The production of tourist knives is constantly being improved, and metallurgical plants are coming up with new alloys. They make the cost of the final product lower, and the quality of such knives is not inferior to imported analogues. In Russia, samples made of 95X18 stainless steel are widely used for knives, the pros and cons of which depend on the purposes of purchase and operation by each individual user.

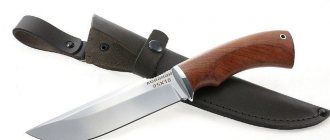

Knife Beaver.

Description of steel 95Х18 for knives

Proper processing of steel results in products that serve their owners for many years. The quality of the alloy is not inferior to imported analogues, and the cost of a finished knife made from 95X18 is less. Modern hunters call this brand “hunting”. Because the knives come out of the required quality and serve without any complaints.

Explanation of marking 95Х18

As with any other steel, the base is iron. Letter 95 indicates a carbon content of 0.95%. The letter X indicates the chromium content, in percentage equal to 18. The high chromium content classifies the alloy as a stainless steel.

What to look for when choosing

A tourist knife, for the production of which 95x18 steel is used, is made with a drop-down blade. Hunting blades are produced with a fixed design. Knives made of steel 95x18 must be selected according to the following criteria:

- Design – it is better to choose a folding design for a tourist knife. It should have a small blade and very compact dimensions. A hunting knife should be of minimal dimensions, but with a significantly larger width and thickness; the blade is fixed with a handle. The product usually comes with a case.

- Size – both tourist and hunting blades must be at least 15 cm in length, but no more than 25 cm for their comfortable use.

- Handle - it should be made of a material that reacts poorly to the environment. The best option would be polymers.

- The quality of the blade - it must be free of chips, nicks, and signs of corrosion.

- Sharpening – the greater the sharpening angle, the rougher the work the knife is intended for.

It is also worth paying attention to other characteristics of the knife:

- blade thickness – optimally 1.5–2 mm;

- the presence of protection on the handle - a lock that prevents the palm from slipping;

- balance between handle and blade.

A high-quality knife made of such steel cannot be cheap due to the high percentage of manual labor. Only a qualified craftsman can hold the metal for the right time at the right temperature, which is important when working with such capricious steel as 95x18.

By purchasing knives from this brand from trusted suppliers or in specialized hunting and tableware stores, you can get:

- product warranty;

- quality certificate;

- professional consultation of your choice.

By following these simple rules, you can be sure that the product will not fail under any operating conditions and will last for many years.

Chemical composition of steel

The percentage of chemical elements is shown in the table:

| C,% | Si,% | Mn,% | Ni,% | S,% | P,% | Cr,% | Ti,% | Cu,% |

| 0,9 — 1 | up to 0.8 | up to 0.8 | up to 0.6 | 0,025 | 0,03 | 17 — 19 | up to 0.2 | up to 0.3 |

Table: the importance of chemical elements in steel

| Chemical elements and their significance in the composition of knife steel: | |

| Carbon (C) | Without enough carbon it is very difficult to obtain a suitable hardness. This is the most important element in steel, it increases its strength. |

| Chromium (Cr) | gives the alloy increased anti-corrosion properties, chromium carbides increase wear resistance and hardenability. The high chromium content in the alloy affects its brittleness. |

| Manganese (Mn) | increases wear resistance and strength. Its content has a positive effect on the grain structure of the alloy and also contributes to excellent hardenability. |

| Molybdenum (Mo) | prevents steel from becoming brittle and allows it to maintain strength at high temperatures. Also increases corrosion resistance, strength, toughness. |

| Silicon (Si) | increases the strength and wear resistance of steel, like manganese, it makes steel more stable and reliable. |

| Vanadium (V) | forms the structure of carbides in such a way as to increase wear resistance, survivability and hardenability. |

| Nickel (Ni) | increases corrosion resistance and prevents steel from rotting. Increases the strength of steel. |

| Niobium (Nb) | the best carbide former, which provides corrosion resistance, ductility, and wear resistance. |

| Tungsten (W) | increases the wear resistance of steel, increases its stability during hardening and resistance to high temperatures. |

| Cobalt (Co) | enhances the effects of other individual elements in more complex alloys. Increases strength and hardness. |

| Sulfur (S) | is a harmful impurity, leading to the formation of cracks and tears. Typically, the sulfur content of high-quality steel is limited. The presence of sulfides is unacceptable for critical parts. |

| Phosphorus (P) | worsens the plastic properties of the alloy, causing the phenomenon of cold brittleness. In steels, phosphorus content is allowed in very small quantities. |

Main indicators and properties

The material belongs to the class of corrosion-resistant steels, used for the manufacture of critical durable parts, which are subject to increased resistance to wear and work under the influence of moderate aggressive influences at temperatures increased to 500ºС . On an industrial scale it is supplied in the form of rolled products, shaped, calibrated and ground rods, silver bars, strips, forgings and forged blanks.

