Steel grades: table of markings with explanations

Steel is the most common alloy. The variety of applications results in a large number of varieties with different requirements, both in terms of mechanical and chemical characteristics of steel. Different grades of steel imply not only a variety of chemical composition, but also manufacturing technology.

Steel grades

The variety of alloys is based on the chemical composition of the metal, since the alloying components determine the final result, and the manufacturing and processing technology only emphasizes and highlights individual characteristics. Some elements included in the composition may impair performance, so individual elements of the label may indicate the absence or low content of such substances.

Deciphering the markings allows you to determine the content of the main elements of the alloy and, in part, the production technology, as well as evaluate the technical characteristics, and with them the scope of possible application.

In addition to differences in composition and processing, steel is also divided into categories based on mechanical strength. There are 5 categories, which differ in test methods for compliance with mechanical strength. Tensile and impact strength tests are carried out on control samples.

Types of steels and features of their markings

Various areas of application of steel require that it have strictly defined properties - physical, chemical. In one case, the highest possible wear resistance is required, in others, increased resistance to corrosion, in others, attention is paid to magnetic properties.

There are many types. The bulk of the smelted metal goes into the production of structural steel, which includes the following types:

- Construction Low alloy steel with good weldability. The main purpose is the production of building structures.

- Spring. They have high elasticity, fatigue strength, and fracture resistance. Used for the production of springs and leaf springs.

- Bearing. The main criterion is high wear resistance, strength, low fluidity. It is used for the production of units and components of bearings for various purposes.

- Corrosion resistant (stainless). High-alloy steel with increased resistance to aggressive substances.

- Heat resistant. It is distinguished by its ability to work for a long time under load at elevated temperatures. Area of application: engine parts, including gas turbine engines.

- Instrumental. Used for the production of metal and woodworking and measuring instruments.

- Fast cutting. For the manufacture of tools for metalworking equipment.

- Cementable. It is used in the manufacture of parts and assemblies operating under high dynamic loads under conditions of surface wear.

- Steel classification

When deciphering the designations, it is necessary to take into account that each of the types corresponds to a strictly defined letter in the marking.

Classification by chemical composition

The main alloying additives are metals. By varying the quantitative composition of additives and their mass fraction, a wide variety of steel grades are obtained. Pure iron itself has low technical properties. Low mechanical strength and high susceptibility to corrosion require the introduction of additional substances into the alloy composition, which are aimed at improving one of the qualities, or several at once.

Often, the improvement of some characteristics entails the deterioration of others. Thus, high-alloy stainless steels may have low mechanical strength, while high-quality carbon steels, along with high strength, receive weakened corrosion properties.

As mentioned above, one of the classifications of steel grades is its chemical composition. The main components of all steels without exception are iron and carbon, the content of which should not exceed 2.14%. Depending on the amount and proportions of additives, the iron content in the composition should be at least 50%.

Based on the amount of carbon contained, steels are classified into three groups:

- Low-carbon – carbon content less than 0.25%;

- Medium carbon – 0.25-0.6% carbon;

- High carbon, with a carbon content of more than 0.6%.

An increase in the percentage of carbon increases the hardness of the metal, but at the same time its strength decreases.

To improve performance, a certain amount of chemical elements is introduced into the alloy. Such steels are called alloyed. For alloy steels there is also a division into three groups:

- Low alloy, containing additives up to 2.5%;

- Medium alloyed, which contain from 2.5 to 10% alloying elements;

- Highly alloyed. alloying impurities varies from 10 to 50%.

The marking of steels reflects the presence and percentage of alloying additives. When deciphered, each element is assigned a specific letter, next to which there is a number corresponding to its content as a percentage. The absence of numbers indicates that the additive is present in the alloy in an amount of less than 1-1.5%. The presence of carbon in the composition is not reflected, since it is included in all compositions, but its content is indicated at the very beginning of the labeling.

The marking can also indicate the purpose of the alloy. Since this classification also uses letter designations, the order of their arrangement is regulated - at the beginning, middle and end of the marking.

Classification by purpose

The classification of steel types by purpose has already been given above. Marking of structural steels includes the following designations:

- Construction - denoted by the letter C and numbers characterizing the yield strength.

