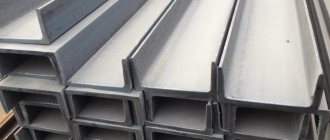

Steel channel 20 is a type of rolled metal with a U-shaped cross section with equal or unequal flanges. Wall height - 20 cm. Equal-flange channel 20 is manufactured by hot rolling in accordance with GOST 8240-97 or bending on profile bending lines in accordance with GOST 8278-83. Uneven-flanged products are produced by bending strip or sheet blanks. Their range complies with GOST 8281-80. For the manufacture of products for ordinary use, carbon steel of ordinary quality of various degrees of deoxidation and high-quality structural steel are used. For channel 20, designed for operation under high loads and/or at low temperatures, low-alloy steels of type 09G2S are in demand.

Manufacturing channel 20

Following GOST 8240-97, 20mm channel is produced only at enterprises.

However, when purchasing, you should personally verify this and check the product for a certificate of conformity. Otherwise, huge defects may arise during the operation of buildings or the structure may completely collapse. The production is mainly based on alloys with the addition of structural carbon and low-alloy steel. Such alloys have special grades st2ps and st3sp, respectively. Alloys have many different metals in their chemical composition (for example, aluminum).

Maximum deviations of parameters (channel sizes) in the table.

| Parameter | Parameter value range | Maximum deviation |

| Height h | Up to 80 | ±1.5 |

| Over 80 to 200 | ±2.0 | |

| Over 200 to 400 | ±3.0 | |

| Shelf width b | Up to 40 | ±1.5 |

| Over 40 to 89 | ±2.0 | |

| Over 89 | ±3.0 | |

| Shelf thickness t | To 10 | -0.5 |

| Over 10 to 11 | -0.8 | |

| Over 11 | -1.0 | |

| Wall thickness s | Up to 5.1 | ±0.5 |

| Over 5.1 to 6.0 | ±0.6 | |

| Over 6.0 | ±0.7 | |

| Warp of shelf D with shelf width b, no more | Up to 95 | 1.0 |

| Over 95 | 0.015b | |

| Wall deflection ƒ along the height h of the profile section, no more | Up to 100 | 0.5 |

| Over 100 to 200 | 1.0 | |

| Over 200 to 400 | 1.5 |

Manufacturing process

Manufacturers of 20P channel of this type use the hot-rolled method to produce materials. The essence of the technology is that raw materials undergo several stages of mechanical deformation, which is carried out on a special mill. The equipment is equipped with a number of rolling units, which successively change the geometry of the metal until it acquires the required profile. When setting up systems, they are guided by the final dimensional indicators, with the exception of the values of the radii of curvature of the shelves on the inside, the edges of the shelves and the angle between their surfaces. These parameters are set taking into account the correct construction of the calibers.

The difference between this technology and alternatives is that before profiling begins, the 20P channel blank goes through a stage of heating to a high temperature. The exact indicators depend on the selected metal, that is, the level at which it is heated to a state of increased ductility. At this stage, the raw material is given a quality that allows the manufacturer of the 20P channel to eliminate the occurrence of internal stresses in the structure, as well as reduce the wear of the working elements of the systems and the number of profiling stages.

After reaching the specified mark, processing of the metal workpiece begins. It passes successively through rollers, which with each step give a geometry closer to the required result. When leaving the rollers, the steel part takes on a standard size shape.

Due to heating, the metal structure becomes uniform, and such materials withstand the load better than alternatives. No additional temperature treatment is required to reduce internal stresses of the product. However, in comparison with analogues, the prices of 20P channel are higher, since the production stages, in particular, heating to the required level, require the expenditure of significant resources.

Scope of product application

A rolled steel product has high physical and mechanical properties, can be easily processed with metalworking tools, welded, cut, and drilled. Due to the U-shaped cross-section, the channel maintains the specified parameters under high operating loads, which is especially important in various areas of the national economy.

The channel is often found as a loaded structure in production:

- cranes;

- motor transport;

- river and sea vessels;

- railway cars;

- interfloor ceilings, roofing;

- ramp;

- pieces of furniture;

- door and window openings;

- railing;

- fences;

- stairs

The standard type of shaped profile for structural elements is produced from rolled ferrous metal and rust-resistant stainless steel. A steel beam is converted into a thick-walled channel after hot rolling in a section mill; products with thin flanges, made of alloys and non-ferrous metals, are formed in a roll forming mill by pressing.

