Steel is the most famous iron alloy in the world. In fact, when talking about iron structures and objects, we are talking about products (or their production) from one or another steel. 99% of the alloy is classified as a structural steel, so there are virtually no tools or equipment that use it.

In this article we will try to touch upon such topics as the classification of grades, the price of steel, its properties and use in construction.

What is steel

Steel is an alloy of iron and carbon. In normal cases, the proportion of carbon ranges from 0.1 to 2.14%. But, given that alloy steels can contain many additional ingredients, today steel means an alloy in which the share of iron is at least 45%.

This video will tell you what steel is and how it is produced:

Concept and features

The main attractive qualities of steel are high strength with the availability of raw materials and a relatively simple production method. It is this combination that puts iron alloys in the position of absolute leader. Today there is simply no area of the national economy where steel does not occupy the position of a structural material.

- Iron and carbon are essential components of an alloy. Of these, iron provides ductility and toughness, due to which steel is classified as a deformable, malleable alloy. And carbon is hardness and strength, since hardness is always combined with fragility. The carbon addition is small and even in specialized formulations does not exceed 3.4%.

- In addition, due to the production method, steel always contains some proportion of manganese - up to 1%, and silicon - up to 0.4%. These impurities have little effect on the properties of the composition if they do not exceed the specified norm. For the same reasons, the composition also contains harmful impurities - phosphorus, sulfur, unbound nitrogen and oxygen. During the melting and alloying process, they try to get rid of these ingredients, since they reduce the strength and ductility properties of the alloys.

- Other additives are artificially introduced into the alloy in order to change the quality of the material. Thus, the addition of chromium gives steel heat resistance, and nickel - corrosion resistance and toughness.

- An extremely useful quality of iron alloys is that the change in properties is influenced by very small additions of other substances by weight. This allows you to significantly diversify the quality of the material. In addition, the properties of the alloy are greatly influenced by the method of manufacturing the product itself - cold deformation, hot deformation, quenching, and so on.

Relation to cast iron

Cast iron is closest to steel in properties and composition. Some of the material is made from cast iron. However, in practice, the differences in characteristics are quite noticeable:

- steel is stronger and harder than cast iron;

- Cast iron is actually lighter than steel and has a lower melting point. The massiveness of cast iron products creates a misleading impression, since it is less durable;

- steel is easier to machine due to its low carbon content. It is preferable to cast cast iron;

- cast iron has lower thermal conductivity, that is, products made from it store heat better than steel ones;

- Cast iron cannot be subjected to a procedure such as hardening. And the latter can significantly increase the strength of the material.

Next, we will consider the advantages and disadvantages of steel.

Advantages and disadvantages

It is quite difficult to describe the pros and cons of the material. In practice, we deal with steel products, and from an alloy of various grades, and, therefore, properties. And one of the features of the material is precisely that the method of manufacturing a product from it also affects its properties. The quality of a welded pipe cannot be compared with the characteristics of a cold-rolled steel pipeline.

In general, we can talk about the following advantages of steel:

- high strength and hardness - characteristic of all types;

- a huge variety of properties due to different composition and different processing methods;

- viscosity and elasticity sufficient for use in all areas where resistance to shock, static and dynamic loads in the absence of residual deformation is required;

- ease of machining – welding, cutting, bending;

- very high wear resistance compared to other structural materials and, accordingly, durability;

- the prevalence of raw materials and an economically viable production method, which determines the affordable cost of alloys.

The disadvantages include the following:

- The biggest drawback of the material is its lack of resistance to corrosion. To avoid damage, special types of steel are produced - stainless steel, but their cost is noticeably higher. More often, the problem is solved by coating steel products with a protective layer of metal or polymer;

- the alloy accumulates electricity, which significantly increases electrochemical corrosion. Any large structures - machine bodies, pipelines - require special protection;

- the alloy is not lightweight, steel structures are heavy and significantly make objects heavier;

- The manufacture of steel products is a multi-stage process. Shortcomings and errors at any stage result in a significant reduction in quality.

