Chemical composition of steel

U10 steel is used for the production of cutting tools. It refers to alloys with low hardenability and not characterized by high heat resistance. Cutting tools made from this alloy are small in size. Let's look at the chemical composition of steels in the tables:

Steel U10

| C,% | Si,% | Mn,% | Ni,% | S,% | P,% | Cr,% | Cu,% |

| 0,96 — 1,03 | 0,17 — 0,33 | 0,17 — 0,33 | up to 0.25 | up to 0.028 | up to 0.03 | up to 0.2 | up to 0.25 |

Steel U10A

| C,% | Si,% | Mn,% | Ni,% | S,% | P,% | Cr,% | Cu,% |

| 0,96 — 1,03 | 0,17 — 0,33 | 0,17 — 0,28 | up to 0.2 | up to 0.018 | up to 0.025 | up to 0.2 | up to 0.2 |

U10 steel occupies an average value in the group of carbon steels. They have value as a structural and instrumental material. In accordance with the customer's specifications, the content of some alloying elements may vary in hundredths of the total volume of metal.

| Chemical elements and their significance in the composition of knife steel: | |

| Carbon (C) | Without enough carbon it is very difficult to obtain a suitable hardness. This is the most important element in steel, it increases its strength. |

| Chromium (Cr) | gives the alloy increased anti-corrosion properties, chromium carbides increase wear resistance and hardenability. The high chromium content in the alloy affects its brittleness. |

| Manganese (Mn) | increases wear resistance and strength. Its content has a positive effect on the grain structure of the alloy and also contributes to excellent hardenability. |

| Molybdenum (Mo) | prevents steel from becoming brittle and allows it to maintain strength at high temperatures. Also increases corrosion resistance, strength, toughness. |

| Silicon (Si) | increases the strength and wear resistance of steel, like manganese, it makes steel more stable and reliable. |

| Vanadium (V) | forms the structure of carbides in such a way as to increase wear resistance, survivability and hardenability. |

| Nickel (Ni) | increases corrosion resistance and prevents steel from rotting. Increases the strength of steel. |

| Niobium (Nb) | the best carbide former, which provides corrosion resistance, ductility, and wear resistance. |

| Tungsten (W) | increases the wear resistance of steel, increases its stability during hardening and resistance to high temperatures. |

| Cobalt (Co) | enhances the effects of other individual elements in more complex alloys. Increases strength and hardness. |

| Sulfur (S) | is a harmful impurity, leading to the formation of cracks and tears. Typically, the sulfur content of high-quality steel is limited. The presence of sulfides is unacceptable for critical parts. |

| Phosphorus (P) | worsens the plastic properties of the alloy, causing the phenomenon of cold brittleness. In steels, phosphorus content is allowed in very small quantities. |

Types of annealing

It is customary to divide this operation into two main types. Annealing of steel can be of the 1st and 2nd type. In the first case, phase recrystallization does not occur, but the metal acquires the desired qualities. The consequences of mechanical processing of metal in rolling mills and dies are eliminated.

Hardening of the steel surface after physical impact at a metallurgical plant is called cold hardening.

The main purpose of annealing steel of the 1st type is to reduce strength and increase ductility necessary for further processing. Partial recrystallization reduces internal stresses, which makes products more reliable and durable.

Annealing of type 2 steel is characterized by dramatic changes in the structure. Phase recrystallization is achieved by heating the metal above critical points and precisely implementing the cooling regime in temperature and time. These types of annealing and their purpose are determined by production tasks to obtain the necessary qualities of the metal. Critical temperatures are a serious risk factor. In some cases, for example, when burned, irreversible changes in the structure occur. This metal is sent for smelting. Heat treatment, annealing and normalization of steels is a complex process that makes it possible to obtain products from initial raw materials that meet the requirements of manufacturers of final products according to the specified characteristics.

