Since people learned how to process metal, it is simply impossible to imagine life without knives. They cut meat, cut fruit, give them as souvenirs and use them as weapons. There are quite ordinary examples of such products, with a wooden or plastic handle, and there are one-piece, unique specimens, among which knives made of damask steel with a hardness of 64 HRC stand out. Such blades have a long and interesting history, as well as their secrets. How they appeared, why they are better than other knives, and how to choose them – the material collected in the article will tell you.

History of the appearance of the alloy

Due to its unique characteristics, damask steel has always been more expensive than conventional alloys. Alloy knives and swords provided real advantages in battle. Such a product could cut the enemy's weapon. Steel blades became the subject of rumors and legends.

History of the creation of damask steel

There are no specific facts about the history of the creation of steel. But the first mentions date back to the times of Alexander the Great’s campaigns in India. It is from there that there is evidence of durable swords of Indian warriors. They easily cut through Macedonian weapons and armor.

Saber made of damask steel.

The only conclusion that comes to mind is that India was the historical homeland of damask steel.

And it appeared several centuries before our era. Archaeologists have found several centers in India where damask steel was made. Thanks to the development of trade, such products came to Syria and Persia.

In Central Asia, damask steel was called taban, khorasan and farand. But Timur's conquests led to the decline of this industry. As a result, by the 12th-14th centuries, the carefully protected methods of making damask steel were lost.

There are weapons and armor dating back to the 16th-18th centuries that were made from this steel. But it was a sample of the simplest damask steel, the technology of which was not complicated. And the quality of these items was an order of magnitude lower than the ancient products.

Bulat steel P.P. Anosova

Many craftsmen tried to revive steel production technology. And the famous metallurgist Pavel Petrovich Anosov succeeded in this matter. The head of the Zlatoust factories was very interested in the topic of damask steel. And in 1837, his works made it possible to recreate the alloy.

Return of a Legend

Closer to the beginning of the 20th century, the technologies developed by Anosov were again lost. A revival of interest in steel appeared again during the Soviet period. Experimentally, Anosov’s feat was repeated by metallurgist Sergei Baranov. Test melts allowed us to achieve the desired result. This was confirmed by the conclusion of the Russian Academy of Sciences.

Damask steel knives.

Iron Stream

At the beginning of the 18th century, Russian metallurgy began to develop rapidly. To implement his grandiose plans to expand the Russian state, Tsar Peter I needed a large number of high-quality weapons, and for their production they needed, first of all, iron and cast iron. Relying on domestic and foreign experience, Peter I organized iron ore mining and factory construction, unprecedented for that time. From 1700 to 1800, 123 ironworks were built in the Urals alone. By the end of the king’s life there were 233 of them, and by the end of the 18th century there were already 3,100 of them, not counting the mining factories. Pig iron production in Russia during this time increased from 150 thousand poods in 1700 to 9.91 million poods in 1800.

Abu-r-Raykhan Muhammad ibn Ahmad al-Biruni - Central Asian scientist-encyclopedist (4.09. 973 - 9.12.1048)

The victory of Russian metallurgy over Swedish was no less significant than the victory of the Russian army over the Swedes in 1721. For example, in 1716, the first batch of Russian iron in the amount of 2,200 pounds was exported to England, and in 1732, the export of iron already exceeded 200 thousand pounds. In 1722, a decree of Peter I was issued, which, in fact, gave the first technical conditions for the quality of iron:

“His Imperial Majesty ordered to send from the Berg College to all iron factories where iron is made, so that from now on the iron will be tested in this way, and released to the indicated places, and sold with the following marks.

First test: dig round pillars six inches thick in diameter into the ground so far that it is motionless, and hollow out holes in them the size of the strips, and push iron into that hole, and circle around that pillar three times, then back away from it. remove the post, and if it does not break, and there is no breaking mark, then stamp No. 1 on it in addition to the factory mark.

The second test: taking the iron strips, hit the anvil three times, then turn the other end back and hit them three times with all your might, and whichever one will withstand, and there will be no sign of a break, then each one, in addition to the factory mark, is branded with No. 2.

On the latter, which does not withstand those tests, put in addition to the factory stamps No. 3. And without stamps, strip iron should not be sold at all.”

Patterns of welding damask steel, enlarged 2-4 times

Each type of steel was rated according to its “own” number of “bends”: spring steel with six “bends”, coin steel with eight, tool and Damascus steel with twelve.

The leadership style of Peter I was also characterized by the strictest control over the implementation of his decrees. Thus, by decree dated January 11, 1723, he ordered: “The gun office from St. Petersburg should move to Tula and monitor the serviceability of the guns day and night. Let the clerks and clerks watch how Alderman places the brands. If you have doubts, check it yourself by inspection and shooting. And shoot two guns every month until they deteriorate. If a hitch occurs in the army, especially during a battle, due to the oversight of the clerks and clerks, the senior clerk will be given a job as a clerk, and the clerk will be deprived of his Sunday glass for a year.”

In the 18th century, Russia became the largest exporter of iron to Western Europe. In 1788 alone, 38.4 thousand tons of iron were exported from Russia to England and 5.8 thousand tons to other countries.

Zlatoust cavalry saber

In 1751, on November 20, the Tula industrialists Mosolovs entered into a contract with the Orenburg chancellery for the construction of an ironworks. In 1754, in the Kosotursky tract, on the Ai River, half a mile from the mouth of the Tesma River, the Zlatoust Plant was founded - one of the largest metallurgical plants in the Southern Urals. Having reached its design capacity, already in 1773 the plant was producing up to 140 thousand pounds of cast iron, 90 thousand pounds of iron and 1.885 thousand pounds of copper.

Over the course of 75 years, from 1701 to 1776, a whole complex of metallurgical plants was erected in the Urals: Nevyansky (1701), Kamensky (1701), Nizhne-Tagilsky (1725), Kononikolsky (1750), Preobrazhensky ( 1758), Verkhne-Avzyanopetrovsky (1755), Nizhne-Avzyanopetrovsky (1756), Katav-Ivanovsky (1757), Beloretsky (1761), Zlatoustovsky (1773), Miasssky (1776) . By the beginning of the 19th century, the Urals emerged as a grandiose industrial region on a global scale.

