To this day, a huge amount of minerals are mined in the world. These include metals, precious stones, and fuel. It is impossible to imagine everyday life without them. If we turn to the metals that are most mined in the world, then third place belongs to copper, after iron and aluminum. It’s hard to imagine, but without this simple and ordinary metal, problems will arise in such industries as electrical engineering, heating engineering, medicine, and many others. Copper - what kind of ore is it? What properties does it have? How is it mined? And what are the world's reserves?

Properties and characteristics

Copper ore is a special compound of chemical elements in which the concentration of copper reaches a value of at least 0.5–1%. Only such ore is suitable for processing and further use. It occupies number 25 in the periodic table and has the name “cuprum”, from Latin.

Copper is a fairly flexible and soft element that has a golden-pink hue. This metal is easily oxidized, and therefore, at the slightest contact with air, it becomes covered with a reddish acid film. This material is characterized by:

- good electrical conductivity;

- high thermal conductivity;

- resistance to corrosion and destructive effects.

Copper also has antibacterial properties. It easily destroys all kinds of influenza viruses, as well as bacterial infections.

If you mix it with another mineral, you get interesting alloys. People use many of them in everyday life, without even realizing that they are holding copper in their hands. Thus, the following are known: brass, bronze, various babbits and jewelry alloys.

Scheme and modes of enrichment of sulfide ores

Sulfide copper ores in most cases are characterized by extremely uneven dissemination of copper minerals, which predetermines the need to use multi-stage enrichment schemes.

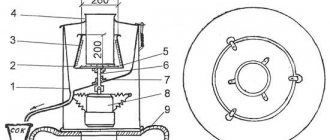

Intergrowths of copper sulfides with both pyrite and rock minerals can usually be isolated after relatively coarse grinding of the ore: up to 50–65% class -0.074 mm. To open the aggregates, it is necessary to further grind either the concentrate, or the intermediate product, or both of these enrichment products to 80 - 95% -0.074 mm (Fig. 3.1). However, flotation cycle designs are usually simple.

Xanthates and aeroflots are most often used as collectors in the flotation of copper and iron sulfides, and pine oil and daufros are used as foaming agents. If copper in ores is represented mainly by secondary copper sulfides, then a mixture of xanthates or aerosols with stronger collectors or apolar oils is used as a collector.

The reagent regime for flotation of layered ores (Fig. 3.1) is usually simple: flotation is carried out in a slightly alkaline environment created by lime (up to 1 kg/t), in the presence of a collector and a foaming agent. The use of higher xanthates in control flotation operations provides higher technological performance compared to lower xanthates and more complete extraction of associated rare, non-ferrous and noble metals into the concentrate.

Rice. 3.1. Technological scheme for the enrichment of sulfide copper ores of the Dzhezkazgan deposit

Flotation of sulfide copper ores with an average pyrite content is carried out according to a collective flotation scheme with subsequent separation of the collective concentrate into copper and pyrite or according to a selective flotation scheme with the sequential separation of copper and pyrite concentrates. The more economical of them is the collective-selective flotation scheme.

The pH value during collective flotation does not exceed 7.5 to ensure effective flotation of iron sulfides into concentrate. Selective flotation of ores and separation of collective copper-pyrite concentrate are usually carried out in a lime environment at a pH less than 10 to ensure effective depression of iron sulfides. Lime consumption in this case depends on the pyrite content and the degree of ore affected by oxidation processes and is in the range of 1-5 kg/t.

The separation of copper and iron sulfides during flotation enrichment of solid copper-pyrite ores is carried out according to a selective scheme in a highly alkaline environment (pH 10-12), created by loading lime (up to 15-20 kg/t) usually after aeration of the pulp before flotation for the oxidation of sulfoxide compounds, ferrous iron salts and additional depression of pyrrhatine and pyrite. Copper flotation tailings are a finished pyrite concentrate if the rock content in the original ore does not exceed 10-15%. In other cases, pyrite concentrates are obtained by reflotation of copper flotation tailings after their thickening and subsequent dilution with fresh water or acidic mine waters. To improve the quality of pyrite concentrates, desliming them in hydrocyclones is sometimes practiced.

Applications of copper ore

Due to the beneficial properties of copper, it is used in electrical engineering. This metal is used to make wires and power cables that are necessary in human daily life.

It is also interesting that when copper is mixed with other materials, no less useful things are obtained. For example, an alloy with nickel is necessary in instrument making. A mixture with tungsten is used for filaments in conventional light bulbs. In addition, copper is necessary in the manufacture of radiators and air conditioners because it has good thermal conductivity.

