Often, for production purposes, it becomes necessary to change the parameters of steel; one way to do this is heat treatment . By their principle, most heat treatment technologies involve changing the structure of steels through heating, holding and cooling.

Despite the fact that all these technologies have the same goals and operating principles, they all differ in temperature and time conditions. Heat treatment can be either an intermediate or a final process during production. In the first case, the material is prepared for subsequent processing, and in the second, new properties are given to it.

One such technology is steel normalization. This is the name for heat treatment, in which the material is heated to a temperature 30-50 degrees above Ast or Ac3, and then it is cooled in still air.

Principles of normalization

Like other heat treatment technologies, normalization can be either an intermediate or a final operation to improve the structure of steel. Most often it is used in the first case; as a final procedure, normalization is mainly used in the production of long products such as rails, channels and more.

The key feature of normalization is that the steel is heated to a temperature that is 30-50 degrees higher than the upper critical values, and the material is also held and cooled.

This or that temperature is selected depending on the type of material. Hypereutectoid materials are normalized at a temperature between points Ac 1 and Ac 3, but hypoeutectoid materials are normalized at temperatures above Ac 3. As a result, materials of the first type obtain the same hardness, since carbon passes into the solution in the same amount, and austenite is also fixed in the same amount. The structure includes cement and martensite.

Thanks to this composition, the wear resistance and hardness of the hypereutectoid material increases. If high-carbon steel heats up above Ac 3, the growth of austenite grains will increase and, accordingly, internal stresses will increase. The carbon concentration will also increase, and as a result, the martensitic transformation temperature will decrease. As a result, the material becomes less durable and hard and can be changed.

And hypoeutectoid steel, when heated above a critical value, becomes very viscous. This is explained by the fact that fine-grained austenite is formed in low-carbon steel. This component, after cooling, transforms into fine-crystalline martensite. Temperature values in the interval between Ac 1 and Ac 3 cannot be used for processing, since in this case the structure of hypoeutectoid steel receives ferrite, which reduces its hardness after normalization, and after tempering, its mechanical properties.

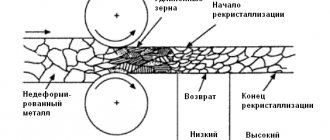

The holding time depends on the degree of homogenization of the material structure. The standard indicator is an hour of exposure per 25 mm of thickness. The intensity of cooling to one degree or another determines the size of the plates and the amount of perlite.

These quantities are interdependent. Even more perlite will form with increasing cooling intensity, reducing the distance between the plates and their thickness. All this increases the hardness and strength of the normalized material. Due to the low cooling intensity, a material with less hardness and strength is formed.

If objects with large differences in cross-section are processed, then the thermal stress must be reduced to prevent warping during heating or cooling. Also, before starting work, they should be heated in a salt bath.

When the temperature of the product decreases to the lower critical point, cooling can be accelerated by placing it in water or oil.

Features of the work

Normalization is uniform heating of the workpiece to a temperature above the critical one. After heating, the parts are maintained at the same temperature. Then the workpiece is cooled. Initially, it slowly cools down to the lower critical temperature, then the master immerses it in coolant to speed up the process.

Principles of conducting

Heat treatment of metal is necessary if its structure and, consequently, technical characteristics change.

There are two types of metals that can be heat treated:

The choice of temperature depends on the type of metal. For example, for hypereutectoid billets, the heating process is carried out at temperatures located between the marks AC1–AC3. As for hypoevectoid parts, they are processed at temperatures above the AC3 point. Materials belonging to the first group achieve the same hardness index.

Duration

The cooling rate depends on the amount of perlite contained in the workpiece and the size of the plates being processed. If the cooling rate is increased and the procedure time is reduced, the amount of perlite formed during the heat treatment process will increase. Strength and hardness indicators will also increase.

Cooling steel

Purpose of the process

Normalization is designed to change the microstructure of steel; it does the following:

- reduces internal stress;

- through recrystallization, it refines the coarse-grained structure of welds, castings or forgings.