A copy of the saber of Tsar Mikhail Fedorovich, made by master gunsmith Ilya Prosvit.

Chemical composition and properties of damask steel

Thanks to a special manufacturing technology, damask steel has a unique internal structure. The alloy has high hardness and elasticity with a unique appearance. Bulat steel is an alloy of iron and carbon.

Due to the production features, the surface of the finished product has a beautiful pattern. This material has been used for the manufacture of bladed weapons since ancient times. The chemical composition of the alloy is closer to cast iron than to steel.

But at the same time it retains the malleability and ductility inherent in low-carbon steels. But the high carbon content of about 2% makes the alloy incredibly hard. Ordinary metals cannot achieve such hardness, even after hardening.

Damask steel reaches a value of 70 HRC, the result is more than worthy. The unique pattern on the blade and the beautiful cut will not leave any knife lover indifferent.

Eight types of welded damask steel (damascus)

With Damascus, everything is much more interesting: there are at least eight varieties of welded damask steel, also known as Damascus. Before we get to them, it's worth making a quick note.

In principle, it is possible to create stainless Damascus. To do this, you need to assemble a package of steel alloyed with the necessary additives and start welding it in a vacuum, laying it in layers and unforging it, and then repeating this cycle again. Technically, this is quite difficult, but modern technologies successfully cope with the task, as exemplified by chef’s knives with patterned stainless steel linings.

Kanetsugu kitchen knife from the Tojiro range with patterned steel handles

"Wild" Damascus

This is the same damask that is obtained if the master does not use special tools and technologies, that is, if the process occurs naturally. Sheets of steel with different chemical compositions are folded together, welded and unforged; then they are cut in half, folded again, and all actions are repeated. The result is layered steel. If its forging does not have a clear plan, then the pattern turns out disordered, or “wild”.

“Wild” and simple damask are two subtypes of the technique, which has no characteristic features, but is the usual overlay of layers on top of each other, followed by free-style forging

Stamp Damascus

When making this type of patterned steel, the blacksmith uses a tool called a stamp: thanks to it, a beautiful pattern appears on the surface of the layered Damascus plate, not very reminiscent of the pattern on plain Damascus. Depending on the stamp's pattern, it may resemble a ladder, the growth layers of a tree cut, the surface of water in the rain, or a combination of these patterns.

Stamp Damascus is produced using a special tool - a stamp.

Mosaic Damascus

Mosaic damasks are often distinguished not only by the technology of forging, but also by the composition itself - the package is assembled in the manner of a mosaic from steel blanks of different shapes and compositions so that as a result of overlaying and forging, such a characteristic pattern is obtained.

The mosaic on the surface of this type of Damascus is the “merit” not of technology, but of the correct selection of steel package

Mosaic Powder Damascus

One of the most difficult types of damask; a technology that is rarely practiced in Russia.

To create a blade like the one in the photo, you need to prepare a cliche with a certain slotted pattern made of steel. Then the cliche is filled with powdered steel, which, when etched, will contrast with the base, and under the influence of high temperatures and pressure it turns into a monolith. Now from this ingot it is possible to forge a blade using conventional technology, welding or alternating patterned layers with each other.

Powder mosaic damascus is a rare phenomenon in Russia

Twisted Damascus

Twisted Damascus, also known as Turkish, is created by twisting a piece of several welded rods around itself. The pattern will depend on the number and composition of steels in the original package, the angle of twist and the depth of the cut. As with mosaic technology, from the resulting “twist” you can then unforge a blade using conventional technology, welding or alternating patterned layers with each other.

Twisted Damascus (aka Turkish) gets a characteristic pattern when the blacksmith twists the workpiece several times during the forging process

Mosaic end damascus

The technique for making this type of damascus is somewhat different from others. A patterned mosaic of parts of various shapes and different steels is applied to a blade made of homogeneous steel. Then the workpiece is boiled under a vacuum press. Thus, no folding or torsion is used in its manufacture. When a fully forged block is ready, the plates that previously served as the basis for assembling the mosaic are cut off from it.

The side covers of such damascus are sections from a finished forged block

Fiber Damascus

Another foreign method of forging Damascus. Its composition is no different from the standard one, and neither is the beginning of unchaining. But about halfway through the process, the blacksmith turns the workpiece 90 degrees and begins to unforge it again. This is how characteristic “short” (compared to ordinary) divorces are obtained.

The short “fibers” of this type of damascus are the result of a special technique where the blacksmith turns a half-forged piece and starts all over again.

Multi-row Damascus

This is a view, rather, not of a material, but of a finished product, that is, a blade. Strips of damask of different designs (mosaic, twisted, etc.) are placed side by side and forged together in order to create a visually impressive combination of patterns. The composition and manufacturing technique of these strips often differ: closer to the cutting edge, a durable and sharp type of damascus is placed, and closer to the butt, a durable and tough type with especially beautiful patterns is placed.

It is more correct to call the blade itself multi-row, not Damascus

Pros and cons of steel

The main properties and features of damask steel are primarily determined by the carbon content in the alloy. An important role is played by the temperature values that are achieved during the steel melting process. If you overheat the raw materials, the result will be disastrous.

The production of damask steel is a complex process.

When making knives, it is necessary to connect metal packages to each other using forge-type welding. Thanks to this technology, a characteristic structure consisting of several layers is obtained.

To achieve the planned results, it is necessary to implement correct annealing and act strictly according to the recipe. Manufacturing tricks ensure high quality products. Let's see what advantages and disadvantages they have:

pros

- this type of steel withstands mechanical shocks and bending loads very well;

- damask steel is a highly hard material that is characterized by increased wear resistance;

- this alloy has a very long service life, the material can last for decades;

- damask steel is characterized by excellent cutting abilities; the metal makes wonderful knives;

- steel is capable of holding an edge on a knife for a very long time; once the product is sharpened, it can be used for a very long time without problems;

- beauty and sophistication of products, indescribable and unique patterns on the surface.