Next, we will consider the marking and classification of steels by quality, purpose, as well as composition and other characteristics.

Story

The documented history of rafting begins two millennia BC:

- Samples almost 4 thousand years old have been unearthed in Turkey.

- The material has become available to Europeans since Antiquity.

- The most famous artifacts of the Middle Ages were damask swords. Since that era, it has been the main material for edged weapons.

For centuries, the secret of making Damascus steel and Japanese samurai swords was kept secret.

- The heyday of steel production came in connection with the wars of the 19th century. The 20th century expanded the range with tank armor, aircraft hulls, and helmets.

In the third millennium, the alloy does not lose ground to the materials of the new generation.

Types of metal

Calculating the number of alloys known and used today is a very difficult task. Classifying them is no less difficult: the properties of the material depend on the composition, production method, nature of the additives, processing method, and so on.

The most commonly used classifications are:

- according to the chemical composition of steels - carbon and alloyed;

- by structural composition - austenitic, ferritic, and so on;

- according to the content of impurities - regular quality, high-quality, and so on;

- by processing method - thermal hardening - annealing, thermomechanical - forging, chemical-thermal - nitriding;

- by purpose - tool, structural, special steels and so on.

This video will tell you about stainless steel:

Chemical composition

An alloy is essentially a solid solution. Moreover, the component dissolves in a solid base material according to different laws than in a liquid. The basis for the production of all iron alloys is the ability of iron to polymorphism, that is, the formation of different structural phases at different temperatures. Thanks to this, carbon and other elements dissolved in iron at high temperatures do not precipitate when the temperature drops, as happens with ordinary liquids, but form a joint structure.

According to their composition, steels are divided into carbon and alloy.

Carbon

Carbon - the main, that is, the alloying component that determines the properties, is carbon. There are 3 types:

- low-carbon – less than 0.3%. The alloys are distinguished by their malleability and resistance to dynamic loads;

- medium-carbon - the proportion of carbon varies from 0.3 to 0.7%;

- high-carbon ones contain more than 0.7% carbon. They are distinguished by higher strength and hardness.

This division is associated with the transformations that occur in alloys. Up to a carbon content of 0.8%, the alloy retains a hypoeutectoid structure, that is, it has a ferrite-pearlite structure. As the proportion of carbon increases, the structure changes to eutectoid and hypereutectoid, which corresponds to pearlite and cementite. The phase ratio largely determines the strength characteristics.

The user is faced not so much with low- or high-carbon steel, but with the composition of a certain grade. The brand is determined by the ratio of several criteria, and not just carbon content.

There are 3 groups based on their purpose:

- A – mechanical qualities are standardized. The group is divided into 3 categories and 6 brands. The grade St is designated from 0 to 6. St0 is steel rejected for some indicators, used in insignificant structures. St6 – most closely corresponds to the concept of high-quality steel;

- B – standardized according to its chemical composition, divided into 2 categories and 6 grades, designated BST from 0 to 6. As the number increases, the strength and fluidity of the material increases;

- group B is standardized both in terms of mechanical parameters and composition. It is divided into 5 marks, designated VSt.

An additional classification based on manganese content is applied. I – with normal content of the element, that is, 0.25–0.8%, and II – with increased content, up to 1.2%

Alloyed

Alloyed steels are steels into which additional ingredients are specially introduced to impart other qualities to the composition. Classification is made according to the total volume of all alloying additives - not manganese or phosphorus impurities.

There are 3 types:

- low-alloy – with a total volume of additives up to 2.5%;

- medium alloyed – contains from 2.5 to 10% impurities;

- in highly alloyed materials the proportion of additives exceeds 10%.

