Home / Consumables

Back

Reading time: 13 min

0

304

- What types of electrodes are there?

- Basic electrode coating - characteristics

- From the history of coatings

- Purpose of electrode coating What functions does high-quality coating provide?

- Coating diameter

- Non-consumable electrodes

What types of electrodes are there?

Electrodes applicable for manual arc welding are divided into consumable and non-consumable. Rods that melt during welding are made of cast iron, steel, copper or other metal, depending on the material. They play the role of an anode or cathode, and also act as a filler material. They can be covered or uncovered.

The coating in the melting rods performs many functions, from holding the arc to forming a gas cloud that prevents oxidation of the weld. Non-consumable electrodes for welding are made from various refractory materials - graphite, tungsten or coal. They serve to ignite and hold the arc, and filling the seam with additives is carried out using manual supply of fusible material.

About metalworking

Processing of threaded surfaces is an operation that is carried out by removing a layer of material (chips) from the machined surface or without removing chips, i.e., plastic deformation. In the first case, we are talking about cutting a thread, and in the second, about rolling it. When assembling and repairing equipment and carrying out installation work, cutting or rolling threads is used manually or using hand-held mechanized tools.

A threaded rod that has a screw surface along its entire length or some part of it is called a screw , and a hole that has a screw surface is called a nut .

Thread elements (Fig. 1) are certain numerical parameters that characterize the thread.

Thread pitch P is the distance in millimeters between the tops of two adjacent threads, measured parallel to its axis.

Profile height H is the distance from the top of the thread to the base of the profile, measured in the direction perpendicular to the thread axis.

Rice. 1. Elements of triangular thread: α - profile angle; P - thread pitch; d is the outer diameter of the thread; d1 - internal thread diameter; d2 - average thread diameter; H - thread profile height

Rice. 3.24. Elements of triangular thread: a - profile angle; P - thread pitch; d is the outer diameter of the thread; d1 - internal thread diameter; d2 - average thread diameter; H - thread profile height

Profile angle α is the angle between the straight sections of the sides of the thread profile.

The outer diameter of the thread d is the largest diameter of the thread, which is measured along its tops in a direction perpendicular to the axis.

The internal diameter of a thread is the smallest distance between opposing thread roots, measured perpendicular to the axis.

The average thread diameter d2 is the diameter of a conditional circle drawn in the middle of the thread profile between the bottom of the recess and the top of the protrusion, measured in the direction perpendicular to the axis.

Tools and devices for cutting external and internal threads by hand. To cut external and internal threads manually, special thread-cutting tools (taps and dies) and devices are used to create the torque on the tool necessary to provide cutting forces during the processing process.

The tap (Fig. 2) consists of two parts: the working part, which ensures the cutting process, and the tail, at the end of which there is a square protrusion for installing the driver. The working part of the tap includes a cutting (taking) part, which ensures the removal of the main allowance for processing, and a calibrating part, which carries out the final processing of the thread. Taps for manual threading are made in the form of sets of two or three pieces (rough, medium and finishing), which are marked with circular marks on the tail part (one, two and three marks, respectively).

Rice. 2. Tap: 1 - thread (turn); 2 - square; 3— shank; 4 - groove

To create torque on the cutting tool (tap), special devices are used - wrenches of various designs.

The universal driver (Fig. 3) is a frame with two crackers - movable and fixed, forming a square hole and securing the tail part of the tap.

Rice. 3. Sliding knob: 1 - frame; 2 - coupling; 3 - handle; 4, 5 - movable and fixed cracker, respectively; a is the side of the square

A driver with switching cams (safety) (Fig. 4, a) allows you to protect the tap from breakage by disengaging the cams of the body and bushing when the force transmitted by the driver exceeds the permissible value.

The end driver (Fig. 4, b) is used when cutting threads in hard-to-reach places, as it allows you to work with one hand.

A ratchet driver (Fig. 4, c) is used for cutting threads in hard-to-reach places, when the driver can be turned at a small angle at a time.

Rice. 4. Gates: a - safety: 1 - body; 2 - bushing; 3 - spring; b - end; c - with ratchet

A die is a tool for cutting external threads, consisting of two parts: a tapping and a calibrating one. Their purpose is the same as that of the corresponding parts of the working part of the tap. When manually cutting threads, dies of various designs are used.

Round dies (Fig. 5, a) are a threaded ring with several grooves for forming cutting edges and removing chips. They are made whole and cut. Due to their springy properties, the dies allow you to adjust the average diameter of the thread being cut.

Square dies (Fig. 5, b) consist of two halves, which are secured in a special frame with handles - a clamp.

The clamp provides the ability to regulate the average diameter of the thread being cut.

Rice. 5. Threading dies: a - round: 1 - intake part; 2 - calibrating part; 3 - chip groove; b - square (sliding): 1 - die; 2 - die

To create a torque and ensure the cutting process when cutting external threads with dies, special devices are used - cranks (for round dies) and clamps (for split dies).

The driver for round dies (Fig. 6) is a round frame with a recess in which a round die is placed, held from turning by three locking screws. The fourth screw allows you to adjust the average diameter of the thread when using a split round die to cut it.

Rice. 6. Driver for round dies.

The die (see Fig. 5, b) is a square frame with protrusions into which the grooves of the die fit. One of the halves of the die can be moved using a screw, adjusting the average diameter of the thread being cut.

Hand-held power tools for cutting internal threads can be equipped with either a pneumatic or an electric drive.

A pneumatically driven thread cutter (Fig. 7) is designed for cutting small diameter threads. The pneumatic motor 1 rotates the spindle 4. When you press the handle 3 of the housing, threading occurs. When the pressure on handle 3 is released, the spindle 4 moves under the influence of the spring and its movement is reversed. In this case, the tap 5 is rapidly unscrewed from the hole in the workpiece 6. The tool is turned on by pressing the trigger 2.

Rice. 7. Thread cutter with pneumatic drive: 1 - pneumatic motor; 2 - trigger; 3 - handle; 4 - spindle; 5 - tap; 6 - blank

Electrically driven thread cutter (Fig. equipped with a built-in electric motor, reversing mechanism and gearbox.

Rice. 8. Electrically driven thread cutter

Preparing rods and holes for threading. During the thread cutting process, not only the removal of a layer of material from the surface of the workpiece occurs, but also plastic deformation of the machined surface, which is accompanied by the extrusion of part of the workpiece metal from the recesses of the thread turns to the tops. This phenomenon must be taken into account when determining the diameters of rods and holes for threading. Therefore, it is advisable to determine the dimensions of the workpieces using reference tables, in which they are given taking into account all the factors affecting the cutting process.

In practice, the diameter of the hole for the thread is chosen equal to its nominal size, reduced by the pitch. For example, when cutting an M10 thread, the hole diameter should be 10 - 1.5 = 8.5 mm.