Minuses

- Damask steel blades are very difficult to sharpen. Greater hardness of the material will require special devices and knowledge;

- the type of steel in question cannot boast of high corrosion properties; a metal blade may begin to rust;

- the complex production process affects the cost of finished products.

Knife blades made of damask steel.

Bulat and Damascus: how to choose a real knife

Photo

by the author We have known Alexander for a long time. I have always been amazed by his products. I don’t know why, but I “feel” his blades, for example, when I’m at exhibitions. Perhaps this is because the master has placed some kind of secret in them? BULAT

— So, I’ll start our conversation with the traditional question: what are damascus and damask steel?

— There is a lot of talk about these miracle metals. I have heard about them from people who least of all delve into the meaning and essence of damascus and damask steel, but at the same time want to be known as the greatest experts in this field.

To understand the essence of the issue, let's return to the origins of damask steel, because as historical chronicles indicate, first there was damask steel, which is an alloy of iron and carbon. The production of cast metal began in India.

| The package of the future blade consists of layers of different structures. PHOTO RIKROSE/FLICKR.COM (CC BY-NC-ND 2.0) |

It was established that that metal with the given qualities was melted in small clay bowls with low edges - in crucibles. Iron ore or ready-made iron ingots were placed in the crucible. A charge containing coal (mostly charcoal) was also added there.

During the smelting process, iron was saturated with carbon from coal and oxygen from the air. It was impossible to allow the metal to become oversaturated with oxygen. The result was an ingot in the shape of a hemisphere. They called him "Wootz". Subsequently, the ingot was cut in half and sold in this form.

| After forging welding, the metal takes the form of a monolith. PHOTO RIKROSE/FLICKR.COM (CC BY-NC-ND 2.0) |

— How could people determine that they were being sold damask steel and not a cheap fake?

— In any case, a crystalline structure should appear on the surface of the ingot. This structure was especially visible in the section.

— What did you do with the ingot later?

“Next, it was necessary to correctly forge this ingot in order to subsequently make blades from this damask steel. This stage has its own small subtleties.

The fact is that in order to obtain a high-quality damask blade during forging, it is necessary to make the damask steel cleaner. To do this, it is necessary to “expel” (or squeeze out) all gases contained in the metal, which can have a detrimental effect on the quality of damask steel if they remain in it.

This is a kind of dirt that spoils the purity of the metal. The more monolithic the structure of damask steel, the better the quality of its blades. But not all blacksmiths succeed.

| The history of Damascus and damask steel goes back thousands of years. |

— Does it mean that in this case the quality of damask steel is sharply reduced?

- Yes it is.

— I know that the forging process is as important as it is interesting. This is real creativity. They often try to attribute various magical actions to the birth of the blade.

But, in my opinion, every master with a capital “M” develops his own style of communicating with metal. Probably someone will say that iron is iron.

But I am more than sure that the master puts a piece of his soul into all outstanding creations, which in our case are high-quality blades. And this cannot be replaced by any production automation that exists at this stage of development of civilization. How, in general terms, should you continue to work with damask steel?

| Damascus is produced by forging from metal plates. |

— Bulat requires a lot of attention. When forging, you cannot underheat the metal, as it may burst, and overheat it, as the pattern will disappear, and if the overheating is even greater, the metal can also burst.

— How to monitor the temperature of damask steel?

- This can only be determined by its color and is obtained with certain experience.

High-class craftsmen have their own secrets of communicating with metal, but not everyone likes to voice them. However, in the case of Alexander, I was amazed that he was ready to talk about everything in detail.

And when I asked if he was afraid to share secrets with competitors, the meaning of his answer was something like this: “If it’s given, so it’s given. No, you can’t buy it anywhere!” And in this case there should be a sense of metal. But let's return to our blacksmith's shop.

— What other important details that arise during the processing of damask steel would you note?

— One of the features of damask steel is the ability to increase temperature during forging. Therefore, you have to stop the process in order to cool the workpiece. At the same time, the damask steel must be well forged, and during forging on an anvil, part of the workpiece still has time to cool. And so you have to heat it up again to the desired temperature.

It is very important to maintain this temperature balance. The highest quality damask steel can only be obtained by using high-quality charcoal. There is virtually no sulfur in charcoal, which makes the metal brittle.

— So, we have a blank of high-quality damask steel. What do we do with it next?

— The blank is forged in a certain way. The result is a square piece. During forging of the workpiece, gases are “expelled” from it and those cavities (or cavities) that are formed in the places where gases escape are forged.

It is important that the entire structure of the workpiece is as close as possible to the monolith. It is this square that is the “cradle” from which future blades are drawn by forging. The square is forged into a strip depending on the size of the blade (thickness and length).

Throughout the entire forging process, the metal must be shifted as much as possible, just as a cook kneads dough. But here, as in every matter, you cannot overdo it.

Forging for too long leads to refinement of the crystalline structure of the metal. In this case, the drawing practically disappears. The quality of damask steel is lost. The blank for a specific product is cut off from the square after drawing.

| The Damascus blade consists of hundreds of thin layers welded using the forging method. PHOTO BY DMITRY VSTOVSKY |

— I heard that many of our modern craftsmen finish working with metal at this stage. Is it so?

- Unfortunately, so. After the workpiece is cut out, they try to shape the future product using emery. In this case, the most valuable layers of metal, which carry the greatest hardness, are ground off. Such “masters” concentrate only on giving the blade the most attractive appearance possible.

This is basically easy to do. But at the same time, the utilitarian qualities of the product are at stake. Or rather, they are reduced to a very low level.

I know of cases where “masters” weld metal bags or even just rods “on edge”, then by forging they give them the appearance of a forged product.

With this method, the internal structure of the metal cannot be compared to real damask steel or damask. I always finish the workpiece by forging and thus allow the metal to retain its monolithic structure, and this leads to a high quality blade.