Channel assortment 20

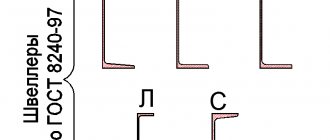

The range of channels is large and has special letter designations in order not to be confused and to easily recognize the production method:

- “P” - channel 20P has parallel edges of the shelves.

- “U” - the internal edges of the shelves are located at an angle.

- “C” is a special channel. GOST does not define the parameters of this product. Since such channels are made to order, and the client himself sets the parameters he needs.

- "L" - light. Manufacturing is carried out in accordance with GOST, but only light metals will be added during the production process.

- “E” is an economical channel. Less metal is used in production.

- “B” - such a channel is used only for the construction of cars or cars.

- “T” is a metal product that has found its application for tractors.

All channels are produced in several ways:

- Hot rolling method.

- Cold rolled or bent channel.

- Special method.

The channel 20 can be produced by hot rolling. The production process is described in more detail in GOST 8240-97.

Table with dimensions of light series channels with parallel flange edges.

| Series L channel number | h | b | s | t | R | r | Cross-sectional area F cm2 | Weight 1m/kg | Reference values for axes | X0cm | ||||||

| no more | X–X | Y–Y | ||||||||||||||

| mm | Ix cm4 | Wx cm3 | Ix cm | Sx cm3 | Iy cm4 | Wy cm3 | i0 cm | |||||||||

| 12L | 120 | 30 | 3.0 | 4.8 | 7 | – | 6.39 | 5.02 | 135.26 | 22.54 | 4.60 | 13.43 | 5.02 | 2.24 | 0.89 | 0.76 |

| 14L | 140 | 32 | 3.2 | 5.6 | 7 | – | 7.57 | 5.94 | 212.94 | 30.42 | 5.31 | 18.23 | 6.55 | 2.70 | 0.93 | 0.78 |

| 16L | 160 | 35 | 3.4 | 5.3 | 8 | – | 9.04 | 7.10 | 331.96 | 41.49 | 6.06 | 24.84 | 9.23 | 3.46 | 1.01 | 0.83 |

| 18L | 180 | 40 | 3.6 | 5.6 | 8 | – | 10.81 | 8.49 | 503.87 | 55.98 | 6.83 | 33.49 | 14.64 | 4.10 | 1.16 | 0.94 |

| 20L | 200 | 45 | 3.8 | 6.0 | 9 | – | 12.89 | 10.12 | 748.17 | 74.82 | 7.62 | 44.59 | 22.37 | 6.51 | 1.32 | 1.06 |

| 22L | 220 | 50 | 4.0 | 6.4 | 10 | – | 15.11 | 11.86 | 1070.97 | 97.36 | 8.42 | 57.82 | 32.85 | 8.61 | 1.47 | 1.19 |

| 24L | 240 | 55 | 4.2 | 6.8 | 10 | – | 17.41 | 13.66 | 1476.39 | 123.03 | 9.21 | 72.90 | 46.25 | 11.04 | 1.63 | 1.31 |

| 27L | 270 | 60 | 4.5 | 7.3 | 11 | – | 20.77 | 16.30 | 2218.16 | 164.31 | 10.33 | 97.48 | 65.10 | 14.17 | 1.77 | 1.40 |

| 30L | 300 | 65 | 4.8 | 7.8 | 11 | – | 24.30 | 19.07 | 3186.74 | 212.45 | 11.45 | 126.24 | 89.08 | 17.84 | 1.91 | 1.51 |

Series L channels must have a wall deflection size of no more than 0.15s.

Technical characteristics of channel 20

The product under consideration is heavier than the 16P channel, for example, because the parameters are higher in terms of strength characteristics, but the mass of the components has also increased. The production is carried out based on the requirements of the state-level regulatory document for channel 20P GOST 8240, which came into force in 1997 and has not undergone major revisions since then.

The width of the rolled product corresponds to 200 mm and is indicated in the marking in centimeters, that is, divided by 10. The height of the shelves is 76 mm, while the elements have a thickness of 9.0 mm. The thickness of the wall, on the contrary, is uniform along its entire length, with the exception of the rounded bases at the transitions to the shelves, is equal to 5.2 mm. The external corners of the profile are straight, and the internal ones are rounded, due to this the product receives greater rigidity and strength, in comparison with such an analogue as a bent channel, in which both corners are rounded. The radius value from the inside is equal to 9.5 mm. The edges of the product shelves are also rounded on the inside of the part, the radius is 5.5 mm.