Alloying significantly complicates the structure of the solid solution, which leads to the emergence of a complex classification based on structural composition. Brands are marked by composition: the proportion of carbon must be indicated. And then the proportions of alloying additives are indicated in decreasing order. If the proportion of impurity is less than 1%, the substance is not indicated.

Both non-metals and metals are used as additives.

- Manganese – increases the strength and hardness of the material, improves cutting properties. But at the same time it contributes to an increase in grain, which reduces resistance to impact loads.

- Chrome – improves resistance to shock and static loads, and also increases heat resistance. With a large proportion of chromium, the material becomes stainless.

- Nickel – increases the elasticity of the alloy. With significant content, it imparts corrosion resistance and heat resistance to steel.

- Molybdenum - increases the hardness of the alloy, but at the same time reduces brittleness.

The best known of alloy steels is, of course, stainless steel. Most often it is chrome-nickel and chromium steel with a chromium content of up to 27%.

Phase and structural composition

Making steel is a complex and controversial process. Its peculiarity is that during melting the alloy undergoes phase transformations, which determine the combination of strength and elasticity.

Carbon alloying occurs in 2 stages. In the first stage, when heated to 725 C, iron combines with carbon, forming carbide, that is, a chemical compound called cementite. At normal temperatures, steel contains a mixture of cementite and ferrite. When the temperature rises above 725 C, cementite dissolves in iron, forming another phase - austenite.

This feature is associated with the classification of the alloy according to its structural composition in a normalized form:

- pearlitic - these are mainly low-carbon and low-alloy steels;

- martensitic – with a high content of additives;

- authenite – highly alloyed.

In the annealed state, the following structural classes are distinguished:

- hypoeutectoid,

- hypereutectoid,

- ledeburite,

- ferritic,

- austenitic.

What is the meaning of such a division? The fact is that alloying additives have different effects on different steel structures. Thus, the dissolution of alloying elements in ferrite leads to an increase in tensile strength, with the exception of manganese and silicon, which strengthen the alloy. When alloying austenite, the yield strength decreases with a relatively high strength. As a result, the material is easily and quickly strengthened during deformation - work hardening.

Classification by deoxidizing agent

When melting metals, a common problem is the gas dissolved in them - oxygen, nitrogen, hydrogen; to remove it, they resort to deoxidation. Depending on the completeness of the process, there are 3 types:

- calm - the metal does not contain ferrous oxide. The alloy is completely free of gases, so its properties are most stable and uniform. It is used for critical structures, since the technology for its production is expensive;

- semi-calm - hardens without boiling, but is accompanied by the release of gases. Some gases remain, but can be removed by rolling the alloy. Typically, semi-quenched steel is used as a structural steel;

- boiling - contains dissolved gases. This affects the properties: the material is prone to cracking during welding, for example, but since the production of boiling steel requires the least cost, such an alloy is also produced for many simple structures.

Classification by purpose

A rather arbitrary division of steels according to the areas of application of steel.

- Construction - alloys of regular quality and low-alloy, designed for high static and, in some cases, dynamic loads. The main requirement for them is good weldability. In fact, depending on the nature of the construction project, materials of very different quality are used.

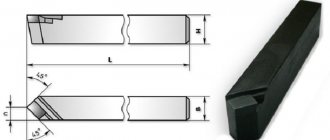

- Tool - as a rule, high-carbon and high-alloy, used in the manufacture of tools. There are stamped alloys, cutting alloys and steels for measuring instruments. Cutting materials are distinguished by their hardness and heat resistance, and the material for measuring instruments is highly wear-resistant.

- Structural – with low manganese content. These are cemented, high-strength, automatic, ball-bearing, wear-resistant and so on, used for the manufacture of a wide variety of components and structures. Such a huge variety of properties is achieved through alloying.

- Sometimes special steels - heat-resistant, heat-resistant, acid-resistant, but in fact they are a type of structural steel.