“But, as you know, it’s not enough to forge a blade; you also need to properly harden it and temper it.” How do you do it?

— Hardening and tempering are components of a single process. They serve to increase the cutting properties of the blade. This is a purely individual process.

For example, products forged from one ingot of damask steel are hardened and tempered in the same way. For another ingot, this regime may be different.

— How are damask steel blades sharpened?

— It all depends on the type of product and its practical purpose. Sharpening methods are different. There is a combined sharpening. This is when in one place (usually closer to the handle) the blade is made thicker (and hence the sharpening will be more like a wedge), and then the blade is sharpened like a razor. This is how you can sharpen hunting knives.

The part of the blade that is located at the handle usually performs rougher work: cutting the skin of an animal, planing and cutting wooden surfaces, knots, while the more finely sharpened central and nose parts of the blade will help perform work on skinning and cutting animal meat, as well as other more delicate works.

| Damask steel is made by casting, after which the workpiece is sawed in half to evaluate the quality of the resulting metal. |

DAMASUS STEEL

— Alexander, let’s now return to Damascus steel. There are many legends about products made from it, but even more fables due to low awareness. So what is it?

— Unlike damask steel, which is smelted, Damascus steel is welded. It can be welded from different types of steel or steel and iron.

Presumably, in its historical beginning, crystalline iron, obtained from ore by smelting, had a porous structure. The reason for this was the presence of a large number of impurities. This iron was forged. Some of the iron remained soft, while some became carbonized.

During the further forging process, hard and soft iron were mixed. The hard one served as a base, to which the softer one was forged on both sides.

Thus, the result was a package where the softer layers wore off faster than the middle with a harder layer. In this situation, it turned out that the blade sharpened spontaneously. A striking example of such a knife is the ancient Scythian knife “Akinak”.

The basis of Damascus steel is a package of different grades of steel or steel and iron. When forge welding metals, it is important to avoid overheating, which releases carbon.

Compared to damask steel, Damascus was easier to manufacture. I actually make three packets: one for the middle and two for the side layers of the “cheek”.

On some products I tried to unforge packages of up to 50,000 layers in total. But you shouldn’t get carried away with a large number of layers, since when the metal is processed for such a long time, carbon comes out of it. The outer layers of my products generally contain 400–450 layers, and the inner layers contain more than 1000.

The quality of the future blade depends on how this process goes. The tighter and more monolithic the craftsman manages to bind all the layers of the package, the higher the quality will be.

| Alexander graduated from the Suzdal Art and Restoration School. He began to seriously forge blades from damask steel and damascus in 1985. He produced over 1000 original works, including blades of hunting knives, sabers, checkers, daggers, dirks and axes. The master's products are in private collections in the USA, Germany, France, Spain, and Russia. The works were exhibited at the State Armory Chamber, at all-Russian and foreign weapons exhibitions. At the moment, Alexander is, perhaps, the only successor to the work of the famous blacksmith, master gunsmith Vyacheslav Ivanovich Basov, who revived the famous school of weapons, blade forging art in Russia. Photo by the author |

— What can you say about the legend according to which swords made of Damascus steel in ancient times were worn under a wide belt of oriental clothing?

— There have always been more legends than were necessary. Of course, there were such swords. But there were not as many of them as some were accustomed to claim. The very combination of the elasticity of a metal and its hardness is hardly comparable, at first glance.

But some ancient masters managed to achieve this. It is unlikely that there could be many such products. It is known for certain that there are four swords of this kind located in Iran.

It goes without saying that such products have the status of national property. They were treated in the same way as the famous samurai swords in Japan.

— Alexander, let’s try to compare the production of blades from damask steel and damask. What are the characteristic features of this process for each of them?

— In general, damask steel is more plastic due to its crystalline structural lattice. Moreover, it can have a much higher hardness. If we take 60 Rockwell hardness units (this is a very high number for steel), then it is characteristic only of tool steels that are used to process metal.

All main types of hunting knives have a hardness of 54 to 58 units on the same scale. But the same 60 units for Damascus steel is the norm.

For damask steel, the norm is 64 units. This is the hardness of a file. But with such hardness, a damask blade can bend into an arc.

High density, corrosion resistance and high cutting properties are characteristic features of damask steel blades. And this is due to the fact that damask steel should initially be more monolithic and not loose.

| The price of Damascus blades is quite high. PHOTO VADIMDEM/DEPOSITPHOTOS.COM |

— Alexander, please analyze the products that we see on the windows of hunting stores. First of all, I mean blades made of Damascus steel, or more precisely, what they are trying to pass off as Damascus steel.

— To be honest, I wouldn’t really like to discuss this for many reasons. But in short I can say the following. Those products that can sometimes be seen on store shelves, even at a stretch, cannot be called what sellers claim them to be.

I have already said that recently many craftsmen have appeared who can give you about 100 (!) products made from Damascus steel per month. What do you think these blades will be like? Mostly on store shelves we see products with a maximum number of layers from 100 to 300.

A true Damascus blade doesn't even start with that many layers. The price of such products speaks for itself. How many of us have seen, for example, a Mercedes at the price of a Zaporozhets? I'm sure no one ever.

— What would you advise to those who want to buy a knife made of real damask steel or Damascus?

— If a person is seriously interested in this kind of knives, he must obtain certain knowledge about the subject of his interest. This can be learned from books or from experts in this matter. Sometimes a few minutes is enough for me to explain to a person the difference between a blade made of real damask steel and a fake.

If a person understands the subject of the conversation, he will immediately understand everything, and later he will even proudly tell others about it. And this, I think, is very good.

PS On behalf of the readers, I express my deep gratitude to Alexander Bychkov, a master with a capital letter, a successor of Russian blacksmithing traditions, for introducing us to the mysterious world of working with metal, and I wish him good health and further creative success.

Interviewed by Dmitry Vstovsky May 4, 2022 at 09:43

Alloy characteristics

According to its characteristics and structure, damask steel is a composite that is chemically and physically structurally heterogeneous. There is a theory that the role of a matrix in the metal is played by a soft plastic base of ferrite.