When cutting external threads, the diameter of the rod should be 0.1 ... 0.2 mm less than the nominal diameter of the thread, depending on its size.

When processing external and internal threads, it is necessary to adhere to a number of rules.

- Manual threading must be done with the tap or die generously lubricated with machine oil.

- When cutting threads by hand, you should periodically cut off the resulting chips by moving the tap or die back 1/2 turn.

- After cutting the thread, it is necessary to control its quality: by external inspection (avoiding scuffing and torn threads) and with a thread gauge, the bore of which should be screwed on easily, by hand.

The rules for cutting external threads manually are as follows.

- Before cutting the thread, check the diameter of the rod, which should be 0.1 ... 0.2 mm less than the nominal thread size.

- Make a chamfer at the top of the rod so that it is concentric with the axis of the rod. In this case, its diameter should not be less than the internal diameter of the thread, and the angle of inclination relative to the axis of the rod should be 60°.

- The rod should be firmly secured in the vice, checking its perpendicularity to the clamping jaws using a square.

The rules for processing internal threads manually are as follows.

- Check that the diameter of the hole matches the size of the thread being cut.

- Check that the hole depth meets the drawing requirements when cutting blind threads.

- Using a square, check that the tap axis is perpendicular to the plane of the workpiece in the hole of which the thread is being cut.

- Use all taps in the set when cutting threads.

- Periodically clean blind holes from chips when cutting threads into them.

Threading on pipes is carried out using special tools - clamps and thread-cutting dies.

A die with sliding dies (Fig. 9) is a device most often used for cutting external threads on pipes. The die is equipped with a set of sliding dies for cutting threads with a diameter of 1/2…3/4; 1…11/4; and 11/2…2″. The clamp is mounted in such a way that four dies 5 moving in its body 1 can simultaneously approach the center or diverge from it. The movement of the dies is ensured by a special rotary device driven by a handle 4. The precise installation of the dies to the size of the thread being cut is carried out using a dial located on the body, and the installation movements are carried out by a worm gear 3. After installation, the position of the dies is fixed with a special device - a “pawl”. The cutting force is transmitted to the tool using handles 2.

Rice. 9. Jig for cutting pipe threads: 1 - body; 2 — handles; 3 - worm gear; 4 — handle for moving dies; 5 - dies

A round thread-cutting comb (Fig. 10, a) is used for cutting pipe threads on lathes and drilling machines. Combs are produced in sets of four. Thread cutting is carried out using a special self-opening screw-cutting head (Fig. 10, b).

Rice. 10. Round thread-cutting comb (a) and self-opening head for attaching it (b)

To facilitate the operation of the tool and improve the quality of threads obtained when cutting threads, COTS is used. Their choice depends on the material of the workpiece being processed. For example, an emulsion is used to cool steel workpieces (structural, tool and alloy steel). Kerosene should be used to cool cast iron and aluminum. Threading in copper, brass and bronze workpieces can be done without cooling.

Basic electrode coating - characteristics

Any electrode coating is a mixture of crushed components and a binder.

The powder mixture is applied to a metal rod and serves to protect against various external factors. The main coating is designated by the letter “B”. This mixture is produced from calcium and magnesium carbonates. These include elements such as marble, magnesite, dolomite. Fluorspar (CaF2) is also added to the listed minerals as a slag diluent. Therefore, they are also called calcium fluoride coated electrodes.

Characteristics:

- The gas-protective environment that is formed during the welding process consists almost entirely of CO and CO2.

- The low hydrogen content allows the formation of strong seams without the risk of cracks.

- Low content of oxygen and various impurities (for example, sulfur and phosphorus) in the weld metal.

- In most cases, operation should be carried out on direct current. The presence of plastic spar in the coating composition impairs the performance of alternating current electrodes. Therefore, most often a direct current of reverse polarity is needed.

Exam tickets to test the knowledge of welding specialists level 1

TICKET 9

QUESTION 1. When welding which steels listed below are cold cracks more likely to occur?

1. With carbon content up to 0.25%.

2. With a carbon content of more than 0.4%.

3. With carbon content from 0.25% to 0.35%.

QUESTION 2. What letter of the Russian alphabet denotes carbon and zirconium in steel markings?

1. The presence of carbon is not indicated by a letter, zirconium-C.

2. Carbon -U, zirconium - do not indicate.

3. Carbon - C, zirconium - K.

QUESTION 3. What steels are classified as austenitic steels?

1. 08Х18Н9, 03Х16Н9М2, 10Х17Н13М2Т.

2. 08Х13, 05Х12Н2М, 08Х14МФ.

3. 12MH, 12ХМ, 20ХМА.

QUESTION 4. What physical quantity is determined during static bending? (I - IV)

1. Bending strength.

2. Bending toughness.

3. Bend angle.

QUESTION 5. What form of static characteristic should the power source for the RDS have?

1. Steeply falling.

2. Tough.

3. Increasing.

QUESTION 6. What should be monitored when checking the condition and dimensions of welding electrodes?

1. The length of the uncovered part of the electrode.

2. Electrode length.

3. The diameter of the metal rod, the thickness of the coating and the uniformity of its application.

QUESTION 7. What do the letter “E” and the numbers following it mean in the marking of electrodes?

1. Electrode brand and development number.

2. Manufacturer and coating number.

3. Type of electrode and guaranteed tensile strength of the metal deposited by them in kgf/mm2.

QUESTION 8. What is the role of alloying elements in the electrode coating?

1. Give the deposited metal special properties.

2. Provide good separability of the slag crust.

3. Reduce the degree of splashing of liquid metal.

QUESTION 9. Which brands of electrodes have a basic coating?

1. ANO-3, ANO-6, MR-3.

2. UONII 13/45, UONII 13/55, SM-11.

3. ANO-7, ANO-8.

QUESTION 10. Indicate the type (alternating or direct) and polarity of current (direct or reverse) recommended for performing manual arc welding with cellulose-coated electrodes.

1. On direct current, straight polarity.

2. On direct current, reverse polarity.

3. On alternating current.

QUESTION 11: When do hot cracks form?

1. A few minutes after the welded joint has cooled below a temperature of 1000C.

2. During crystallization of the weld metal.

3. Some time after the welded joint has cooled to room temperature.

QUESTION 12. Specify the reasons for the formation of slag inclusions during RDS?

1. Incorrect choice of welding modes, use of low-quality electrodes, poor cleaning of the surface of the previous layer of the weld.

2. Use of electrodes with thick coating, welding without cutting edges.

3. Welding at high ambient humidity or at low temperature.

QUESTION 13. How to fix seams with an undercut depth of more than 15% of the edge thickness?

