Chrome plating is one of the most common methods of protecting metal products from corrosion, as well as their decorative design. Today, there are several technologies for carrying out such a procedure, for the implementation of which various equipment for chrome plating is used.

DIY chrome valve cover

Description of the basic operating principle

Now we sell equipment for chrome plating, both domestic and foreign. Foreign developments are distinguished by their convenience and efficiency in operation, as well as their compactness. But they are much more expensive than their Russian counterparts.

As for the configuration, it usually consists of:

- working stand;

- pressure gauges (preferably a whole set);

- spray bottle;

- pistol

It is these parts that carry out both the blowing of products for processing and other work processes. Domestic analogues are much cheaper. But they often lack the ability to perform decorative finishing.

When such equipment is used for chrome plating, the description of the process will look like this:

- Any paintwork previously applied must be completely removed. Any contamination must be removed. Grinding and degreasing are carried out.

- After this, move on to the primer layer.

- Heat treatment of products helps improve adhesion to other materials.

- The next step is to use a spray gun to apply the chrome layer.

- Varnish or self-adhesive film is used to provide additional protection.

Thus, the metal receives maximum protection from corrosion processes. Chemical metallization also helps to cope with this problem. It is performed with special reagents, which are also used in the chrome plating process. The procedure promotes the formation of a thin layer of chromium. The main characteristic is a high level of protection. Just like the chrome plating equipment itself.

On video: equipment for chemical metallization.

Main defects and removal of low-quality chrome plating

Receiving a defective coating should not frighten a novice electroplater. A poor-quality layer of chromium can be removed in a solution of hydrochloric acid (100-200 g/l). After this, the parts are washed in water, and the chrome plating process can be repeated.

Most often there are several main defects:

- Peeling of the chrome film. The main reason is poor adhesion due to insufficient degreasing. After removing the coating, the surface is cleaned and reactivated again.

- Chromium growths (dendrites) on sharp edges and corners. This defect indicates a high current density on sharp edges. If possible, it is better to round the edges or install screens in problem areas.

- Matte finish. To achieve shine, it is necessary to increase the temperature of the solution, reduce the current, or add chromic anhydride.

Uneven surface shine

- High current strength.

- Electrolyte temperature is lower than recommended.

There is no "shine"

- Lack or excess of CrO3 in solution.

- The current rating is too high.

- The proportion of acid is less than required.

Brown spots on chrome plating

- Excess chromium.

- Lack of acid.

There are small shells on the coating

- Poor quality machining of the workpiece.

- Hydrogen is not removed from the surface during the reaction. In this case, you should change the method of “hanging” the sample and the drying method.

“Softened” coating

- Increased electrolyte temperature.

- Reduced current.

Chromium plating peeling

- Instability of supply voltage.

- Poor degreasing.

- The electrolyte has cooled down during processing for too long.

If someone thought that chrome plating is, in general, a simple thing, then they will have to be somewhat disappointed. Even if we are talking about a small “thing,” there are enough nuances. But it is especially worth warning about the pitfalls of those who are thinking of putting this business on stream at home.

Sources

- https://ometalledo.ru/kak-xromirovat-metall-v-domashnix-usloviyax.html

- https://pechistroy.ru/stroymaterialy/hromirovaniya-metallicheskih-izdeliy-v-domashnih-usloviyah.html

- https://obrabotkametalla.info/mexanizm/xromirovanie-detalej-v-domashnix-usloviyax

- https://www.rocta.ru/info/hromirovanie-detalej-svoimi-rukami-v-domashnih-usloviyah-kak-ehto-opisanie-tekhnologii/

- https://plavitmetall.ru/obrabotka/xromirovanie-v-domashnix-usloviyax.html

- https://pressadv.ru/samodelkinu/hromirovanie-detalej-v-domashnih-usloviyah.html

- https://fizmatlit.com/kak-hromirovat-metall-v-domashnih-usloviyah/

- https://boldproject.ru/raznoe/hromirovaniye-v-domashnih-usloviyah.html

- https://metalloy.ru/obrabotka/zashhita/kak-hromirovat-metall

- https://metmastanki.ru/hromirovanie-detaley-v-domashnih-usloviyah

- https://tokar.guru/metally/hromirovanie-detaley-v-domashnih-usloviyah-svoimi-rukami.html