Mechanical performance

Steel, when properly processed, acquires the properties of strength and flexibility, but improper hardening and untimely tempering will give the steel negative parameters. Steel is not so easy to sharpen on a machine, but with proper processing the knife will be sharp for a long time . Processing options:

- for hardening, oil is used at a temperature in the range of 1000–1050ºС;

- tempering is carried out with air or oil at a temperature of 200–300ºС;

- complete annealing of the rod is done at 885–920ºС;

- incomplete annealing is carried out at 730–790ºС;

- heating is performed at 850–860ºС;

- Cold treatment is performed at 70–80ºС.

Technological characteristics

To produce strip and section steel, rolling or reforging of the initial billet is used at high temperatures followed by slow cooling:

- the forging temperature begins at 1190ºС, ends at 840ºС, then is maintained at 750ºС, then cools;

- profiles with a cross section of up to 700 mm are annealed with recrystallization and subsequent tempering;

- steel 95x18 is not used for the manufacture of structures that are subsequently subject to welding;

- the specific gravity of steel is 7740 kg per cubic meter;

- material hardness 230-240 MPa.

Physical and mechanical properties of steel 95Х18

Due to its high characteristics and wear resistance, 95Х18 steel is in great demand in metallurgy. When the product operates in aggressive environments, the alloy retains high corrosion resistance. With proper production, blades can be hardened to 62 HRC.

Steel is able to retain its properties even when heated to 500 °C. After passing this mark, the characteristics drop sharply. Heat treatment plays an important role in the alloy manufacturing process. The exact quenching and tempering requirements must be followed.

Steel is hardened at temperatures of 1060-1080 °C. At the same time, it must be kept in this heated state for an hour. Then you need to quickly cool the product in oil. This process makes the connection stronger by refining the internal grains of the steel.

To prevent the formation of microcracks and relieve high residual stress after hardening, the steel must be tempered. This is a thermal process carried out at temperatures of 130-150 °C. The workpiece should be kept in this state for an hour.

Mechanical characteristics

Hardening of steel in violation of technological conditions, as well as untimely tempering, noticeably worsen the technical parameters of 95x18 steel. Like other martensitic steels, the 95x18 alloy is densified during quenching, and during the annealing process, a ledeburite structure is formed with some excess carbide, which has morphological differences.

- Primary carbides appear after the liquid phase and have an elongated shape in the direction of rolling or forging.

- Secondary elements are noticeably smaller, appear during the cooling stage, and are located in the body and along the edges of the initial austenites.

With increasing processing temperature, the hardness of the alloy increases. Under the condition of high-quality hardening, according to the technological map, the Rockwell hardness of steel 95x18 reaches 58-60 units. At the same time, the hardness of the metal in MPa is 230−245 units.

The specific gravity of the alloy per cubic meter is 7.75 tons.

Other mechanical parameters of alloy 95x18:

- density - 7.75 × 10 3 kg/m3;

- thermal conductivity - 24.3 W;

- the specific heat capacity of this grade of metal at 20˚C is 0.483×10 3J;

- degree of electrical resistivity - 0.68×10 6 Ohm/m.

Action of alloying impurities

Steel blanks 95Х18.

A chromium content in steel of more than 12% causes surface transformation of the metal. This results in a kind of protection with a thin oxide film. External irritants cannot cause much harm to steel.

It is clear that the chromium content of 18% makes 95X18 steel resistant to the external environment. It is highly resistant to corrosion and is not afraid of water, some acids and aggressive environments.

The formation of carbides in the alloy also has a positive effect on its quality. Steel 95Х18 includes structures of the type (Cr,Fe)7C3 or (Cr,Fe)23C6, and sometimes both at the same time. This increases abrasive wear of the metal.

Which is certainly a positive characteristic in the manufacture of cutting tools.

But there is also a negative point in the large presence of chromium. Metal cannot be produced in sheet metal. But this deficiency can be compensated for by the presence of nickel. Manganese and silicon have a similar effect. They improve the strength characteristics of the metal during the tempering process.

Steel Division

Steels have high rigidity combined with static strength .