1. Mechanically remove the metal in the undercut area and apply a thread suture.

2. Fuse the undercut area with a thread seam.

3. Make a smooth transition by mechanical removal from the deposited bead to the base metal.

QUESTION 14. Which of the following groups of steels are classified as high-chromium?

1. 03Х16Н9М2, 08Х18Н10, 10ХН1М.

2. 08Х13, 06Х12Н3Д, 1Х12В2МФ.

3. 10Х2М, 20ХМА.

QUESTION 15. What tool is used for visual and measuring inspection to detect unacceptable surface cracks in a weld?

1. Welder template.

2. Magnifying glass and ruler.

3. Measuring microscope.

QUESTION 16. What causes the appearance of pores in the weld metal?

1. Strong wind when welding in an open area.

2. High welding speed.

3. The gap in the joint is too small.

QUESTION 17: Who connects the welding power source to the switchboard?

1. Welding team foreman or foreman.

2. A welder who has passed the electrical safety exam.

3. Electrician on duty.

QUESTION 18. What causes the appearance of lack of penetration at the root of the seam?

1. Small gap in the joint during assembly for welding.

2. Excessive cutting angle.

3. Overestimation of the welding current during welding.

QUESTION 19. At what age are welders allowed to perform welding work?

1. From 16 years old.

2. From 18 years of age.

3. From the age of 20.

QUESTION 20. What determines the choice of thickness of protective glass for a welding helmet during welding welding?

1. From the visual acuity of the welder.

2. On the magnitude of the welding current.

3. On the magnitude of the welding current and arc voltage.

To go to the next page, use the page navigation below

Pages: 9

From the history of coatings

The development of high-quality electrode coatings and their industrial development can be considered one of the largest scientific and technical achievements that played a huge role in the development of world technology. Despite the fact that the first patent for coating electrodes was received by the founder of ESAB, Oskar Kelberg, back in 1906, the production of coated electrodes in the USSR began only in the 30s of the 20th century. Initially, electrodes with a thin coating were used, which performed the only role of stabilizing the welding arc. It consisted of only two components - powdered chalk and liquid glass. Chalk provided ionization of the arc, and liquid glass, along with the ionization function, also played the role of a binding component.

Welding with an electrode with chalk coating, although it made it possible to weld metal in principle, did not provide protection for the molten pool from atmospheric gases. The seams made with such electrodes had a nitrogen content of 50 times, oxygen 5-10 times more than the base metal. At the same time, the carbon content in the deposited metal decreased by 4 times. All this made it possible to use chalk electrodes only for welding non-critical structures. The production of electrodes with multicomponent coatings, which, along with arc stabilization and protection of the weld pool from atmospheric gases, began in the USSR only in 1935.

Electrodes with cellulose coating (symbol C)

Up to 50% of the composition of electrodes with a cellulose coating is made up of organic components, usually cellulose. It may also contain organic resins, ferroalloys, talc and other substances.

The weld metal obtained using cellulose electrodes corresponds in chemical composition to semi-quiet or calm steel. At the same time, it contains an increased amount of hydrogen. In terms of the mechanical properties of the weld metal, electrodes with this coating correspond to types E42, E46 and E50 according to GOST 9467-75 and have a tensile strength of up to 412 MPa, 451 MPa and 490 MPa , respectively.

Their main feature is the ability to make vertical seams from top to bottom. This is achieved due to the formation of a small amount of slag, which does not flow down, as well as a large amount of protective gases. During one-sided welding by weight, electrodes with a cellulose coating are characterized by the formation of a uniform back seam bead.

It should be noted that these electrodes have an increased amount of spatter and reduced ductility of the weld metal, due to the large amount of hydrogen generated during the combustion of organic components.

Advantages of cellulose-coated electrodes

- Easy ignition and stable arc burning

- Ability to perform welding work on both direct and alternating current

- Easy slag separation

- Possibility of welding in all spatial positions

- Excellent weld pool protection

- No release of dangerous toxins

- Clean root seam

Disadvantages of cellulose-coated electrodes

- Heavy splashes of metal

- Scaly surface suture

- High hydrogen content in shielding gas

- Tendency to small undercuts along edges (cracks)

- It is necessary to calcinate the electrodes before starting work.

Areas of use

Cellulose electrodes are used in welding low-alloy steels. Effective when welding the root seam of main pipelines.

Purpose of electrode coating

The main task that manufacturers assign to the coating of electrodes for manual arc welding is the protection of the melting metal. They protect the melting metal from interaction with air, preventing oxidation, and make the finished seam high-quality and durable.

When working with a welding machine, the protective coating creates a shell of slag on droplets of electrode metal moving along the arc gap, as well as on the melting surface of the parts being welded to each other.

A protective layer of slag reduces the speed at which the metal cools and the speed of its hardening, due to which gas and other inclusions have time to escape from it, which negatively affect the strength of the structure. As a rule, protective spraying consists of a whole complex of slag-forming elements, such as kaolin or titanium concentrate.

What functions does high-quality coating provide?

The coating covering the metal rods performs a number of primary and secondary tasks. The most important ones include:

- Protection of the arc itself and the metal in the area of the weld pool from interaction with nitrogen, oxygen, and hydrogen contained in water vapor present in the atmosphere. Coating the rod creates a two-stage protection: vapors of carbon dioxide and carbon oxides enveloping the working area, and a slag film on the surface layer of the molten metal;

- ensuring high-quality crystallization of the seam without the formation of pores, slagging and cracks.

Secondary, but no less important tasks:

- ensuring uninterrupted arc burning in a wide range of operating modes, simplifying the ignition process. Arc stability is achieved due to the presence in the surface layer of the rod of components that are not prone to ionization in a large volume. This helps to increase the number of combustion-stabilizing ions in the arc space;

- removal of oxygen dissolved in it from the metal of the weld pool. To do this, ferroalloys are added to the coating composition, which are lighter and faster than the metal itself and react with oxygen;

- cleaning the weld metal from impurities (refining).

What does the electrode coating consist of?

To create an electrode coating with specified properties, various ingredients and their combinations are used. All of them can be divided into categories according to the role they perform in welding.

The main component of the electrode coating

- Gas-forming. When welding, they create a gas cloud around the arc. This gas prevents oxygen, hydrogen and nitrogen from the atmosphere from penetrating the metal. This category includes: cellulose, food flour, wood flour, dextrin, starch and carbonates.

- Slag-forming. A slag layer is formed, which protects the metal from the atmosphere and slows down its cooling. These include: dolomite, marble, kaolin, manganese ore, quartz sand, chalk, feldspar, titanium concentrate and other substances that can be converted into slag.

- Alloying. These additives give the weld metal special properties: strength, ductility, resistance to oxidation, high and low temperatures. Among these substances: tungsten, molybdenum, titanium, manganese, nickel, vanadium and chromium.

