Blackening of steel with ferric chloride

It depends on what is considered ordinary steel

and what they said in chemistry lessons. poison in an acidic environment - get salt

Nothing precipitates if the ferric chloride solution is fresh and no printed circuit boards have been etched in it before. However, if the boards were etched, the steel will be copper-plated. The copper plating will be loose and easy to wear off.

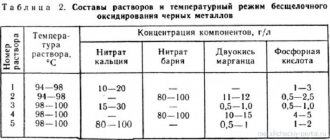

To precipitate, as it always seemed to me, comes from the word sediment. So, an oxide film forms on the surface of the steel, and its composition (chemical formula), I personally like, the main thing is that the resistance to corrosion increases.

You know better

, he didn’t tell me that. And I didn’t know him.

I’ll try to say like a Sergeant: “You have been banned from Google. ?"(WITH)

, as well as correctly painted, glued, oiled. , you can continue for a long time, as long as your imagination is enough.

and by morning only phosphoric acid salts will remain on the hemp.

It is useless to argue with Vilenych (Udod) on this topic; he has a Nobel Prize in forging blades from shkh and rusting metals.

Sheb - if you don’t want to etch your blades, don’t etch, carbon and alloyed ones will give stains after the first use, nothing will suffer except aesthetics, just as etching will not add anything to the knife except aesthetics. and everything else is just lyrics on the topic. Sorry, but I’m tired of big names and “terms”

Well, how is it? Ferrous oxide is deposited, in theory. Among other things - but everything else must be periodically cleaned with a brush when etching.

50% at best, from experience with X12MF (and not CH, but orthophosphoric acid), with 65G and SH - much less. They recommend high-quality polishing of the entire surface of the blade - as a factor for minimizing corrosion.

Welcome to our weapons shop. There is no obvious heavy rusting, but... slowly, little by little, the blued trunks rust like nails

What will happen when etching aluminum in cold liquid? Is it collapsing? We need to remove the copper plating.

Source

Metal Blackening Technology

Blackening of metal is carried out in a certain sequence of actions:

How not to blue metal (and how to do it)

- First, chemical degreasing is carried out, which is necessary to remove residual grease and other contaminants from the surface of the product.

- Then washing is carried out, as a result of which the remaining alkaline solution is removed.

- Next, the part is etched by immersing it in an HCl solution. And again the washing is done.

- The next stage is activation, when the product is immersed in a solution with special additives for several minutes.

- Afterwards the part is washed again.

- Then a black mixture is applied to the engraved metal surface and fired. This composition, in molten form, evenly fills the design, giving a subtle contrast with the rest of the surface of the product.

- Next, the part is immersed in a bath of cold water for half an hour or an hour.

- At the very end, the product is sealed with a special inhibited water-repellent compound to protect the metal from rust.

V. BLUE BLUEING

On iron metal it is possible to reproduce a wide variety of tones, shades and nuances of blue - from blue to blue-black inclusive.

The simplest way to chemically color iron and its alloys is direct heating in air, surface oxidation with atmospheric oxygen. This is how bluing is done in faded colors, which we talked about in the previous chapter. Among the range of tarnish colors, blue-colored colors appear. Only through long-term experience can one achieve in each given case (for a certain size and shape of products and a certain material) the establishment of conditions under which the same color tone is always obtained. When constantly working on the same products, you should definitely stick to the once-tested heating recipe, almost certainly achieving the desired result every time.

It should always be borne in mind that smaller things heat up to a certain temperature faster than larger ones, and therefore both of them should never be heated at the same time in a common bath or at all together; There is always a risk of “over-burning” (that is, going beyond the blue color) of small products and under-exposing (not reaching the required blue tone) larger ones.

In practice, the easiest way to achieve uniform heating of small objects blackened in large quantities is to enclose them in an iron drum (equipped with holes), which is rotated on a spit over a hot coal forge. The holding time of things in the drum is learned from experience. During operation, you can monitor the end of heating by minutely removing the sample for inspection. Heat bluing is a “dry” processing method. For wet bluing of iron and steel to a uniform blue color, the following tested bath (1) is used:

Bath composition 1

To prepare it, dissolve red blood salt and iron sesquichloride separately in 500 g. water and both solutions are poured into one bottle.