The goals of normalization can be completely different. Using this process, the hardness of steel can be increased or decreased, the same applies to the strength of the material and its toughness. It all depends on the mechanical and thermal characteristics of the steel. Using this technology, it is possible to both reduce residual stresses and improve the degree of machinability of steel using one or another method.

Steel castings are subjected to this treatment for the following purposes:

- to homogenize their structure;

- to increase susceptibility to heat hardening;

- to reduce residual stresses.

Products obtained by forming are subjected to normalization after forging and rolling in order to reduce the heterogeneity of the structure and its banding.

Normalization together with tempering is needed to replace the hardening of products with complex shapes or with sharp changes in cross-section. This will prevent defects.

This technology is also used to improve the structure of the product before hardening, increase its machinability through cutting, eliminate the secondary cement network in hypereutectoid steel, and also prepare the steel for final heat treatment.

Features of normalization annealing for steels with different carbon contents

The goals and features of normalization depend on the composition of the steel:

For low-carbon grades, normalizing effectively replaces annealing because it combines increased hardness with improved cutability and a cleaner surface.

- For medium carbon steel castings, high temper normalization replaces high temper quenching. The advantages of the first option are lower deformation forces in the parts, and, therefore, a reduced likelihood of cracks.

- For some high-alloy grades, normalization with air cooling replaces quenching and tempering, which provides savings when performing one heat treatment operation (normalization) instead of two (quenching + tempering).

Steel grade 45 and its features

This steel is an alloy of iron and carbon. Steel grade 45 due to its hardness is traditionally in high demand in various industrial sectors. In this alloy, the share of iron is about 45 percent. The properties of a material are directly related to its alloying elements and the amount of carbon, which is very important in the production of rolled metal products. This or that temperature treatment allows you to obtain a durable product. After normalization, the hardness of grade 45 is directly related to the temperature during operation.

This steel is carbon structural steel. Normalization should be carried out outdoors, and not in a special oven, unlike other stages of processing. Grade 45 is easily and quickly amenable to mechanical processing, in particular:

- drilling;

- turning;

- milling.

The following products are produced on the basis of this steel:

- bandages;

- cams;

- cylinders;

- gears;

- crankshafts and camshafts;

- gear shaft;

- spindles.

Equipment and materials

Furnaces for hardening and annealing steel are used as equipment for normalization. Gas heating can be used in furnace equipment. Such systems contain:

The principle of heating the inner chamber of the furnace from gas can be realized through the air space, then the burner is located in the center. Regeneration and recovery burner designs can also be used.

In resistance furnaces, where an indirect heating method is used, the heating system can be made according to different principles. Most often, thyristor circuits are used here to control power, which in turn are controlled using microprocessor circuits.

Dear site visitors, everyone who understands the technological process of performing steel normalization operations, leave your additions to the article in the comments!

Searching for records using a filter:

Holding at normalization temperature

The role of the duration of exposure at the normalization temperature is only to ensure homogenization of the austenitic structure before cooling begins. One hour of exposure for every 25 mm of section thickness is the norm.

The cooling rate during normalization significantly affects the amount of perlite, its size and the thickness of the pearlite plates. The higher the cooling rate, the more perlite is formed, and its plates become thinner and closer to each other. Increasing the proportion of pearlite in the structure and its grinding increases the strength and hardness of steel. Lower cooling rates mean less strong and harder steel.

After the products have cooled uniformly across their cross-section below the lower critical point Ar1, they can be cooled in water or oil to reduce the overall cooling time.

Other heat treatment methods

In addition to normalization, heat treatment of steel includes the following processes:

- annealing;

- hardening;

- vacation;

- cryogenic treatment;

- dispersion hardening.