Impurity content

Steel can contain useful impurities, that is, alloying elements, and harmful ones. Based on the content of harmful substances, 4 groups are distinguished:

- ordinary - or ordinary quality, with a share of sulfur not exceeding 0.06% and phosphorus not exceeding 0.07%;

- qualitative - the allowed proportion of sulfur is no more than 0.04% and phosphorus is no more than 0.035%. The process of their manufacture is more expensive, but the mechanical properties of steel are also higher;

- high-quality - the proportion of sulfur does not exceed 0.025%, and phosphorus - 0.025%. Alloys are produced mainly in electric furnaces to achieve high purity;

- especially high-quality - smelted in electric furnaces using special methods. This way, only high-alloy steels with a sulfur content of up to 0.015% and phosphorus - 0.025% are produced.

Next, we will consider the technology and process of steel production, its stages and types.

Designation with alloying elements

Further it is more difficult, since the alloying composition comes into play. Below we show a table - a letter combination:

| Letter in marking | Chemical element sign | Name |

| X | Cr | Chromium |

| WITH | Si | Silicon |

| T | Ti | Titanium |

| D | Cu | Copper |

| IN | Wo | Tungsten |

| G | Mn | Manganese |

| F | W | Vanadium |

| H | Ni | Nickel |

| K | Co | Cobalt |

| M | Mo | Molybdenum |

Let's show it using a certain brand as an example: The first digit always indicates the number of hundredths of carbon. Then the letter designations that are responsible for the additives are listed. If there is no letter next to it, then this component is less than 1%. At the back, the very last letter (not shown in the example) can be “A” or “W” - this is high-quality or especially high-quality steel, respectively.

Alloy production

The process of manufacturing the alloy comes down to the processing of cast iron, during which excess impurities are annealed and alloying elements are introduced. Several methods are used for this.

- Open-hearth - molten or solid cast iron with ore is smelted in an open-hearth furnace at 2000 C to anneal off excess carbon. Additives are introduced at the end of the melt. The steel is poured into ladles and transported to the rolling mill.

- Oxygen converter – more productive. Air or a mixture of air and oxygen is blown through the cast iron in the furnace, achieving faster and more complete annealing.

- Electric melting - melting is carried out in a closed furnace at 2200 C, which prevents gases from entering the alloy. An expensive method that only produces high-quality compounds.

- Direct method - in a shaft furnace, pellets obtained from iron ore are blown with combustion products of natural gas - a mixture of oxygen, carbon monoxide, ammonia, at a temperature of 1000 C.

The steel making process does not end there. In cases where it is necessary to obtain the most durable material, additional processing is resorted to.

Thermal method

Thermal methods include:

- annealing – heating and slow cooling of different types and at different speeds;

- hardening - heating above the critical temperature, which causes recrystallization of the alloy, and faster cooling;

- tempering is a procedure carried out after hardening in order to reduce the stress of the metal;

- normalization is the same annealing, but carried out not in an oven, but in air.

Thermo-mechanical method

Thermomechanical methods combine mechanical and thermal effects:

- high-temperature TMT - hardening - hardening, hardening, is carried out immediately after heating, while the alloy retains its austenitic structure. The change due to plastic deformation during rolling or stamping is retained by 70% and after cooling the steel turns out to be stronger;

- for low-temperature TMT – cold-rolled steel. The alloy is heated to achieve an austenitic state, cooled below the recrystallization points to achieve the appearance of a martensitic phase - within 400–600 C. Then hardening is carried out - hardening, rolling. When cooled, the effect is completely preserved.

Thermochemical treatment

Thermochemical treatment is the heating of alloys and holding them in certain chemical environments. The most well-known methods include:

- carburization – saturation of the alloy surface with carbon. In this way a wear-resistant top layer is obtained;

- nitriding – saturation of steel with nitrogen. The goal is the same - to obtain a top wear-resistant layer, but compared to carburization, nitriding provides higher corrosion resistance;

- nitrocarburization and cyanidation - saturation of the surface layer with both carbon and nitrogen. Provides higher speed and productivity of the process.