There are other aspects for channel 20 GOST 8240, which are assessed rather during the design process and are more important for the expert community of the metallurgical sector and engineers purchasing materials:

- cross-sectional area of the component in the transverse direction corresponds to 23.4 cm²

- moments of inertia along the X and Y axes are equal to 1530 cm4, respectively; and 134 cm4;

- moments of resistance in the same directions are equal to 153 cm³ and 25.2 cm³;

- the radius of gyration is 8.08 and 2.39 cm for the X and Y axis;

- the static half-section moment is equal to 88 cm³.

Before buying a 20P channel, it is worth considering two more aspects that are appropriate to know, both for ordinary builders when implementing household projects, and for representatives of the professional community. The first of them is the mass of a linear meter, and the second is the price of a 20P channel. In the second case, we are talking about a significant spread, which depends on the region and product parameters related to the capabilities of the manufacturing company. It is important to take into account that the cost is affected by a fairly pronounced seasonality, that is, at the end of the construction season, the prices of channel 20 fall slightly, and with its beginning they rise, usually within 10 percent.

Channel 20 is a U-shaped metal product. Thanks to this, the channel is able to withstand enormous loads, despite its low weight.

Channel 20 has the following technical parameters:

- Shelf height 200mm.

- Width 76mm.

- The wall thickness of the channel is 5.2mm.

- The thickness of the shelves is 9mm.

- Cross section 24mm2.

- The radius of internal curves is 9.5mm.

In the photo you can see a 20mm channel.

Hot-rolled steel channels (special) according to GOST 8240-97

This table presents the geometric characteristics of hot-rolled special steel channels (series C)

| Channel No. (series C) | h [mm] | b [mm] | s [mm] | t [mm] | R [mm] | r [mm] | Shelf slope, % | A [cm2] | m [kg] | Ix [cm4] | Wx [cm3] | ix [cm] | Iy [cm4] | Wy [cm3] | iy [cm] | X0 [cm] |

| 8C | 80 | 45 | 5,5 | 9,0 | 9,0 | 1,5 | 6 | 11,80 | 9,26 | 115,82 | 28,95 | 3,13 | 22,24 | 7,63 | 1,38 | 1,57 |

| 14C | 140 | 58 | 6,0 | 9,5 | 9,5 | 4,75 | — | 18,51 | 14,53 | 563,70 | 80,50 | 5,52 | 53,20 | 13,01 | 1,70 | 1,71 |

| 14Ca | 140 | 60 | 8,0 | 9,5 | 9,5 | 5,0 | 10 | 21,30 | 16,72 | 609,10 | 87,01 | 5,35 | 61,02 | 14,09 | 1,69 | 1,67 |

| 16C | 160 | 63 | 6,5 | 10,0 | 10,0 | 5,0 | — | 21,95 | 17,53 | 866,20 | 108,30 | 6,28 | 73,30 | 16,30 | 1,83 | 1,80 |

| 16Ca | 160 | 65 | 8,5 | 10,0 | 10,0 | 5,0 | — | 25,15 | 19,74 | 934,50 | 116,80 | 6,10 | 83,40 | 17,55 | 1,82 | 1,75 |

| 18C | 180 | 68 | 7,0 | 10,5 | 10,5 | 5,3 | — | 25,70 | 20,20 | 1272,00 | 141,00 | 7,04 | 98,50 | 20,10 | 1,96 | 1,88 |

| 18Ca | 180 | 70 | 9,0 | 10,5 | 10,5 | 5,3 | — | 29,30 | 23,00 | 1370,00 | 152,00 | 6,84 | 111,00 | 21,30 | 1,95 | 1,84 |

| 18Sat | 180 | 100 | 8,0 | 10,5 | 10,5 | 5,0 | 6 | 34,04 | 26,72 | 1791,01 | 199,00 | 7,25 | 305,48 | 43,58 | 3,00 | 2,99 |

| 20C | 200 | 73 | 7,0 | 11,0 | 11,0 | 5,5 | 10 | 28,83 | 22,63 | 1780,37 | 178,04 | 7,86 | 128,04 | 24,19 | 2,11 | 2,02 |

| 20Ca | 200 | 75 | 9,0 | 11,0 | 11,0 | 5,5 | 10 | 32,83 | 25,77 | 1913,71 | 191,37 | 7,64 | 143,63 | 25,88 | 2,09 | 1,95 |

| 20Sat | 200 | 100 | 8,0 | 11,0 | 11,0 | 5,5 | 6 | 36,58 | 28,71 | 2360,88 | 236,09 | 8,03 | 327,23 | 46,30 | 2,99 | 2,93 |

| 24C | 240 | 85 | 9,5 | 14,0 | 14,0 | 7,0 | — | 44,46 | 34,90 | 3841,35 | 320,11 | 9,29 | 268,89 | 43,70 | 2,46 | 2,35 |