- Deoxidizing. Oxygen in welded joints increases the brittleness of the metal. You can remove it by adding aluminum, silicon, titanium or manganese to the molten metal.

- Stabilizing. They could also be classified as gas-forming, since they also emit gas. But this gas is not intended to protect the weld pool, but to maintain the arc. This includes chromate, saltpeter, potash and other potassium compounds.

- Binders. The purpose of these coating components is to connect the coating elements to each other and to the welding wire. Liquid glass is most widely used as a binding component.

- Shaping. They improve the plastic properties of the coating, which is important when applying the coating by machine. These substances include kaolin, bentonite and others.

To increase the efficiency of the welding process, iron powder can be added to the electrode coating.

Some ingredients can perform more than one function: for example, create a protective gas cloud that supports the arc, and then turn into slag that protects the weld metal.

Main types of electrode coating

For manual welding, 4 types of electrode surface coatings are used, which are determined by markings (letters A, B, P, C). Let's consider the features of their composition and application.

1. Sour (A)

They consist of oxides of iron and manganese, silica, ferromanganese, cellulose, and starch. They form a stable burning arc and ensure its rapid ignition when powered with low voltage. Power supply is carried out by alternating or direct current. Insensitive to rusted edges that are fused. The disadvantages are harmful fumes when heated, splashing of the molten substance. For this type of material, temperature calcination before use is not allowed. Low slag detachability can lead (with several layers) to slag surfacing. The main area of application is alloying low-alloy steel. Consumables OZCH-2 are recommended for cast iron, and TsL-6 for molybdenum alloys.

2. Basic or calcium fluoride (B)

The composition includes calcium and magnesium carbonates, fusible spar, ferromanganese. Due to weak oxidation, they ensure the release of oxygen from the molten material. The use of consumables helps protect against the formation of cracks in the seams; maximum efficiency is achieved when electric welding rigid structures with several layers. The best with such a coating are considered to be the Japanese Kobelco LB-52U, domestic UONI 13/55, OZL-8 and FUBAG FB 13/55.

To maintain a stable arc, you will need a DC source of reverse polarity. With alternating current, the spar that is included in the composition creates uneven combustion. Disadvantages include susceptibility to moisture, so consumables must be stored in a dry place and calcined immediately before use. The edges of the structures must first be cleaned of rust so that pores do not appear in the seams.

3. Rutile (R)

Contains the addition of titanium dioxide (rutile), calcium and magnesium carbonates, ferromanganese, silica. Among the available options, you can consider Fubag FB 3. Consumables give good results when soldering rusty areas and connecting primed elements without the formation of pores. Even welders with little experience can achieve an even, durable seam; no preliminary grinding of the edge is required. Alloying is allowed in any position of the structure. There is virtually no melt spatter.

4. Cellulose (C)

Consumables are used in most cases for welding pipelines transporting liquids. They are not suitable for conditions where transportation at high temperatures is planned. Electrodes can be reused. Before use, the rods must be dried and calcined.

Slag-forming materials and alloying additives (ferromanganese, silicates, titanium dioxide) are added to organic substances (up to 50% oxycellulose, starch). They provide good arc burning with a constant supply current and allow welders to develop high productivity due to the ease of welding. Welding can be done in any position. The process releases a little slag, so it is convenient to use such consumables when placing the structure vertically. They are also suitable for hard-to-reach places. The downside is that the surface of the seams is rough, so additional sanding will be required. During operation, up to 15% of the molten material is sprayed. In addition to the main coatings, combined types of electrode coatings are also often used, for example, acid-rutile (AC) or rutile-cellulose (RC) consumables Fubag FB 46.

To decide which type of coating electrodes are needed, the following factors should be taken into account:

- Thickness and composition of the welded structure (copper, cast iron, stainless, low-carbon or high-alloy steel). For example, consumables of the LMZ-1 and ANV-1 brands are optimal for high-alloy steel.

- Operating requirements (pre-calcination, position of the rod during operation). The easiest way to weld is in a horizontal position; in a vertical position, slag may drain. Work in hard-to-reach places at an angle is performed by qualified welders.

- The brand of the welding machine used. Often in the name of welding equipment there are inserts indicating the specifics of the use of consumables. A striking example will be the IN 226 CEL model, the name of which indicates the ability to effectively work with cellulose-coated electrodes.

Types of electrode coatings

Home / Library / Welding materials / Types of electrode coatings

Industrial protective coatings for arc welding electrodes of mainly steels can be classified into the following main types based on their metallurgical effect in the weld pool.

Stabilizing coating , into which chemical compounds of potassium, sodium, as well as calcium, magnesium and barium carbonates are introduced to increase the stability of arc combustion, especially on alternating current.

The presence of alkali and alkaline earth metal salts in the coating leads to a decrease in the energy released at the cathode. Due to large losses as a result of waste and spattering, low melting speed, and the inability to weld at high welding currents, electrodes with a stabilizing coating have very low productivity.

Acid (ore-acidic) coating , which is based on oxides of manganese, iron, and silicon. Gas protection is carried out by organic components that burn during the melting process of the electrode. Ferromanganese is introduced into the coating as deoxidizing agents. From an energy point of view, electrodes with this coating have a number of advantages: they are characterized by a fairly high melting rate and provide welding in forced modes. Acid-coated electrodes also have high melting capacity. They are most technologically advanced when welding in the lower position, but can also be used to make vertical and horizontal seams.

The oxidation coating contains predominantly iron oxides and various silicates (kaolin, talc, mica, feldspar, etc.). Most oxidation-coated electrodes contain no deoxidizers at all. A small amount of ferromanganese is added to some compositions.

The slag when welding with these electrodes is heavy, dense, but very easily separated. In most cases, it is capable of self-separation even when welded for cutting.

Electrodes with such a coating have low melting ability. Slag and metal bath are very fluid. Therefore, their use is primarily limited to welding horizontal or vertical fillet welds, as well as boat fillet welds.

In the countries of the former USSR, electrodes of this type were practically not used. Abroad, they are used mainly when welding non-critical structures to make decorative smooth fine-scaled seams, especially narrow ones, i.e. in cases where low characteristics of the mechanical properties of the weld metal are required.

The rutile coating consists primarily of rutile with the addition of feldspar, magnesite and other slag-forming components. Instead of rutile, the coating may contain 45-50% ilmenite. To create gas protection, organic substances (cellulose, dextrin) and carbonates are introduced into the coating.

Ferromanganese is used as an alloying and deoxidizing component. With complex deoxidation, the tendency of the weld metal to form pores increases.

In order to increase the deposition rate, iron powder is often introduced into coatings of this type.

Electrodes with rutile coating have high welding and technological properties and ensure the production of seams with smooth and smooth outlines in all spatial positions. Very widely used in industry and construction.