This metal is also used in the following industries:

- mechanical engineering;

- construction;

- shipbuilding.

There is another useful property for which this metal is highly valued and is often used in construction. It is slightly susceptible to corrosion. Products made from it will last for several decades before they begin to disintegrate.

Copper is also used in jewelry. Sometimes jewelry is created exclusively from this metal, sometimes with an admixture of gold. Since the material is soft and flexible, it is convenient to create delicate and sophisticated jewelry. Now there is a trend to introduce door handles and railings made of copper, as it has antibacterial properties.

This is interesting! The Statue of Liberty was clad in copper. It took 80 tons to make. In the kingdom of Nepal, this metal is considered sacred.

In agriculture, copper plays an important role. It is added to many fertilizers. Many gardeners are familiar with copper sulfate, which they use to treat plants against harmful insects.

Copper refining

Refining copper to obtain copper requires purity; blister copper is subjected to fire and electrolytic refining, and in this case, in addition to removing harmful impurities, noble metals can also be extracted. Fire refining of blister copper is carried out in furnaces reminiscent of reverberatory furnaces used for smelting matte from copper concentrates. Electrolysis is carried out in baths lined inside with lead or vinyl plastic.

Fire refining of copper

Basic operations of fire refining of copper:

- loading solid copper into the furnace and melting it or pouring liquid copper

- oxidation of copper and impurities by blowing copper with air and removing slag from the furnace

- reduction of copper oxide (Cu2O) dissolved in copper and removal of gases dissolved in copper

- release of copper from the furnace and casting into anode ingots

During the period of removing impurities from copper in the gas phase, an oxidizing atmosphere is maintained by blowing the melt with air through iron tubes immersed in it at one end. In this case, copper is oxidized, and Cu2O dissolves in copper (up to a certain limit). Sulfur is removed from copper by reaction (48), and impurities by the reaction Mepr + Cu2O Û MenpO + 2Cu.

Impurities present in copper can be divided into three groups: easily removed (S, Zn, Fe, Pb, Sn) - removal rate 70-99%; partially removable (Ni, As, Sb, Se, Te, Bi) – removal rate 5-70%; completely unremovable (Au, Ag). A total of 0.2-0.5% impurities remain in copper.

After removing impurities and removing slag, the Cu2O remaining in the copper is restored (copper deoxidation) and gases dissolved in copper are removed - teasing for ductility and teasing for density, taking place in the reverse order. When teasing, copper is mixed with reducing gases obtained by immersing poles or logs in copper at one end, and by blowing copper with natural gas or fuel oil mixed with steam. In all cases, the main reducing agents for Cu2O are CO and H2:

Cu2O + CO = 2Cu + CO2

Cu2O + H2 = 2Cu + H2O

The process is carried out until the residual oxygen content in copper is 0.05-0.2%. The slag of refining furnaces contains 35-70% copper (their yield is 1.2-4%). They are usually used as cold additives when converting mattes.

Electrolytic copper refining

Electrolytic refining of copper makes it possible to obtain an almost pure product. Anodes for electrolytic refining of copper are plates 700-900 mm wide, 700-1000 mm long, 30-50 mm thick and weighing 160-350 kg. Anodes have ears with which they rest on the sides of the bath or tires through which electric current is supplied. The cathodes in commercial baths are sheets of pure copper 0.4-0.8 mm thick. Cathode bases are produced in matrix baths in which sheets of pure polished copper, stainless steel or titanium serve as cathodes. An electrolyte bath is a rectangular box, the body of which is currently made of reinforced concrete. The inside is lined with acid-resistant material (lead, vinyl plastic, etc.). Electrolyte is an aqueous solution of copper sulfate (35-50 g/l copper) and sulfuric acid (125-230 g/l H2SO4). Cathodes and anodes are suspended into baths parallel to each other, one at a time at a distance of 90-120 mm between the centers of the same electrodes. The number of pairs of electrodes in the bath is 24-49 (one less anode). The anodes are connected to the positive and cathodes to the negative pole of the DC source. Electrolysis baths are connected in series, combining into blocks and series.

To produce copper wire, pure refined copper is used, from which a wire rod with a diameter of 8 mm or more is first made, which is then pulled through dies, resulting in one or more broaches resulting in wire of different diameters.

Groups of copper ores

Copper is a metal that has a huge number of varieties, each of which has its own properties. There are more than 200 species. However, no more than 20 are used in production. Scientists combine all these varieties into several groups.

Stratiform - a group characterized by deposits that were formed by sedimentary methods. Slate is often found with this metal.