By changing the percentage of carbon, alloying elements and temperature treatment conditions, these indicators can be increased or decreased over a wide range. Such experiments make it possible to diversify the chemical composition, change the properties and use the resulting materials in different areas of industry and economy. Steels enriched with carbon are divided according to its percentage content:

- low carbon, with a content of less than 0.31%;

- medium carbon – composed of 0.31–0.75%;

- high-carbon, containing more than 0.75% carbon.

Depending on the intended use, a distinction is made between structural and tool steels . The first large group includes metals used in construction, for the manufacture of parts of mechanisms and devices. Precision measuring and cutting tools are made from materials of the second group, and hot and cold working dies are produced.

Taking into account the quality indicator, steel is divided into ordinary, high-quality and high-quality. This characteristic is determined by the properties obtained during metallurgical production. Carbon steels are classified as ordinary materials, alloyed steels (enriched with carbon) are classified as high-quality materials.

Pros and cons of steel 95X18

Alloy 95X18 tolerates aggressive environments very well. Salt and alkali are of no use to her. High corrosion resistance is also noted when working with various acids. Let's try to take a closer look at the advantages and disadvantages of steel:

pros

- Hardness. The steel is hardened to 58-62 HRC. Knives made of steel 95Х18 can withstand heavy loads without being deformed;

- The alloy is resistant to corrosion. The alloy is not afraid of exposure to aggressive environments, water, acids and salts. Despite prolonged contact with such oxidizing agents, rust will not appear on the blade. The blade will remain in its original attractive form;

- High strength. The correct quenching and tempering process gives the steel high strength. Knives made of alloy 95X18 can withstand heavy external loads;

- Not high cost. Steel 95X18 is in no way inferior to foreign analogues, but at the same time its cost is an order of magnitude lower. This attracts its buyer;

- High wear resistance. Blades made from this steel do not lose their sharpness for a long time, even with prolonged use;

- Easy to sharpen. No special tools are required to trim the cutting edge. A regular whetstone will do the job. But it would be preferable to use a diamond-coated bar;

- Appearance. The polished blade made of this steel grade has a bright metallic sheen. No acid or salt will make it fade.

Minuses

- Steel does not tolerate shock loads well. It cannot be made into a throwing weapon;

- Knives made from this alloy do not have a large margin of fracture strength;

- Forging a blade at home is almost impossible. If the technological process is not followed, it will become fragile.

Type of delivery

The production of bladed weapons and high-strength parts for working under conditions of extreme friction is not the entire range of products manufactured from 95Х18 steel. This metal can be supplied in a variety of forms, including:

- long and shaped rolled products;

- calibrated or grinding rod, as well as silver;

- band;

- forgings, forged blanks.

Forging blank 95x18

The production of steel rods from 95X18 metal requires a different heat treatment technology, in particular heating occurs over a longer period of time, but at lower temperatures. In this case, the HRC hardness index decreases from a value of 60 to values of 30 and below.

Bladed weapon

If you type “steel 95X18” into Yandex images, the results will show solid knives and blades made of this steel.

Blades and knives made of 95X18 steel remain the most popular on the domestic market. In terms of production scale, they are undoubtedly inferior to the production of high-strength parts and other areas of use of 95X18. However, the number of people interested in making knives is quite large. From this point of view, steel can be considered not as a metal of industrial significance, but as a material from which works of art are made. And the very process of creating a knife or other bladed weapon is akin to skilled work, since it requires both experience and a certain ability to feel the metal.

Video - Hardening 95X18 at home

Production technology and heat treatment

In the steel production process, 95X18 is considered to be quite finicky. This partly affects its cost. Metal products go through four important stages before hitting store shelves:

- First, castings are produced and then annealed. For this purpose, they are heated to temperatures of 885-920 °C. Leave them for a couple of hours. Time is determined by specific technical conditions.

- Then comes the forging. At this stage, plates of the required size are formed. During forging, steel gets rid of a number of imperfections. This is a kind of prevention for metal. Thus, excess gases are displaced and thereby the pores in its structure are filled. Forging also refines the grain within the steel's structure, making the alloy stronger.

- Hardening. The process allows future products to be given more strength. To achieve a state of crystal lattice instability, the alloy is heated to 900-1125 °C. Then the workpiece is cooled sharply in water or oil. The process takes about an hour, which negatively affects the characteristics of the steel and the metal becomes brittle.

- Vacation. The process is necessary to give the alloy the desired characteristics. Depending on the technical conditions, steel is tempered at temperatures of 150-650 °C. In this way, excess brittleness of the alloy is removed. The steel is kept in this condition for about an hour.

The most important condition is the hardening mode; this process is regulated by production. If violated, the steel may become brittle or soft.