The cellulose coating contains predominantly organic components to produce large amounts of gases. Rutilosilicate components are most often used as a slag-forming base. In addition to this, the electrode coating sometimes contains a number of special components, such as asbestos.

Deoxidation of the weld pool is most often carried out with the help of ferromanganese, since the introduction of active deoxidizers (ferrotitanium and especially ferrosilicon) would increase the sensitivity of the weld metal to the formation of pores.

Cellulose-coated electrodes are characterized by high melting capacity and significant melting speed. They provide welding in all spatial positions, including welding from top to bottom, with high linear speeds reaching 25 m/h. Welding of the root seam is carried out using the support method with the formation of the reverse side of the seam. Therefore, when welding, there is no need to weld the seams from the inside and the most favorable, from the point of view of performance, form of penetration of welded joints is ensured. Electrodes with a coating of this type are most widely used in domestic practice for welding joints of main pipelines.

The disadvantages include increased losses of electrode metal due to spattering, the formation of narrow crack-like undercuts along the edges being welded, a rough flaky surface of the welds, and a high level of diffusively mobile hydrogen in the weld metal.

The main coating is primarily based on calcium carbonate and calcium fluoride (other fluoride compounds are used much less frequently). Gas protection is created by a stream of CO2 formed during the dissociation of calcium carbonate during the heating and melting of the coating. As deoxidizing agents, the coating may include ferrosilicon, ferromanganese, ferrotitanium and aluminum.

To alloy the weld metal, metal powders can be introduced into the coating.

Welding with electrodes with a basic coating is carried out using direct current of reverse polarity. For welding with alternating current, special measures are required: additional introduction of ionizers into the coating composition, the use of electrodes with a special two-layer coating, etc.

Basic slag is generally suitable for welding in all spatial positions. However, to ensure top-down welding, it must be given special physical properties. The workability of the base coating when welding root seams is usually worse compared to cellulose.

The disadvantages of the main coating include low manufacturability when welding with alternating current; difficulties in the manufacture of electrodes, in particular the use of special additives - plasticizers; sensitivity to the formation of pores when the coating is moistened and the presence of moisture, scale or rust on the welded edges. Due to the high degree of deoxidation, the weld pool adsorbs hydrogen in significantly larger quantities compared to the non-deoxidized one. Therefore, it is necessary to strictly limit the moisture content in the electrode coating by high-temperature calcination at manufacturing plants, re-calcination before welding, storage immediately before welding in special thermal cases, etc.

In domestic practice and abroad, the base coating is used mainly in the manufacture of special-purpose electrodes: high-strength, cold-resistant, heat-resistant, corrosion-resistant, etc.

Rutile carbonate and carbonate-rutile coatings emerged as a result of attempts to combine the advantages of rutile and basic coatings. As a result, the toughness and ductility of the weld metal is slightly increased compared to welds made with rutile electrodes. In addition to this, the welding and technological properties of the electrodes are improved in comparison, for example, with electrodes of the main type, while simultaneously reducing sensitivity to the formation of pores in the weld metal.

Special electrode coatings are classified as so-called hydrophobic coatings. The need for these coatings arises, for example, when performing welding work in particularly humid conditions: with high atmospheric humidity, under water, etc. There are two ways to create hydrophobic coatings: up to 10% of special ones are added to the usual binder of electrode coatings (liquid glass) organosilicon compounds - hydrophobic polymers, which can also be used as synthetic resins, varnishes, etc. The introduction of polymers allows, during the polymerization process, in a mixture with a hardener (ore mineral components), to obtain a hydrophobic resin of complex composition, filling the pores between the coating particles and blocking the paths moisture penetration into the inner layers of the coating; replacement of the silicate binder with a polymerizing organic one, which has a number of special physicochemical properties (required viscosity, adhesion to metal; plasticizing ability; suitable curing mode, etc.).

When used as binding polymers, it is possible to reduce the moisture content in the electrode coating several times and maintain the necessary mechanical strength when working in a humid atmosphere and under water.

The specified classification of electrode coatings, adopted according to international standardization (ISO 2560-73 standard), is to a certain extent arbitrary even when applied to general-purpose electrodes. In the countries of the former USSR and abroad there are a number of intermediate coatings, and for special-purpose electrodes intended, for example, for welding and surfacing of non-ferrous metals and their alloys - specific ones that cannot be classified into groups.

| Selection of flux and wire based on basicity and activity diagrams → |

Share link:

Welding electrode coatings for manual arc welding: types, composition, designations

An electrode for manual arc welding is a metal rod with a protective coating. The components of the coating provide protection of the welding zone from oxidation by air and contribute to increased ionization. Coated rods are used for both ferrous and non-ferrous metals, as well as alloys.

The main task that manufacturers assign to the coating of electrodes for manual arc welding is the protection of the melting metal. They protect the melting metal from interaction with air, preventing oxidation, and make the finished seam high-quality and durable.

When working with a welding machine, the protective coating creates a shell of slag on droplets of electrode metal moving along the arc gap, as well as on the melting surface of the parts being welded to each other.

A protective layer of slag reduces the speed at which the metal cools and the speed of its hardening, due to which gas and other inclusions have time to escape from it, which negatively affect the strength of the structure. As a rule, protective spraying consists of a whole complex of slag-forming elements, such as kaolin or titanium concentrate.

The coating covering the metal rods performs a number of primary and secondary tasks. The most important ones include:

- Protection of the arc itself and the metal in the area of the weld pool from interaction with nitrogen, oxygen, and hydrogen contained in water vapor present in the atmosphere. Coating the rod creates a two-stage protection: vapors of carbon dioxide and carbon oxides enveloping the working area, and a slag film on the surface layer of the molten metal;

- ensuring high-quality crystallization of the seam without the formation of pores, slagging and cracks.

Secondary, but no less important tasks:

- ensuring uninterrupted arc burning in a wide range of operating modes, simplifying the ignition process. Arc stability is achieved due to the presence in the surface layer of the rod of components that are not prone to ionization in a large volume. This helps to increase the number of combustion-stabilizing ions in the arc space;

- removal of oxygen dissolved in it from the metal of the weld pool. To do this, ferroalloys are added to the coating composition, which are lighter and faster than the metal itself and react with oxygen;

- cleaning the weld metal from impurities (refining).

Let's consider what types of electrode coatings there are, their components and how which one is designated. There are four main types of coatings used in the production of welding electrodes:

- acid type coating, designated by the letter A;

- main (B) coating;

- cellulose coating (C);

- rutile (R).

The coating of welding electrodes is selected based on what type of steel is planned to be welded, the load on the structure and other factors.

Coating diameter

On sale you can find many brands of electrodes designed for different types of metal and the strength of the expected loads on the future structure.

Coated rods have two diameters: the diameter of the electrode itself and the total diameter of the rod and coating.

