Bronze is an alloy of copper and special additives that are necessary to give the metal certain technological properties. Bronze may contain the following components: Sn (tin), Mn (manganese), Be (beryllium), Pb (lead), Si (silicon), Cr (chromium), P (phosphorus), Fe (iron) and other elements.

Bronze alloy is resistant to abrasion, corrosion, and aggressive environments such as sea water. These properties are achieved by adding alloying components in certain proportions. The ratio of components is regulated by regulatory documents: GOST, industry standards, methods, enterprise standards.

What is bronze?

Bronze is an alloy based on copper and other metals. The composition may vary depending on which the parameters of the finished material change. Manganese, iron, chromium, and phosphorus can be used as additional components. The optimal content of alloying impurities in a bronze alloy is 2.5%.

The color of the material depends on the amount of copper in the material. For example, bright flame bronze pieces contain more than 35% copper. A mixture of zinc and copper cannot be classified as a variety of bronze. This is a separate mixture called brass.

History of discovery

The first finds of bronze alloys were discovered in the third millennium BC. Back then, people mixed copper with tin to create a material with special characteristics and appearance. At that time, dishes, figurines, jewelry, and tools were made from bronze. The bronze alloy gained great popularity during the Middle Ages. Weapons and shells were made from them.

Structure and composition

The composition of a bronze alloy consists of certain components. Not every mixture can be called a bronze material. For example, brass and cupronickel contain a large amount of copper, but are not considered bronze. Thus, the additional components are various metals with the exception of zinc and nickel. The characteristics of the mixture depend on the amount of alloying metals. Copper-based mixtures can be divided into two groups:

- Tin - the percentage of tin in such bronze alloys is greater than other alloying impurities. The finished material has high elasticity and hardness. It melts easily, making it easy to process. To improve the corrosion resistance and castability of the mixture, other alloying impurities are added to its composition.

- Special - these mixtures do not contain tin. Additional components include iron, silicon, and aluminum. The characteristics of the material depend on the alloying impurities used.

Special bronze mixtures are considered more universal than tin mixtures.

Bronze alloy

Properties and characteristics

To understand where this material can be used, you need to take into account the properties and characteristics of bronze. Mixture properties:

- good weldability;

- resistance to acids and salt water;

- high corrosion resistance;

- melting point - up to 1140 degrees Celsius;

- density - up to 8700 kg/m3.

Properties may vary depending on the percentage of alloying components.

Production of material

The quality of bronze depends on the process of its production. For this purpose, induction furnaces and additional melting substances are used. Production process:

- The oven is heating up and coal is poured into it. If wood material is not available, flux is used.

- The furnace is filled with copper. It should melt.

- Molten metal must be deoxidized with copper phosphorous

- The melt is saturated with alloying impurities. The annealing temperature increases uniformly.

- The molten components are mixed and continue to heat.

- The last step before casting into molds is re-deoxidation of the mixture.

The molten metal is poured into molds that go through a press treatment. After the castings have cooled, they are used in further production.

Pouring into forms

How to distinguish at home?

In practice, there are several simple and proven methods to help identify metals.

How to distinguish bronze from brass using a magnet?

- When it comes to a variety of alloys, it can be quite difficult to distinguish bronze from brass, because they can be almost identical. Many experts believe that bronze is heavier than brass. This is indeed due to the content of tin and lead, which are quite heavy.

- Brass is much lighter due to the presence of zinc. You can conduct a few simple experiments to find out which metal is in front of you. Bronze is almost always magnetic due to the presence of tin.

- That is, if you apply a strong enough magnet, you will see significant magnetization. The higher the tin content in the metal, the stronger the magnetization. Brass, in turn, does not exhibit magnetic properties, that is, when a magnet is placed, it does not stick at all.

Material processing

Determination by weight

This is another method of distinguishing metals. To identify the difference, it is enough to simply weigh bars of the same volume from different alloys in your hands. A bronze specimen will weigh much heavier than a brass blank.

However, the mass of the product is also affected by the density of the connections. Therefore, it is not always recommended to use weight as a clear criterion for distinguishing metals. For example, bronze with a low tin content (2-8%) is distinguished by the fact that it will weigh lighter than its brass counterpart.