| 26C | 260 | 65 | 10,0 | 16,0 | 15,0 | 3,0 | — | 44,09 | 34,61 | 4088,00 | 314,50 | 9,63 | 115,60 | 171,60 | 5,03 | 3,91 |

| 26Ca | 260 | 90 | 10,0 | 15,0 | 15,0 | 7,5 | 8 | 50,60 | 39,72 | 5130,83 | 394,68 | 10,07 | 343,15 | 52,62 | 2,60 | 2,48 |

| 30C | 300 | 85 | 7,5 | 13,5 | 13,5 | 7,0 | 10 | 43,88 | 34,44 | 6045,43 | 403,03 | 11,74 | 260,74 | 41,41 | 2,44 | 2,20 |

| 30Ca | 300 | 87 | 9,5 | 13,5 | 13,5 | 7,0 | 10 | 49,88 | 39,15 | 6495,43 | 433,03 | 11,41 | 288,78 | 43,93 | 2,41 | 2,13 |

| 30Sat | 300 | 89 | 11,5 | 13,5 | 13,5 | 7,0 | 10 | 55,88 | 43,86 | 6945,43 | 463,03 | 11,15 | 315,35 | 46,29 | 2,38 | 2,09 |

Channel weight 20

Despite the fact that the channel contains an alloy, the part is durable and weighs little. Channel 20 has a small mass per linear meter. This is the main advantage, thanks to which the channel is in great demand among builders. The weight of 1 meter of channel 20 is 18.40 kg.

Advantages of channel 20

- The material meets all strength requirements.

- Channel 20 gives greater rigidity.

- Not subject to deformation and corrosion.

- Light weight, making working with the part easy, even at height.

Channel 20 GOST is a standard instruction for the proposed assortment. Each enterprise must comply with GOST. In this case, the result is an ideal channel that can be safely used in any production area.

Classes E and L

The economical and lightweight series of shaped metal products are distinguished by wall thickness: it is less than the standard one. In grade 16p the parameter is (in mm):

- Economical - 4.7 (wall) and 8.4 (each shelf);

- Lungs - 3.4 (wall) and 5.3 (each shelf).

It is this characteristic that determines: the mass of one meter and the total weight of the beam, the quantity in one ton, the retail and wholesale price. Accordingly, the physical characteristics change: load resistance, strength, rigidity. The scope of application of beams, their durability, reliability, and, therefore, the quality of construction depend on these parameters.

Rental classes

9.5 mm

2.30 cm

5.2 mm

200 mm

9.0 mm

76 mm

Channel dimensions 20P

You can buy channel 20 of various types, which apply to the entire range of products as a whole. Common groups are as follows:

- products characterized by the presence of a slope between the shelves. Such materials are marked with the letter U, for example, channel 20U, and are distinguished by the presence of an angle between the structural elements and the vertical. It is convenient to use such products as guides, since the geometry provides reliable support for rollers and similar systems;

- the second group is designated P, and the product in question is included in it. Manufacturers of 20P channel create materials of this class with parallel flanges. Such products have greater rigidity if force is applied to the site, since the shelves interfere with deformation, therefore the products have found wide application in the construction industry and mechanical engineering, including in the form of load-bearing elements;

- the third class is marked E, that is, economical products whose edges are parallel. The series got its name due to the fact that the prices of channel 20 of this class are more affordable than analogues. This factor is achieved by reducing metal costs when producing a profile; it is obvious that the load-bearing characteristics suffer from this first of all, therefore the rolled product is guaranteed to work in conditions with less constant/variable influences. For serious loads it is worth buying a 20P channel;

- category L, that is, light profiles, can be called similar in characteristics. The components of the structures are lightweight, which makes them a reasonable solution when it is necessary to give the system high strength while saving weight;

- Manufacturers of channel 20 also produce materials marked C, that is, special products. These components have a slope of internal edges, which makes them similar to the U class. For this reason, the cross-section in the transverse direction of the marked groups is similar, similarly, the P, E and L profiles have common features. The slope of the shelves for a special type and U corresponds to a spread from 4 to 10 percent.

In addition to the above classes, there is a division according to rolling accuracy. You can buy channel 20 with high profiling accuracy and increased accuracy, group A and B, respectively. The severity of permissible deviations from the table parameters, and therefore reliability during operation, depends on the indicator. The material is better able to calculate the load-bearing capacity during design, since there is a higher probability of maintaining the optimal level. You have to pay for the characteristics by increasing the price of the channel by 20 P.