When choosing a suitable option, the diameter is one of the determining factors: the larger it is, the greater the thickness of the metal that can be connected using a rod.

Important! The operating mode of the welding machine is set based on the thickness of the parts being connected and the diameter of the rods. It is important to correctly calculate the current strength, since if the current is too strong, the metal can simply be burned through, and if the current is too weak, it will not be possible to form an arc. The diameter of the coated rod affects not only the ease of working with the material when welding, but also provides the necessary characteristics of the completed connection, affects the strength of the resulting structure.

So, for example, electrodes marked E42A and E46 are used for welding parts made of low-alloy steels.

The letter “E” in the marking means a piece electrode, widely used for manual arc welding at home.

The number following the letter is the minimum value of the guaranteed tensile strength of the seam. The higher this number, the greater the load the welded part will withstand.

For example, products of the E42 type provide a resistance of at least 42 kgf/mm2, and rods marked E46 provide a resistance of at least 46 kgf/mm2.

E42A electrodes are used for metal with similar quality tensile properties, but in conditions where higher parameters of impact strength and relative elongation of the resulting weld are required.

The improved characteristics are indicated by the letter “A” in the marking, which indicates the acidic type of coating of the rod.

Coating thickness

Blue coating of electrode brand MR-3S

In addition to the characteristics of the coating applied to the electrode rod and the diameter of the electrode itself, when selecting materials for welding, they also focus on the thickness of the protective coating.

The coating thickness of the electrode rod is the ratio of the overall diameter (D) and the diameter of the internal rod (d). That is, a thicker electrode may have less coating thickness if it has a lower D/d ratio.

Each diameter of the inner rod has its own coating thickness. There are 4 categories of electrodes, differing in coating thickness:

- thin or stabilizing electrodes (the letter M is used to designate them) with a ratio of 1.2 or more;

- middle electrodes (designated C) with a ratio of 1.45 or greater;

- thick, having a ratio less than or equal to 1.8, which are also called high-quality (marked with the letter D);

- especially thick electrodes are also included in the quality category and have a diameter ratio of over 1.8 (can be recognized by the letter G in the marking).

The thickness of the coating of high-quality electrodes ranges from 0.5 to 2.5 mm, which is 20-40% of the mass of the internal rod. If we take iron powder into account, the diameter will be 3.5 mm and the mass fraction will be 50%. Such electrodes are used when a high-quality seam that can withstand heavy loads is needed.

Thin or stabilizing electrodes, the coating thickness of which is approximately 0.1-0.3 mm, make the arc burning smooth and continuous, but do not in any way affect the quality characteristics of the deposited steel.

Cover sizes

When carrying out various welding operations, the correct choice of electrodes plays an important role. The greater the thickness of the product being welded, the larger the diameter of the electrode. Depending on this, the current value on the equipment is set.

Arc welding with coated electrodes requires a competent selection of these consumables. When choosing electrodes, the size of the coating on it should be analyzed. Each diameter value requires a specific coating thickness. The coating is applied to a certain length of the rod.

The gradation of this size, defined in GOST 9466-75, starts with thin ones and ends with especially thick ones. Between them are medium and thick. Coatings that have the status of thin are designated as “M”, medium ones as “C”. Thick ones are designated “D”, and especially thick ones are designated “G”. These letters are part of the general designation for coated electrodes.

For electrodes considered to be of the highest quality, the coating thickness is in the range from 0.5 to 2.5 millimeters. For electrodes with a small diameter, this size does not exceed 0.3 millimeters. The mass of the coating is approximately half of the total weight of the consumable element.

Coating, which is a solid porous substance, covers almost the entire rod, with the exception of a small area at its edge, approximately 20-30 millimeters in size. This area is left in order to place the electrode in a special holder to fix it, which makes it easier to work with.

Best Basic Coated Electrodes

The electrodes with a basic coating discussed in this article are used for DC welding. When burned, they release a lot of carbon dioxide, which serves as a protection for the weld pool.

Such electrodes are used for welding critical structures, while ensuring a high-quality and reliable connection. However, you cannot do without a fly in the ointment, since electrodes with a basic coating have increased sensitivity to moisture. Cooking with such electrodes when they become damp becomes problematic.

Let's look at the most popular electrodes with a basic coating, which are of high quality.

Electrodes Kobelco LB-52U

Kobelco LB-52U - electrodes that are produced in Japan by one of the country's largest concerns Kobe Steel, Ltd. The main purpose of these electrodes with a basic coating is welding low-carbon steel, where it is impossible to use double-sided metal welding (pipeline welding).

As a result, Kobelco LB-52U electrodes are distinguished not only by the ability to create a plastic seam, but also by a very small amount of slag. The weld seam formed by LB-52U electrodes does not have cavities or other defects that remain after conventional electrodes.

The strength of the weld reaches 588 N/mm², which is a fairly high indicator. The only drawback of Kobelco LB-52U electrodes is, as mentioned above, excessive exposure in a humid environment. Therefore, in order to cook normally with these electrodes, they will need to be calcined. The calcination temperature of electrodes with the main coating (Kobelco LB-52U) is not less than 300 degrees.

Electrodes OZL-8 (LEZ)

The main purpose of OZL-8 electrodes is welding stainless steels with a high percentage of nickel and chromium. Welding with LEZ electrodes is carried out using direct current of reverse polarity. The created seam is characterized by high resistance to corrosion, as well as decent strength properties.

Here, as when welding with previous electrodes with a basic coating, a small amount of slag is formed. In addition, the slag is almost immediately separated from the surface of the cooled weld. What is equally important is that the seam does not crack when it cools. However, sudden cooling of the weld should not be allowed to prevent a decrease in the strength of the joint.

Electrodes UONI 13-55

Perhaps the most popular electrodes with a basic coating among welders. The main advantages of UONI 13/55 are associated with the high strength of the weld seam, as well as its resistance to various loads. In appearance, the surface of the weld seam produced by these electrodes somewhat resembles frozen glass.

Acid coated electrodes (symbol A)

The composition of acid-coated electrodes includes: oxides of iron, manganese and silicon. It is worth noting that toxic manganese oxides can be harmful to human health. Therefore, acid-coated electrodes are losing their popularity and are used less and less. Instead, mixed ones are used - rutile-acid.

According to the mechanical properties of the weld metal, electrodes with this type of coating belong to types E38 and E42 according to GOST 9467-75, having a tensile strength of up to 412 MPa . They are insensitive to scale and rust on the metal being welded, and also allow working with an extended arc. Welding with them can be performed on direct and alternating current.

When working with electrodes with this type of coating, due to the release of a large amount of oxygen during welding, the temperature of the arc increases and the surface tension of the molten metal decreases, which makes it very fluid. This allows you to increase the welding speed, but carries the risk of undercuts (one of the defects of the welded joint). In this case, the weld metal has an increased tendency to form hot cracks.

