Most professional and home welders sooner or later face the need to weld pipes. Not surprising! This is one of the most common types of welding. But pipe welding is characterized by increased requirements for the quality and tightness of seams, especially for gas and water supply units. For these purposes, special electrodes are used.

Electrodes for welding pipelines are designed taking into account all the features of the future operation of pipes. The seams are strong and durable, they can withstand maximum temperature loads. Such electrodes have a special composition, due to which they ensure good quality of welded joints. Novice welders usually have a lot of questions on this topic. How to choose the right electrodes? What rods should be used to weld the tubing pipe? Which electrodes are best for welding pipes? We will try to answer these and many other questions in this article.

Electrodes for gas pipeline

What electrode should be used to weld a pipe if it is planned to supply main gas through it? We recommend OK-46, LB-52 or UONI-13/55 electrodes (the same electrodes can be used to weld tubing pipes). All of the listed brands have a suitable composition; they can be made using manganese, phosphorus, sulfur or silicon. And OK-46 electrodes with rutile coating are considered universal. In our experience, they are especially convenient for welding parts with a wide gap.

There is also a brand LB 52U on the market with a basic coating. Let's take a closer look at it. Such electrodes contain a small amount of hydrogen, so the seam is of very high quality. At the same time, the arc is stable, ignites easily, and completely cooks the metal.

If you have to weld particularly critical components (for example, rotary ones), and the pipe is made of carbon or low-alloy steel, then we recommend electrodes for welding pipes of the MTG-01K brand. The arc burns stably, slag is removed easily and quickly, and metal spattering is insignificant.

STEPS OF WORK WITH GALVANIZATION

Removing zinc coating

This procedure is necessary to ensure that molten zinc, once in the weld area, does not deteriorate its quality. There are three main methods of stripping:

Mechanical

This method of stripping galvanized steel is carried out using harsh abrasives, metal brushes and sandpaper.

Chemical

It involves exposing the coating to acid or alkali. After the required exposure, the product is thoroughly washed and dried.

Thermal

It involves firing the edges of the product using a gas burner. It should be taken into account that exposure to high temperatures provokes the release of toxic fumes.

Selection of electrodes

In order to choose which electrodes to use for galvanizing , it is necessary to take into account a number of nuances. The choice of electrodes is carried out taking into account the type of steel being welded.

There are 2 main types of electrodes:

- With rutile coating (ANO-4, MR-3, OZS-4). Suitable for welding steel with low carbon content. The presence of titanium oxide greatly simplifies arc ignition, guarantees the strength of the weld and its tightness, and also minimizes spattering;

- With strongly basic fluxes (UONI13/45, UONI13/55, DSK-50). Suitable for low alloy steels.

Selection of filler material

The main requirement for wire used as a filler material is a low melting point, varying from 900 to 1100 degrees. Compliance with this condition will allow you to achieve a high-quality seam, since in this case the wire will melt without damaging or melting the material itself.

Electrodes for heating pipes

If you need to weld heating pipes with high quality, we recommend the following brands of electrodes: E42A, UONI 13/45 (diameter 3 mm). These rods have a thick coating that allows you to weld carbon steel comfortably. Also suitable for welding heating pipes are the E-09X1MF and TsL-20 grades. They are designed to form a strong seam when welding heat-resistant steel. These rods also have a fairly thick coating. If you need to weld stainless, carbon or alloy steel, then use TsL-9 electrodes with a basic coating. There is little hydrogen in such rods, and we already know that this guarantees excellent weld quality.

If you plan to weld pipes in which there will be a continuous supply of hot water and there may be increased pressure, then use pipe electrodes of the MP-3 brand. These same rods can be used to weld a tubing pipe. Electrodes of this brand have a rutile coating and are made of special wire. Manufacturers offer diameters from 3 to 5 mm. When working with this brand, tilt the electrode towards the deposition and use a short arc. Then the welded joint will be as tight as possible.

It is very important to set the current correctly. The smaller the thickness of the metal and the diameter of the electrode, the lower the voltage value. If you set the voltage too low, the metal may not be welded. And vice versa: if you set the current value too high, the part may become deformed. Therefore, pay attention to the thickness of the metal and the dimensions of the electrode.

Diametral section

The diameter of the electrodes for pipelines is of great importance. This value affects the consumption of filler material and the properties of the seams.

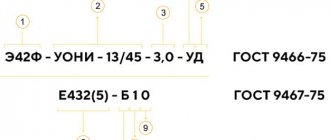

The nominal diameter is the thickness of the rod without coating. The coating thickness is different for each type of electrode and is regulated by GOST 9466-75.

The coating can be determined by the ratio of the total diameter of the electrode to the diameter of the rod:

- A coating is considered thin if the ratio is equal or less than 1.2.

- Average coverage is defined as equal to or less than 1.45.

- If the diameter ratio is equal or less than 1.8, the coating is thick.

- If the diameter ratio is more than 1.8. That coating will be especially thick.

It is worth noting that imported products must also meet these rules. However, it is rarely possible to note that their diameters comply with Russian standards.

Electrodes for water supply

For welding water pipes, we recommend the following brands: MN-5, MNZh5 (for copper pipes), NZH-13 (for stainless steel pipes) and MNCh-2 (for welding cast iron pipes). If you have to weld at home with an inverter, and the pipes are made of ferrous metal, then you can use the MP-3s brand. They can qualitatively weld even a pipe with a diameter of 32 by 2.8 mm at low current.

