Knives are a must-have accessory for any kitchen. But their range of applications is not limited to home use. They will come in handy when hunting, hiking, or fishing.

Steel 95Х18 and Х12МФ are considered one of the best materials for the manufacture of cutting tools. Each of them has its own advantages and disadvantages, so when choosing to understand which knife is better, X12MF or 95X18, it’s a good idea to know the features of each steel grade so as not to be disappointed in your expectations.

Chemical composition of steel Kh12MF, its properties, scope

X12MF is a tool alloy die steel that contains 1.45-1.65% carbon . It is characterized by the presence of alloying elements such as chromium (X) - 11-12.5%, molybdenum (M) - 0.4-0.6% and vanadium (F) - 0.15-0.3%. Contains in small quantities silicon (C) - 0.1-0.4%, manganese (G) - 0.15-0.45%, nickel (H) - up to 0.35%, phosphorus (P) - up to 0 .03%, copper (D) - up to 0.3% and sulfur (they try to minimize its content, so it is not labeled) - up to 0.03%.

Chromium (X) improves cutting properties, resistance to wear and corrosion, increases the strength and hardenability of the alloy.

Vanadium (F) increases heat resistance and improves the structure of the metal. With a small concentration (from 0.3 to 0.5%), it greatly improves the strength and ductility of the metal, which cannot be said about alloys with a high vanadium content.

The addition of molybdenum (Mo) increases the toughness and hardenability of high chromium steel. It also impairs scale resistance. Because of this, the amount of molybdenum in die steels is limited to 1.8% .

X12MF steel is well processed:

- Cutting , which helps obtain accurate dimensions of the finished part.

- Pressure , which increases the productivity of product manufacturing and saves material.

It sands satisfactorily, but is also quite fragile. Characterized by good mechanical properties:

- High strength.

- Plastic.

- Wear resistance.

- Good heat resistance and hardenability.

Products made from it have anti-corrosion properties , but with prolonged exposure to an aggressive (acidic or alkaline) environment, dark spots or a rusty coating may appear on them.

This grade of alloy is widely used in the metalworking industry. It is used to make parts of industrial equipment that have high requirements for surface quality and mechanical resistance, such as:

- Rollers profiled with complex shapes.

- The working elements of dies are matrices.

- Portages.

- Standard gears.

- Rolling dies for extruding external threads.

Reviews from real owners

Since this steel has been used for making knives for quite a long time, there are many reviews about it on gunsmith forums. It should be noted that most of them are positive. Among them, we can highlight:

Personally, I have 2 of these knives in my arsenal. One is a hunting Husky, the other is a folding camping one. I go hunting regularly and use them all the time. For several years, the folding one has not yet worked, but the husky had to be sharpened once. I am very pleased with the purchase. I think that you can and should take knives from 95X18.

Previously, such steel was called medical. My father had many camp knives made from it. I, too, like him, am fond of hunting, and I don’t see an alternative. You can, of course, buy a knife made from foreign steel, but is it worth overpaying? The quality does not change, but the price increases noticeably.

Also, disks for circular saws are made from such steel, and then homemade knives are made from them.

Chemical composition of steel 95x18, properties, application

Steel 95x18 - corrosion-resistant (stainless) ordinary. Contains 0.95% carbon (C) and 18% chromium (X). It also contains silicon (C) and manganese (G) - up to 0.8% each, nickel (N) - up to 0.6%, phosphorus (P) - up to 0.03%, copper (D) - up to 0.3%, titanium (T) - up to 0.2% and sulfur - up to 0.025%.

This grade of alloy is characterized by high levels of hardness, wear resistance, heat resistance (up to 500 °C), and corrosion resistance. The presence of 18% chromium indicates that this steel belongs to stainless steel. Products made from this alloy are resistant to chemically aggressive environments. Based on this, Steel 95X18 is used:

- In the aviation industry.

- Mechanical engineering.

- Making bladed weapons.

Due to its high resistance to wear, parts that operate under friction are made from it:

- Axles.

- Shafts.

- Bearings.

- Rods.

- Bushings.

Comparison with analogues

Steel 95X18 has characteristics similar to its domestic and foreign counterparts. To make it easier to choose a specific metal, we compared them.

Which is better 95x18 or d2

Both grades of steel were developed for the manufacture of highly loaded parts operating under constant friction, so their performance indicators are very similar. The high content of carbon and chromium made it possible to use them for the manufacture of camping and tourist knives. Both steels hold an edge well, and the blade can be adjusted without using a special tool.

Application experience shows that 95X18 has better corrosion resistance and is less brittle than D2 steel. In addition, its cost is an order of magnitude lower, which is another undoubted advantage.

| Parameter | 95Х18 | D2 |

| Average hardness, units. H.R.C. | 58 – 60 | 57 – 61 |

| Chromium content, % | 18 | 12 |

| Carbon content, % | 0,9 – 1,0 | 1,5 |

| Maximum permissible phosphorus content, % | 0,03 | 0,04 |

| Maximum permissible sulfur content, % | 0,025 | 0,03 |

Comparison of 95x18 and x12MF - which is better

These steel grades were developed for the manufacture of machine parts in heavy engineering and have similar strength and wear resistance indicators. Their balanced characteristics were liked by domestic gunsmiths, who began to use them for the manufacture of hunting knives.

The high hardness of blades made of X12MF steel allows you to cut harder materials and stay sharp longer. However, they are very fragile, and correcting the sharpening in field conditions is problematic. The main difference between these steels is corrosion and acid resistance.