- Pyrite is a group consisting of a combination of copper and nuggets. This type of metal is widely used in jewelry.

- Hydrothermal - a group whose characteristic feature is that these deposits often contain gold, silver and other minerals along with copper. Their number exceeds the norm.

- Skarn rocks - deposits of such ores are local. They are found among limestone rocks. Here the copper concentration does not exceed 30%. Moreover, it is uneven.

- Igneous—this group includes species in which mixtures of copper and nickel predominate. Such rocks are the result of magmatic processes, that is, the solidification and change of magma or lava.

- Carbonate - this group consists of mixtures of iron and copper. So far, only one such deposit has been discovered in the whole world - in South Africa.

Schemes and modes of flotation enrichment of oxidized and mixed copper ores

The difference in the intergrowths and dissemination of copper sulfides and oxides, their flotation properties and the tendency of oxidized copper minerals to overgrind has led to the widespread use of separate flotation of sulfide and oxidized copper minerals in factories.

Collective flotation of copper and iron sulfides is carried out in a slightly alkaline environment (pH up to 8.5), and a significant part of the collector is usually fed into a mill for hydrophobization of sulfides. The resulting collective copper-pyrite concentrates are separated in a lime environment at a pH greater than 10. If iron sulfides are significantly activated by copper salts and their depression in a lime environment is insufficient, the separation of the collective concentrate is carried out in a slightly alkaline environment (pH less than 9) with cyanide additives (up to 200 g/ T).

Flotation of oxidized copper minerals with oxyhydryl collectors is used (for example, at the Katanga plant) when the ore contains siliceous or clayey rocks with a low content of iron carbonates and hydroxides in it. In this case, only malachite is extracted well, cuprite is much worse, and chrysocolla and other copper silicates are very poorly extracted.

Flotation of oxidized copper minerals with sulfhydryl collectors after preliminary sulfidization is the most common method of beneficiation of ores with carbonate and highly ferruginous rocks, when the use of fatty acids, their soaps and other oxyhydryl collectors is practically impossible. The most common sulfidizing reagent in factories is sodium hydrasulfide or its oxide with sodium sulfide. At all factories, the sulfidizer (0.3-2 kg/t) is supplied in stages: in several stages along the front of the main and control flotation in order to obtain a denser film of copper sulfide on the surface of the sulfidized minerals. The optimal pH value of the pulp during flotation of oxidized copper ores after sulfidization is approximately 9. The extraction of oxidized copper usually increases in the following cases: when loading xanthate and aeroflot together, feeding up to 40% of the collector into the mill, using higher xanthatates, adding technical products containing apolar hydrocarbons. The use of strong collectors (mercaptans, higher xanthates, etc.) can also provide an increase in the extraction of precious metals present in the ore. Depression of flotation of rock minerals is most often carried out by loading liquid glass. The main losses of oxidized “free” copper are observed in fine grades, especially during the processing of highly slurry ores. To increase the efficiency of processing such ores, a number of factories (see Fig. 3.1) use a scheme with separate flotation of sands and sludge. At some foreign factories (Bancroft, Nchanga, etc.), a mixture of sulfhydryl and oxyhydryl collectors is used during the flotation of oxidized copper minerals after preliminary sulfidization.

What ores do copper come from?

Copper is extremely rare in the form of nuggets. It is always mined with additional impurities. The largest nugget was found in the USA. It weighs more than 420 tons.

A total of 20 types are used in heavy industry. The most famous and widely used of them are chalcocite, chalcopyrite and bornite. What are their properties?

- Chalcocite is the most concentrated copper. Here its concentration can be up to 80%.

- Chalcopyrite is copper, which is part of polymetals and has hydrothermal origin.

- Bornite - this type has a bluish tint due to impurities of iron and silver. Concentration - more than 60%.

- Kovelin belongs to the hydrothermal group, like chalcopyrite. The concentration is 64%.

It is from these ores that most of the metal is obtained, which is then used by humans.

Copper ore mining methods

As already mentioned, copper has different ways of formation and origin. Some layers are closer to the surface, some further. Depending on this, the method of extracting this metal is determined. So, there are closed and open methods.

The closed method is used if minerals are located underground at a distance of more than 600 meters from the surface. Most often they lie much deeper. In this case, long mines are built that stretch for several tens of kilometers. They are equipped with all the necessary equipment, in particular machinery. To mine copper, you need special machines that have a drilling mechanism with spikes. The machine literally crushes and scratches rocks, thereby extracting copper. Drilling can also be classified as closed methods.