Advantages of acid-coated electrodes

- Easy ignition and stable arc burning

- Ability to carry out welding work on direct and alternating current

- When welding rusty or scaled metal, no pores form

- Resistance to moisture and mechanical stress

- Provides an even weld seam

- Good slag peel removal

Disadvantages of acid-coated electrodes

- Risk of undercuts

- Release of dangerous toxins

- Risk of hot cracking during welding

Areas of use

This type of electrode is used for welding non-critical low-alloy steel structures in construction and mechanical engineering.

Additional types of electrodes

Consumables are divided into groups according to the method of operation.

Non-consumable electrodes

The products are designed for automatic and semi-automatic welding.

The following is supplied to the work area:

- protective gas (in most cases - argon);

- filler material.

Non-consumable electrodes are designed for automatic welding.

Refractory consumables do not have a coating.

They are made from the following materials:

- Tungsten. The metal is used in its pure form or with the addition of thorium, lanthanum, cerium, yttrium or zirconium. The type of additive is determined by color marking.

- Artificial pressed graphite.

- Electrical coal.

Non-melting consumables are used to cook:

- steel;

- cast iron;

- aluminum;

- copper;

- brass;

- bronze

When welding with a non-consumable electrode on direct current, the anode spot (on the “plus” side) has a higher temperature than the cathode spot.

Therefore, to connect thin-walled workpieces, reverse polarity is used: “+” is connected to the consumable. Otherwise, the metal will burn out.

Consumable electrodes

Products of this type are used in manual arc welding.

Consumable electrodes are used in manual arc welding.

During operation, the rod material is transferred to the weld pool.

Consumables are made from welding wire Sv-08 or Sv-08A.

The following types of steel are used (77 grades in total):

- carbon;

- alloyed;

- highly alloyed.

The product is selected in accordance with the material of the workpieces.

When welding with direct current, the cathode spot is hotter (on the “minus” side). Therefore, thin-walled workpieces are connected with direct polarity: “-” is connected to the consumable.

Electrodes made of non-ferrous metal

Such consumables are used for joining workpieces made of aluminum, copper, nickel, and other non-ferrous metals and their alloys. Select a rod from the same material as the parts to be welded.

The following brands are used:

- Aluminum - OZA-1 and OZA-2.

- Aluminum alloys - AF-4aKr and A-2.

- Copper, bronze, brass - MN-5, KM-100, AMNTs/LKZ-AB.

- Nickel and its alloys - KhN-1 or MZOK.

Non-ferrous metal electrodes are used for aluminum, copper, and nickel.

Electrodes for aluminum welding are made from Sv-A1 wire with a halide coating. They are suitable for all brands of metal.

Process parameters:

- D.C;

- reverse polarity;

- lower spatial position of the seam.

KM-100 consumables and similar ones are made of copper wire and equipped with a main coating (calcium fluoride). It is characterized by a reduced release of oxygen, which has a destructive effect on the metal. It is possible to combine copper with carbon steel.

Process parameters:

- D.C;

- reverse polarity;

- lower spatial position of the seam.

Electrodes for resistance welding are also made of copper or bronze.

Consumables of the MZOK brand and similar ones are made from nickel-copper wire with a basic type of coating.

Process parameters:

- D.C;

- direct and reverse polarity;

- any spatial position of the seam.

How to apply the coating

As mentioned above, the thickness of the coating directly depends on the diameter of the rod itself. Various technologies can be used to apply such a coating. Coating is applied during their manufacture using special equipment. Such equipment operates in a fully automatic mode, which improves the quality of coating on electrodes. Solid elements in the composition of the coating can be ground and additionally applied to the viscous base of the coating. To ensure a single fraction of such solid components, they are sifted through special filters, and only after that they are applied to the surface of the surfacing material. In some cases, when applying the coating, the finished composition is pre-fired, which makes it possible to remove sulfur, which can deteriorate the quality of the welded joint. At the last stage of coating, the machine dips the rods into the prepared mixture, and at the end we get a uniform layer of coating.

Selection criteria

Unfortunately, Russian electrodes are inferior to many foreign analogues in most parameters. However, “breakthroughs” in this area have already emerged. Russian electrode products, produced at the still few joint ventures, are no longer inferior to many venerable brands in terms of quality stability. Some factories of domestic subordination also began to “catch up” to them. However, in cases where it is necessary to confidently ensure high quality of the seam, professionals still prefer to use more expensive, but also higher quality, foreign-made electrodes. Electrodes of any type are suitable for welding inverters; not all types are suitable for AC welding machines.

When selecting the best electrodes for review, we were guided by the following criteria:

- production volumes;

- product quality;

- the manufacturer's inclusion in reviews of the electrode industry;

- reviews from professionals.

For a fair comparison of prices, we included in the review only the most commonly used electrodes with a diameter of 3 mm.

The main parameter of any welding electrode, which determines most of its properties - from ease of ignition to the quality of the seam - is the composition of its coating. The most common types of coatings today are:

- Rutile electrodes (and electrodes with a mixed coating on this basis - rutile-cellulose and so on) have become one of the most popular due to their ease of ignition, including re-ignition, and reduced (within reasonable limits) sensitivity to dampness. They can be used on both alternating and direct current in all directions of the seam, but when choosing a rutile electrode you need to be careful - you can buy both a good electrode and one that contaminates the seam with a huge number of slag pits, suitable only for tack welding.

- Basic coated electrodes are most often used for DC welding in critical areas. When the coating burns, carbon dioxide is released in large quantities, which reliably protects the weld pool from exposure to oxygen. The seam itself is more ductile than when welding with common types of rutile electrodes. The other side of the coin is increased sensitivity to humidity and difficult ignition: it is much more difficult to cook with such electrodes.

§ 15. PROPERTIES OF ELECTRODES

Coatings (coatings) of electrodes.

Electrode coatings (coatings) consist of slag-forming, gas-forming, deoxidizing, alloying, stabilizing and binding (adhesive) components.