Pros and cons of U10A steel

To weld surfaces made of alloy U10 and U10A, preliminary heat treatment of the metal is required. The material is difficult to weld. Steel has its positive and negative sides, let’s look at them in more detail:

pros

- knives made from the alloy are very sharp, such a blade can be sharpened to razor sharpness;

- the cutting edge of alloy knives remains sharp for a very long time, the products do not become dull for a very long time;

- metal products are resistant to chipping, bending of the edges of the cutting edge is not dangerous, even when cutting a small carcass while hunting;

- a knife can replace a screwdriver and can be used in aggressive environments;

- used for the production of exclusive products by private craftsmen;

- Thanks to the simple production technology, the cost of the finished product is not very high;

- the material meets all necessary hygienic standards;

- a knife made of this alloy can serve its owner for up to 50 years;

- ease of care for alloy products, it is enough to remove moisture from the surface of the blade and nothing else is required;

- the alloy is easily etched in a solution of ammonium persulfate and water;

- collectors like the appearance of alloy products.

Minuses

- steel products are shock-resistant;

- It will not be possible to sharpen a knife in the field, the hardness is too high;

- steel does not resist corrosion well.

Diffusion annealing

According to industry norms, this type of heat treatment can be classified as extreme. The metal is heated to the highest possible temperature, exceeding critical points. The technology is often used for alloys with complex and low-melting compounds. At the same time, the structure of hypereutectoid steel after annealing becomes less hard and much more ductile, which allows the use of a wide range of techniques for further processing. The method requires full control and adherence to technology, since there are high risks of overheating and burnout, which can lead to partial or complete loss of the necessary qualities and such metal will be unsuitable for further operations. The exact temperature for complete annealing of hypoeutectoid steel and other grades of metal is available in special reference books.

Properly performed heat treatment allows you to obtain:

- equilibrium chemical composition;

- grain growth;

- dissolution of excess phases;

- education, pore growth.

Application of U10 steel

Alloys U10 and U10A are used for the manufacture of tools and devices that experience loads without overheating the tip. Such tools include taps for cutting internal threads, wood saw blades, rasps, axes, and cold-action die stampers.

Cold-rolled steel strip is used for the manufacture of various springs, probes, valves, bifurcating blades, lamella contacts, and parts for the watch industry. The thickness of the tape ranges from 20 microns to 2.5 mm, the difference is quite noticeable.

U10 steel is used to make saw blades for drives, cores, cross saws, needle wire, conventional drilling cutters and cold forming dies. Simplified gauges, scrapers, rolling rollers and files are also produced from the alloy.

Alloy U10A is used for the manufacture of knives for general utility and special purposes. They are used in home life and catering establishments. The stamping of U10 steel should be no wider than 3 cm, then the product will be of decent quality.

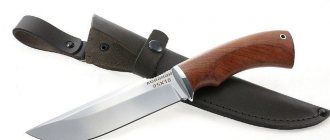

Examples of knives made of steel U10 and U10A.

Standards

| Name | Code | Standards |

| Sheets and strips | B23 | GOST 103-2006 |

| Long and shaped rolled products | B22 | GOST 1133-71, GOST 2590-2006, GOST 2591-2006, GOST 2879-2006 |

| Long and shaped rolled products | B32 | GOST 1435-99, GOST 5210-95, GOST 7417-75, GOST 8559-75, GOST 8560-78, GOST 14955-77, TU 14-11-245-88, TU 14-1-1271-75 |

| Sheets and strips | B33 | GOST 4405-75, TU 14-131-971-2001 |

| Medium and high carbon steel wire | B72 | GOST 5468-88, GOST 9389-75 |

| Blanks. Blanks. Slabs | B31 | TU 14-1-3300-81 |

Treatment

Pendulum temperature changes are carried out exclusively in chamber and shaft furnaces. Processing with constant heat removal and spheroidization are necessary for U10 steel. The temperature should be 760 degrees.

Exposure in such conditions is necessary for 2.5 hours. During continuous operation of the furnace, isothermal annealing is carried out.

Heating occurs taking into account the heating of steel at one millimeter per minute. A conveyor is used for proper processing.

During the annealing process, the steel acquires a fine-grained structure. Such indicators are better than the corresponding coarse-grained one. Spherodization gives the alloy a granular structure. With each passage of the temperature stage, the workpieces are kept for 45 minutes.