- https://kraskaok.ru/hromiruem-detali-v-domashnih-usloviyah-tehnologiya-i-neobhodimoe-oborudovanie/

- https://kraskaved.com/kraski/rabota/smeshivanie-i-kolor/xromirovanie-svoimi-rukami.html

- https://ismith.ru/metalworking/xromirovanie-v-domashnix-usloviyax/

- https://unit-car.com/tuning/122-hromirovanie-detaley-v-domashnih-usloviyah.html

Pseudo-chrome plating and real processing

Using paint that contains up to 75 percent chromium is one of the simplest metal processing options. But this decision does not apply to metallization in the full sense of the word. They simply use paint on the surface of the product that requires treatment.

With this method of chrome plating, an ordinary paint brush or spray bottle will become indispensable assistants. However, there is also chrome spray paint on sale, which simplifies the painting process.

If the work is done according to all the rules, the result will last for at least five years. This result is achieved by any chrome plating installation. But, if such a layer is damaged, then corrosion will quickly begin to penetrate inside the product.

If you carry out truly effective metallization with your own hands, then you need to use:

- source of direct electric current;

- electrolyte for chrome plating;

- a special container where galvanic processes will take place.

This is a minimum set, without which chrome plating becomes completely impossible.

Chemical chromium plating technology

The algorithm for chrome plating, which is carried out by galvanization, can be described as follows:

- The product for processing is placed in a special bath, which is pre-filled with electrolytic solutions.

- Afterwards everything is connected to the current source, with a plus sign.

- Any chromium-based workpiece is connected to the negative contact at the power source.

- The chrome billet absorbs the electricity. It goes into the electrolyte, to an additional product. Next, the ions that make up chromium are separated. They are passed through the surface of the electrolyte, and then taken over by the part being used. It is sometimes difficult to get a set with them.

- Chromium ions settle on the surface and bind to it at the molecular level. The result is the formation of a layer that provides maximum protection.

It is the chemical type of metallization that contributes to the creation of the most reliable protective layer.

This technology allows you to apply a layer of not only chromium to the surface, but also of other metals, including: aluminum, silver, zinc. The installation for chemical metallization remains the same. It is important to use a suitable current source, then the speed of the process for chrome plating parts will be appropriate.

But we must remember that the process of chemical metallization involves the release of substances harmful to human health. Therefore, to carry out the procedure in a domestic environment, only non-residential premises should be used. Personal protective equipment will also not be superfluous.

Equipment for chrome plating - what you need to apply chrome

Chrome plating is one of the most common methods of protecting metal products from corrosion, as well as their decorative design. Today, there are several technologies for carrying out such a procedure, for the implementation of which various equipment for chrome plating is used.

Principle of operation

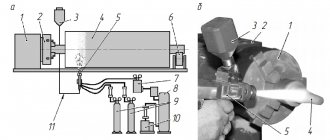

On the modern market you can purchase both foreign and domestic equipment for chrome plating. The first, although compact, convenient and efficient in operation, is quite expensive.

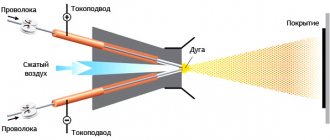

The set of such equipment includes a working stand, a set of pressure gauges, a spray gun and a gun, with which the workpiece is blown.

Domestic equipment used for chrome plating of parts costs much less than foreign equipment, but does not allow decorative processing (with its help you can only imitate its results).

Professional installation for chemical chrome plating. All controls and controls are conveniently located on the front panel

Chrome plating when using such equipment is performed as follows:

- Before chrome plating, the surface to be treated is cleaned of paint and varnish coatings, any contaminants, sanded and degreased.

- Then a layer of primer is applied to it.

- To improve the adhesion of the applied primer to the metal, the latter can be subjected to heat treatment.

- After this, a layer of chromium is applied to the surface of the cooled product using a spray gun.