The products to be settled are immersed in this bath for the time necessary for the required color tone to appear.

Dark blue color on iron and steel is applied to the bathroom (2):

Bath composition 2

Both salts are dissolved in water separately, and both solutions are mixed. When used, carefully heat the bath, slowly bringing it to a boil. In this case, iron and steel objects are covered with a dark blue coating (lead sulphide). Once the correct tone is achieved, the products are removed, rinsed with water, dried and placed in a warm place for a few more hours.

Hot baths of molten (rather than dissolved in water) reagents are also recommended. One of them (3), especially suitable for small products made of malleable iron and cast iron, is composed of molten (cut) sulfur, into which a little soot is mixed after melting. When processed in such a bath, the products are covered with a film of iron sulfide, which acquires a beautiful dark blue polish from brushing (brushing).

Another bath (4) is molten saltpeter (temperature about 315°). Its action is obviously based on the oxidation of iron with oxygen released during melting by saltpeter.

Popular bluing methods

Blueing technology includes several methods, the main ones being the following:

- Alkaline method. In this case, you will have to work with oxidizing agents at a temperature of 130-150 degrees. Thanks to alkaline oxidation, iron is oxidized. But you should not work with this method in a house or apartment, as an unpleasant odor is released during the work.

- Acid method. In this case, the work is performed in acidic solutions using a chemical or electrochemical method. It is important to place the item in the solution for the specified time and act in accordance with the instructions.

- Thermal method. This type of bluing is considered the oldest and simplest in existence. This technology involves heating steel in the open air. The procedure continues until the top layer of metal reacts chemically with oxygen. The higher the heat, the darker the part will become.

VI. BROWN BLUEING

A good brown color on iron and steel is achieved by bluing using a paste (5) from a mixture of equal parts of olive and antimony oils:

Recipe 5

This paste is applied to the object to be harrowed (usually gun barrels are blued with it) and left for 24 hours, after which it is washed with a woolen rag and a fresh portion is applied, which is also left for 24 hours. As a result of the chemical action of the paste on the iron of the object, a bronze-brown film of iron oxide (containing metallic antimony) is formed, firmly fused with the bulk of the metal. Thus, polished products are given a gloss by wiping with a waxed brush.

For small items, you can reduce the two-day processing time with this paste to just a few minutes by heating the items coated with the paste to 200-220°. Olive oil can be replaced with flaxseed oil. Usually, coating twice is sufficient. For large products, this method is practically inapplicable due to the difficulty of uniform heating; The coloring on them is usually spotty.

Some practitioners impart a brown bluing to iron and steel by heating objects coated with animal (usually ox) fat for 1/2-1 hour to a temperature of 200-100° (6). Fats are often replaced with vegetable oils, such as flaxseed (7). For darker tones, add sulfur color to the fat (8).

Instead of antimony trichloride in recipe (6), you can take iron sesquichloride, for example in the ratio (9):

Recipe 9

Having coated an object with this ointment, let it act for several hours, after which its surface is brushed with a steel brush, coated with ointment again, brushed again, and so on. Kratsovka must be carried out especially thoroughly.

The shades have a greenish or reddish tint, depending on the predominance of olive oil or chemicals in the composition.

Dipping baths (for turning steel and iron brown by dipping) can be prepared from iron sesquichloride, dissolving it in water or alcohol.

Water bath (10)

alcohol bath (11)

Recommendations

Are you wondering how to bury metal objects yourself? To do this, you can use one of the methods that suits you. Using professional advice, you will get the perfect color of the metal, and the process itself will be carried out in a way that is safe for you.

Cold bluing involves the use of a bath or special container. But it cannot be made of any material. A wooden bath or galvanized container is optimal.

It would be good if the container was additionally equipped with hangers-hooks for placing parts in the solution. These elements can be made in the form of curved racks or mounted on a wall. Everything is determined by the height of the sides of the container and the dimensions of the workpiece.

To blue the steel, the container must be properly degreased. The best solution for this is an organic-based solvent. This can be acetone, perchlorethylene or B-70 gasoline. The base remains inert towards these compounds. But for each type of metal it is necessary to select the optimal solution. Only with its help can you obtain the optimal color and maximize the characteristics of the product.