How to test bronze by heating and filing at home

We provide you with two more verification options:

- Use a gas burner as it produces the highest temperatures (up to 600 degrees). A home stove will not be enough for this operation. In addition, the experiment will have to be carried out in a separate room (workshop or garage). Take the workpiece and hold it over the fire for a long time. Bronze will not change the appearance. And dark spots will appear on the surface of the brass product.

- If you have the possibility of completely melting the original sample, then conduct such an experiment. When overheated, a white flame and scattering flakes of the same color appeared. This means that Zn burns out and you have brass. It has good ductility. During deformation, it will not lose its physical properties, but bronze will certainly crumble and break if overheated.

- Sawing is the most affordable method that you can do at home without financial costs. Take a hacksaw and try to saw off samples. The brass product can be sawed well and easily, thereby forming layers. The shavings will have a twisted appearance. Metal containing tin when exposed to a sharp object will break into small pieces, producing fine dust. If you try to bend or flatten the sample, you will not achieve a positive result; you will only ruin the workpiece.

This is interesting: Copper resistivity. Formula for calculation

Drill Usage and Marking

Using a drill you can easily identify brass. But it is important to remember that the tool will damage the metal object. The fact is that during operation of the drill, chips come out from under the drill, which for copper are quite long and ornate, while for brass they are, on the contrary, short and needle-shaped. After all, the metal is much softer than its alloy.

Sometimes on a piece of the material being examined you can see markings that can easily tell you what is in front of a person. So, the mark on copper begins with the letter “M”, and on brass - with “L”. But in other countries, product labeling is somewhat different from Russian:

- In the USA you can see C2, C3, C4 badges on brass alloy.

- In the European Union, the letter C is placed on copper and brass, but after it on the metal you can see A, B, C, D, and on the alloy - L, M, N, P, R.

This method makes it quite easy to distinguish pure copper from brass. If markings are present, then you should not resort to other recognition methods.

Varieties

Experts distinguish the following types of bronze:

- Lead - a composition in which the main alloying additive is lead. The finished material is resistant to high pressure. Used in the manufacture of moving elements in industrial equipment.

- Silica-zinc - in addition to the main component, this composition contains tin and silicon. The mixture has good plasticity and fluidity. It is easy to work with the material and make products of complex shapes from it. It welds well and is resistant to low temperatures.

- Beryllium bronze is a hard material. Resistant to high temperatures and corrosion. The composition includes cobalt, nickel and iron.

- Aluminum - the mixture contains 95% copper and 5% aluminum. The material has a golden hue and shines in the light. Resistant to alkalis and acids. Does not change characteristics when exposed to low temperatures, has high strength.

If it is necessary to strengthen the structure of the material, nickel is added to it. Electrical conductivity is reduced with chromium.

Receiving technology

Bronze is a product of alloying copper with alloying additives.

The process takes place in electric induction furnaces or crucible furnaces:

- Metals from ore or recyclable materials (household, industrial waste) are used as a source charge in the production of the material.

- The furnace is heated, coal or flux is loaded, then copper.

- The copper melt is degassed (deoxidized).

- Heated refractory components-ligatures are added.

- The mass is stirred and heated until all the contents are melted.

- A deoxidizing agent (copper phosphorous) is added again to remove copper oxides.

- The final stage of bronze production is casting into molds.

The output is flat or three-dimensional ingots. They are sent to a rolling or forging shop.

Rolled metal products: pipe, strip, circle, bushings, rod, wire.

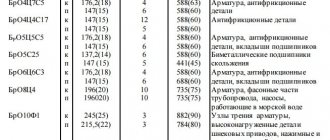

Marking

To help buyers and manufacturers understand bronze alloys, special markings for bronze were created. It is a set of numbers and letters that indicate the name of the components and their percentage in the composition:

- At the beginning of the marking the letters “Br” are indicated, which indicate the name of the material.

- After the main designation there is a letter indicating alloying additives.

- The marking closes with a number indicating the percentage of the alloying component.

An example of a bronze grade is BrO5. The alloy contains 5% tin. The markings of all compounds with a copper base are indicated in tables that can be found on the Internet.

Women's jewelry in the SeViMi store catalog

New

Women's Dragon bracelet

39.00 rub.

New

Silver earrings Style

33.00 rub.