- To protect the coating applied as a result of chrome plating, you can use varnish or self-adhesive film.

A coating applied in this way cannot provide reliable protection of the metal from corrosion. Chemical metallization, performed using special chemical reagents for chrome plating, can effectively solve this problem. As a result of this procedure, a thin layer of chromium is formed, characterized by high protective properties.

The difference between pseudo-chrome plating and real chrome plating

The simplest method of chrome plating, which cannot be considered full metallization, involves the use of paint containing at least 75% chrome dust.

Metal-containing paint is applied to the surface of a cold product (for this, use a spray gun or a regular paint brush). Thus, a kind of barrier is created that protects the metal from corrosion.

The result of such chrome plating, if done correctly, can last at least five years. However, if the coating is damaged, corrosion will affect not only the surface of the metal, but also its deep layers.

Truly effective chemical metallization involves the use of:

- a special container in which galvanic processes take place;

- electrolyte for chrome plating;

- source of constant electric current.

This set of accessories and consumables is the minimum for chrome plating.

A complete set of chrome plating equipment also includes degreasing and washing baths, an oil separator and drying chambers.

Application of chromium in production conditions

The algorithm for the standard chrome plating procedure performed under production conditions is as follows.

- The workpiece is placed in a bath filled with an electrolytic solution.

- It is then connected to the positive contact of the electrical current source.

- Any workpiece made of chromium is connected to the negative contact of the current source.

- After the electric current begins to flow to the chromium workpiece, to the workpiece and into the electrolyte, chromium ions will begin to separate from the workpiece and move through the electrolyte to the workpiece.

- By settling on its surface and bonding with it at the molecular level, chromium ions form a reliable and very durable protective layer on it.

Chemical metallization allows you to form the most reliable coating, characterized by high protective properties. Using this technology, a layer of not only chromium, but also zinc, silver, aluminum and other metals can be applied to a metal part.

It should be borne in mind that chemical metallization is accompanied by the release of chemicals harmful to health, therefore, if you are planning to carry it out at home, you must use only non-residential premises.

Naturally, personal protective equipment should not be neglected.

To ensure a uniform rate of chemical reaction, to independently perform chemical metallization, it is necessary to correctly select a source of direct electric current.

Thermochemical metallization technology

In the recent past, metal gilding was carried out using thermochemical metallization technology. The essence of this technology, the use of which makes it possible to apply coatings not only of gold, but also of other metals, to the surface of a product, is as follows:

- A special composition consisting of metal dust and a binder made from wood resins is applied to the metal.

- After the applied layer has completely dried, the product is placed in a muffle furnace.

- Under the influence of the high temperature created inside the furnace, the binder composition burns out, and the metal dust melts, forming a thin protective layer.

Today there are several variations of this technology. The first of them is that the metal layer is applied under high pressure, while the product itself is in a furnace heated to the required temperature.

Another option for metallization involves that a layer of metal is first sprayed onto the surface to be treated, and then the product is fired in a furnace.

Thermochemical metallization

At the end of the last century, gilding of metal was carried out using thermochemical metallization technology.

This is another way to apply metal coatings for additional protection. Its main features, as well as for the equipment for chemical metallization itself, are as follows:

- A special composition is applied to the metal, in which metal dust is combined with a binder component. It is usually based on wood resins. Their selection varies.

- The product is placed inside a muffle furnace when the raw materials harden.

- Inside this structure, a sufficiently high temperature is maintained, when exposed to which the connecting element simply begins to burn out. Metal dust melts. Thus, a dense layer is formed for additional protection.

This chemical metallization is currently used in several variations. The first of them is based on the main principle according to which a layer of metal is applied to the surface of the product while constantly maintaining high pressure. The product itself is located inside an oven heated to a certain temperature.

An option is possible when a layer of metal is pre-sprayed onto the surface of the product. After this, the product is placed in a kiln for firing.

This chemical metallization is also available in a more simplified, home version:

- Metal dust is applied to the surface in one layer.

- Melt the dust using a regular construction hair dryer. This promotes the formation of a thin layer on the surface.