- Bearing - designated by the letter Ш. Next comes the designation and content of alloying additives, mainly chromium.

- Instrumental unalloyed - denoted by the letter U and carbon content in tenths of a percent.

- High-speed - denoted by the letter P and symbols of alloying components.

- Unalloyed structural steel has the symbols Cn and a number indicating the carbon content in tenths or hundredths of a percent.

Classification of steel by purpose

The remaining varieties, including tool grades made of alloy steels, do not have special designations other than their chemical composition, so the decoding and purpose of individual types can only be determined from reference literature.

Classification by structure

The structure of steel refers to the internal structure of the metal, which can vary significantly depending on heat treatment conditions and mechanical influences. The shape and size of grains depend on the composition and ratio of alloying additives and production technology.

The basis of steel grains is a crystal lattice of iron, which includes atoms of impurities - carbon, metals. Carbon can form solid solutions in the crystal lattice, or it can create chemical compounds, carbides, with iron.

Metal additives exist in the form of solutions, and many of them affect the state of the carbon solution.

The structure of steel changes with temperature changes. These changes are called phases. Each phase exists in a certain temperature range, but alloying additives can significantly shift the boundaries of the transition of one phase to another.

The following are the main phases of the state of the metal:

- Austenite. Carbon atoms are located inside the iron crystal lattice. This phase exists in the range of 1400-700 °C. If the composition contains from 8 to 10% nickel, the austenite phase can persist at room temperature.

- Ferrite. Solid solution of carbon in iron.

- Martensite. Supersaturated carbon solution. This phase is characteristic of hardened steel.

- Bainite. The phase is formed by rapid cooling of austenite to a temperature of 200-500 °C. Characterized by a mixture of ferrite and iron carbide.

- Perlite. Equilibrium mixture of ferrite and carbide. It is formed when austenite is slowly cooled to a temperature of 727 °C.

Titanium alloys

US alloys Grade (grade, grade) comes in front For aviation alloys supplied under AMS (Aircraft Materials Specification), numbers and letter suffixes characterize the nominal composition of the alloy. Grades of technical titanium are marked with the letters CP and numbers indicating the yield strength in ksi (6.9 N/mm2). For military alloys supplied according to MIL (military specification), the letter indices A , AB and B characterize the phase composition of the alloys (α, α+β, β), followed by their serial numbers. Alloys used in the manufacture of rod and wire electrodes for welding and supplied in accordance with the AWS (American Welding Society) standard are marked with the word ERTi and the alloy serial number (for grades of technical titanium) or a combination of numbers and letter indices reflecting the nominal composition of the alloy.

UK alloys supplied according to BS standards (British Standard, Aviation Series), the letter indices in the brand characterize the alloying system, and for grades of technical titanium the letters CP and tensile strength are given in N/mm2; for alloys supplied according to the standards of IMI, which is the main titanium manufacturer in the UK, the letters in the brand indicate the company index and the alloy reference numbers.

German alloys supplied according to DIN and WL (standard for aircraft materials), the index Ti , followed by alphabetic and digital symbols characterizing the nominal chemical composition (for alloys) or serial numbers (for grades of technical titanium), as well as conventional numbers included in coding system.

French alloys supplied by AESMA (Association of European Manufacturers for the Aircraft Industry), the Ti and conventional coding numbers are given; for alloys supplied according to AIR (French Aviation Standard), the letter T and yield strength values in ksi (for grades of technical titanium) or conventional alphabetic and numerical symbols characterizing the composition of the alloy (for alloyed alloys).

Japanese alloys supplied under JIS, the word “ class ” is placed in front, followed by the serial number of the alloy; for aviation alloys supplied according to proprietary standards - digital and letter indices according to a system similar to that adopted by AMS.

Along with properties, an important criterion for the quality of semi-finished products from titanium alloys is the nature of their structure. Despite some differences in the principles of its assessment and the requirements established in Russian and foreign standards, the general approach to acceptable and unacceptable structures is the same.

More complete and comprehensive information on the chemical composition and level of mechanical properties of specific semi-finished titanium alloys in certain structural states is given in the relevant standards.