Iron carbide gives the alloy high viscosity. Self-sharpening is due to the wear resistance of the blade.

The soft fibers grind off on the cutting edge, and fibers with cementite come to the surface. This principle forms a micropyle.

And it already provides the ripping principle of cutting. It is very difficult to bend damask steel, but if it succeeds, the bend can reach an angle of 120 degrees. And after that the steel will straighten and retain its properties. Sharpening a damask steel blade is a rather lengthy and not easy process.

The mythical tests of cutting horsehair and a scarf in the air with a knife really take place. And at the same time, the sharpness of the blade remains for a very long time. The patterns on the surface of the blade can be striped, wavy or mesh.

The more complex the design, the higher the cost of the blade. It is formed during cooling. Damask knives are not made with engravings or designs; their natural beauty is at its best.

Examples of knives made of damask steel.

A matter of national importance

In 1828, the government set the task: “At the Zlatoust arms factory, introduce the manufacture of sabers of equal quality to those made in Asia.” Soon the tsar was informed that “the best craftsman in Tiflis, Karamon Eliazaroshvili,” had pledged to reveal the “hereditary secret” he had received from his father Geurg (George) and “teach people to make weapons using this secret.” As a test, he made sabers and daggers from “real” (i.e. cast) and “in the manner of damask steel” (i.e. welding damask steel). At the same time, the master used both “Indian iron” and “Turkish steel”. “Turkish cast iron powder” is a traditional raw material that his ancestors dealt with in Erzurum. Thus, in 1833, the craftsmen of the Zlatoust state-owned factories were able to make weapons from welding damask steel, using iron and steel from domestic factories. “It is impossible not to recognize in Eliazaroshvili’s welding blades,” contemporaries responded, “a high dignity for sabers, which is proven by the very test often used on them, namely cutting off the head of a bull with one blow.” Eliazaroshvili himself received a thousand chervonets as a gift and was awarded a gold medal.

The Zlatoust plant was a metallurgical enterprise with a full cycle. The plant smelted cast iron from which hammers, anvils, wheels, cannonballs, bombs, weights, pots, pans and other household utensils were cast. In total, he produced 11 types of iron and steel.

Zlatoust dragoon officer's saber, model 1881

In 1812, a special white weapons factory was founded at the Zlatoust plant, which in 1816 sent the first batch of edged weapons along the Ai River. Soon Zlatoust became widely known for making mainly sabers of the “Damascus” type (welding damask steel). Ironically, these sabers were for some reason known as “Turkish”. In addition to sabers, the plant's weapons factory produced checkers, broadswords, sapper and high-quality hunting knives, which were famous far beyond the borders of Russia. However, tool steel was inferior in quality to English steel: cast steel was not yet produced at the plant.

Scope of application of damask steel

Bulat steel is used mainly for making knives. They are made for various purposes and types. Today on the market you can find products for hunting or fishing. There are not only tourist products, but also military ones.

Throwing knives are made from this metal. Collectible knives are also made from steel. Such products can be very expensive. The handles of such knives are made mainly from natural materials. They may contain decorative stones and inserts made of precious metals.

Collectible knives are made only by hand. For this reason, products cannot be cheap. But unfortunately, the material in question could not receive proper distribution in other areas. In many other indicators, damask steel is inferior to modern alloy steel.

Do you already have a damask steel knife?

Not really

Main types of knives and scope of application

Damask steel is used in the manufacture of the following types of knives:

- all-metal,

- with fixed blade,

- folding.

As for the scope of application, the models can be divided into knives for hunting, fishing, tourists, and military. Throwing models and collectible weapons stand separately.

Knives for collectors can be very expensive - valuable wood, precious stones, metals, natural horn are used to make them, not to mention the manual work on each knife.

Knife made of damask steel.

The difference between crucible damask steel and welded steel

To obtain high-quality damask steel, there are several types of production. But experienced blacksmiths keep them secret. It is important to understand that damask steel is not a secret chemical formula, but the correct sequence of heating and melting.

After the billet leaves the furnace, damask steel with a developed dendritic lattice is obtained. It can be seen with the naked eye. Today you can find two main methods of producing damask steel:

Sample No. 1

If the reader has an opposing opinion about the methods of production and properties of damask steel, a discussion will take place if the opponent presents equally weighty arguments, but based on completely opposite principles; If based on what is stated in my article, then there is nothing to argue about.

Types of damask steel knives

The patterns on the blade do not always indicate that you have damask steel in your hands; it could also be damascus. The unique properties of damask steel have found application in knives. Today, such products are manufactured mainly by small workshops. The industry considers the alloy to be irrelevant.

There is no large scale production of knives. This is due to the fact that the manufacturing process is complex and there is no great need for such blades on the market. Alloy production is considered a delicate process, which is quite difficult to put on a conveyor belt.

Combat

Most of these items are made for collectors. Real life application is not intended. Knives of this type are made with decorative inserts and handles. Products are also susceptible to corrosion; they are treated with a special compound before storage.

Basically, these knives are made to order. Combat knives and swords can copy various designs from bygone eras. The use of such products in combat remains questionable. For army and airborne missions, the properties of damask steel are not in demand.

Damask steel combat knives.

Folding knives

Folding knives made of damask steel are quite rare. In most cases, blades made of Damascus steel or etched to look like damask steel are sold under their guise. Real folding knives are made from damask steel, made to order and they are not cheap.

Such products have all the properties of damask steel, but have a number of disadvantages. A regular sharpening stone cannot sharpen a blade. The process may take several hours. Although the dulling of the product occurs many times slower.

The use of a folding knife made of damask steel also has many problems. You need to take care of the knife, otherwise it will quickly begin to rust. You can etch the knife with lemon juice, but the pattern of the steel will be damaged. You can order a blade made of stainless steel, but it will be twice as expensive.

Folding products made of damask steel.

