edge for up to 3 months.

- Due to its high surface hardness, steel is resistant to chipping.

- AUS-8 has a high impact strength value. In this regard, it is used for the manufacture of large blades: axes, machetes, etc.

- Simple heat treatment technology compared to other steels for making knives.

- When a knife is exposed to water for a long time (from 7 days), traces of pitting corrosion appear on the blade - this is a disadvantage of knives.

- Strong dependence of hardness on the quality of heat treatment.

Rate this article:

Rating: 5/5 — 2 votes

Sharpening knives made of AUS 8 steel

The hardness of the blade plays an important role when sharpening it. Knife ratings of 60-62 HRC can often be found in the kitchen today. Such products are not replaced because they break, but simply when the blade gets boring. But we should not forget about proper care of the product.

When processing a cutting edge, you must first treat it with large and medium-sized stones.

The grain of the stones at the first stage is 320-600 grit. The grain is reduced gradually, depending on the condition of the blade.

For finishing the cutting edge, abrasives with a grain size of 800-1500 grit are used. A master of his craft can use stones of 3000 grit for finishing. But for a blade used in the kitchen this is not required. In practice, knives after a stone of 1000 grit will shave your hand.

Corrosion resistance

Chromium in the alloy makes it resistant to acidic environments within the pH range of 4.3-4.8. Also, the blade is not afraid of 3% alkalis. Long-term exposure to water and organic solvents is not harmful to the product. You can safely use detergents in the kitchen. The blade is not afraid of solutions used during sanitary treatment.

Products made of AUS-8 steel.

Which is better steel D2 or AUS 8

A conventional alloy contains iron, carbon and various impurities. The difference between steels comes from additives. Because of this, there are differences in heat treatment and in the process of plastic deformation of bodies during production. There are several points on which alloys differ:

- on heat treatment;

- for rental;

- by type of alloying additives.

The quality of steel is determined by the following characteristics:

- rigidity;

- wear resistance;

- hardness;

- protection of edges from rubble;

- corrosion resistance.

To obtain the best quality material, you should monitor the ratio of hardness and stiffness. When comparing D2 and AUS 8 steels, you can find a fairly large number of differences with each other. But first of all, it all depends on the requirements of the consumer.

For what purpose will the blade be used? When manufacturing products, the following requirements are met:

- blade strength;

- cutting edge sharpness;

- ease of sharpening;

- corrosion resistance.

D2 steel is not a rigid material, well suited for those who like hunting, fishing and hiking. This brand of blade is quite resistant to damage and in capable hands will replace an entire military arsenal. But sharpening the blade is quite problematic; special equipment is required.

Again, once sharpened correctly, the product will last for a long time. The D2 is more expensive than the AUS 8. But the product also requires constant care. If you need a knife for aggressive use, then of course it is better to choose D2 steel.

AUS 8 steel is more practical for everyday use or hunting. It is often used for folding knives. It sharpens well and holds an edge for a long time. For these purposes, no special equipment is required; a regular sharpener or pocket sharpener will do.

The alloy has a rough structure, which will prevent chipping due to unsuccessful impacts. Quite decent value for money. Easy to process and suitable for housewives. Does not require intensive self-care. You just need to monitor the condition of the cutting edge, and the knife is always ready for use.

Problems of heat treatment of D2 steel

Due to the widespread use of D2 steel and its use on knives in the budget segment, it affects the quality of the steel itself. Production standards are neglected and the quality of heat treatment is poor. In an effort to reduce production costs, many firms use the minimum scheme.

They do not try to achieve the highest performance from steel. In some cases, the manufacturer prefers not to risk increased fragility. It specifically reduces the hardness of steel, without hardening it even to 60 HRC. A side effect is low wear resistance.

But there are also incidents in the other direction. When the manufacturer, on the contrary, increases the hardness of the product to 64 HRC, but neglects the use of cryotreatment. Such steel becomes too brittle and very sensitive to lateral loads.

Products made of D2 steel.

Knives made of steel AUS 8

The knives are made from stainless steel in Japan and are of excellent quality. It withstands shock loads well and sharpens quickly. But on the other hand, it holds an average sharpening and requires relatively frequent adjustments. Let's look at several products made from AUS 8 steel.

Fixed Knife – Cold Steel Mini Tac Tanto

This model features an incredibly comfortable handle with special finger grooves. It is made of fiberglass, which has amazing performance properties. The blade is made from AUS-8 steel and has a length of 80 millimeters. These parameters are optimal for travel accessories. Blade characteristics:

- Knife length: 170 mm;

- Blade length: 80 mm;

- Handle length: 90 mm;

- Blade width: 27 mm;

- Butt thickness: 3.0 mm;

- Blade material: AUS-8;

- Handle material: G-10;

- Manufacture: Cold Steel, USA;

- Weight: 82 grams.