Advantages and disadvantages

The characteristics of the alloy depend on the composition and manufacturing method. There are also universal properties.

Advantages of steel:

- Strength, hardness.

- Viscosity, elasticity.

- Possibility of mechanical processing. Steel fragments are easy to bend, weld, and cut.

- Wear resistance, durability.

- Prevalence of raw materials.

- Simplicity, cost-effective production.

- Selecting a material with the desired properties. They are provided by a variety of composition and processing methods.

Plus the price availability of products.

Disadvantages of the material:

- Massiveness.

- Vulnerability to corrosion.

- Tendency to accumulate electrical potential.

These flaws are not critical; there are ways to neutralize them.

Material cost

The cost of the material is no less varied than the number of brands. Standard steel on the London Metal Exchange in December 2016 costs $325 per ton. Stainless steel costs are noticeably higher, with cold-rolled 304 grade stainless steel priced between $1,890 and $1,925 per ton in December.

Steel is the most popular and most widespread metal alloy in the world. When talking about the role of iron in the national economy, we mean specifically various steel alloys.

To see how steel melts, watch the video below:

What does the marking say?

We have listed the main reasons for classifying steels - purpose, structure, content of components. It is based on these factors that the brand is determined. So, for example, the most common subtype - structural alloys of ordinary quality without alloying additives - can be labeled as “St”. Then comes a number that determines the amount of carbon.

Classification by structure

The structure of steel is formed during its manufacturing process, during casting and processing under high temperatures. The chemical bonds of a material determine its relationship to any class. This ratio is taken into account for the use of steel in a particular area. Let's take a closer look at these classes:

- Austenite. This class is characterized by strength and uniformity. They are resistant to heat and rust, and can be used to work in hazardous environments or transport corrosive elements.

- Ferrite. Representatives of the class of ferrites are magnetic, making them optimal for use in radio engineering and electronics for the manufacture of antennas and other equipment.

- Martensite. This type of steel is obtained through alloying and heat treatment. The material can return to shape after mechanical processing. The use of martensite representatives is complicated by additional processing requirements.

- Perlite. Perlite is called decomposition upon cooling after heating. This condition is created artificially for plastic deformation.

- Cementite. Representatives of the species are physically elastic and hard.

Application of carbon steel

It is worth noting that a certain type and grade of steel has its own area of application. Thus, carbon tool steel of high and increased strength of various grades is used for the production of metalworking chisels, hammers, screwdrivers, scythes, carpentry tools, saws, scissors, chipper knives, and wood turning tools.

Various products are made from low-carbon steels using cold stamping, as well as for small parts (lightly loaded toothed wheels, pushers). Medium-carbon steels are also used for the manufacture of small-sized parts - gears, connecting rods, flywheels. Steels with the highest carbon content - high carbon - are used to produce springs of various sizes and different types of springs.

Drills, forging tools, cutters, as well as tools for working stone and wood are produced from high-quality carbon steel grades U7, U8G, U9, U12 and U13.

Classification by degree of deoxidation

Deoxidation is a process that leads to a decrease in the oxygen content in the melt. This process is necessary in order to avoid the appearance of rust on rolled metal. The degree of deoxidation provides for the following classification:

- calm (SP) - have a homogeneous structure, contain a minimum amount of gases and non-metals; used for expensive alloys and the manufacture of metal structures;

- semi-quiet (PS) - their properties make it possible to produce load-bearing elements of welded and riveted structures; Bolts and nuts are made from PS, which can be used at low air humidity and high temperature;

- boiling steel (KP) – a brittle type of steel; suitable for the production of boiler parts and structures in contact with explosive substances; The main disadvantage is the rapid appearance of rust.

The following additives usually participate in the deoxidation reaction: aluminum, manganese, silicon.