Forging of U10 steel begins at a temperature of 1180 degrees and ends at 800. Workpieces up to 100 mm2 are cooled openly. If the part is large in size, it is left in the hot furnace, and the cooling takes place along with it. Hardening is carried out at 800 degrees.

Full, partial annealing

Heat treatment is used to achieve the required qualities of the metal. The purpose of steel annealing is defined as obtaining specified technological properties. They can be both general and quite specific. Thus, incomplete annealing of hypereutectoid steel is acceptable in the manufacture of structural elements, but in the production of parts with specified characteristics it will be insufficient. Changes in the metal structure in both types of processing are different. Not only the annealing time of the steel plays a role, but also the temperature. An important factor in successfully solving the problem is the cooling mode.

When steel is not completely annealed, the temperature does not reach the upper critical point. The requirements for cooling time are also less stringent. When performing complete annealing of steels, the metal is heated above the critical point. Then the specified time is maintained and the cooling schedule is accurately followed. When heat treatment and annealing, it is important to take into account the grade of raw materials, hardness, and chemical composition, since the technology and modes are determined by GOST standards.

Heat treatment of taps

Heating is done in salt baths. In this way, the heat treatment of steel is carried out so that the surface layers receive additional hardness, and the core remains viscous. This adds extra durability to the tap.

As a result, the service life of the tool increases. Taps made of U10A alloy, with a diameter of up to 8 mm, are cooled in oil. If the workpiece is large, it is cooled in water. Both types of workpieces are tempered in an oil bath at temperatures up to 180 degrees.

The hardness of the product after tempering reaches 57-63 HRC. When choosing a cutting tool, a technologist must understand that the U10 alloy and its analogues lose their properties at 190-200 °C. Any person who has been involved in plumbing work has paid attention to the long service life of products made from U10.

Steel is a product of increased hardness; it makes excellent files and needle files.

But these qualities are not very good for knives. Yes, the blades hold an edge for a long time, this is undoubtedly a plus. But the material is highly fragile.

A product made of pure U10A alloy can crack at any second. For the production of knives, a package of U10A and 7ХНМ alloys is used. This combination allows you to achieve high-quality blades. They are used in tourism, hunting, fishing and even extreme sports.

Isothermal annealing

This type of processing is mainly used for alloy alloys. Isometric annealing of steel involves heating the metal to an austenitic state, followed by accelerated cooling to 660-680° C. Then the workpiece is kept at this temperature until the austenite turns into pearlite. After this, the metal is cooled in air naturally.

This is the fastest and most effective way to increase the ductility of metals with high chromium content.

High-temperature annealing of stainless steel and some other structural and tool alloys is done in this way. This technology makes it possible to reduce the hardness of alloyed materials to a level that allows the workpiece to be effectively processed later on metal-cutting equipment.

Isothermal annealing is characterized by a special cooling method. For a given time, the material is maintained at the temperature specified in the standards at one level, and does not drop gradually, as in other processing options. The formation of a homogeneous structure occurs due to the complete decomposition of austenite and the transformation of ferrites and pearlites. Heat-resistant alloys are processed in this way.

This technique is effective for processing small products, stampings, and tool blanks.

Isothermal annealing has a short technological cycle, but is quite effective for solving many production problems.

Analogs

Substitutes for the alloy can be called Russian steel grades U11 and U12. According to the markings, it becomes clear that the alloys contain slightly more carbon. Oddly enough, U10A steel has quite a lot of analogues. Let's look at them in more detail:

- Hungarian: S-101/102;

- Italian: ABN/C-100-KN;

- Spanish: C-102;

- French: C-105-E2U;

- British alloy: 1645;

- Romanian: OSC-10;

- Swedish: 1880;

- Czechoslovakian: 19191;

- Pan-European: AFNOR-NF;

- Japanese: SK-3;

- American: T-72301;

- Spanish: F. 515;

- Polish: N-10 (E);

- Chinese: T10 (A).