- Grinding and subsequent polishing with your own hands allows you to make the surface as smooth and even as possible, meeting all requirements.

Chemical metallization by this method requires the use of the following materials and technologies:

- composition for finishing coating;

- a machine with which everything is polished;

- hair dryer to create a flow of air with increased temperature;

- spray bottle for applying metal powder.

A set of tools is easy to obtain in a specialized store.

Chrome plating business – Equipment for chrome plating

In this article we want to draw your attention to quite simple and obvious things for many. But due to the fact that questions on the topic of organizing a business are among the most frequently asked, we tried to systematize the answers.

Why chemical metallization services could be your business

The mirror coating is a thin film of silver. Silver, gold and various shiny things are associated with wealth. There is a demand for such coatings, and it is constantly growing. Clients want to have exclusive things. And where there is an exclusive, there is handmade, one-piece products and high cost.

What is the cost of coverage

This is generally one of the most frequently asked questions. People who have an understanding of business understand that profit is calculated using a much more complex formula than cost + trade markup.

Running a business is difficult; you have to work harder than anyone else. You can’t buy a camera and press its button to become rich. You cannot buy a sewing machine and become a Couturier without sitting down to use it.

Many customers will be handling such products, the cost of covering which will be several times higher than a new product. It is unlikely that you will be able to earn anything here other than your own experience and honing your skills.

For example, decorative chrome parts of production cars, like new parts in a store, cost much less than restoring a peeling coating using metallization. Simply put, we recommend buying new. Frankly poor and greedy customers ask for chrome to be applied to car wheels.

They want to add attributes of a premium car to their twenty-year-old car. However, they will most likely bring old, broken discs. Not even new with regular paint. They are, of course, not ready to buy new chrome wheels produced in a factory.

They need you to restore their junk to perfect condition, but they are almost never willing to pay for it. Chromizing old wheels is not a business. You can make CDs for yourself, for friends, or as an advertisement for your services. But it's not worth trying to make money on this. And, of course, chrome wheels are not intended for everyday use.

Unless, of course, you want to turn your exclusive into commonplace. So, cost and profit are the subject of a whole report. The main thing you should know is that some truly exclusive products are paid for in six figures. But you will have to work for more than one week. A business plan will be needed for those who plan to use borrowed funds.

We can, of course, help in compiling it. And we have done such individual work more than once, but we’d rather do a project for your workshop: how to plan the room, what additional equipment, where to install it, how to work with a positive result, etc.

Why chrome anyway?

Familiar things that will become unusual and eye-catching. There is no need to try to replace other technologies with decorative coating by spraying. There is no need to invent anything. Here are simple instructions:

- How to chrome an entire car? Use self-adhesive film of the desired color. It's cheaper, faster and can be removed at any time.

- How to chrome car wheels? It’s better to buy new, factory-made ones, made by vacuum deposition of aluminum, titanium or galvanic method.

- How to restore chrome parts of equipment? If spare parts are available for sale, it is cheaper and easier to buy a new one. If the part is from old equipment, use the spraying method. The chrome plating of a metal part can be restored by electroplating if conditions exist in your area. Restoring old parts using the galvanic method is also a labor-intensive and painstaking process, more expensive than the spraying method. Once we carried out an order to restore parts of a retro car (bumpers, handles, moldings) on a subcontract basis. The client sent the parts to galvanic production. From there the parts were transferred to us, we applied a silver layer using our installation and returned them to the galvanists. They handed over the finished parts to the customer, he was satisfied with the work, although he is still sure that the coating was applied using an electrochemical method.

- How to chrome interior items? Use the spray method. Products that will be located indoors are cheaper and faster to cover with a mirror layer using a spray gun. In this case, the product can be made of any material, including one that is unstable to high temperatures.

- How to chrome advertising structures? For products that are used outdoors, under constant temperature changes, under the influence of ultraviolet radiation, dust, wind, birds, insects, there are other solutions offered by outdoor advertising manufacturers. Advertising structures, volumetric signs, are made of mirrored plastic for engraving, for example Rowmark and, of course, stainless steel.