The high chromium content makes 95X18 more resistant to environmental influences, while the blade made of X12FM requires careful care.

| Parameter | 95Х18 | X12MF |

| Average hardness, units. H.R.C. | 58 – 60 | 62 – 64 |

| Chromium content, % | 18 | 11,75 |

| Carbon content, % | 0,9 – 1,0 | 1,55 |

| Maximum permissible phosphorus content, % | 0,03 | 0,03 |

| Maximum permissible sulfur content, % | 0,025 | 0,03 |

What do these brands have in common?

Steel grades X12MF and 95X18 are different in chemical composition, mechanical characteristics, and areas of application. But they are both well machined by cutting , which facilitates their use in mechanical engineering . And the chromium contained in these alloys, when interacting with oxygen, forms an oxide film on the surface that is capable of self-healing, giving them anti-corrosion properties.

The anti-corrosion and mechanical properties of these steels make them popular in the production of knives. The density of the structure of these grades of materials gives approximately the same wear resistance to the cutting part of the blade.

Price segment

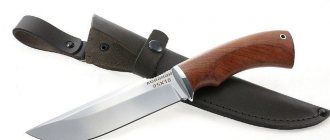

Steel 95X18 is used by craftsmen to make camping and hunting knives in the mid-price segment. Due to its low cost, blades made from it are inexpensive. The price range ranges from 2500 – 3500 rubles per piece.

Knife "Jager" with a handle made of black hornbeam. Price 2875 rubles.

Knife “Sturgeon” with wenge handle. Price 3145 rubles.

Performance characteristics of knives made of X12MF and 95X18 steels, differences

Knives made from X12MF Steel are highly durable and retain their blade sharpness for a long time, but if the heat treatment is improper or the permissible load is exceeded, they can chip. With prolonged contact with an aggressive environment, they are subject to corrosion, so a knife made of this alloy constantly requires careful care. In addition, with a Rockwell hardness of 60-62 HRc , it is quite difficult to sharpen a blade made of this material.

Anti-corrosion and mechanical characteristics are better for steel 95X18. It has high hardness (on the Rockwell scale: 57-59 HRc - slightly lower than X12MF), cutting edge resistance, and excellent anti-corrosion properties. A 95X18 knife is easier to sharpen . If the load is exceeded, the blade may bend.

Disadvantages and cons

Basically, all the mistakes of a knife with such steel are associated with poor production . Therefore, carefully choose the manufacturing company, otherwise the result will be sad. Therefore, it is better to choose a well-known company with good reviews for your purchase than a dubious company that no one knows anything about. After all, well-processed steel is the key to quality, otherwise you will lose your knife the first time you try to open a can of canned food.

So, let's highlight a few disadvantages:

- If steel is not properly cared for, rust may soon appear.

- If manufacturing rules were not followed during production, the blade will easily break.

- Again, due to a bad manufacturer, the blade may have poor sharpness.

- If you do not control the contact of the knife with moisture, corrosion will begin.

- Fragility. Therefore, it is not recommended to throw, throw, etc.

But in order for a knife to serve for a long time, you need to properly care for it. Here are some basic operating rules:

Recommendations for the use of knives from these brands

The main characteristics of X12MF steel: high mechanical strength, wear resistance, excellent cutting ability. Metal cutting dies made from this alloy retain their cutting ability even after cutting out several thousand pieces, therefore a knife made from this metal will last a long time without sharpening . But to maintain an aesthetic appearance, the blade will have to be taken care of more carefully. Knives made of X12MF steel are suitable for cutting up carcasses; the most reliable hunting and tourist blades are made from it.

Knives made of steel 95X18 are characterized by slightly less cutting edge durability, ease of sharpening and excellent corrosion resistance. The alloy acquires anti-corrosion properties due to a high concentration of chromium and alloying with molybdenum. Thus, maintenance of a knife blade made of steel 95X18 is minimal . When working with it, it is recommended to avoid large lateral loads (fracture) with a butt thickness of less than 4 mm.

Conclusion: if the beauty of the knife is important and there is no need to use it under lateral loads, then steel 95X18 is more suitable.

ProductsComment

Characteristics

95Х18 is a high-alloy chromium steel of the martensitic class. It has a high carbon content, which gives it exceptional anti-corrosion properties.

The combination of elements used to alloy it made it possible to give the metal resistance to acids, as well as to the formation of scale.

Choosing knife steel - which is better, X12MF or 95X18?

We have already written about knife steels several times. Here is a review of the best foreign-made knife steels, here about damask steel. We even managed to write an article about the ideal hardness of blades and how sharpening is checked. Someday we will gather our strength and write an article about the best domestically produced knife steels, so subscribe to the channel and wait!

Today we want to compare two popular domestically produced knife steels with each other, and find out which one is better. This is the popular stainless steel 95X18, from which many Russian knife companies make knives, and X12MF, more popular among knife makers.

Need help on steels

Good day everyone!

One of these days I’m going to go to a metal depot to buy some steel. The question is: how can you visually distinguish steel grades (what are the verification methods) such as x12 (mf, f1), 40x13, 30x13, 95x18? how will they be different? Thanks in advance for your answers, if I wrote it in the wrong place please correct me! I'm interested because I'm afraid that when buying one steel they may slip in a completely different one!

choopokapra

How can you visually distinguish steel grades (what are the testing methods) such as x12 (mf, f1), 40x13, 30x13, 95x18? how will they be different?

choopokapra

I'm afraid that when buying one steel they may slip in a completely different one

choopokapra

How can you visually distinguish steel grades?

alex-wolff

yes nikah. there are only a couple of ways to check

Find a way out to the spectrum.

There are no options for spectral analysis, I was already interested