Slag-forming components protect the molten metal from exposure to oxygen and nitrogen in the air and partially refine (purify) it. They form slag shells around droplets of electrode metal passing through the arc gap, and a slag coating on the surface of the weld metal; slag-forming components reduce the cooling rate of the metal and promote the release of non-metallic inclusions from it. Slag-forming components may include titanium concentrate, manganese ore, feldspar, kaolin , chalk, marble, quartz sand, dolomite, as well as substances that increase the stability of the arc. During combustion, gas-forming components create gas protection for the welding zone, which also protects the molten metal from oxygen and nitrogen in the air. Gas-forming components consist of wood flour, cotton yarn, starch, food flour, dextrin and cellulose. Deoxidizing components are necessary to deoxidize the molten metal of the weld pool. These include elements that have a greater affinity for oxygen than iron, for example manganese, silicon, titanium, aluminum, etc. Most deoxidizers are introduced into the electrode coating in the form of ferroalloys. Alloying components are necessary in the coating to give the weld metal special properties: heat resistance, wear resistance, corrosion resistance and increased mechanical properties. Alloying elements are manganese, chromium, titanium, vanadium, molybdenum, nickel, tungsten and some other elements. Stabilizing constituents are those elements that have a low ionization potential, such as potassium, sodium and calcium. Binding (adhesive) components are used to bind the components of the coating to each other and to the electrode rod. They use potassium or sodium liquid glass, dextrin, gelatin and others. The main binder is liquid glass. According to their metallurgical action, there are acid ore, calcium fluoride, rutile and gas-shield (organic) coatings. There are also other types of coatings - stabilizing, carbonic-rutile, halide and special. All coatings must meet the following requirements: ensure stable arc burning; the physical properties of the slag formed during melting of the electrode should ensure normal formation of the seam and convenient manipulation of the electrode; there should be no reactions between slags, gases and metal that could cause the formation of pores in welds; coating materials must be well crushed and not react with liquid glass or with each other in a batch; the composition of the coatings must ensure acceptable sanitary and hygienic working conditions during the manufacture of electrodes and during their combustion. The physical properties of the resulting slags have a significant impact on the welding process and the formation of the weld. In all electrode coatings, when melting, the density of the slag should be lower than the density of the metal of the weld pool, which will ensure that it floats out of the weld pool. The temperature range of slag solidification must be lower than the crystallization temperature of the metal of the weld pool, otherwise the slag layer will not allow the gases released from the weld pool to pass through. The slag should cover the entire surface of the weld in an even layer. The slags formed during the melting of electrode coatings are “long” and “short”. “Long” slags are those that contain a significant amount of silica. Their viscosity increases slowly with decreasing temperature. Electrodes with coatings that form “long” slags during melting are not suitable for welding in vertical and ceiling planes, since the weld pool remains in a liquid state for a long time. For welding in all spatial positions, electrodes are used, the coatings of which produce “short” slags when melted; The viscosity of molten slag increases quickly with decreasing temperature, so crystallized slag prevents the weld metal, which is still in a liquid state, from draining. “Short” slags produce electrodes with rutile and calcium fluoride coatings. Quite good separation of the slag crust from the metal surface is obtained by using slags having a linear expansion coefficient that differs from the linear expansion coefficient of the metal. Properties of weld metal and technological characteristics of electrodes.

Electrodes are characterized by the properties of the metal they deposit, which include: strength, ductility, elongation, impact strength, hardness, corrosion resistance, aging resistance, and during surfacing operations, wear resistance. Along with the quality of the weld metal obtained by welding with this electrode, its technological properties are also important. The main technological properties of the electrode include its productivity, suitability for welding in various spatial positions, arc stability at direct and alternating current, permissible maximum and minimum arc length, weld shape, deposition, melting and loss coefficients.

Self-test questions

1. What characteristics determine the properties of electrodes?

2. What components are included in the electrode coating? 3. How are coatings classified? Previous page

| table of contents | Next page |

Buying electrodes: how to determine quality

When purchasing this product, you should immediately pay attention to several points:

- expiration date (indicated on the packaging) - it should not be exceeded;

- quality of the coating - it should not crumble from the core, otherwise it has either been stored for a very long time or is a product with an initial manufacturing defect;

- In addition, the coating must be applied to the core evenly, with the same layer thickness.

In addition, you should immediately eliminate the risk of it becoming damp by placing the electrodes in special cases. If the latter does happen, the products can be dried or calcined at +400 °C.

Effect of moisture on materials

Electrode coatings have a porous structure that absorbs moisture and water very well. As a result, there is a loss of protective properties and characteristics, and the quality of the seam.

Electrode durability rules:

- Store consumables in hermetically sealed containers. If the package is open, place it in an airtight container to prevent moisture and water from entering.

- Before use, you can dry it in ovens designed for this purpose, adhering to the specified temperature and time.

- An electrode that has not been used for 3 hours must be dried.

- More than 4 dryings in ovens are not recommended; this will lead to the coating falling off.

- The rutile shell manifests itself at the slightest moisture; you must first dry the product at a temperature of up to 200C and only use it for work after a day.

Electrode marking

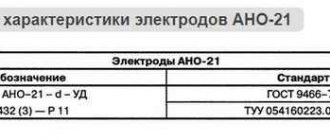

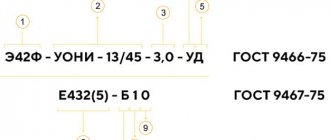

There are dozens of modifications of types and brands of electrodes, so for successful orientation in their varieties, universal marking was introduced. Of course, by the marking of the electrode you can always understand what kind of coating it has. The main parameters in this case are the thickness and type of coating. In addition, the marking mentions the permissible spatial position of the weld, as well as the type of current.

An example of deciphering the markings of a coated electrode

For example, consider electrode E46.

- 1 – indicates the thickness of the coating (D is thick);

- 2 - means the type of coating (P is rutile);

- 3 - indicates the permissible position of the seam (1 - suitable for all positions);

- 4 is the type of current (1 means alternating and direct current of any polarity).

Requirements for electrodes

When choosing rods for work, you should carefully consider and evaluate them. The coating must be free of chips and damage, otherwise it will not be possible to achieve uniform heating and a uniform seam. At the tip of the electrode, the thickness of the lubricant should be the same as on the entire rod - thanks to this, the electric arc will pass through the center.

It is worth checking the humidity of the coating; sometimes the increased humidity of the coating does not allow the rod to light easily. Hence, the requirements for storing electrodes in a dry place, preferably hermetically sealed. Craftsmen recommend putting bags of salt in the packaging to remove excess moisture. If it happens that the electrodes become damp, they can be dried in the kitchen oven at low temperature. This parameter is indicated on the product packaging. You can also leave it in a ventilated, dry room.

During welding work, to obtain a high-quality, durable, stable seam, the following points must be taken into account:

- The correct amperage for a particular product.

- Suitable diameter of the welding electrode for the product and type of work.

- Taking into account the size and thickness of the materials being welded.

Having selected the parameters, the welder creates a stable, well-burning arc, which will ensure the implementation of welding work at a high level.

Application

Basic coated electrodes are excellent for use in the following applications:

- welding of mild steels with high sulfur content;

- steels with a high content of sulfur, carbon, phosphorus;

- welding of hardening steels, in which cold cracks can form;

- when welding low-alloy and high-alloy steels, which are used under heavy loads and high temperatures;

- if you need to weld parts of large thickness;

- when welding rigid structures.