A small, convenient product from Cold Steel.

Knife – Flint from Kizlyar Supreme

The Flint knife boasts a 132 mm blade made of AUS-8 stainless steel. This is more than enough for a wide variety of household and outdoor work. The blade is made very competently: a small thickness of 2.4 mm at the butt immediately gives it a head start in terms of cutting and, at the same time, takes it out of the category of edged weapons. In the cutting part, the knife is cut very thin - about 0.3 mm, and you will appreciate this in work. Knife characteristics:

- Total length: 247 mm;

- Blade length: 132 mm;

- Butt thickness: 2.4 mm;

- Blade width: 34 mm;

- Handle length: 116 mm;

- Blade material: AUS-8 steel;

- Blade processing: polishing;

- Hardness: 57-59 HRC;

- Weight: 148 grams;

- Handle material: walnut root.

Hunting product from Kizlyar Supreme.

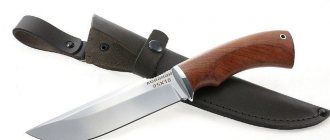

Knife – Kizlyar Baikal-2

Universal knife from the Kizlyar company. This model is suitable for both light work, such as peeling vegetables, and more rough work, such as chopping branches. The blade is made of durable AUS-8 steel with Stonewash coating, the handle is made of elastron. The set includes a sheath made of genuine leather. Blade characteristics:

- Total length: 270 mm;

- Blade length: 150 mm;

- Handle length: 120 mm;

- Blade thickness: 4.7 mm;

- Blade material: AUS-8;

- Handle: elastron;

- Weight: 251 grams.

A universal product from Kizlyar.

Composition of steel grade AUS-8

The characteristics of a metal depend on its chemical composition. AUS-8 is a high-alloy alloy consisting of the following components:

| Chemical formula | Name | Content in % |

| C | Carbon | 0,70- 0,75 |

| Cr | Chromium | 13-14,5 |

| Si | Silicon | 1,0 |

| Mn | Manganese | 0,5 |

| Ni | Nickel | 0,49 |

| Mo | Molybdenum | 0,1-0,3 |

| V | Vanadium | 0,1-0,26 |

Carbon gives the alloy strength. The knife keeps sharpening for 2-3 months, no chips appear on it. When the carbon content exceeds the ductility of the material, the steel becomes brittle and more difficult to process.

Chromium improves the alloy's resistance to corrosion and temperature changes that occur during the hardening process. Chrome-plated items are resistant to aggressive chemical compounds. They become resistant to corrosion and abrasive substances.

Silicon makes steel stronger, increases its elasticity, reduces oxidation processes, removing oxygen from the metal.

The high manganese content in AUS-8 steel makes products made from it harder and more durable.

Manganese enhances the hardness of the alloy and is a deoxidizing agent. Removes oxygen, phosphorus and sulfur from the material, improves the surfaces of products, protects them from mechanical influences. Sulfur and phosphorus are impurities harmful to steel. If the content is exceeded, they cause harm to the metal in the form of cracks appearing during the hardening process.

Nickel is added to make the alloy more resistant to wear and corrosion.

Molybdenum is a refractory substance. In the composition of steel, it is responsible for viscosity and rigidity, making the material more ductile and able to withstand overheating during hardening.

Vanadium increases the density of steel and is a deoxidizing agent. The alloy becomes resistant to chemicals. After sharpening, the blade becomes sharp and retains it for a long time.

More than a hundred years of working with steel have allowed us to develop the processes of hardening and tempering, as well as metal rolling. Rolling is carried out at a temperature of about 1000˚C, hardening occurs at 1040-1060˚, and a temperature of 150˚C is chosen for tempering. As a result, the product becomes hard, does not deform when impacted, and is easy to sharpen.

Analogs

The Japanese alloy AUS-8 has analogues in other countries:

- Russian copies - 75Х16МФ, 95Х18;

- French - Steel Z100CD17;

- alloy from Sweden - AEB-L;

- USA - Steel 440B;

- Polish steel H18;

- German - 1.4125;

- Chinese - 8Cr14MoV.

Alloys created in Russia repeat the properties of AUS-8 with minor differences.

AEB-L and Steel 440B steel are analogues of AUS-8 steel from Sweden and the USA, respectively.