Materials Science

All metals known in nature belong to two groups - ferrous and non-ferrous metals. Ferrous metals include iron and its alloys (steel and cast iron). In addition, ferrous metals include manganese, a silver-white metal; but in metallurgy and in everyday slang this element is rarely mentioned in the list of ferrous metals. All other metals and alloys that do not contain iron or contain it in small quantities are classified as non-ferrous metals.

This classification is due to a number of reasons, primarily the chemical and mechanical properties of iron-containing metals and alloys with low corrosion resistance (except for some steels with specific additives) and magnetism. Ferrous metals attract machine builders due to their good machinability, mechanical strength, and low price.

Non-ferrous metals have a number of unique properties - high electrical conductivity, resistance to corrosion, low specific gravity with high strength, and in some cases, high aesthetic and jewelry qualities. Generally, non-ferrous metals are more expensive due to their relative rarity in nature, as well as the difficulty of isolating them from rocks.

Non-ferrous metals are most often classified into light, heavy and noble metals.

So, the basis of ferrous metals is iron. However, this metal is practically never found in nature in its pure form due to its relatively low corrosion resistance, so iron in its pure form is not used in mechanical engineering, but alloys are used, the basis of which is compounds of iron and carbon - steels and cast irons. Steels are multicomponent alloys with a carbon content of up to 2.14%. Cast iron is an alloy of iron and carbon with a carbon content of more than 2.14%.

Steels and cast irons are very widely used in mechanical engineering. At the same time, minor additions of non-ferrous metals or non-metallic elements to steel or cast iron alloys make it possible to significantly change their chemical and mechanical properties depending on the needs of machine builders, while slightly affecting the cost of the resulting alloy.

***

Example of decoding 12Х18Н10Т: classification of steel and decoding of markings

Steels occupy the leading place among all metal materials used in mechanical engineering, instrument making, construction and many other fields. They have valuable technological characteristics and are widely in demand due to their mechanical properties and physical and chemical parameters.

Steels have an advantage over a large number of other materials not only due to the complex of their technological and structural characteristics, but also due to their affordable cost.

Steel production technologies are constantly being improved; this is not only about improving quality. New brands appear with special sets of required characteristics.

The characteristics of each specific steel depend on its classification and the set of elements included in its composition.

Let's look at the principles of steel classification .

Principles of steel classification

There are five main classification criteria by which steels are divided:

- chemical composition;

- appointment;

- quality;

- degree of deoxidation;

- structure.

Let's take a closer look at each sign.

Classification by degree of deoxidation

Deoxidation is the process of removing oxygen from steel in a liquid state.

According to the degree of deoxidation, the following groups are distinguished:

- calm (completely deoxidized);

- semi-calm;

- boiling (slightly deoxidized).

The name of the subgroups corresponds to the nature of the solidification process.

Effect of carbon content and alloying elements

It is the carbon content in steel, as well as the name and amount of alloying additives introduced into its composition, that are most interesting for analyzing the resulting properties of a particular grade.

Carbon comes first in importance, because steel is an alloy of iron and carbon . An increase in carbon content leads to an increase in strength with a simultaneous decrease in ductility. It also determines the ability of steel to be processed (cutting, weldability, forming).

Alloying elements are added in the required proportions depending on the need to obtain certain properties. Each element has its own characteristics. For example, chromium improves mechanical properties, nickel reduces the threshold of cold brittleness, tungsten and molybdenum help increase the heat resistance of a quick cutter, etc.

Russian steel marking system

There is no unified steel marking system on the global metals market. In parallel, there are Russian, European , American and Japanese systems . The lack of a uniform standard introduces certain difficulties in international trade transactions.

Steel marking

In Russia, alphanumeric or numeric designation of steels is accepted

Marking and decoding of carbon steels of ordinary quality

Steels contain increased amounts of sulfur and phosphorus. Marked St.2kp., BSt.3kp, VSt.3ps, VSt.4sp. They are deciphered as follows: St is the index of a given steel group, numbers from 0 to 6 are the conditional number of the steel grade. As the grade number increases, the strength of the steel increases and the ductility decreases. An example of such steels containing carbon, sulfur and phosphorus is shown in the table below.