The principle of implementation and goals of each technology are the same, however, each has its own distinctive features:

- annealing - thanks to it, the structure of pearlite will be as thin as possible, since cooling occurs in the furnace. Annealing can reduce structural heterogeneity, as well as stress after processing by casting or injection, give the structure a fine grain or improve cutting;

- hardening - the technology principle is the same, but the temperatures are higher compared to normalization and the cooling rate is also higher. The process occurs in liquids. Thanks to hardening, the strength and hardness of the material increases, and the parts will eventually have low impact strength and fragility;

- Tempering - Tempering done after hardening reduces stress and brittleness. For this purpose, the material is heated to a low temperature and cooled outside. As the temperature rises, tensile strength and hardness fall, and impact strength increases;

- cryogenic treatment - thanks to it the material will have a uniform structure and hardness; this technology is most suitable for hardened carbon steel;

- dispersion hardening is a final treatment during which dispersed particles are released in a solid solution after hardening at low heat to impart strength to the material.

To perform heat treatment you will need the following:

- tanks with water and oil;

- sanding paper;

- metallographic microscope;

- furnace with thermoelectric pyrometer;

- Rockwell hardness testers;

- sets of microsections (sorbitol, martensite, ferrite-martensite, etc.).

Essentially similar heat treatment processes

In addition to normalization, the following operations can be added to the list of heat treatment of steels:

The annealing operation provides a high-quality, finer structure of pearlite; this occurs because furnaces are used to cool the parts. The purpose of this operation is to reduce the heterogeneity of the structure, remove stress, and increase machinability.

The principles underlying the hardening operation are identical to those of normalization, but there are some differences. For example, when hardening, much higher temperatures and high cooling rates are used. Hardening leads to improved strength characteristics, hardness, etc. But often workpieces that have undergone hardening are characterized by reduced viscosity and high fragility.

Tempering of parts is used after the hardening operation. Tempering reduces brittleness and internal stress. In this case, the temperature range is lower than that used in normalization. The parts are cooled in air. As the temperature increases, the tensile strength and hardness decrease and at the same time the impact strength increases.

Cryogenic treatment of steel results in a uniform metal structure and increased hardness. This processing technology is used for hardened carbon steel.

Selecting a heat treatment method for steel

Normalization or another method of heat treatment of steel is chosen depending on the concentration of carbon in it. If the material contains it in amounts up to 0.2%, then the most acceptable method is normalization. If 0.3−0.4% carbon is present, then both normalization and annealing will do.

The choice of one or another processing method should also depend on the required properties. For example, normalization will give the product a fine-grained structure, and, compared to annealing, greater hardness and strength.

In many cases, normalization is the most preferred method of processing materials, since it has many advantages over others. In many industries, in particular mechanical engineering, it is most often used for heat treatment .

Normalization and its application in practice

When assigning a heat treatment method, the technologist must take into account the carbon concentration. Steels in which the carbon content does not exceed 0.4% can be processed by both normalization and annealing. Normalization minimizes the grain size in the structure and increases strength characteristics.

Comparing the time spent between normalization and other methods, we can conclude that processing by other methods takes longer.

Due to the speed of the operation, the coverage of a large number of steels, the quality of the resulting parameters (hardness, strength, etc.), this is why normalization is widely used in mechanical engineering.

Source

Application

The choice of any of the considered processing methods is determined by the carbon concentration in the steel. For materials with a value of this indicator up to 0.2%, it is preferable to use normalization. Steels with a carbon amount of 0.3 - 0.4% are processed by both normalization and annealing. In such cases, the choice of method is based on the required properties of the material. Thus, normalization of steel gives it a fine-grained structure, greater strength and hardness compared to annealing. In addition, this technology is a more productive process. Therefore, other things being equal, it is more preferable. It is preferred to hardening due to the fragility of the products obtained in this way and when processing objects with differences in cross-section in order to avoid defects.

Thus, normalization can be considered an intermediate technology in relation to them: it produces a material that is harder than annealing, but less brittle than quenching, improving the structure and reducing stress. In view of this, normalization has become more widespread in mechanical engineering.