The hardness of steel after hardening is determined by the grain size of the authensite contained in the crystal lattice of the steel. The knife production plant is supplied in the form of slabs. From special rods, varietal blanks are produced.

Blanks for making knives, steel 95Х18.

Which are then forged manually or using forging machines. The blanks themselves are forged cold or hot, depending on the requirements. Manual labor in the production of blades is simply necessary. We haven’t yet learned how to work without it.

Steel production

Steel is produced from foundry or pig iron , iron-containing materials and products obtained by reduction. Metal waste and scrap are used. Additives are added to them to form slag, for example, lime, spar, deoxidizers (aluminum, ferromanganese) are used, and alloying materials are added.

Steel production is divided into two methods - converter and hearth processes. The first involves refining cast iron from impurities by blowing it with oxygen. Such technologies do not require the use of an external heat source, since molten cast iron containing oxides (phosphorus, carbon, manganese and silicon) is able to provide the required amount of heat to keep the steel in a liquid state.

The hearth process takes place inside blast furnaces or electric furnaces and requires an additional heat source from outside. They are used for melting solid metal scrap and charge. At this stage, the main one is the open-hearth process, which requires the combustion of liquid, solid or gaseous heat carriers. Next, the molten steel is poured into a ladle . This time is used for enrichment with alloying additives.

Oxygen-converter smelting method

This method involves removing carbon and impurities from cast iron by oxidation using oxygen blowing in convector smelters. The capacity of such a furnace is 50–60 tons, it is shaped like a pear and rotates around an axis .

From the furnace lining, the converter method is divided into Bessemer and Thomas. The Bessemer method is used for melting cast iron with a high percentage of silicon. When blowing, silicon oxidizes and releases a significant amount of heat. Burnout of almost all silicon raises the temperature to 1500–1600ºС, and carbon begins to burn out, while iron is oxidized at the same time. The resulting iron oxide dissolves well in cast iron and turns into steel. Phosphorus also goes into the composition of steels, which after casting usually contain less than 0.21% carbon and are used for technical purposes. They are used to make bolts, nails, wire and iron for roofing.

The Thomas method was developed for processing cast iron with phosphorus in its composition. The furnace lining is made of calcium and magnesium oxides . Thus, slag-forming substances contain a significant number of oxides with basic properties. The phosphate anhydrite obtained as a result of combustion reacts with excess calcium and turns into slag deposits. The main source of heat is the combustion of phosphorus.

The Bessemer and Thomas methods make it possible to obtain steel with a low carbon index; their use for high-tech parts and assemblies is not recommended.

Scope of application of steel 95Х18

Due to its characteristics and low cost, 95X18 steel is widely used in many branches of modern production. The alloy is used in aviation instrument making for the manufacture of mechanisms and components that are subject to increased wear resistance requirements.

Rolling and sliding bearings are also made from this alloy.

In mechanical engineering, 95X18 is used for parts that operate under conditions of abrasive wear. Steel is used to produce: shafts, bushings, axles, valves, springs and other products of a similar nature.

In the production of knives, steel 95X18 takes its place of honor. This niche is probably the most popular for rafting. Blades are made from it for a wide variety of purposes. They are used in tourism, hunting and outdoor activities.

Analogs

The marking of steel 95X18 is exclusively a Russian version; in other countries the alloy is called differently. There are not so few analogues in foreign countries. In fact, the composition of the analogues is not 100% identical to the 95X18 alloy; there are slight deviations.

But they are calculated in hundredths and, accordingly, can be neglected. Analogs in different countries:

- USA - 440B, 440C, 440FSe, A756;

- Germany – 1.4125, X102CrMo17, X105CrMo17;

- Japan – SUS440C;

- France – X105CrMo17, Z100CD17;

- European Union – X102CrMo17;

- Poland – H18;

- Czech Republic – 17042.

Knives made of steel 95X18.

Foreign classification

As noted above, the name of steel 95Х18 is an exclusively Russian-language version, while the foreign marking of this metal is somewhat different. Imported analogues have different names, depending on the country producing the metal. Thus, the overseas analogues of 95X18 steel are grades 440C and 440B. These grades of steel are produced in the USA. In the European Union, the metal X105CrMo17 and X102CrMo17, produced by German steelmakers, have identical properties. The Poles were a little more prudent, calling the high-chrome steel H18. The Land of the Rising Sun uses the eastern analogue of SUS440C, produced on the basis of American steel.

- 440C, 440B - USA;

- X105CrMo17, X102CrMo17 - Germany;

- H18 - Poland;

- SUS440C - Japan.