Even if you are doing cold bluing, the work should be done outdoors or in a room with good ventilation. This is due to harmful fumes and a strong chemical odor.

If you cannot clean the surface well with a brush or abrasive, use etching. Each type of metal has its own remedy. If you have a ferrous metal product, the bluing liquid includes 100 grams of nitric, 50 grams of sulfuric and 150 grams of hydrochloric acids per 1 liter of distilled water. The surface is treated for at least 2.5 hours. Chemical polishing is used to give a smooth surface.

Thus, you can do the bluing of a steel object yourself. To do this, it is important to choose the most suitable processing method and adhere to a clear sequence of actions. As a result, you will get a corrosion-resistant surface in a suitable shade.

VII. BLUE GRAY COLOR

For bluing in a gray color, you can use a bath of a relatively complex composition, but which allows, depending on the duration of treatment of iron and steel products with it, to obtain various variations of gray color with a transition to black.

Bath composition (12)

| bismuth chloride | 20g |

| sublimate | 40g |

| copper chloride | 20g |

| hydrochloric acid 24°C | 120g |

| alcohol 90° | 100g |

| water | 1000g |

First, mix the acid with water, pour in alcohol and dissolve all three named salts separately in three separate portions of liquid, after which the individual resulting solutions are poured together.

Objects brought into this bath must be absolutely clean and free of grease. The products pickled in it are then transferred to boiling water for half an hour. If the shade is not dark enough, repeat the bath treatment. After drying, the products are wiped with a waxed brush. A beautiful, firmly adhering gray layer (consisting of copper oxide) on small iron objects can be caused by heating them on a sheet of tin after coating with the composition (13).

Recipe 13

The dissolution of copper nitrate in alcohol in the cold takes a very long time. It is more expedient to carefully melt the salt over low heat (in a porcelain crucible), add to it (putting out the fire) the required amount of alcohol and quickly cool while stirring.

Application of rust varnish

This bluing agent is often used to obtain a smooth and even surface. It contains steel shavings, but they can be replaced with cast iron shavings. In this case, financial investments will be minimal. In this case, the workpiece must be placed in a chemical agent. The result is red or black iron oxide. This instruction, as a means for cold bluing, gives a long-lasting and effective result.

To get rid of red deposits, use a brush with fairly stiff metal bristles. As a result, only black oxide remains.

First, the metal is machined and degreased. Then the product is placed in a special composition. The bluing agent is prepared in a porcelain container. It is important to wear gloves to protect your skin. The composition is made using hydrochloric acid. It is poured in a small amount into a container. It is mixed with metal filings, nitric acid and iron rust.

VIII. BLUE BLUE

In factory practice, iron and cast iron objects are blued, forming a relatively thick layer of black scale (iron oxide) on them. For this purpose, they are heated to a cherry-red heat in regenerative furnaces, and alternately (6-10 times) either flue gases or flue gases diluted with air are introduced (for heating).

Another factory method is a long (5-10 hour) treatment of products with highly superheated water steam.

In amateur and artisanal practice, these methods are unlikely to be applicable. In an amateur workshop setting, you can achieve a great richness of black shades using another method of hot bluing, which involves burning fatty substances such as lard, vegetable oils, waxes and the like on the surface of the product. So, if you burn a well-prepared (cleaned, degreased, pickled and washed) iron product, greased with linseed oil at a dark red heat temperature, it will turn shiny black (14).

This method of bluing is very widely used in practice. In order for fats, oils or waxes applied to products to adhere well to their surface, it is recommended to heat the product so much before coating it that a pale yellow discoloration appears. Lubricated objects should be held over the heat of a coal forge or in a suitably hot oven (“air bath”) for so long until all the oil evaporates or burns out and the smell disappears from it, and the surface of the object seems completely dry.

Some features

Blueing steel at home is not difficult. Oxidizing agents are used for processing other metal products:

- cast iron;

- copper, which acquire an intense red color.

There are a number of features that it is advisable to remember:

- If the products are heat-sensitive or hardened, then it is better not to touch them. Blueing will degrade performance.

- To complete the process, you must remember to wash the product with a special product. After drying, oil lubrication is sometimes required.

- It is not difficult to find the necessary substances in stores, for example, saltpeter, citric acid.

- It is also possible to remove blackening. For this you will need a special pencil.