Earrings in the style of minimalism Grace

35.00 rub.

New

Earrings with black enamel Rich

43.00 rub.

NewMother of Pearl

Earrings Tenderness with mother of pearl

37.00 rub.

Advantages and disadvantages

To evaluate a bronze alloy, you need to talk about its strengths and weaknesses.

Pros:

- The presence of mixtures with different types of metals and additional components allows their use in various areas of industry.

- Creation of alloys with different characteristics. You can vary the ratio and percentage of alloying components.

- The material can be recycled again.

- High elasticity.

- Resistant to corrosion, acids and alkalis.

The disadvantage is the high cost of bronze alloys. Because of this, buyers often prefer other materials.

Why was zinc added to copper and why are zinc statues not cast?

Copper is alloyed with zinc to create alloys with properties that copper and zinc do not have individually. Copper is a good conductor of heat and electricity. Copper is ductile, stretches, and can be stamped. Copper wires, copper tubes for refrigerators, heaters or air conditioners, copper utensils fully realize the properties of copper, such as heat and electrical conductivity, and high ductility. Corrosion resistance and chemical inertness to household solutions make it possible to produce copper cookware, frying pans, and pots. But the downside of the properties of copper is that it has insufficient strength, hardness, corrosion resistance and high cost for widespread use in technology as a structural material. For five thousand years, people have been modifying copper by adding other metals to the melt to measure its properties.

Application area

Bronze alloys are used in various industries. High resistance to friction and corrosion allows the use of bronze products in aggressive conditions, as moving parts for industrial equipment.

Bronze is used in modern industry, the manufacture of sculptures, household utensils, and parts for pipelines.

Bronze products

From strings to bearings

The formula for success of bronze is a combination of rare qualities of the “union of metals”.

Therefore, its use has only increased since the end of the Bronze Age.

The trumpeter plays the anthem...

The music would not be so beautiful and expressive if it were not for the amazing melodious fusion. At first, the properties of bronze were appreciated by priests. In the Middle Ages, the church demanded more and more “bell bronze”. Asian clergymen made full use of the sonorous voice of bronze: they made bells, “singing bowls”, gamelans, and gongs from it.

Nowadays bronze sings with the strings of pianos, double basses, harpsichords, banjos, and guitars.

Phosphor bronze saxophones have a unique voice.

For industry

It is clear that the industry did not fail to snatch its piece of the bronze pie.

- Mechanical engineering (bearings, shut-off valves, bushings, friction units of fittings); rolled metal (sheets, pipes, rods).

- Bronze wire - for wires, cables, welding electrodes.

- Aviation and shipbuilding, rocketry and the simplest bearing shells - our alloys are in demand everywhere.

- In the jewelry industry, aluminum bronze with its golden color is used to make cheap costume jewelry. Bronze alloys were often used for coinage, especially in ancient times.

Bronze products

Bronze alloy price

The cost of bronze alloys depends on several factors:

- What alloying additives are included in the alloy and in what percentage.

- In what form is the product sold? The more complex the design, the more expensive it will cost.

- Appearance and condition. If the surface of a bronze item has cracks, scratches, scale or dents, its value will decrease.

For wholesale buyers, purchases are made at reduced prices. The cost of a bronze rod is 500 rubles.

Bronze is considered the oldest alloy. It is used in different areas of industry due to the variety of materials based on it. The characteristics of this metal make it possible to use it under the influence of acids and alkalis, as well as install bronze parts in industrial equipment.

Conformity of tin bronze grades according to GOST 613-79 and the replaced GOST 613-65

| Bronze grades according to GOST 613-79 | Bronze grades according to GOST 613-65 | Bronze grades according to GOST 613-79 | Bronze grades according to GOST 613-65 |

| Brozts12S5 | BrOTsSZ-12-5 | BrO6TS6SZ | — |

| BroZTS7S5N1 | BrOTsSNZ-7-5-1 | BrO8TS4 | — |

| BrO4TS7S5 | BrOTsSZ,5-7-5 | BrO10F1 | — |

| BrO4Ts4S17 | BrOTsS4-4-17 | BrO10TS2 | — |

| BrO5TS5S5 | BrOTs5-5-6 | BrO10S10 | — |

| BrO5S25 |