The range of rolled products deserves special attention; according to the standard, you can buy a 20 P channel, as well as various standard sizes from 50 to 400 mm wide with flanges from 32 to 115 mm.

Channel weight 20

Before choosing a shaped channel 20, manufactured according to the conditions of the state standard, it is necessary to calculate the characteristics of the future design. Using the table, specialists involved in the production cycle will help you select shaped metal products of the desired steel grade, configuration, optimal size and permissible load. To order, products can be manufactured according to individual drawings.

With a weight of 18.4 kg per meter, the channel is ideal for the construction of canopies, pavilions, terminals, rails for cranes, floors of a production workshop, bridges, overpasses. Products are supplied in batches of 60 tons, in bundles, packs or individually. Products are equipped with a Certificate of Quality and tags with information about the dimensional parameters of the product, batch number, number of units in the pack and its weight. Delivery of products is carried out by motor transport, wagons and long containers.

Classification, dimensions and cross-section

All performance characteristics of range 8240−89 are regulated by specifications and standard requirements. Based on the overall dimensions, nominal weight and cross-sectional dimensions, you can calculate the weight of the structure and select equal-flange and non-equal-flange shaped bars. For lightweight frames, a bent aluminum channel that is resistant to atmospheric and climatic factors is used.

Calculation method for channel bending

Most often, the channel is used as an element that works for bending. Consequently, not a single calculation of a given profile can be done without determining its strength under the influence of bending loads. Today, many software products and channel calculators have been created that allow you to make mass, strength and verification calculations.

We will show you how to independently find the moment of resistance in just 3 steps and select the appropriate channel size taking into account the existing loads.

1. First you need to determine the maximum value of the moment in the channel profile, which is calculated by the formula:

- M = 9.81 x q x l²/ 8 / 1000, where

q is the value of the distributed load l is the length of the channel.

2. Knowing the bending moment, we determine the required value of the moment of resistance of the channel section to ensure its strength:

- Wн = M x 1000 / Ry, where

Ry is the calculated value of the material’s yield strength (according to SNiP 2-23-81).

| Name of steel | Steel grade according to GOST | Ry, MPa, with rolled thickness |

| S245 | St3ps5, Stsp5 | 240 MPa (2 - 20 mm), 230 MPa (20 - 30 mm) |

| S275 | St3ps | 240 MPa (2 - 20 mm) |

| S345 | 12G2S, 09G2S | 335 MPa (2 - 10 mm), 315 MPa (10 - 20 mm), 300 MPa (20 - 40 mm) |

3. We compare the obtained calculated value of the moment of resistance of the channel and the theoretical values in the GOST tables, select the required size of the rolled product.

| U series channel number | Moment of resistance | Series P channel number | Moment of resistance | Channel size according to GOST 8278 | Moment of resistance |

| 5U | 9,1 | 5P | 9,1 | 50x40x3 | 5,62 |

| 6.5U | 15 | 6.5P | 15 | 60x32x2.5 | 5,1 |

| 8U | 22,4 | 8P | 22,5 | 60x32x3 | 5,85 |

| 10U | 34,8 | 10P | 34,9 | 80x32x4 | 10,71 |

| 12U | 50,6 | 12P | 50,8 | 80x50x4 | 15,92 |

| 14U | 70,2 | 14P | 70,4 | 80x60x4 | 18,81 |

| 16U | 93,4 | 16P | 93,8 | 100x50x3 | 17,18 |

| 18U | 121 | 18P | 121 | 100x50x4 | 21,57 |

| 20U | 152 | 20P | 153 | 100x50x5 | 25,56 |

| 22U | 192 | 22P | 193 | 120x50x3 | 21,98 |

| 24U | 242 | 24P | 243 | 120x60x4 | 32,25 |

| 27U | 308 | 27P | 310 | 120x60x5 | 38,6 |

| 30U | 387 | 30P | 389 | 140x60x5 | 47,8 |

| 40U | 761 | 40P | 763 | 140x60x6 | 55,08 |

| — | — | — | — | 160x50x4 | 41,76 |

| — | — | — | — | 160x60x4 | 48,84 |

| — | — | — | — | 160x60x5 | 58,38 |

| — | — | — | — | 160x80x4 | 60,01 |

| — | — | — | — | 160x80x5 | 72,69 |

| — | — | — | 180x70x6 | 79,15 | |

| — | — | — | — | 180x80x5 | 85,22 |

| — | — | — | — | 200x80x4 | 80,94 |

| — | — | — | — | 200x80x6 | 114,84 |

| — | — | — | — | 200x100x6 | 137,43 |

| — | — | — | — | 250x125x6 | 221,64 |