Hunting

Such knives are also mainly purchased for collections, and not for practical use. This is due to the fact that the blade does not resist corrosion well and needs to be sharpened for a long time. When sharpening a knife, you should act slowly and avoid scratching the blade. The process uses diamond abrasive stones.

Hunting knives made of damask steel.

Kitchen

Kitchen products are not widely used, for the same reasons as other knives. When choosing a product, you should pay attention to the following points:

- knives made from ordinary damask steel are highly susceptible to corrosion, they will require careful care;

- All products are made individually; there are simply no serial blades;

- A simple sharpener cannot sharpen such a blade and the process will take at least two hours;

- a kitchen product will be comparable in cost to a hunting knife.

For kitchen work, it is recommended to use stainless steel. But keep in mind that its cost will increase and it is difficult to find a master who will take on such work.

Sets of kitchen knives made of damask steel.

Understanding the terminology

In general, everything here is not as difficult as it might seem. What these materials have in common is the presence of a pattern, but their manufacturing technologies differ radically. The legendary Indian damask steel is, unfortunately, a lost technology: it was once passed down orally and was so carefully hidden that it was completely lost several centuries ago. The production of damask steel was not cheap, and already in the 17th century, affordable and sufficiently high-quality industrial steel began to appear, so the demand for damask steel fell and then completely disappeared. Everything we know about it (partly thanks to history, partly thanks to the experiments of the Russian metallurgist Pavel Petrovich Anosov) fits into a couple of phrases - damask steel was exceptionally strong, sharp and, of course, legendaryly beautiful. In Rus', damask steel was often called kharalug (horolug), or kharaluzhnaya (horoluzhnaya) * steel, although in fairy tales we often encounter the term “damask steel” itself.

* You can find one or the other spelling. Perhaps the option taken out of brackets would be more correct, since, firstly, it is precisely this one that is found in ancient sources, in the same “Tale of Igor’s Campaign”, and secondly, it preserves the letter “a” in the common Turkic root “hara” /“kara” (“black”).

By the way, about fairy tales and epics. They attribute almost magical properties to damask blades, but it is wrong to think that this is some kind of non-existent, fairy-tale metal. In fact, damask steel was simply the best option for its time. Practical tests of even the best samples that have survived to this day show properties close to ordinary inexpensive carbon steels of modern manufacture. However, in the Middle Ages, the bulk of blades were made from such low-quality raw materials that even such properties seemed mystical and magical to contemporaries.

At one time, Anosov, in the first half of the 19th century, managed to create an alloy that fully met all the characteristics of damask steel. Although, of course, we cannot know for sure how similar the technology and composition discovered by our metallurgist are to the “original”. The fact is that there were several technologies for producing damask steel even in ancient times: it is not known for certain whether Anosov recreated one of them or came up with his own.

The damask steel blade of the Turkish saber is what we call historical damask steel

And now we come to the actual clarification. Historically, there were two main technologies for producing patterned steel. One of them involved casting, the other involved welding and forging several types of steels together; the first retained the name damask steel, and the second began to be called damask.

So:

- Cast damask steel is patterned steel in the historical sense we are familiar with, produced by casting and forging methods.

- Welded damask steel (or Damascus) is patterned steel produced primarily by forging methods.

High-quality weapons were made from special “damask steel” ingots called wootz. It was the beauty of the damask pattern that was associated with its magnificent properties. But wootz was expensive and difficult to produce, which spurred the search for technologies for creating patterned blades by alternative means. What is now called Damascus began to be produced specially, by folding and forging several layers of blanks from different types of steel. The new material was not inferior in strength to damask steel, and in appearance it turned out to be much more beautiful than cast damask steel.

Now, a little more about the types of damask steel and types of damascus - we will make this division because we classify materials according to different principles: regarding damask steel, we will talk about the alloying elements in its composition, and regarding damascus, we will also talk about several technologies.

How does a damask steel knife work against alloy steels?

A properly sharpened damask steel knife will outperform any alloy product. Many people argue about the benefits of damask steel. To demonstrate aggressive cutting, a rope is cut. The tested products were sharpened at 20 degrees.

The test shows fantastic results; a damask steel blade outperformed alloy steel three times in terms of the number of pieces cut. In a specific case, we can say that damask steel blades are truly superior to ordinary knives.

Description of damask knives, weapons from the ancient world

Damask knives have long been overgrown with various legends and myths. Some people believe that knives are made of unique steel that can cut any material, they can serve the owner for decades, and the blade of the blade practically does not need sharpening. Some people say that compared to current alloys, damask steel has begun to lose ground and is only suitable as a souvenir.

What to look for when choosing

To purchase a normal damask steel product, you should pay attention to the following things:

- The monolithic damask steel rings clearly and continuously. If the blade is not solid, but consists of layers of fluctuations of various types, then the sound will be low and short.

- Pay attention to the assembly of the knife, it should be without gaps and there should be no burrs on the blade.

- The drawing should be chaotic on a dark background. Lines and dots should be clear and large in nature. If the lines are large, smooth and symmetrical, then you have Damascus.

- From a responsible manufacturer, the specified parameters of the weight and size of the blade must match the real product.

- Check the availability of documents - certificate and warranty card.

Which knives did you like best?

HuntingKitchen

Sharpening features

Believing that a damask steel knife will never become dull is, at the very least, stupid. Any product will have to be sharpened sooner or later. Although damask steel is distinguished by its stable cutting edge, it will still have to be sharpened. This process has its own characteristics:

- the blade should be sharpened at the required angle; it is best to maintain the angle that the master set for it at the very beginning;

- Please note that it will take a lot of time and effort to sharpen the product, the blade is very hard;

- Large grain stones will not work here; you will need Japanese water or diamond stones.

Modern damask knives

Damask steel remains a universal material from which various models of knives are produced for different needs:

- hunting, fishing and tourist (popular folding knives);

- military;

- household (as a rule, these are knives with a small blade, which are suitable for cutting fish and meat, slicing vegetables and fruits);

- gift

The latter are popular among collectors because of their unique design, jewelry made of precious stones, and inserts made of expensive wood. Among utility knives made of damask steel, fillet models are popular.