If you need to make a vertical seam, then use MNCh-2 electrodes. TsCh-4 is suitable for cold and hot welding, but note that it can only be used in the lower position. By the way, when choosing electrodes, pay attention to the presence of coating. Be sure to buy rods with coating, as it will protect the welding area from the negative effects of oxygen. We recommend electrodes for welding thick coated pipelines.

If you have a specific type of work to do, consult with the salesperson in the store. Read the information on the packages carefully. For most work, pipe electrodes from such manufacturers as UONI, OZS, ANO, KOBELKO, ESAB are suitable. Among domestic manufacturers, we also recommend electrodes from the Ural and Kamensk plants.

Welding methods

To connect galvanized pipes, two methods are used to choose from:

- Electric arc.

- Gas.

Accordingly, the first method requires the use of electrodes and the second a gas burner. With the electric arc method, the thickness of the pipes to be welded plays an important role. If it is significant, then before starting it is necessary to chamfer the edges of the pipes. Thin-walled pipes can be welded without pre-treatment.

In addition to the correct choice of electrodes, the quality of the connection will depend on the qualifications of the welder and his experience. Welding zinc-coated pipes requires quick but careful work. First, the galvanized pipes are joined with a small gap. The gap between the parts is necessary in order to improve penetration. In addition, this improves the visibility of the resulting seam and makes it possible to move the electrode more correctly.

For fixing, it is necessary to perform at least three tacks to avoid distortion of the pipes during operation. The current value should be increased slightly so that you can first burn through the galvanization itself, which otherwise may prevent the arc from occurring, after which you can begin to calmly fuse the metal.

The speed at which the electrode is guided is important. If the process is carried out too slowly, then burn-through may occur, and with fast welding, areas of lack of fusion will appear. The burner flame should be directed not at the pipes, but at the solder. When welding, it is necessary to maintain a constant flame to avoid lack of penetration.

The gas method uses a smaller torch than for welding ferrous metals.

If the torch nozzle is too large, the workpiece may overheat and the zinc will begin to evaporate. If you select a torch with a small nozzle size, sufficient heating will not occur and solder may stick to the surface of the pipe. After completing welding using any of the proposed methods, it is necessary to clean the seam and cover its location with an anti-corrosion compound designed specifically for galvanized pipes.

Electrodes for other works

In this article we have already mentioned the tubing pipe several times. This is not an accident. Question “What electrodes should be used to weld a tubing pipe?” is actively discussed on the Internet, and causes controversy among many welders. We do not pretend to be true, but we still recommend using electrodes of the UONI 13/45 or 13/55 brands for these purposes. The fact is that this type of pipe is usually made of high-alloy steel with increased strength, and this metal requires electrodes with a special composition. The above brands do an excellent job; the seam is quite reliable and durable. But keep in mind that you should not undertake pipe welding without proper experience and a good welding machine, otherwise you risk ruining the work.

Nuances of technology

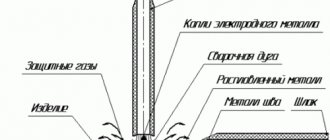

Before starting the final connection of the ends of the pipes, it is necessary to make several tacks along their diameter with the same electrodes that are planned to be used for welding. For a small diameter, four tacks will be sufficient; as the diameter increases, the number of tacks should be increased. This will help fix the connected ends of the pipes to each other.

When joining pipe ends, a continuous seam must be placed at the joint. To do this, the electrode should be guided along the diameter without leaving the surface. In order to heat the metal more deeply, the electrode is moved not perpendicular to the surface, but at an angle of 30-60 degrees so that the weld pool moves behind it.

If a rotary joint is welded, for example, when changing the direction of the pipeline, it is recommended to use a special device called a rotator. The convenience of its use lies in the fact that after the parts are secured in the desired position, there is free access to all sides of the pipes. In the absence of such a device, first a pair of seams are placed on one side of the circle, and then the product is unrolled and the connection is made on the other sides in stages.

When welding non-rotating joints, the connection starts from the bottom while sequentially moving the electrode upward.

Welding galvanization with a gas torch

A common technology without damaging the zinc layer is the use of electrodes for welding galvanized pipes. For its base, a special flux is used.

Scheme of pipe welding methods.

Welding of galvanized steel on ferrous metal is carried out according to the following steps:

- First of all, the workpieces to be welded are prepared. They must be cleaned of grease, dirt and dust.

- After this, flux is applied to the prepared surface. It should cover the entire area where the weld will be located. Only thanks to this, the galvanized coating will be completely protected from overheating and fumes.

- Then, at the site of the intended fastening of the welded galvanization, steel electrodes that have a special coating are used. To more securely fasten the two parts, they should be melted a little. This can be done with a gas burner - a certain section of the pipe that does not have a flux layer is heated.

- If during welding work the structure of the alloy that protected the surface was damaged, then the coating needs to be urgently restored so that corrosion does not occur. First, the workpiece is completely cooled and a special anti-corrosion agent must be applied to the damaged area.

Tungsten electrodes for argon arc welding

For manual and automatic welding in argon, rods of lanthanum tungsten or yttriated tungsten grade SVI-1 with diameter D

= 2÷4 mm (Fig. 10.4).

Rice.

10.4. Shape of sharpening the tungsten electrode To easily excite the arc and increase the stability of its combustion, the end of the tungsten electrode is sharpened into a cone (Fig. 10.4). In this case, the length of the conical part l

should be 6–10 mm, and the diameter of the blunting

d

= 0.2÷0.5 mm.