Japanese scissors made of SUS440C steel analogue 95X18

95X18 or X12MF which is better for a knife

Both steels were developed for use in heavy engineering. All kinds of machine parts were made from them. But today gunsmiths like these alloys. As it turned out, they make excellent blades.

The harder structure of X12MF steel allows cutting materials of high rigidity. But the blade does not dull for a very long time. Steel 95X18 has the same fragility as X12MF , so sharpening the blade simply won’t work.

The main difference between these steels is the amount of chromium content. What makes the 95X18 alloy more resistant to corrosion and aggressive environments.

But products made from X12MF require careful care.

The hardness of the alloys is approximately at the same level. But X12MF steel wins in this indicator. So the choice of metal is up to you. What do you choose, high hardness and careful care of the blade. Or high anti-corrosion, but the product is slightly weaker in hardness.

Which steel do you choose 95X18 or X12MF?

Steel 95Х18Steel Х12МФ

Scrap pricing

The cost of scrap steel 95X18 fluctuates within higher limits compared to other grades. Pricing is affected by the increased chromium content. The cost is constantly changing, and it makes no sense to write current prices.

You can find out more accurately at the metal collection points. It consists of the following indicators:

- supply and demand in a particular region;

- quotes on world ferrous metals exchanges play a role;

- compliance of the alloy in terms of chemical composition in accordance with GOST 5632-72;

- scrap metal surface condition;

- in what form of delivery: sheet, strip, circle or other;

- large dimensions will require additional cutting of the material, which will affect the cost;

- The volume of delivery is also important; the cost will be higher for larger weights of steel.

Knives made of steel 95Х18

Products made from steel 95X18 are not afraid of corrosion and hold an edge well. The steel is not powdered, so its cost is not high. Sharpening blades is quite simple. You can sharpen knives with a regular whetstone. We present several examples of this steel grade.

Knife A&R – Leshy-T

In comparison with the classic model – “Leshy”, the new blade has a reduced weight of the product. The cut of the lens-shaped slopes is raised to 21 mm. The new Leshiy-T model has a reduced heel area and a longer cutting edge. Installation of the overhead handle, dismountable. The rivets are replaced with bolts. There is a hole for a lanyard. Blade characteristics:

- Total length: 263 mm;

- Blade length: 149 mm;

- Blade width: 28 mm;

- Blade spine thickness: 3.2 mm;

- Blade steel: 95Х18;

- Handle material: micarta;

- Production: AiR, Zlatoust;

- Weight: 162 grams.

New model of the Leshy-T knife.

Tourist knife AiR – Splinter

The knife is positioned as a product for outdoor activities. It is small in size and quite light with a narrow blade of a classic shape. The blade has concave lens-shaped slopes from half the width of the blade. With a knife you can skin a hunting trophy, skin and gut an animal carcass. Convenient through-mounted handle shape. There is a hole for a lanyard. The characteristics of the blade are as follows:

- Knife length: 228 mm;

- Blade length: 118 mm;

- Handle length: 110 mm;

- Blade width: 18 mm;

- Butt thickness: 1.5 mm;

- Blade material: 95Х18;

- Handle material: wood, Karelian pine;

- Production: AiR Zlatoust, Russia;

- Weight: 69 grams.

Knife "Splinter" for outdoor activities.

Knife A&R – Snipe

Small universal blade made of steel 95X18. A durable knife with a classic shape and a narrow blade. Lenticular bevels form a thin, perfectly cutting blade. The handle is mounted through. There is a hole for a lanyard. Blade characteristics:

- Knife length: 260 mm;

- Blade length: 135 mm;

- Blade width: 28 mm;

- Butt thickness: 2.3 mm;

- Blade material: 95Х18;

- Handle material: birch bark;

- Production: AiR Zlatoust, Russia;

- Weight: 130 grams.

Classic knife "Snipe".

What knives are they used for?

This brand is used mainly for the production of hunting and tourist knives. The blade made of 95X18 steel remains sharp for a long time. If it needs sharpening, it can be done even in field conditions. An ordinary cobblestone is suitable for these purposes. High protection against corrosion is also highly valued by hunters and tourists, since it is not always possible to properly dry a knife in camping conditions.

Knife Varan-2, forged steel - RUB 3,590.

Collectible knives made from 95X18 steel are valued. The blades remain sharp for a long time, are not subject to rust and have an impeccable appearance.

Knife Bear (steel 95×18), gilding — 3000 rub.

95X18 steel is rarely used for the production of kitchen knives, since it is not intended for cutting anything hard.