Preparation is important:

- Before starting, you need to clean the surface and sand it.

- Degrease with a special solution.

- Don't forget about rubber gloves to protect your hands. The processed product must not be touched.

- Create ventilation, exhaust.

- Select a vessel with suitable properties. The volume should allow the product to be processed to be completely drowned. A material that is not afraid of the substances used is suitable: glass, porcelain, stainless steel, earthenware.

As for color, it can also be important for some products. You can get different colors: from yellow to black, its shades. Therefore, strictly speaking, blackening and bluing are not the same thing.

To achieve the desired color, you will have to further clarify the components of the solutions or pay attention to the heat treatment mode. For example, one way is as follows:

- Take copper nitrate (70 g) and alcohol denatured alcohol (30 g).

- The salt is heated until it melts.

- Add denatured alcohol.

- The product is coated with this mixture.

- Heat until the desired shade is obtained. The color will change.

IX. BLUING WITH BRONZE SHOW

Iron and steel can be burnished in a variety of colors (blue, crimson, brown, black) with a more or less clearly defined bronze tint. The methods related here are combined under the name “chemical bronzing”.

Bronzing blue (35). A well-prepared blackened object is placed in vinegar (diluted acetic acid). After removing it from the vinegar and wiping it dry, lubricate it with hydrochloric acid using a linen cloth. After 15 minutes, they are buried in the sand of a heated sand bath, from time to time, exposing part of the surface of the object to observe its condition. As soon as the moment has arrived when the surface has taken on a beautiful, uniform, deep blue color, the object is removed from the sand.

Bronzing in brown color. By rubbing objects treated as above (bronzed blue) with “wooden” oil (on a cloth), you can transform the blue “bronze” into brown (36).

Another way is this. The objects to be bronzed are exposed to vapors of a heated mixture of conc. for 3-5 minutes. hydrochloric and nitric acids (the so-called “regia vodka”; extreme caution is required when working with it, because this mixture of acids when heated is extremely dangerous and its vapors are especially harmful!), after which it is heated to a temperature of 300-500 ° for so long until a bronze tint will not appear on the surface of the products. After cooling, the product is rubbed well with Vaseline and heated again, increasing it until the Vaseline evaporates. After allowing it to cool, rub it with Vaseline again, this is how light brown tones are obtained (37).

By adding acetic acid to aqua regia, you can obtain bronze colors of yellow-chocolate tones using the described method (38).

Methods and technology for bluing (oxidizing) metal at home

This metal processing can solve two problems. Firstly, this material is given an attractive appearance, as if it is “rejuvenated”. This is the most common understanding of the essence of the process, but rather narrow. Secondly, and this is most important, the level of its protection against corrosion increases. It is believed that bluing is possible only under production conditions. However, this is not entirely true.

What is the difference

The result of industrial processing is a change in the chemical and structural composition of the “upper” layer of metal. The resulting iron oxide plays the role of a protective coating for the entire workpiece. Even if this method is feasible at home, it is extremely unprofitable, since it will require not only special knowledge, but also significant material investments.

All substances listed below are just an example. They have many analogues of both Russian and foreign production. Not every seller understands bluing technology. But if you name something specific, then even if such a product is not on sale, the manager will easily find a replacement for it.

Regardless of the chosen bluing method, the entire process is divided into several stages, which can be briefly described as follows:

- cleaning (+ grinding);

- degreasing;

- applying a bluing agent;

- finishing treatment.

There may be different nuances and details for different methods, but the general algorithm of actions remains unchanged.

Please note that after degreasing, you cannot touch the workpiece with your fingers. Therefore, it is necessary to work in clean rubberized gloves.

Cold bluing

From the name it is clear that the metal is not exposed to thermal effects during operation. Special solutions are used for processing. The only difference is in the way they cover the part.

Brush

Products applied to the surface form a dense film. This method is also called “blackening”. You can use the domestic composition "Raven 3". Among the imported ones - the so-called “Parisian oxide”.

Advantages

- Simplicity of technology.

- Burnishing can be done in any conditions, without any preparation of the workplace.

Flaws

- Difficulty in bluing parts with a complex configuration or relief.

- Mechanical stress damages the coating layer.

- Additional polishing will be required to achieve a “smooth” base.