According to guarantees upon delivery, there are three groups of steels: A, B and C. For steels of group A, mechanical properties are guaranteed upon delivery; the index of group A is not indicated in the designation. For steels of group B, the chemical composition is guaranteed. For group B steels, both mechanical properties and chemical composition are guaranteed upon delivery. The indices kp, ps, sp indicate the degree of deoxidation of the steel: kp - boiling, ps - semi-calm, sp - calm.

Quality carbon steels

High-quality steels are supplied with guaranteed mechanical properties and chemical composition (group B). The degree of deoxidation is generally calm. Structural high-quality carbon steels are marked with a two-digit number indicating the average carbon content in hundredths of a percent. The degree of deoxidation is indicated if it differs from calm. Steel 08, steel 10 ps, steel 45.

carbon, respectively, 0.08%, 0.10%, 0.45%.

Tool quality carbon steels

They are marked with the letter U (carbon tool steel) and a number indicating the carbon content in tenths of a percent. U8 steel, U13 steel.

carbon, respectively, 0.8% and 1.3%

Marking and decoding of alloy steels

Designation is alphanumeric. Alloying elements have symbols - they are designated by letters of the Russian alphabet.

Designations and interpretation of letters of alloying elements of steels

A – nitrogen (indicated in the middle of the mark) B – niobium C – tungsten D – manganese D – copper E – selenium – cobalt M – molybdenum N – nickel P – phosphorus P – boron – silicon T – titanium P – vanadium X – chromium C – zirconium Y – aluminum

H - rare earth

Alloy structural steels

At the beginning of the stamp there is a two-digit number indicating the carbon content in hundredths of a percent. Alloying elements are listed below. The number following the symbol of the element shows its content as a percentage; if the number does not appear, then the content of the element does not exceed 1.5%. Steel 30Х2М.

This grade of steel contains about 0.30% carbon, 2% chromium, and less than 1% molybdenum.

Alloy tool steels

At the beginning of the brand there is a single-digit number indicating the carbon content in tenths of a percent. If the carbon content is more than 1%, the number is not indicated; then alloying elements are listed, indicating their content.

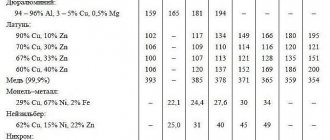

Copper and copper alloys

The United States uses the Unified Numbering System for Metals and Alloys (UNS). The designation consists of the letter C (copper) and a five-digit number corresponding to the chemical composition. Alloys with numbers less than 80000 are pressure-processed, higher alloys are cast.

Pressure-processed alloys in German have an alphanumeric designation system: Cu - means that the alloy is based on copper, the main alloying elements are indicated by their chemical symbols. The numbers following them show the mass fraction of the elements. Casting alloys have a different, more complex designation system. All alloys (both workable and cast) also have numerical designations, so for each German alloy two designations are given: alphanumeric and digital.

Pressure-processed alloys in Japanese have the same designation system as in the USA, only the number of digits is four. Moreover, alloys whose designations coincide with the designations of US alloys (with the exception of the fifth digit in the US mark) are close in composition to the corresponding US alloys (for example, the Japanese copper-nickel alloy C7060 and the American C70600 ).

Let us give examples of the designation of foreign alloys.

In the USA according to ASTM S8A-77: B133 , B152 , B359 , C11000.

In Germany according to DIN 1787-73: ECu57 , ECu58 .

In Japan according to JIS H3510, H3100, H3300: C1100 .

In the USA, wrought brasses are defined by ASTM: B36, B475, B171, B121, B591, B 289, B135, B694, B453, B283, B111, B587, B359, B124, B592 and are marked with a letter and numbers. For example, C2100 , C26800 , C28000 , C4100 , C46400 , C3800 , C68700 .

In Germany - according to DIN 17660, DIN 17673. They are marked by elements and their chemical composition. For example, CuZn5 , CuZn20 , CuZn38Sn1 , CuZn40Mn2 .

In Japan - according to JIS: H3100, H3250, H3300.

Alloys are marked, as in the USA, using an alphanumeric method. For example, C2100 , C2680 , C2800 , C3560 , C3710 , C3603 , C6782 .

In foreign countries , bronze markings are also similar to brass; in Japan , the type (class) of material is sometimes additionally specified.