Currently, cermets are a serious competitor to damask steel. They are similar in cutting properties and cost, and are not subject to rust. But ceramic knives are much less suitable for use in “field” conditions; compared to damask steel, they are more fragile and inferior in terms of beauty.

Modern manufacturers of damask knives try to experiment and add other elements to the alloy, giving the blade new properties.

Thus, the addition of chrome and nickel additives increases rust resistance. Collectible models can be coated with a layer of silver to add more beauty.

Rules of use and care

For proper use of the products, you must follow the following rules:

- After using a knife, it should be rinsed in running water and wiped dry.

- The damask steel blade should be stored in a warm and dry place, the possibility of condensation should be excluded.

- For long-term storage, use a leather case and cover the blade with paraffin.

- If pockets of rust appear, use kerosene against it. Strongly aggressive substances are contraindicated.

Knife blades made of damask steel.

Damask steel: what is damask steel and where did it come from?

Damask steel is an alloy of iron and carbon, and the content of the latter is very high, and is almost close to its composition in cast iron. After specific heat treatment, the hardness of this alloy reaches 64 HRC, and its etched surface has a characteristic and very beautiful pattern.

However, if you compare damask alloy and simple high-carbon steel, you can see the same pattern as when comparing diamond and coal: the composition is the same, but the properties are different. The technology for producing damask steel is extremely complex and does not lie on the surface.

Data from archaeological research suggest that even 2.5 thousand years ago, Indian blacksmiths knew how to make weapons from a special metal. Indian patterned steel cost a fortune, and the masters of the blacksmith caste strictly guarded their secrets. Experienced craftsmen forged blades from it over several years, using rather small hammers instead of a standard hammer by blacksmiths.

Demand for weapons made of damask steel

Weapons and household products made from damask steel are in constant demand. Despite the emergence of modern alloys, damask steel remains desirable among collectors, hunters and ordinary people. Today steel can be called a real brand.

Damask steel is only suitable for making knives. She doesn’t find herself in other industries. But it should be noted that there are a lot of low quality fakes on the market. And such knives are only suitable as a decorative item.

It should be noted that the production of real damask steel is quite difficult. For this reason, the products are very expensive. It will not be possible to make such a knife in a simple garage. But there are simply no blanks in the form of bars on the market.

Does damask steel rust?

Bulat is susceptible to corrosion and requires careful care. Due to its weak resistance, the knife must be thoroughly cleaned and wiped after each use.

For removal, use rags, plus use alkaline oils (or neutral types). In an environment with high humidity, the blade should be wiped with Vaseline after each use for preventive purposes.

But some craftsmen (for example, P. Pampukha) were able to produce stainless damask steel by adding a number of additional elements to it. But the cost of such a knife is many times higher.

Steel knives

Bulat is a collective name for hard and viscous alloys of iron and carbon. Chemically, damask steel differs from steel in the quantitative carbon content. This alloy is characterized by the fact that it has good impact strength, is able to resist corrosion for a long time and at the same time keeps the cutting edge sharp for a long time.

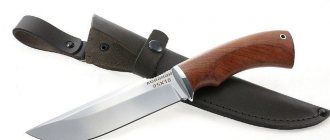

Knife – Veles

The Veles knife is a powerful tool for rough work. The knife has a through-type mounting, which means that the shank reaches the end of the handle. This gives the knife greater reliability. Supplied with a traditional leather sheath with vertical suspension. Product characteristics:

- Knife length: 275 mm;

- Blade length: 145 mm;

- Handle length: 130 mm;

- Butt thickness: 2.2 mm;

- Blade steel: Bulat;

- Handle material: Wood;

- Manufacturer: Bulat LLC, Russia;

- Weight: 188 grams.

Blade for rough work.

Kitchen knife – Chef

A handmade knife from Zlatoust craftsmen guarantees high quality and long service life. The handle is made of stabilized wood, the guard is made of carbon. Pins are inserted to decorate the handle. The blade is made of damask steel, which is famous for its good cutting and ability to hold an edge for a long time. Knife characteristics:

- Steel: Cast damask steel;

- Handle: Stabilized burl;

- Total length: 325;

- Blade length: 190;

- Blade width: 46;

- Blade thickness: 3.5;

- Blade hardness: 62 HRC.

A knife for working in the kitchen.

Knife – Cherry (NR-43)

An excellent replica of a scout knife from Zlatoust craftsmen, the knife is made of high-quality materials and the famous damask steel. The handle is made of micarta in “military” color with inserts of ebonite and nickel silver. The guard is made of stainless steel, and the butt is made of titanium. The kit includes a key for disassembling the knife. Product characteristics:

- Steel: Cast damask steel;

- Handle: Micarta;

- Total length: 270;

- Blade length: 157;

- Blade width: 24;

- Blade thickness: 4.0;

- Blade hardness: 62-64 HRC.

Military knife - cherry.

Where and how damask steel was hardened: historical prerequisites for quality

Bulat steel is the highest quality steel. It is from this that military weapons are made. Knives made of this steel have high elasticity and toughness; the combination of these two characteristics allows the knife to have high cutting qualities.

Bulat steel is a cast carbon steel that has a specific structure. The hardness of a damask steel blade after heat treatment is 64 HRC.

Bulat vs Damascus

Both damask steel and damascus are beautiful steels that are quite close in appearance and character. Damascus is formed by bonding several plates of different metals. This is done as follows: several thin plates are taken and forged several times, after which the metals are mixed and Damascus is formed.

Bulat steel is boiled. The secret of this metal lies in the composition and proportions of the alloy. During cooking, pay attention to every little detail. The metal alloy should be welded, but not overexposed to heat. Further processing of the alloy depends on the preference of the craftsman. You can unforge the entire ingot, or you can cut it lengthwise or crosswise; the future design and strength of the blade will depend on these actions.

Where did damask steel come from?