The open method is used more often, but only if the minerals are located at a depth of no more than 500 meters. In this case, the top layers that have no value are removed. Then the copper mining itself occurs. Explosive devices are often used to make the job easier. This method of extraction is extremely harmful to the environment. After the deposit dries up, it is abandoned, and the pit remains on the surface of the earth. Water accumulates in it and soil corrosion occurs, which leads to the formation of ravines.

Copper production process

After the metal has been removed from the bowels of the earth, it must be processed and the product itself must be produced. There are three technologies in total:

The first method is pyrometallurgical, which involves processing ore using fire refining. During this processing, all minerals and their elements are extracted from the ore. This technology makes it possible to extract copper even from the most scarce rocks, where its concentration is below 0.5%.

The second method - hydrometallurgical - is used less frequently, and only for processing already oxidized copper or its nuggets with a poor metal concentration. These technologies make it possible to use all the copper that is in a particular ore.

The third method is electrolysis, a special process in which ore is purified using electricity and liquid. This method appeared relatively recently.

Combined schemes with preliminary roasting of ore and subsequent flotation

Combined schemes with preliminary reduction roasting of ore and subsequent flotation of the resulting grains of metallic copper are used for processing oxidized copper ores that are not suitable for leaching due to the high content of acid-soluble rock carbonates in them, for extracting copper from difficult ores with a high content of silicates, complex aluminosilicates and copper aluminophosphates and copper-containing iron hydroxides.

The segregation-flotation process has received industrial application abroad (in Chile, the USA, Peru, Mauritania, Zambia, Japan, etc.). It includes segregation roasting of crushed ore with additives (0.5-2%) of a solid carbonaceous reducing agent (coke, coal) and table salt (NaCl) for 10-60 minutes at a temperature of 700-850 °C. As a result of the reactions that occur during firing, copper is reduced to metallic with the simultaneous enlargement of reducing particles to 80-10 microns. The resulting cinder is cooled without air access and subjected to flotation with a sulfhydryl collector (100-300 g/t) and foaming agent additives. In a copper-rich concentrate, which usually contains 35-70% copper with a recovery of about 90%, the bismuth and noble metals present in the ore are also extracted during the flotation process.

The segregation-flotation process ensures the highest recovery of metals during the processing of difficult-to-process oxidized and mixed copper ores. However, it is at the same time the most complex and expensive process, requiring significant costs for the construction of a roasting shop. The process is usually not economical if the ore contains less than 3% copper, and this significantly limits the ability to process large quantities of complex copper ores using it.

Mining of copper ores in the world

The deposits do not have any system that allows them to be found. It is distributed in a wide variety of geographical areas and is located randomly. Thus, copper is mined in many countries, in particular in the USA, Peru, Kazakhstan, Chile, Russia, China, Indonesia, and Cuba. All types of copper are mined, regardless of its concentration in the ore. For example, chalcocite copper is produced in America.

It is interesting that there are practically no rich deposits left in the world. Copper has been mined for several hundred years, and therefore all major sources have long since dried up. So now there is an active reduction in the process of using concentrated material in production. Most often, ore with a concentration of this metal not exceeding 0.5% is used. This allows you to spend the necessary material more economically.

Mineral composition and technological challenges in the beneficiation of copper ores

Copper is extracted from sulfide, oxidized and mixed copper and copper-pyrite ores.

Industrial sulfide ores include ores containing more than 0.3–0.4% copper, which is at least 85–90% represented by sulfide minerals (chalcopyrite, barnite and chalcocite). An invariable companion of copper sulfides in ores is iron sulfide - pyrite.

Oxidized and mixed copper ores are found in the upper horizons of copper deposits. Easily floated oxidized copper minerals include malachite, azurite, atacamite, cuprite, tenorite; hard-to-float minerals include chrysocolla, dioptase, practically non-recoverable aluminosilicates and copper phosphates, as well as copper closely associated with iron and manganese hydroxides.

The main method of beneficiation of oxidized and mixed ores is flotation. Gravitational and magnetic enrichment methods play a subordinate role. At the same time, the problems of effective separation of sulfide and oxidized copper minerals from the rock, separation of copper and iron sulfides, obtaining oxidized concentrates, increasing the complexity of the use of raw materials due to additional extraction of noble metals, magnetite and other valuable components into separate products or concentrates are solved. Copper is extracted from difficult-to-float and “refractory” ores using hydrometallurgical methods or combined schemes involving the use of metallurgical and enrichment methods. The copper concentrates obtained during enrichment contain 15–40% copper, pyrite concentrates from 38 to 50% sulfur and no more than 1% lead and zinc.