physical characteristics

| Temperature | r, kg/m3 | l, W/(m °С) | R, NOM m | a, 10-6 1/°С |

| 0 | 7810 | 40 | 420 | — |

| 20 | 7810 | 40 | 420 | — |

| 100 | — | 44 | — | 115 |

| 300 | — | 41 | — | 125 |

| 600 | — | 38 | — | 139 |

| 900 | — | 34 | — | 154 |

| 200 | — | — | — | 119 |

| 400 | — | — | — | 13 |

| 500 | — | — | — | 134 |

| 700 | — | — | — | 143 |

| 800 | — | — | — | 139 |

| 1000 | — | — | — | 154 |

| 1200 | — | — | — | 133 |

Knives made of steel U10/U10A

The blades of knives made of carbon tool steel U10 have high characteristics. The alloy holds an edge well and has high wear resistance, but does not resist corrosion well, so knives should be thoroughly wiped after use. Steel is considered an alloy of increased hardness and it ranges around 60-64HRC.

Kitchen knife – CoolToolme JP Gyuto

CoolToolme are designer kitchen knives of the premium segment of domestic production. Initially, CTm Knives were aimed at professional chefs, but over time they deserved a wider consumer. Many blades are made to order according to the personal wishes of the buyer. Knife characteristics:

- Total length: 346 mm;

- Blade length: 224 mm;

- Butt thickness: 3.8 mm;

- Blade material: U10;

- Handle material: Wood;

- Manufacturer: CTM Knives, Russia;

- Weight: 224 grams.

Designer kitchen knife CoolToolme JP Gyuto.

Cutting knife – Specialist

The handmade knife is made of forged carbon steel U10A with a blued blade. Handle made of printed leather and textolite. This knife is ideal for hunting and tourism. The leather handle is warm, pleasant to the touch and does not slip in the hand. Product characteristics:

- Manufacturer: ZlatProfit;

- Steel: U10A;

- Handle: Leather;

- Total length: 250 mm;

- Blade length: 140 mm;

- Blade width: 30 mm;

- Blade thickness: 4.0 mm;

- Blade hardness: 60-62 HRC.

A carving knife is special.

Folding knife – Achilles

Folding knife Achilles is a handmade knife from craftsmen from the city of Zlatoust, the blade of the knife is made of carbon steel U10A with blued finish and decorated with engraving in the style of Zlatoust engraving on steel. The reliable mechanism of the Achilles folding knife will ensure long and safe use in any harsh conditions. Blade characteristics:

- Steel: U10A;

- Handle handle: Walnut;

- Total length: 220.0mm;

- Blade length: 110.0 mm;

- Blade width: 25 mm;

- Blade thickness: 3.0 mm;

- Blade hardness: 62 HRC.

Handmade Achilles folding knife.

Mechanical characteristics

| Section, mm | σB, MPa | d5, % | d4 | y, % |

| Annealed cold-rolled strip of the highest quality category | ||||

| 4 | ≤750 | — | ≥10 | — |

| A sample with a diameter of 5 mm and a length of 25 mm is deformed and annealed. Deformation speed 10 mm/min. Strain rate 0.007 1/s | ||||

| — | ≥105 | ≥50 | — | ≥87 |

| Cold-rolled strip (strength class indicated) | ||||

| — | 750-900 | — | — | — |

| A sample with a diameter of 5 mm and a length of 25 mm is deformed and annealed. Deformation speed 10 mm/min. Strain rate 0.007 1/s | ||||

| — | ≥90 | ≥52 | — | ≥100 |

| Cold-rolled strip (strength class indicated) | ||||

| — | 900-1050 | — | — | — |

| A sample with a diameter of 5 mm and a length of 25 mm is deformed and annealed. Deformation speed 10 mm/min. Strain rate 0.007 1/s | ||||

| — | ≥55 | ≥59 | — | ≥100 |

| Cold-rolled strip (strength class indicated) | ||||

| — | 1050-1200 | — | — | — |

| A sample with a diameter of 5 mm and a length of 25 mm is deformed and annealed. Deformation speed 10 mm/min. Strain rate 0.007 1/s | ||||

| — | ≥29 | ≥70 | — | ≥100 |

| — | ≥18 | ≥78 | — | ≥100 |

| — | ≥16 | ≥86 | — | ≥100 |