Bulat steel came from India. In India, as you know, people can meditate for decades or make one sword for several years. For example, the old Hindu blacksmiths had hammers that looked more like hammers, which meant they had more time to work. The blacksmiths who forged weapons were scrupulous about the secrets of damask steel and the technology of its manufacture. They passed on knowledge only by word of mouth to their eldest son. This was done for a reason: even in ancient times there was a global arms market with fairly strong competition.

Somewhat later, after India, the craftsmen of Syria and Spain mastered the art of making damask steel. Currently, there is documentary evidence that the production of sabers and daggers made of damask steel was established in Rus'.

Legends still tell about the wonderful properties of damask steel. Memories of her are found in the records of historians, monks, and novels.

The very first information about damask steel has reached modern times from participants in the campaigns of Alexander the Great.

By the end of the 18th century. all the secrets of producing damask steel were lost.

2 legends about damask steel

At the end of the 4th century. BC, Alexander the Great and the Indian king Porus, at the head of their troops, met on the Hydaspes River. The bloody battle ended tragically for the Indians - the Indian troops were defeated, and King Porus, who fought bravely and was mortally wounded, was captured. Alexander the Great was amazed - the king’s armor had no scratches or dents from spears and arrows. The reason for this was the shell, which was made of metal of amazing hardness.

Indian swords were also made from the same metal. After Alexander the Great's campaign in India, methods of obtaining highly durable swords penetrated into Europe through Syria and Persia. The Persians called this steel “pulat”, and the Europeans called it “damask steel”.

Mention of damask steel can also be found in W. Scott’s novel “The Talisman”. It tells about the competition between the English king Richard the Lionheart and Sultan Saladin.

Saladin's damask saber mercilessly cut iron spears in half and freely cut through the thin silk blanket thrown into the air.

Pattern is a feature of damask steel

Damask steel is visually easy to distinguish from any other. An important feature of damask steel is the pattern. It appears on its surface after etching with various chemical reagents. This pattern is used to judge the possible quality of steel or the method of its production. Since ancient times, damask steel patterns have had their own names: “sham”, “taban”, “kara-taban” and others.

The damask steel pattern is formed during a drop in the casting temperature and represents light lines of a cementite network of deposited carbon along the boundaries of austenite grains. It is important to know that the darker the background and the lighter the lines, the more expensive the damask steel.

Did damask steel exist?

The uniqueness of damask steel blades made scientists doubt: is it possible that damask steel did not exist at all? After all, even today it is not possible to impart such properties to metal, let alone times 2 thousand years distant from us.

It is not easy to verify legends and theories, because during excavations scientists find only fragments of blades. Several years ago, one of the members of the Russian Geographical Society, Doctor of Technical Sciences Igor Taganov, decided to finally debunk the myth about damask steel. He went on expeditions to India and Iran and collected samples of blades.

Not long ago, Taganov donated several fragments to the Department of Plastic Processing of Metals at St. Petersburg State Polytechnic University. It seemed surprising to the professor that with modern methods of analyzing materials, when the composition of any alloy can be described down to almost every atom, damask steel still remains a secret to science. Vasily Mishin, a member of the department, took on the task of studying the samples.

However, instead of proving that damask steel is just a myth, he not only revealed the secret of steel, but also recreated it.

First of all, Vasily Mishin studied the chemical composition of the material from which the blades were made using a spectrometer. The most surprising thing even for modern metallurgists is that the structure of damask steel is completely uncharacteristic of high-carbon steels, but this is what damask steel essentially is. Vasily Mishin managed to recreate the alloy.

Production of damask steel

Bulat is not the same as “Damascus” - “welded” steel. Damask steel is the so-called “cast steel”, and work on a damask blade begins with making a crucible. This is a special fireproof vessel in which steel will be cooked. The crucible is filled with a mixture of a certain composition. Masters often keep the secrets of this composition “more than the apple of their eye.”

A crucible filled with iron or certain types of steel with special additives is placed in the furnace. The furnace raises the temperature necessary to create a homogeneous alloy. After some time, when the furnace has cooled down, the crucible is removed, broken and the steel ingot is removed. This ingot is later forged into strips.

Blades are then made from these strips, both for edged weapons and for ordinary knives.

The technology for producing cast damask steel has many nuances and its implementation requires knowledge at the intuition level of an experienced blacksmith. In a nutshell, the technology is as follows:

- sponge iron is forged with a hammer;

- iron is mixed with charcoal and then placed in a crucible;

- the crucible is heated to a temperature of 1200 degrees;

- Then the crucible cools very slowly and a wuts is obtained - a small ingot of damask steel.

Buy products made of damask steel in our store. You can contact our consultants on the main page of our website, they will promptly answer all your questions.

Source: https://rognar.ru/blog/gde-i-kak-zakalyalas-bulatnaya-stal-istoricheskie-predposylki-kachestva/

Production methods and materials

The secret of damask steel production has been revealed. It turned out that it was simple cast steel, obtained by alloying two types of iron. The secret thanks to which the blade received its characteristics was proper heat treatment:

- The metal was heated to a certain temperature;

- It was then slowly cooled.

- A crystallization effect occurred: cementite formed throughout the depth of the blade, as a result of which the steel became strong.

- They forged it with a lightweight hammer so as not to damage the cementite crystals that appeared.

It turns out that the difficulty lies not in the selection of source materials, but in the reproduction of the required temperature and the careful work of the blacksmith with steel.

Advantages and disadvantages

Bulat is a unique steel that is difficult to compare with anything. I could write a lot about its advantages, but for the sake of fairness I will choose only the main ones.

- high hardness - 64 units, holds sharpening for a long time,

- an organic combination of strength and elasticity - with some effort the blade can be bent, but it is almost impossible to break;

- the ability to sharpen to a razor sharpness and hold an edge for a long time,

- beauty and sophistication thanks to the indescribable pattern on the blade, which appears during the production process.

Disadvantages of damask steel:

- the price is above average, which is fully compensated by the beauty of the blade,

- a large number of fakes - it is not recommended to buy from artisans,

- Dressing a knife requires a certain skill.