Immersion in container

The benefits are obvious. Firstly, the liquid will penetrate into all the nooks and crannies. Secondly, such processing will require significantly less time. Thirdly, the consumption of the substance will be reduced, which will inevitably occur, since during coating, part of the composition will be splashed.

Regardless of the method chosen, after the procedure is completed, the substance is washed off with water and detergent.

Several solution recipes

The proportions of all components are indicated in grams per 1 liter of distilled water.

- Ferric chloride – 75; ethanol – 30; copper sulfate and nitric acid - 20 each.

- Ferric chloride – 170; nitric acid – 13.5; hydrochloric acid and copper sulfate - 4 each.

Technology

The workpiece to be processed is first slightly warmed up so that the substance “fits” better onto the base. You can use gun oil, linseed oil, lignite oil, olive oil, or something similar. The choice of a specific product depends on the type of metal.

How to apply oil is up to everyone to decide for themselves. It would probably be more advisable to dip the part into it. After this, it is subjected to heat treatment. The most common method is firing with a blowtorch.

Feature of the technique

- After immersion in the bath, you need to let the oil drain. Excess of it will lead to stains on the surface of the part.

- During the firing process, it is necessary to control the color change of the workpiece. Once it changes from brown to black, treatment should be stopped.

Burnishing with oxidizer

Various chemical compounds such as nitrites or nitrates are used.

All of them are characterized by their melting point, so you need to focus primarily on your own capabilities, since not every owner has, for example, a muffle furnace.

Temperature sources can be different, so there is no need to complicate your life and be guided by the first recipe you come across - the choice of oxidizing agents is quite large.

Several recipes

- For 1 liter of water: caustic soda – 2.8; disodium hydrogen phosphate – 100; sodium nitrate – 50.

- For 0.6 l: caustic soda – 400; Potassium nitrate and sodium nitrate – 10 each.

All ingredients are in “g”.

The minimum time for immersing the part in the solution is half an hour. After this, it is necessary to rinse with running water, dry and cover with a thin layer of lubricant.

Useful tips

- The bath for “cold” bluing is not made from any material. As a rule, this is “galvanized” or wood. It is necessary to provide hooks in its design for placing parts in the solution. They can be either wall-mounted or made in the form of curved racks. It all depends on the dimensions of the workpiece and the height of the sides of the container.

- For degreasing, it is better to use organic-based solvents (acetone, B-70 gasoline, perchlorethylene and others). The base is inert towards them. If you want to make the product yourself, according to recipes available on the Internet, then you need to take into account that each metal has its own composition.

- Regardless of the method of bluing and the chemicals used, all work must be carried out either in the open air or in a room with good ventilation, since the process is accompanied by harmful fumes.

If proper cleaning cannot be achieved mechanically (with a brush, abrasive), then the etching technique is used.

Each metal or alloy has its own composition. There are also plenty of recipes.

For example, for “ferrous” metals there is this (one of many): nitric, sulfuric and hydrochloric acids (100 + 50 + 150) in “g” per 1 liter of distilled water. The treatment is carried out for about 2.5 hours at a mixture temperature of about 80 °C.

For parts that need to be given an ideal “smooth” surface, chemical polishing is used. It is very effective in cases where the mechanical method does not produce results due to the relief of the base or its complex configuration.

X. BLUEING OF RIFLE BARRELS

A particularly common case of chemical coloring of steel is the bluing of gun barrels. The purpose of such bluing is the usual - to give the barrel a beautiful appearance, protect it from rust (especially if the gun is rarely used) and eliminate the need for frequent cleaning.

There are a fair number of recipes for bluing gun barrels, partly repeating the methods described above, partly specially adapted to the special shape and special service conditions of the product. The choice of one or another of these recipes depends primarily on the color nuance that is desired to be obtained, on the ability to obtain the necessary chemicals, on the strength of the color, and the like. Complete mastery of a particular recipe is a matter of long, persistent experience. One cannot reject a particular recipe if at first it does not produce favorable results; You should always check the entire progress of its execution in order to detect and correct very possible errors. With due diligence, you can not only extract from the recipe all that it can give, but also improve it yourself, achieving more and more excellent results.