Source of the article: https://stankiexpert.ru/spravochnik/materialovedenie/normalizaciya-stali.html

Improved steels

Improved steels are structural materials:

- carbon;

- low alloyed;

- medium alloyed.

| I | II | III |

| Carbon | low alloy | medium alloyed |

| GOST 1050-82 | GOST 4543-71 | GOST 4543-71 |

| 30-60 | Morganzovye 30G-65G, chromium 30Х-40Х | 38Х2МУА and others, but with a carbon content of no more than 0.4% |

| Chromium-molybdenum 30ХМ-40ХМ, 50Г2 | ||

| Multicomponent 30-40KhGSA, 30-40KhMFA | 45ХН2МФА |

Alloy steels can be divided into several categories:

- chromium;

- chromomanganese (chromansil);

- nickel-containing;

- with the addition of tungsten and molybdenum.

It is especially worth noting the poor weldability of the metals being improved. It is produced subject to certain measures that maintain the required characteristics.

Heat treatment: hardening, tempering, normalization, annealing

Metal products used in any sector of the economy must meet wear resistance requirements. For this purpose, exposure to high temperatures is used, as a result of which the desired performance properties are enhanced. This process is called heat treatment.

Heat treatment is a set of operations of heating, cooling and holding metal hard alloys to obtain the required properties by changing the structure and internal structure. Heat treatment is used as an intermediate operation in order to improve machinability by cutting, pressure, or as the final operation of the technological process, which provides the required level of properties of the part.

Various hardening methods have been used for a long time: craftsmen immersed a heated metal strip in wine, oil, or water. For cooling, blacksmiths sometimes used quite interesting methods, for example, they mounted a horse and raced, cooling the product in the air.

Depending on the method of implementation, heat treatment can be of the following types:

-Thermal (normalization, hardening, tempering, annealing, aging, cryogenic treatment).

-Thermo-mechanical. Involves processing at high temperatures in combination with mechanical stress on the alloy.

-Chemical-thermal. It involves heat treatment of metal followed by enrichment of the surface of the product with chemical elements (carbon, nitrogen, chromium, etc.).

Main types of heat treatment:

1. Hardening. It is a type of heat treatment of various materials (metals, glass), consisting of heating them above a critical temperature with rapid subsequent cooling. Performed to obtain nonequilibrium structures with an increased cooling rate. Hardening can be either with a polymorphic transformation or without a polymorphic transformation.

2. Tempering is a technological process, the essence of which is the heat treatment of a metal or alloy hardened to martensite, the main processes in which are the decomposition of martensite, recrystallization and polygonization. It is carried out with the aim of relieving internal stresses and giving the material the necessary operational and mechanical properties.

3. Normalization. In this case, the product is heated to an austenitic state and then cooled in still air. As a result of normalization, internal stresses are reduced and steel recrystallizes. Compared to annealing, normalization is a shorter and more productive process.

4. Annealing. It is a heat treatment operation consisting of heating steel, holding it at a given temperature and then slowly cooling it along with the furnace. As a result of annealing, a stable structure is formed, free from residual stresses. Annealing is one of the most important mass heat treatment operations of steel.

Annealing purpose:

1) Reducing hardness and increasing ductility to facilitate metal cutting;

2) Reduction of internal stress arising after pressure treatment (forging, stamping), machining, etc.;

3) Removing brittleness and increasing impact resistance;

4) Elimination of structural heterogeneity in the composition of the material that occurs during solidification of the casting as a result of segregation.

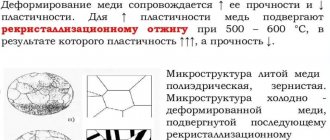

For non-ferrous alloys (aluminum, copper, titanium), heat treatment is also widely used. Non-ferrous alloys are subjected to both softening and strengthening heat treatment, depending on the required properties and scope of application.

Heat treatment of metals and alloys is the main technological process in ferrous and non-ferrous metallurgy. At the moment, technical specialists have at their disposal many heat treatment methods that allow them to achieve the desired properties of each type of processed alloys. Each metal has its own critical temperature, which means that heat treatment must be carried out taking into account the structural and physicochemical characteristics of the substance. Ultimately, this will allow not only to achieve the desired results, but also to significantly streamline production processes.