A mandatory, strict condition for successful work here, as in all cases of chemical coloring of metal, is exhaustively complete, ideal preliminary preparation, as well as subsequent processing. Due to the significant size of the trunks, all techniques suitable for processing smaller and more compact objects cannot be used to work with them. A tarred trough of appropriate size and shape can serve as a vessel for treating trunks with certain liquids. Only the outer surface of the trunk is blued, the inner surface is not treated, and the inside of the trunk is protected from the action of the compounds by plugging both end holes with tightly driven wooden plugs. The protruding ends of these plugs serve as gripping points for clamps or vices when strengthening the barrel to perform various operations related to chemical painting (scraping, grinding, polishing, coating, washing, brushing, and so on).

Here are several more or less commonly used recipes for bluing barrels.

(39). The barrel is heated to intense heat and rubbed with bloodstone for a long time, renewing the heating when it cools. The result is a bluish coloration.

(40), A well-polished trunk is rubbed with olive oil using a cloth, after which it is sprinkled with sifted ash from hardwood and introduced into the charcoal mine. When the trunk noticeably turns white, it is removed and allowed to cool, after which it is first wiped dry, then with olive oil. The barrel gets a gray bluing finish.

(41). 4 parts by weight of antimony oil (antimony trichloride) are heated with 12 parts by weight of olive oil until both substances are completely dissolved and the resulting mixture (on a cloth) is rubbed on the blackened barrel. A day later, the resulting deposit is wiped off by rubbing with oil and the lubrication with the composition and rubbing are repeated again. After another day, the described operation is repeated again, and so on. After 10-12 days, a uniform, firmly adhered color of chocolate, brownish red, or even brown is achieved. Operation goes faster in warmth.

Once the desired tone is achieved, the barrel is wiped down, thoroughly washed with water and either polished with a steel polishing pad or waxed with suede. You can also coat it with shellac varnish (42). Prepare the following composition:

Recipe 42

| nitric acid 45% | 70g |

| alcohol 90° | 140 g |

| copper sulfate | 280g |

| iron filings | 10g |

| water | 1 000g |

All this is mixed (pouring the acid into water, and not vice versa!) and allowed to stand after dissolving the copper sulfate for 2-3 days. Having tightly plugged both holes of the barrel with wooden plugs, coat it (using a sponge) over the entire surface with the prepared composition, trying to ensure that it lies evenly everywhere. A day later, use a brush to scrape off all the loosely adhered part of the film (oxide) formed during this time and repeat the described operation once or twice until a thick brown color is obtained. Then the barrel is wiped and dipped in boiling water containing a little soda (to neutralize traces of acid). After being removed from the water and dried, it is gently rubbed with a wooden polishing pad (made of hard wood), heated to 100° and doused with alcohol shellac varnish, painted with dragon’s blood (see “Varnishes and varnish paints”). After the varnish has completely dried, polish it with a steel polishing pad to give the barrel a pleasant shine.

(43). For bluing iron trunks brown, a solution is prepared.

adding acid and alcohol after dissolving the vitriol. Using a sponge or the like, lightly apply this solution to the prepared barrel and, after complete drying (after several hours), wipe it with a brush made of the thinnest wire and then with a stiff bristle brush. All this is repeated 2-3 times every day and after 3 days a beautiful shiny brown bluing is achieved. For final finishing, the barrel is washed in boiling water, wiped with cloth and lightly greased with olive oil.

(44). Prepare the ointment by rubbing both components:

stored in closed jars.

The prepared trunk is heated and, when heated, is coated with this ointment (using a linen cloth). After 24 hours, wipe with a soft brush and coat again with the same ointment. This is repeated until the color of the trunk, which first became greenish and then reddish, becomes clearly brown. This happens after 4 - 6 days (the warmer, the sooner). Next, the barrel is thoroughly washed with lye until the latter evenly wets the entire surface. After rinsing several more times with clean water, dry, polish with a wooden polishing pad or rub with a soft brush, heat to 100° and pour over the above varnish.

(45). A very beautiful bluing is obtained when using the composition:

If the solution turns out to be opaque, add hydrochloric acid drop by drop until clear. Lubricate the barrel with this solution, repeatedly applying it 3 to 4 times each time. Finally, after each lubrication, wipe with a soft brush. In total, lubricate 12-14 times, using it for 3-4 days. The process is accelerated by weakly heating the barrel.